TECHNICAL REPORT SUMMARY ON THE MATERIAL ASSETS OF THE KLOOF OPERATIONS Situated near Carletonville, Gauteng, South Africa 31 December 2023 Prepared by: Qualified Persons from Sibanye-Stillwater Southern African Gold Operations Exhibit 96.5 i Important Notices Mineral Resources and Mineral Reserves are declared as 100% attributable to Sibanye-Stillwater Ltd (Registrant). Wherever mention is made of “Kloof Operations”, for the purposes of this Technical Report Summary, it encompasses mining activities under Kloof that Sibanye-Stillwater Limited (Sibanye-Stillwater) control in the Gauteng Province, South Africa, unless specifically mentioned differently. Kloof No. 1 Shaft is alternatively referred to as “Main Shaft” or “Thuthukani Shaft” or “KM”, No. 3 Shaft is called “Hlalanathi Shaft” or “K3”, No. 4 Shaft is “Ikamva Shaft” or “K4”, No. 7 Shaft is “Manyano Shaft” or “K7”, No. 8 Shaft is “Masimthembe Shaft” or “K8”, and No. 10 Shaft is “Celemanzi Shaft” or “K10”. These names can be used interchangeably. In this document, a point is used as the decimal marker and the comma is used for the thousands separator (for numbers larger than 999) in the text. In other words, 10,148.32 denotes ten thousand one hundred and forty-eight point three two. The word ‘tonnes’ denotes a metric tonne (1,000 kg). The abbreviation “lb” denotes the weight in pounds in the sense understood in the USA. Cut-off grades and Pay limits are defined as follows: The pay limit (cm.g/t or g/t) of an operation is described as the average value or grade for that operation at which all direct and indirect costs are covered, i.e. the value at which it is estimated that ore can be mined without profit or loss. The cut-off grade (cm.g/t or g/t) of an operation is described as the minimum value or grade at which an area can be mined to maintain an average value in line with the paylimit. The cut-off is unique to the orebody being mined and is dependent on maintaining a mining mix that follows the orebody’s value distribution. Where closure or closed is mentioned in relation to mining or shaft infrastructure in this report, it relates to the cessation of production and not a commitment for final closure and concomitant closure certificate application in terms of section 43(3) of the MPRDA. Trademarks. Certain software and methodologies may be proprietary. Where proprietary names are mentioned, TM or © are omitted for readability. ii Date and Signature Page Qualified Persons Position Signature Signature Date Charl Labuschagne Vice President: Mine Technical Services /s/ Charl Labuschagne 24 April 2024 Lindelani Mudimeli Unit Manager Geology /s/ Lindelani Mudimeli 24 April 2024 Renier van Vuuren Unit Manager Mineral Resources /s/ Renier van Vuuren 24 April 2024 Steven Wild Unit Manager Mine Planning /s/ Steven Wild 24 April 2024 Stephan Botes Unit Manager: Mineral Rights /s/ Stephan Botes 24 April 2024 B Govender Manager Environmental Compliance SA Region /s/ B Govender 24 April 2024 M van der Walt Vice President Finance Integrated Services /s/ M van der Walt 24 April 2024 iii Table of Contents 1 EXECUTIVE SUMMARY 1 1.1 INTRODUCTION 1 1.2 PROPERTY DESCRIPTION, MINERAL RIGHTS AND OWNERSHIP 1 1.3 GEOLOGY AND MINERALISATION 2 1.4 EXPLORATION STATUS, DEVELOPMENT, OPERATIONS AND MINERAL RESOURCE ESTIMATES 2 1.5 MINING METHODS, ORE PROCESSING, INFRASTRUCTURE AND MINERAL RESERVES 5 1.6 CAPITAL AND OPERATING COST ESTIMATES AND ECONOMIC ANALYSIS 8 1.7 PERMITTING REQUIREMENTS 10 1.8 CONCLUSIONS AND RECOMMENDATIONS 11 2 INTRODUCTION 12 2.1 REGISTRANT 12 2.2 COMPLIANCE 13 2.3 TERMS OF REFERENCE AND PURPOSE OF THE TECHNICAL REPORT 14 2.4 SOURCES OF INFORMATION 15 2.5 SITE INSPECTION BY QUALIFIED PERSONS 16 2.6 UNITS, CURRENCIES AND SURVEY COORDINATE SYSTEM 16 2.7 RELIANCE ON INFORMATION PROVIDED BY OTHER EXPERTS 17 3 PROPERTY DESCRIPTION 18 3.1 LOCATION AND OPERATIONS OVERVIEW 18 3.2 MINERAL TITLE 22 3.3 ROYALTIES 28 3.4 LEGAL PROCEEDINGS AND SIGNIFICANT ENCUMBRANCES TO THE PROPERTY 28 4 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY 28 4.1 TOPOGRAPHY, ELEVATION AND VEGETATION 28 4.2 ACCESS, TOWNS AND REGIONAL INFRASTRUCTURE 28 4.3 CLIMATE 29 4.4 INFRASTRUCTURE AND BULK SERVICE SUPPLIES 29 4.5 PERSONNEL SOURCES 29 5 HISTORY 30 5.1 OWNERSHIP HISTORY 30 5.2 PREVIOUS EXPLORATION AND MINE DEVELOPMENT 32 5.2.1 Previous Exploration 32 5.2.2 Previous Development 34 6 GEOLOGICAL SETTING, MINERALISATION AND DEPOSIT 35 6.1 REGIONAL GEOLOGY 35 6.2 DEPOSIT TYPES 38 6.2.1 Formation of Deposits 38 6.2.2 Witwatersrand and other gold-bearing conglomerates 39

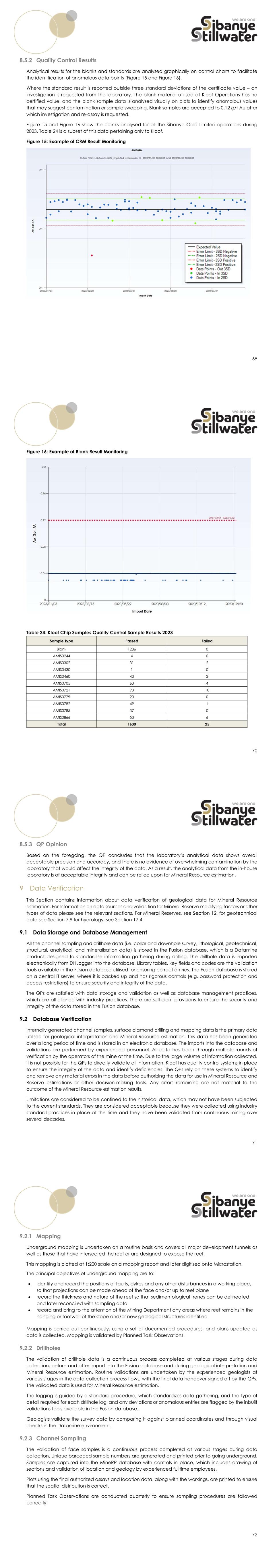

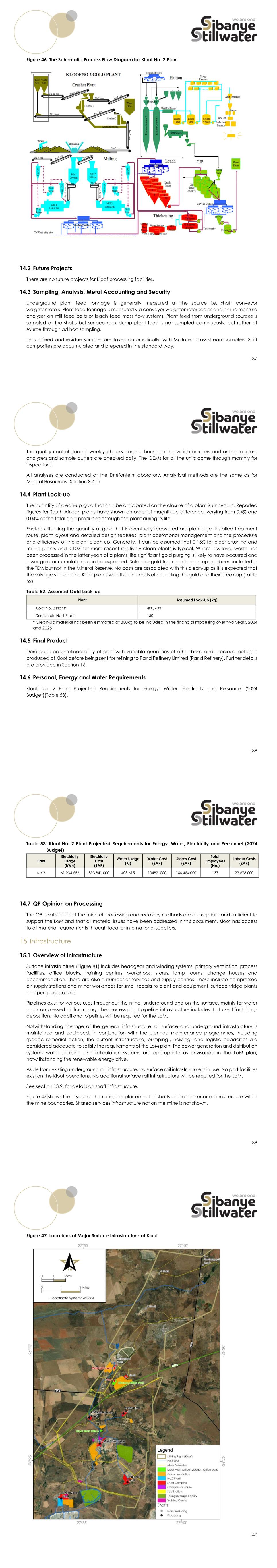

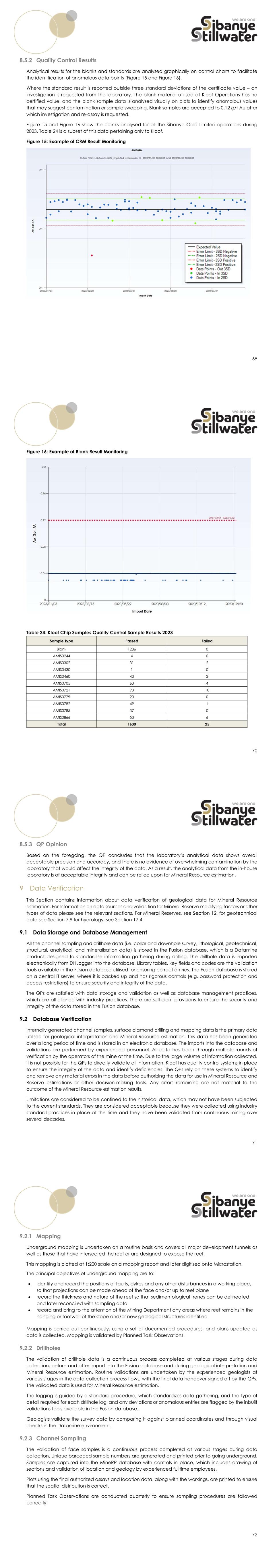

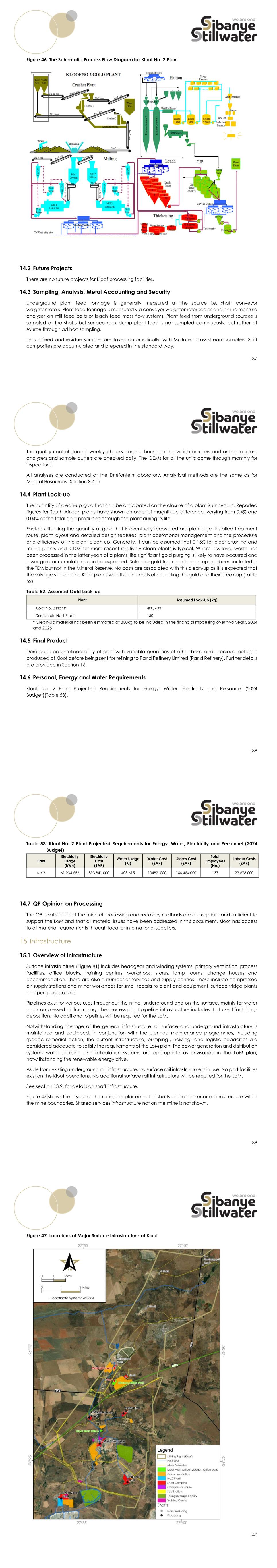

iv 6.3 LOCAL AND PROPERTY GEOLOGY 44 6.3.1 Stratigraphy 44 6.3.2 The Mineralised Horizons 44 6.3.3 Structure 47 6.3.4 Mineralogy 50 6.3.5 Dolomitc Ground and sinkhole formation 51 7 EXPLORATION 52 7.1 EXPLORATION DATA 52 7.2 GEOPHYSICAL SURVEYS 52 7.3 TOPOGRAPHIC SURVEYS 52 7.4 EXPLORATION AND MINERAL RESOURCE EVALUATION DRILLING 52 7.4.1 Overview 52 7.4.2 Planned Drilling 53 7.4.3 Drilling Methods 54 7.5 SURVEY DATA 60 7.6 DENSITY DETERMINATION 60 7.6.1 Underground Drillholes 60 7.6.2 .Surface drillholes 60 7.7 UNDERGROUND MAPPING 61 7.8 HYDROLOGICAL DRILLING AND TESTWORK 61 7.9 GEOTECHNICAL DATA, TESTING AND ANALYSIS 61 7.9.1 Surface Geotechnical 61 7.9.2 Underground Geotechnical 62 8 SAMPLE PREPARATION, ANALYSES AND SECURITY 65 8.1 SAMPLING GOVERNANCE AND QUALITY ASSURANCE 65 8.2 SAMPLING SURFACE 66 8.2.1 Reef Sampling – Surface 66 8.2.2 Surface Waste Rock Dumps 66 8.3 REEF SAMPLING – UNDERGROUND 66 8.3.1 Core Samples 66 8.3.2 Channel Sampling 66 8.4 SAMPLE PREPARATION AND ANALYSIS 67 8.4.1 Laboratory 67 8.4.2 Sample Preparation and Analysis 67 8.4.3 QP Opinion 68 8.5 ANALYTICAL QUALITY CONTROL 68 8.5.1 Nature and Extent of the Quality Control Procedures 68 8.5.2 Quality Control Results 69 8.5.3 QP Opinion 71 9 DATA VERIFICATION 71 9.1 DATA STORAGE AND DATABASE MANAGEMENT 71 9.2 DATABASE VERIFICATION 71 v 9.2.1 Mapping 72 9.2.2 Drillholes 72 9.2.3 Channel Sampling 72 9.3 QP OPINION 73 10 MINERAL PROCESSING AND METALLURGICAL TESTING 73 10.1 NATURE AND EXTENT OF MINERAL PROCESSING 73 10.2 REPRESENTATIVE NATURE OF TEST SAMPLES 73 10.3 LABORATORIES 73 10.4 RESULTS, RECOVERY ESTIMATES AND DELETERIOUS ELEMENTS 74 10.5 QP OPINION ON ADEQUACY OF DATA FOR THE TRS 74 11 MINERAL RESOURCE ESTIMATES 74 11.1 ESTIMATION DOMAINS 74 11.1.1 Compositing 74 11.1.2 Estimation Domains 76 11.2 ESTIMATION TECHNIQUES 81 11.2.1 Grade and Tonnage Estimation 81 11.2.2 Interpolation Methods 87 11.2.3 Grade Control and Reconciliation 93 11.3 MINERAL RESOURCE CLASSIFICATION 94 11.3.1 Classification Criteria 94 11.3.2 Mineral Resource Technical and Economic Factors 95 11.4 MINERAL RESOURCE STATEMENTS 97 11.4.1 Mineral Resources 97 11.4.2 Mineral Resources per Mining Area 101 11.4.3 Changes in the Mineral Resources from Previous Estimates (Inclusive of Mineral Reserves) 102 11.4.4 Metal Equivalents 103 11.5 QP STATEMENT ON THE MINERAL RESOURCE ESTIMATION AND CLASSIFICATION 103 12 MINERAL RESERVE ESTIMATES 103 12.1 MINERAL RESERVE METHODOLOGY 103 12.2 MINE PLANNING PROCESS 104 12.3 HISTORICAL MINING PARAMETERS 105 12.4 SHAFT AND MINE PAYLIMITS 107 12.4.1 Paylimits 107 12.4.2 Modifying Factors and LoM plan 111 12.5 LOM PROJECTS 115 12.6 SPECIFIC INCLUSIONS AND EXCLUSIONS 115 12.6.1 Specific Exclusions 115 12.6.2 Specific Inclusion 115 12.7 MINERAL RESERVE ESTIMATION 115 12.8 SURFACE SOURCES 117 12.9 MINERAL RESERVES STATEMENT 117 12.10 MINERAL RESERVE SENSITIVITY 117 vi 12.11 QP STATEMENT ON THE MINERAL RESERVE ESTIMATION 121 13 MINING METHODS 121 13.1 INTRODUCTION 121 13.2 SHAFT INFRASTRUCTURE, HOISTING AND MINING METHODS 121 13.2.1 Shaft Infrastructure 121 13.2.2 Hoisting 122 13.2.3 Mining Methods 123 13.3 GEOTECHNICAL ANALYSIS 124 13.3.1 Geotechnical Conditions 124 13.3.2 Stress and Seismological Setting 124 13.4 MINE VENTILATION 125 13.5 REFRIGERATION AND COOLING 126 13.6 FLAMMABLE GAS MANAGEMENT 126 13.7 MINE EQUIPMENT 126 13.8 PERSONNEL REQUIREMENTS 127 13.9 REQUIREMENTS FOR STRIPPING, UNDERGROUND DEVELOPMENT AND BACKFILLING 128 13.10 FINAL LAYOUT MAP 128 14 PROCESSING AND RECOVERY METHODS 133 14.1 PROCESSING FACILITIES NO.2 PLANT 133 14.1.1 Production Plan 134 14.1.2 Process Description 136 14.2 FUTURE PROJECTS 137 14.3 SAMPLING, ANALYSIS, METAL ACCOUNTING AND SECURITY 137 14.4 PLANT LOCK-UP 138 14.5 FINAL PRODUCT 138 14.6 PERSONAL, ENERGY AND WATER REQUIREMENTS 138 14.7 QP OPINION ON PROCESSING 139 15 INFRASTRUCTURE 139 15.1 OVERVIEW OF INFRASTRUCTURE 139 15.2 TAILINGS STORAGE FACILITIES 141 15.2.1 Tailings Overview 141 15.2.2 Kloof No 2 TSF 142 15.2.3 Leeudoorn TSF 142 15.2.4 Other Surface Dumps 142 15.3 ELECTRICAL POWER SUPPLY 142 15.4 BULK WATER AND PUMPING 144 15.5 ROADS AND TRANSPORT INFRASTRUCTURE 144 15.6 EQUIPMENT MAINTENANCE 144 15.6.1 Surface Workshops 144 15.6.2 Underground Workshops 144 15.7 OFFICES, HOUSING, TRAINING FACILITIES, HEALTH SERVICES ETC. 144 15.8 QP OPINION ON INFRASTRUCTURE 145 vii 16 MARKET STUDIES 145 16.1 CONCENTRATES AND REFINED PRODUCTS 145 16.2 METALS MARKETING AGREEMENTS 145 16.3 MARKETS 145 16.3.1 Introduction 145 16.3.2 Demand Summary 146 16.3.3 Supply Summary 147 16.3.4 Gold Price Outlook 147 16.4 METALS PRICE DETERMINATION 147 16.4.1 Exchange Rate 148 16.4.2 Gold Price 148 17 ENVIRONMENTAL STUDIES, PERMITTING, PLANS, NEGOTIATIONS/ AGREEMENTS WITH LOCAL INDIVIDUALS OR GROUPS 149 17.1 SOCIAL AND COMMUNITY AGREEMENTS 149 17.1.1 Overview- Mine Community Development 149 17.1.2 Legislation 149 17.1.3 LED Implementation Strategy 149 17.2 HUMAN RESOURCES 152 17.2.1 Introduction 152 17.2.2 Human Resources 152 17.2.3 Legislation 152 17.2.4 Human Resource Development (Training) 154 17.2.5 Remuneration Policies 155 17.2.6 Industrial Relations 155 17.2.7 Employment Equity and Women in Mining (WIM) 155 17.3 HEALTH AND SAFETY 156 17.3.1 Policies and Procedures 156 17.3.2 Statistics 156 17.3.3 Occupational Health and Safety Management 156 17.3.4 HIV/AIDS 156 17.4 ENVIRONMENTAL STUDIES 156 17.4.1 Introduction 156 17.4.2 Baseline Studies 2016-2012 159 17.4.3 Zone of Influence 162 17.4.4 Climate Change and Greenhouse Gas Emissions, Air Quality 170 17.4.5 Biodiversity Management 171 17.4.6 Waste Management 172 17.4.7 Water Use Strategy 172 17.4.8 Environmental Reporting 180 17.4.9 Closure Planning and Cost Estimates 182 17.5 QP’S OPINION ON ESG MATTERS 186 18 CAPITAL AND OPERATING COSTS 186

viii 18.1 OVERVIEW 186 18.2 CAPITAL COSTS 186 18.3 OPERATING COSTS 189 18.3.1 Operating Costs by Activity 189 18.3.2 Operating Costs 189 18.3.3 Surface Sources Costs 189 18.3.4 Processing Costs 189 18.3.5 Allocated Costs 190 19 ECONOMIC ANALYSIS 192 19.1 INTRODUCTION 192 19.2 ECONOMIC ANALYSIS APPROACH 192 19.3 ECONOMIC ANALYSIS BASIS 192 19.4 TEM PARAMETERS 193 19.5 TECHNICAL ECONOMIC MODEL 194 19.6 DCF ANALYSIS 199 19.7 SUMMARY ECONOMIC ANALYSIS 201 19.8 QP OPINION 202 20 ADJACENT PROPERTIES 202 21 OTHER RELEVANT DATA AND INFORMATION 203 21.1 RISK ANALYSIS 203 21.1.1 Financial Accuracy 203 21.1.2 Risk to the Mineral Resources and Mineral Reserves 203 21.2 MINERAL PROCESSING TOLL TREATMENT ARRANGEMENT 205 22 INTERPRETATION AND CONCLUSIONS 209 23 RECOMMENDATIONS 209 24 REFERENCES 209 24.1 LIST OF REPORTS AND SOURCES OF INFORMATION 209 24.1.1 Publications and Reports 209 24.2 GLOSSARY OF TERMS 210 25 RELIANCE ON INFORMATION PROVIDED BY THE REGISTRANT 211 26 QUALIFIED PERSON’S DISCLOSURE 211 ix List of Figures Figure 1: Ownership and Company Structure for Kloof ........................................................... 13 Figure 2: General Location of the Material Assets as at 31 December 2023 ......................... 19 Figure 3: Kloof Operation Overview .......................................................................................... 21 Figure 4: Surface Extent of the Witwatersrand Basin ................................................................ 36 Figure 5: General Stratigraphic Column of the Witwatersrand Basin ..................................... 38 Figure 6: Interpretation of the Paleoenvironment Setting for Conglomerate-hosted Gold Deposits ............................................................................................................. 42 Figure 7: Detail of Paleogravel Deposits and Location of Heavy Mineral Deposition ........... 43 Figure 8: Example of Gold Accumulation (cm.g/t) in a Paleoconglomerate (Middelvlei Reef of the Doornfontein Gold Mine West Wits Line) .............................................. 43 Figure 9: Simplified Geology View of Kloof Mineralised Horizons (Not to Scale) .................... 44 Figure 10: The Slope and Terrace Facies Interpretation (Not to Scale) .................................. 46 Figure 11: Structure Map of Kloof ............................................................................................... 49 Figure 12: Historical Surface Drillholes ........................................................................................ 55 Figure 13: Schematic Vertical Section of a Typical Surface Drillhole ...................................... 56 Figure 14: Plan View of a Typical Drillhole ................................................................................. 57 Figure 15: Example of CRM Result Monitoring .......................................................................... 69 Figure 16: Example of Blank Result Monitoring .......................................................................... 70 Figure 17: Schematic cross-sectional drawing of Reef thickness to mining cut .................... 75 Figure 18: VCR Facies and Domains ......................................................................................... 77 Figure 19: Kloof Reef Facies and Domains ................................................................................ 78 Figure 20: Libanon Reef Facies and Domains ........................................................................... 79 Figure 21: Middelvlei Reef Facies and Domains ....................................................................... 80 Figure 22: Capping Analysis in Snowden Supervisor ................................................................ 82 Figure 23: Example of a Variogram Map .................................................................................. 83 Figure 24: Example of Variogram Validation with Covariance ............................................... 84 Figure 25: KNA for Block Sizes ..................................................................................................... 85 Figure 26: KNA for Discretization................................................................................................. 86 Figure 27: KNA Number of Samples 10x10 Block Size ............................................................... 86 Figure 28: Swath Plot Showing Block Model vs Data for VCR .................................................. 88 Figure 29: VCR cm.g/t Block Model ........................................................................................... 89 x Figure 30: Kloof Reef cm.g/t Block Model ................................................................................. 90 Figure 31: Libanon Reef cm.g/t Block Model............................................................................ 91 Figure 32: Middelvlei Reef cm.g/t Block Model ........................................................................ 92 Figure 33: Plot Showing Monthly Reconciliations for VCR ........................................................ 93 Figure 34: Example of a Pay Limit Cut-off Per Shaft for Mineral Resources ............................ 96 Figure 35: Example of a Cost Curve for a Shaft ........................................................................ 97 Figure 36: Year on Year Changes to the Mineral Resource ................................................... 103 Figure 37: An Example of Cumulative Mining Area vs Grade Curves (Similar to a Grade/Tonnage Curve) .......................................................................................... 110 Figure 38: Relationships Between Incremental, Break-even, and Paylimit cut-off grades per shaft .................................................................................................................... 111 Figure 39: The Kloof Operations Mineral Reserve Reconciliation at 31 December 2023 .... 119 Figure 40: Schematic Section Indicating the Kloof Infrastructure ......................................... 122 Figure 41: Kloof Mine VCR Plan ................................................................................................ 129 Figure 42: Kloof Mine Kloof Reef Plan ...................................................................................... 130 Figure 43: Kloof Mine Libanon Reef Plan ................................................................................. 131 Figure 44: Kloof Mine Middelvlei Reef Plan ............................................................................. 132 Figure 45: Kloof No.2 and Driefontein No. 1 Plant Throughput Forecast from Kloof Mine- ................................................................................................................................... 135 Figure 46: The Schematic Process Flow Diagram for Kloof No. 2 Plant. ................................ 137 Figure 47: Locations of Major Surface Infrastructure at Kloof ................................................ 140 Figure 48: Schematic Layout of Power Points of Supply and Surface Infrastructure ........... 143 Figure 49: Global Annual Demand by Sector* ....................................................................... 146 Figure 50: Kloof Secondary Groundwater Zone of Influence ................................................ 164 Figure 51: Secondary Watercourse Zone of Influence Associated with Kloof ..................... 165 Figure 52: KLoof Zone of Influence in the Wonderfonteinspruit ............................................. 167 Figure 53: Kloof Zone of Influence in the Loopspruit and Leeuspruit Catchments .............. 168 Figure 54: Kloof North Visual Zone of Influence ...................................................................... 169 Figure 55: Kloof Noise Zone of Influence ................................................................................. 170 Figure 56: Sub-quaternary Reaches Around Kloof ................................................................. 175 Figure 57: Wetland Features Within the Vicinity of Kloof ........................................................ 176 Figure 58: Kloof Water Use Context ......................................................................................... 178 Figure 59: The Schematic Process Flow Diagram for Water Handling at the Kloof Operation ................................................................................................................. 179 xi Figure 60: Driefontein No. 1 Plant Throughput Forecast ......................................................... 206

xii List of Tables Table 1: Attributable Mineral Resources Exclusive of Mineral Reserves as at 31 December 2023 ........................................................................................................... 4 Table 2: Attributable Mineral Reserves as at 31 December 2023 .............................................. 7 Table 3: Historical and Forecast Capital Expenditure ................................................................ 8 Table 4: Historical and Forecast Operating Costs ...................................................................... 9 Table 5: NPV (Post-tax) Relative to ZAR/kg Gold Prices at 5 % Discount Rate- Current Operations .................................................................................................................... 9 Table 6: Twin Parameter NPV (Post-tax) Sensitivity at a 5% Discount Rate (Capital Costs) _Current Operations .................................................................................................. 10 Table 7: Twin Parameter NPV (Post-tax) Sensitivity at a 5% Discount Rate (Revenue, Operating Costs) _Current Operations .................................................................... 10 Table 8: Details of QPs Appointed by Sibanye-Stillwater ......................................................... 15 Table 9: Units Definitions .............................................................................................................. 16 Table 10: Technical Experts/Specialists Supporting the QPs .................................................... 18 Table 11: Summary of Mineral Rights held for the Kloof Operations ....................................... 24 Table 12: Summary of Mineral Title Properties - Kloof ............................................................... 27 Table 13: Number of Permanent Employees ............................................................................ 30 Table 14: Origin of Employees .................................................................................................... 30 Table 15: Historical Development .............................................................................................. 31 Table 16:Drilling History ................................................................................................................ 33 Table 17: Historical Production and Financial Parameters ...................................................... 34 Table 18: Geologic and Production Information on the Major Quartz-pebble- Conglomerate Deposits of the World. ..................................................................... 40 Table 19: Drillhole Inventories ..................................................................................................... 53 Table 20: Kloof Drilling Budget .................................................................................................... 54 Table 21: Quality Control in Drilling ............................................................................................ 59 Table 22: Rock Mass Characterization ...................................................................................... 63 Table 23: Rockmass properties Kloof ......................................................................................... 64 Table 24: Kloof Chip Samples Quality Control Sample Results 2023 ....................................... 70 Table 25: Number of Datapoints Used for Mineral Resources Estimation ............................... 76 Table 26: Example of Capping Values Applied to the Final Estimation Dataset ................... 82 Table 27: Example from Three Domains of Variogram Model Parameters (Kloof Reef) ....... 84 xiii Table 28: Kriging Parameters ...................................................................................................... 86 Table 29: Example of Global Mean Values per Domain Example for the VCR ..................... 87 Table 30: Confidence Levels for Key Criteria for Mineral Resource Classification ................. 94 Table 31: Mineral Resources Exclusive of Mineral Reserves as at 31 December 2023 ........... 99 Table 32: Mineral Resources Inclusive of Mineral Reserves as at 31 December 2023 ........... 99 Table 33: Sensitivity Analysis for Mineral Resource Estimates Inclusive of Mineral Reserve Estimates ................................................................................................................... 100 Table 34: Mineral Resource Estimates Exclusive of Mineral Reserve Estimates per Mining Area as at 31 December 2023 ................................................................................ 101 Table 35: Mineral Resource Inclusive of Mineral Reserves per Mining Area as at 31 December 2023 at 100% ......................................................................................... 102 Table 36: Historical Mining Statistics by Section ...................................................................... 106 Table 37: Example of Parameters Used in Determining the Incremental Cut-off Grade .... 108 Table 38: Break-even Cut-off calculation for a shaft ............................................................. 109 Table 39: Paylimits for the Kloof shafts ..................................................................................... 111 Table 40: Mineral Reserve Modifying Factors 2024 ................................................................. 112 Table 41: Historical and Projected Modifying Factors ............................................................ 113 Table 42: LoM Plans – Current Operations 2024-2032 ............................................................. 114 Table 43: Mineral Reserve as at 31 December 2023 at 100% ................................................ 118 Table 44: Attributable Mineral Reserve per Mining Area as at 31 December 2023 at 100% .......................................................................................................................... 118 Table 45: Underground Mineral Reserve Estimates Sensitivity as at 31 December 2023 ..... 120 Table 46: Hoisting Capacities ................................................................................................... 123 Table 47: Major Mine Equipment ............................................................................................. 126 Table 48: Major Process Equipment Utilised at Kloof .............................................................. 134 Table 49: Mineral Processing Plant Capacity.......................................................................... 134 Table 50: Kloof No2 plant Production Forecast and Operational Data ............................... 135 Table 51: Driefontein No.1 Plant Production Forecast and Operational Data- From Kloof Mine .......................................................................................................................... 135 Table 52: Assumed Gold Lock-up ............................................................................................ 138 Table 53: Kloof No. 2 Plant Projected Requirements for Energy, Water, Electricity and Personnel (2024 Budget) ......................................................................................... 139 Table 54: Summary for Active Tailings Dams ........................................................................... 141 Table 55: LoM Assessment of Tailings Facilities ........................................................................ 141 xiv Table 56: Gold Supply 2023 ...................................................................................................... 147 Table 57: Gold Price Scenarios ( Forward prices for Financial Model) ................................. 148 Table 58: SLP Host Community Projects for Kloof (2022-2026)................................................ 150 Table 59: Backlog Projects (2017-2021 SLP) ............................................................................. 151 Table 60: Backlog Projects (2012-2016 SLP) ............................................................................. 151 Table 61: Undertaking and Guidelines .................................................................................... 153 Table 62: Breakdown of Employee Profile as at the end December 2023 ........................... 153 Table 63: Kloof Total Employees - Snapshot Report for the Month December 2023 ........... 153 Table 64: Kloof Total Contractors (Excluding Ad-Hoc Contractors) ...................................... 154 Table 65: Safety Statistics .......................................................................................................... 156 Table 66: Key Environmental Permits and Authorisations ....................................................... 159 Table 67: Summary of Updated Environmental Impacts Studies for Amended EMPr,2021) ................................................................................................................ 161 Table 68: Kloof Emissions Inventory as at 2023 ........................................................................ 171 Table 69: Kloof Environmental Audits ....................................................................................... 180 Table 70: Summary of 2023 Audits for Kloof ............................................................................ 180 Table 71: Kloof Material Risks and Action Plans (Results from 2023 Audits) .......................... 181 Table 72: Kloof Compliance to Legislation.............................................................................. 182 Table 73: Closure Components ................................................................................................ 184 Table 74: Historical and Forecast Capital Expenditure – Current Operations ...................... 188 Table 75: Historical and Forecast Operating Costs -Current Operations ............................. 191 Table 76: TEM Parameters ......................................................................................................... 193 Table 77: TEM – Mining, Processing, Gold Sold and Revenue – 2024-2034 (table split for readability) ............................................................................................................... 195 Table 78: TEM –Cash Costs, Taxation, Capital Expenditure and Free Cash – 2024-2034 ..... 196 Table 79: TEM – TEM – Unit Analysis (ZAR/kg) – 2024-2032 ...................................................... 197 Table 80: NPV (Post-tax) at Various Discount Factors ............................................................ 199 Table 81: Twin Parameter NPV (Post-tax) Sensitivity at a 5% Discount Rate (Revenue, Operating Costs) _Current Operations .................................................................. 200 Table 82: Twin Parameter NPV (Post-tax) Sensitivity at a 5% Discount Rate (Revenue, Capital Expenditure) – Current Operations ........................................................... 200 Table 83: Twin Parameter NPV (Post-tax) Sensitivity at a 5% Discount Rate (Revenue, Discount Rate) – Current Operations ..................................................................... 200 xv Table 84: Summary Revenue and Costs per Area (On Reef Dev excluded from the calculation, Profit excludes Royalty and taxes) .................................................... 201 Table 85: NPV (Post-tax) Relative to ZAR/kg Gold Prices Prices at 5 % Discount Rate- Current Operations .................................................................................................. 202 Table 86: Adjacent Mines, West Wits Line ............................................................................... 203 Table 87: Financial Risks ............................................................................................................ 203 Table 88: Driefontein No.1 Plant Production Forecast and Operational Data – From Dreifontein Mine ....................................................................................................... 207 Table 89: Driefontein No.1 Plant Production Forecast and Operational Data- From Kloof Mine .......................................................................................................................... 208 Table 90: Qualified Person’s Details ......................................................................................... 212

1 1 Executive Summary 1.1 Introduction Sibanye-Stillwater Limited (Sibanye-Stillwater or the Registrant) is a multinational mining and metals processing Group with a diverse portfolio of mining and processing operations and projects and investments across five continents. Sibanye-Stillwater is domiciled in South Africa and listed on both the Johannesburg Stock Exchange (JSE or JSE Limited) and New York Stock Exchange (NYSE). This Technical Report Summary (TRS) covers Sibanye-Stillwater's wholly owned Kloof mine in South Africa’s Gauteng Province. Kloof comprises integrated shaft complexes, a metallurgical plant, and other infrastructure necessary to produce the saleable products and to meet compliance with environmental, health, safety, and social laws and regulations. Owing to the integrated nature of the different shaft complexes and the ore processing operations, Kloof constitutes a single unit (material property). This report updates the TRS filed by Sibanye-Stillwater on the Kloof Operations on 22 April 2022 named Exhibit 96.5 Technical Report Summary of Kloof Operations, which was effective 31 December 2021. There has been no material change to the information between the effective date and the signature date of the Report. The effective date of the Mineral Resource and Mineral Reserve is 31 December 2023 and the date of this TRS is 24 April 2024. This TRS for the Kloof Operations has been prepared in accordance with the disclosure requirements set out under Subpart 1300 of Regulation S-K (SK-1300). 1.2 Property Description, Mineral Rights and Ownership The Kloof operation is an established, ongoing mine consisting of three operating shaft complexes and an ore processing plant, extracting the Ventersdorp Contact Reef (VCR), Middelvlei Reef (MVR), Libanon Reef (LR) and Kloof Reef (KR) producing a Doré, a semi-pure alloy of gold, silver and occasionally base metals. The site is situated in a well-developed area, 50km from Johannesburg, and is easily accessible by major roads including the N12 highway. Sibanye Gold Proprietary Limited (SGL), a wholly owned subsidiary of Sibanye-Stillwater, is the holder of a converted mining right in respect of the Kloof Operations under the Department of Mineral Resources and Energy (DMRE) reference number: GP30/5/1/2/2/66 MR (Kloof MR). The Kloof MR is valid until the 29th of January 2027 and covers a total area of 20,087 hectares (ha), in the Magisterial District of Westonaria, in the Gauteng Province of South Africa. The rights will be renewed before their expiry in 2027. The current Life of Mine (LoM) plan used to support the Mineral Reserves continues until 2032. An application was submitted in terms of Section 102 of the Mineral and Petroleum Resources Development Act (MPRDA) to the DMRE, for ministerial consent to amend the Kloof MR, to incorporate the Kloof PR area of the Farm Rietfontein 349 IQ. The mentioned Section 102 application was submitted on the 27th of September 2013 and was granted in April 2023. 2 There are no material legal proceedings in relation to the Sibanye-Stillwater Kloof Operation. The mining rights referred to in this document are issued in terms of the MPRDA 28 of 2002 in South Africa. The principal terms and conditions are not materially different to other similar operations in the Republic of South Africa. 1.3 Geology and Mineralisation Kloof is located along the West Wits Line that forms part of the Far West Rand of the Witwatersrand Basin. The Witwatersrand Basin comprises a 6,000m vertical thickness of sedimentary rocks, extending laterally for some 350km northeast to southwest by some 120km northwest to southeast, generally dipping at shallow angles toward the centre of the Witwatersrand Basin. The Witwatersrand Basin outcrops at its northern extent near Johannesburg, but to the west, south, and east, it is overlaid by up to 4,000m of volcanic and sedimentary rocks. The Witwatersrand Basin is Archaean in age, meaning that the sedimentary rocks are of the order of 2.8 billion years old. This mine is typical of the many Witwatersrand Basin operations, which have been primary contributors to South Africa’s gold production since 1886. Gold mineralisation occurs within laterally extensive quartz-pebble conglomerates, colloquially called reefs, which are developed above unconformable surfaces. As a result of faulting and primary controls on mineralisation processes, the goldfields are not continuous and are characterised by the presence or dominance of different reef units. The reefs are generally less than two metres thick and are widely considered to represent laterally extensive braided fluvial deposits or unconfined flow deposits, which formed along the flanks of alluvial fan systems around the edge of an inland sea. Dykes and sills of dolerite composition are developed within the Witwatersrand Basin and are associated with several intrusive and extrusive events. Gold generally occurs in its native form, often associated with pyrite, carbon and uranium. Pyrite and gold within the reefs display a variety of forms, some obviously indicative of detrital transport within the depositional system and others suggesting crystallisation within the reef itself. Four conglomerates are exploited at Kloof, namely the Ventersdorp Contact Reef (VCR), Kloof Reef, Libanon Reef, and Middelvlei Reef. As the VCR at the top of the stratigraphy resides on a major unconformity and the underlying sediments are folded in a shallow syncline, the VCR erodes these sediments in the north and south. Accordingly, both the Kloof and Libanon reefs subcrop below the VCR in the extreme north and south of the property. The approximate dip of all reefs is 25 to 35 degrees to the southeast and the strike is approximately northeast-southwest; however, local variations in structure and the slope and terrace model can see these dips increase to 45 degrees. 1.4 Exploration Status, Development, Operations and Mineral Resource Estimates Exploration in the area dates from 1898 and mining from the 1930s, with the sinking of the Venterspost No. 1 Shaft commencing in 1934. Initial exploration drilling was executed from the surface, on irregular grids of around 2,000m depending on the exploration strategy, depth of the mineralised horizons, and 3 geological uncertainty. Once in operation, with underground access established, infill grade control drilling was conducted to provide a 30m to 100m grid depending on geological requirements, evaluation and safety. Kloof in its current form dates from April 2000 when Libanon, Kloof, Leeudoorn and Venterspost mines amalgamated. The Mineral Resources estimation process used on Kloof is based on surface and underground drillholes as well as underground channel samples. The most fundamental controls of gold distribution are the primary sedimentary features such as facies variation and channel directions. Consequently, the modelling of sedimentary features within the reefs and the correlation of payable grades within certain facies is key to in-situ mineral resource estimation, as well as effective operational mine planning and grade control. Estimation is constrained within both geologically homogenous structural and facies zones and is derived from either Ordinary Kriged (OK) or Simple Kriged (SK) small-scale grids. Areas close to current workings will have smaller block sizes ranging from 10m to 25m and are derived from OK. Areas further away will have block sizes of 100m and are estimated using SK. The facies and structural models that form the basis of this report have evolved over a long period. The Mineral Resources estimate for the Kloof Operations is reported as at 31 December 2023. These estimates are in-situ estimates of tonnage and grades reported at a minimum mining width of 120cm, with applicable dip pillar and scattered mining methods as employed at the operation. Cut-off grades are calculated per shaft, based on the planned production and economic parameters. The average cut-off grade applied for this Mineral Resources declaration varies per shaft area reported. Table 1 details the declared Kloof Operations Mineral Resources statements exclusive of Mineral Reserves as at 31 December 2023. There are no mineral or metal equivalent Mineral Resources declared for Kloof, with only gold, the primary mineral of economic interest, being declared. Co- or by-products, which may occur at low abundances and of low economic importance are not estimated. 4 Table 1: Attributable Mineral Resources Exclusive of Mineral Reserves as at 31 December 2023 Classification – Gold 31-Dec-2023 31-Dec-2022 Tonnes Grade Gold Tonnes Grade Gold (Mt) (g/t) (Moz) (Mt) (g/t) (Moz) Measured 26.7 9.6 8.2 24.9 11.2 9.0 Indicated 24.5 5.5 4.3 33.3 6.6 7.1 Measured + Indicated 51.2 7.6 12.5 58.2 8.6 16.1 Inferred 7.0 4.5 1.0 21.7 8.7 6.1 Total 58.2 7.2 13.5 80.0 8.6 22.1 1. Mineral Resources are not Mineral Reserves. 2. Mineral Resources have been reported in accordance with the classification criteria in SK1300. 3. Mineral Resources are reported exclusive of Mineral Reserves. 4. Mineral Resources are calculated using shaft specific cut-off grades. 5. Mineral Resources are reported as in-situ; metallurgical recovery factors have been applied in the cut-off grades calculations and are approximately 98% at Kloof. 6. A 0.0 represents numbers below significant figures reported, and a (“-“) represents absent value.

5 1.5 Mining Methods, Ore Processing, Infrastructure and Mineral Reserves Kloof is a large, established intermediate to ultra-deep level gold mine that is accessed from the surface through several shaft systems to 40 Level (currently the deepest working level), some 3,200m below the surface. Kloof comprises three producing shaft systems that mine different contributions from pillars and open ground. The permanent infrastructure required to access and mine the underground operations and to support the LoM plan is already well established and in use. All facilities are in good condition. Detailed LoM plans for every shaft complex at Kloof support the Mineral Reserve estimates (Table 2) presented below and reported as at 31 December 2023. The mining methods employed at Kloof are typical for a narrow reef, medium to deep level tabular ore body, and vary between shafts consisting of primarily breast with dip pillars, a minor contribution from scattered mining and shaft pillar extraction. Breast stoping with dip pillars has been selected for the below infrastructure projects. Mining spans and pillar width depend on the location, the reef being mined, and the depth of working. All mine designs, as well as strategic planning and major design issues, such as shaft pillar extraction, are done in conjunction with input from qualified rock engineers. The mining methods employed at Kloof are designed based on geotechnical engineering inputs, bearing in mind the depth of mining. Mine design is done in line with the mine and stability pillar design applicable to the relevant characteristics of the area. Payability, stability pillars and geological features determine the extraction ratio, which will vary from very high in the shallower areas of the mine, to as low as 50% in the deeper areas. The Kloof mining complex has two fissure water pumping shafts. These shafts need to pump approximately 50ML/day of fissure water ingress for safety reasons to prevent the operations from flooding. Various safety measures are in place to protect the operations and workers against a potential flooding risk. These are well maintained and tested to minimise any potential flooding risk to the shafts and the mine workings. The LoM production plans for the Kloof Operations were developed through Mineral Resources to Mineral Reserves conversion processes that utilised dilution factors and mining (stoping and development) parameters informed by historical reconciliation results and performance. The use of factors aligned to historical performance enhances the likely achievability of the plans. The LoM plans envisage a relatively stable production level for the first seven years, with a continuing decline in production up to the end of life in 2032 as the shafts near the end of their life and close. Economic viability testing of the LoM plans demonstrated that extraction of the scheduled Indicated and Measured Mineral Resources is economically justified, and the declaration of Mineral Reserves is appropriate. Kloof No. 2 Plant was commissioned in 1990 and currently treats Kloof’s underground ore until mid 2024 when the ore will be trucked to Driefontein No. 1 Plant. Kloof No.2 Plant will be closed. The plants use proven technology and forecast metallurgical recoveries and production profiles employed in the LoM plans are informed by historical production. 6 There is adequate storage capacity at Driefontein No.1 Plant for the additional tailings resulting from processing of Kloof ore at the facility, and the Tailings Storage Facilities (TSFs) are in good condition. 7 Table 2: Attributable Mineral Reserves as at 31 December 2023 Classification – Gold 31-Dec-2023 31-Dec-2022 Tonnes Grade Gold Tonnes Grade Gold (Mt) (g/t) (Moz) (Mt) (g/t) (Moz) Proven 7.6 5.1 1.3 11.0 6.1 2.1 Probable 3.2 5.6 0.6 7.5 5.4 1.3 Grand total 10.8 5.3 1.8 18.6 5.8 3.4 1. Mineral Reserves have been reported in accordance with the classification criteria in SK1300. 2. Mineral Reserves are reported as delivered to the plant (Run-of-Mine)and do not include metallurgical recovery factors, which are applied in the cut-off grades and LoM calculations, which are approximately 98% at Kloof for underground material. 3. Mineral Reserves are calculated with variable pricing for the first five years then a longterm fixed price of 941,374ZAR/kg. 4. Mineral Reserves are estimated using shaft specific cut-off grades. Information on pay limits, cutoffs and modifying factors is found in Sections 12.4., 16.4 and 19.5. 5. A 0.0 represents numbers below significant figures reported, and a (“-“) represents absent value. 8 1.6 Capital and Operating Cost Estimates and Economic Analysis The LoM plan for Kloof provides appropriate capital expenditure budgets to cater for the sustainability of the operation. Sustaining capital (Stay-in -Business, SIB) costs are benchmarked to historical capital expenditure(Table 3). Similarly, the forecast operating costs included in the LoM plan are based on historical annual expenditures and projected near term costs at the operations(Table 4). All costs are estimated to at least the Pre-Feasibility level of accuracy. SIB costs cater for mine and surface equipment, capitalised development, projects, infrastructure and environmental capital expenditure. The capital budget ranges between ZAR1,221m and ZAR221m per annum and is dominated by the costs of capitalised development (approximately 68% of the annual capital costs). SIB capital expenditure ranges between R421m and R32m per annum and also includes ZAR420m of Capex for the Kloof Integration project over 5 years. Table 3: Historical and Forecast Capital Expenditure Historical Real Forecast(5-years) Units 2021 2022 2023 LoM 2024 2025 2026 2027 2028 Total 1 2 3 4 5 Project Capital Expenditure - Excluding Development (ZARm) 198 210 117 - - - - - - Capitalised Development (ZARm) 930 620 912 3 737 791 800 422 480 337 Sustaining Capital (SIB) (ZARm) 488 455 421 1 788 429 421 293 255 192 Total (ZARm) 1 616 1 285 1 450 5 525 1 220 1 221 716 734 528 Kloof has budgeted operating costs for underground and surface operations at ZAR3,922/t processed. Underground milled tonnes contribute 93% and processing of surface material will cease in 2025. Allocated and Centralised Operating Costs are included in the Total Operating Costs.

9 Table 4: Historical and Forecast Operating Costs Historical Real Forecast (5-years) Units 2021 2022 2023 LoM 2024 2025 2026 2027 2028 Total 1 2 3 4 5 Underground Mining (ZAR/t) 3,766 6,072 5,271 4,180 4,380 3,875 3,976 3,879 4,073 U/G Mill Tonnes (kt) 1,863 992 1,399 10,800 1,407 1,422 1,264 1,299 1,240 U/G Operating Cost (ZARm) 7,016 6,023 7,375 45,147 6,162 5,510 5,023 5,039 5,050 Surface Mining (ZAR/t) 209 295 370 450 369 818 - - - Surface Mill Tonnes (kt) 4,139 1,953 1,565 805 659 145 - - - Surface Operating Cost (ZARm) 866 576 579 362 243 119 - - - Total Operating Costs (ZAR/t) 1,313 2,241 2,683 3,922 3,100 3,592 3,976 3,879 4,073 (kt) 6,002 2,945 2,965 11,604 2,066 1,567 1,264 1,299 1,240 (ZARm) 7,882 6,599 7,954 45,509 6,405 5,629 5,023 5,039 5,050 Allocated Centralised Operating Cost (included in the above) (ZARm) 1,392 1,323 1,420 11,457 1,182 1,279 1,132 1,168 1,128 The market fundamentals for gold are forecast to remain in place in the foreseeable future. The budgeted capital and operating costs, forecast metal prices and other economic assumptions utilised for economic viability testing of the LoM plan are reasonable. The post-tax flows for Kloof derive the discounted cash-flow (DCF) results and net present value (NPV) contained in Table 5 at a discount rate of 5%. This discount rate is in line with the local inflation rate in the recent past and the expected rate in the near future. The table also indicates the overall sensitivity of the Operation to the discount rate. The economic model has been undertaken for the purposes of declaring Mineral Reserves and is not intended to be a valuation of the property. Table 5: NPV (Post-tax) Relative to ZAR/kg Gold Prices at 5 % Discount Rate- Current Operations Sensitivity Range -20% -10% -5% 0% 5% 10% 20% NPV@ the base case Discount Rate 5% (ZARm) -5,637 -932 1,421 3,628 5,704 7,444 10,571 Table 6 shows two-variable sensitivity analysis of the NPV Post-Tax to variance in Capital costs at the 5% Discount Rate. 10 Table 7 shows two-variable sensitivity analysis of the NPV Post-Tax to variance in Revenue and in Operating cost at the 5% Discount Rate. This demonstrates sensitivity to the increase in operating costs and the leverage potential to higher gold prices. Table 6: Twin Parameter NPV (Post-tax) Sensitivity at a 5% Discount Rate (Capital Costs) _Current Operations Post-Tax NPV@5% Revenue Sensitivity Range (ZARm) -20% -10% -5% 0% 5% 10% 20% Capital cost sensitivity range -20% -4,653 52 2,404 4,612 6,688 8,428 11,555 -10% -5,145 -440 1,912 4,120 6,196 7,936 11,063 -5% -5,391 -686 1,667 3,874 5,950 7,690 10,817 0% -5,637 -932 1,421 3,628 5,704 7,444 10,571 5% -5,883 -1,178 1,175 3,382 5,458 7,198 10,325 10% -6,129 -1,424 929 3,136 5,212 6,952 10,080 20% -6,621 -1,916 437 2,644 4,720 6,460 9,588 Table 7: Twin Parameter NPV (Post-tax) Sensitivity at a 5% Discount Rate (Revenue, Operating Costs) _Current Operations Post-Tax NPV @ 5%(ZARm) Revenue Sensitivity Range -20% -10% -5% 0% 5% 10% 20% Total Operating Cost Sensitivity Range -20% 125 4,830 7,183 9,390 11,466 13,206 16,333 -10% -2,496 2,209 4,562 6,769 8,846 10,585 13,713 -5% -3,888 817 3,170 5,377 7,454 9,193 12,321 0% -5,637 -932 1,421 3,628 5,704 7,444 10,571 5% -7,430 -2,724 -372 1,836 3,912 5,652 8,779 10% -9,320 -4,615 -2,262 -55 2,022 3,761 6,889 20% -13,148 -8,442 -6,090 -3,882 -1,806 -66 3,061 While the profitability of the entire operation is tested on a total cost basis, the point at which each individual shaft closure is determined is after direct operational cost. As soon as a shaft does not contribute to its own mining and operational cost, it is considered for closure. The direct allocated costs include the overheads specific to the operation while indirect allocated costs refer to those items which belong to the entire group and which are allocated back to each operation based on a formula. 1.7 Permitting Requirements The Sibanye-Stillwater Kloof Operations have in place all the necessary rights and approvals to operate, e.g. mines, processing plant, tailings Storage Facilities (TSFs), and ancillary facilities associated with the operations. There are no legal proceedings that may have an influence on the rights to extract minerals. The legal ownership of all mining and surface rights has been verified. No significant legal issue exists which would influence the likely viability of a project and/or the estimation and classification of the Mineral Resources and Mineral Reserves as reported herein. 11 Any permit and license infringements are corrected as they occur and environmental impacts are managed in close consultation with the appropriate government departments. There are reasonable prospects that the Registrant’s tenure to operate on these premises is secure for the foreseeable future, unless terminated by regulatory authorities for other reasons. Based on an assessment of the current permits, technical submittals, regulatory requirements and compliance history, continued acquisition of permit approvals should be possible. There is a low risk of rejection of permit applications by regulatory agencies for the foreseeable future. 1.8 Conclusions and Recommendations The QPs have conducted a comprehensive review and assessment of all material issues likely to influence the future activities of the Kloof Operations based on information available up to 31 December 2023. There is a comprehensive Risk Register that is reviewed quarterly by the Kloof Operations management team. All the risks have detailed mitigation plans designed to reduce the risk to a manageable level. The Qualified Persons could not identify any unmanaged material risks that would affect the Mineral Resources and Mineral Reserves reported for Kloof Operations. The views expressed in this report have been based on the fundamental assumption that the required management resources and proactive management skills will be focused on meeting the LoM plans and production targets. There are no recommendations for additional work or changes. 12 2 Introduction 2.1 Registrant Sibanye-Stillwater is a multinational mining and metals processing Group with a diverse portfolio of mining and processing operations and projects and investments across five continents. The Registrant is domiciled in South Africa and listed on the Johannesburg Stock Exchange (JSE or JSE Limited) and New York Stock Exchange (NYSE). This TRS covers Sibanye-Stillwater’s Kloof Operations (Kloof or the Kloof Operations). Kloof falls under the Gold Operations of the Southern African Region of Sibanye Gold Limited, trading as Sibanye–Stillwater (Figure 1). Sibanye Gold Limited is a wholly-owned subsidiary of the Registrant. Kloof Operations include shafts, processing facilities and associated infrastructure (the Material Assets) located in the Gauteng Province, South Africa. Mineral Resources and Mineral Reserves report as 100% attributable to the Registrant.

13 Figure 1: Ownership and Company Structure for Kloof 2.2 Compliance Sibanye-Stillwater is listed on the NYSE (Code SBSW) and the JSE (Code SSW). Mineral Resources and Mineral Reserves contained in this TRS were compiled and reported following the United States Securities and Exchange Commission's (the SEC's) Subpart 1300 of Regulation S-K. 14 2.3 Terms of Reference and Purpose of the Technical Report This TRS for the Kloof Operations reports the Mineral Resources and Mineral Reserves estimates as at 31 December 2023. Kloof Operations is an established mine and ore processing plants extracting gold from the Ventersdorp Contact Reef (VCR), Kloof Reef, the Libanon Reef, and the Middelvlei Reef of the Witwatersrand Supergroup sediments. Ore is processed at one plant within the operations and one plant at nearby operations. The operation produces a Doré which is sent for further processing and onward sales to the Rand Refinery in Germiston, Gauteng Province of which Sibanye-Stillwater is a major Shareholder. This report is the first update of the TRS filed by Sibanye-Stillwater on the Kloof Operations superseding the TRS filed on 22 April 2022 named Exhibit 96.5 Technical Report Summary of Kloof operations dated 31 December 2021. The gold rich layers mined are well known from extensive mining which has taken place, at The Far West Rand and the greater Witwatersrand Basin, over the last 140 years. The Mineral Resource for Kloof contained in this TRS is estimated from the extensive surface and underground drillhole and sampling database. The TRS is signed-off by internal Qualified Persons (QPs). These Mineral Resources are the basis for the Mineral Reserve estimates reported for the operation. Furthermore, the Mineral Reserve estimates are based on detailed Life-of-Mine (LoM) plans and technical studies (at least to a Prefeasibility Study level) completed internally by Sibanye-Stillwater personnel utilizing modifying factors and Capital and Operating Costs informed by the historical performance at the operations. This TRS was compiled by in-house QPs for Mineral Resources and Mineral Reserves appointed by Sibanye-Stillwater. The QPs are Technical Experts/Specialists registered with professional bodies that have enforceable codes of conduct. A list of the QPs, their role, qualifications and sections which they have prepared is given in Table 8. 15 Table 8: Details of QPs Appointed by Sibanye-Stillwater Name Position Area of Responsibility Academic and Professional Qualifications Section Sign-off Charl Labuschagne Vice President Mine Technical Services Qualified Person Mineral Resources and Mineral Reserves BSc (Hon) Geology, MSc Environmental Management, GDE Mining Engineering, SACNASP 400237/08 1,2, 3.1,3.3, 4, 5, 7.8, 7.9, 10, 13, 14,15, 16, 17.1-3, 20-26 Lindelani Mudimeli Unit Manager Geology Qualified Person Geology BSc (Hon) Geology, GDE Mining Engineering. SACNASP 013678 GSSA No 967582 1.3, 1.4, 6, 7.1-7.7, 8, 9.1, 9.2.1, 9.2.2, 9.3 Renier van Vuuren Unit Manager Mineral Resources Geology Qualified Person Mineral Resources BSc (Hon) Geology, SACNASP 153249 1.4, 9.2.3,11 Steven Wild Unit Manager Mine Planning Qualified Person Mineral Reserves GDE Mining Engineering, NHD MRM SAIMM 706556 12 Stephan Botes Unit Manager – Mineral Rights Mineral Title LLB, LLM, Postgraduate Certificate in Prospecting and Mining Law, Postgraduate Certificate in Company Law I, Admitted Attorney of the High Court of RSA 1.7, 3.2,3.4 B Govender Sustainable Development Manager Manager Environmental Compliance SA Region Environmental Management MSc, SACNASP 140606, FWISA 17.4 M van der Walt Vice President Finance Integrated Services Financial Reporting, Compliance and Valuation B Com Accounting, B Com Honours Accounting, CA(SA), SAICA No 20026270 1.6, 18, 19 , 21.1.1 SAIMM - Southern African Institute of Mining and Metallurgy SACNASP – South African Council for Natural Scientific Professions SAGC – South African Geomatics Council GSSA – Geological Society of South Africa SAATCA – South African Auditor and Training Certification Authority 2.4 Sources of Information Sibanye-Stillwater Kloof Operations and the Registrant provided most of the technical information utilised for the preparation of this report. This information is contained in internal documents recording various technical studies undertaken in support of the current and planned operations, historical 16 geological work and production performance at the Kloof Operations, and forecast economic parameters and assumptions. Other supplementary information was sourced from the public domain and these sources are acknowledged in the body of the report and listed in the References, Section 24. 2.5 Site Inspection by Qualified Persons The QPs for Mineral Resources and Mineral Reserves who authored this TRS and the supporting Technical Experts/Specialists are all employees of Sibanye-Stillwater working at the Kloof Operations or Corporate Offices. By virtue of their employment, the QPs visit the Kloof Operations while carrying out their normal duties. 2.6 Units, Currencies and Survey Coordinate System In the Republic of South Africa (RSA) metric units are used for all measurements and, therefore, the reporting of quantities is in metric units, unless otherwise stated. All the metal prices and costs are quoted in US Dollars (USD) or South Africa Rand (ZAR). An Exchange rate of 17.00ZAR/USD has been used in this document for Mineral Reserves. The coordinate system employed for most of the surface and underground surveys and maps shown in this TRS is based on the Gauss Conform Projection (UTM), Hartebeeshoek 94 Datum, Ellipsoid WGS84, Central Meridian (Y-50,000; X+2,900,000). Some regional scale maps in this report may be referenced with Cape Datum, Latitude and Longitude coordinates (WG27) for ease of reading. Maps in WGS84 are annotated as such. Units of measurement used in this report are described in Table 9. Table 9: Units Definitions Units Description cm centimetre(s) g gram(s), measure of mass g/cm3 density - grammes per cubic centimetre g/t grams per tonne ha hectares = 100m x 100m kg kilograms = 1000grams, measure of mass km kilometre(s) = 1000 metres km2 square kilometres, measure of area Koz kilo ounces= 1000 ounces (troy) kt kilotonnes ktpm kilotonnes per month litre Metric unit of volume = 1000cm3 m metre(s) m2 square metres m3/a cubic metres per annum

17 Units Description mamsl elevation metres above mean seal level metre metric unit of distance mm millimetre(s) = metre/1000 Moz Million ounces (troy), measure of weight Mt Million metric tonnes Mtpa Million tonnes per annum MVA Million Volt-Amps(Watts) MW Megawatts oz Troy ounces = 31.1034768 grams ppb parts per billion ppm parts per million (grams/metric tonne) sec second t metric tonne = 1000 kilograms = 1.10231131 short ton tonnes metric tonnes = 1000 kilograms = 1.10231131 short ton USD United States Dollars lb pound USA = measure of weight WGS84 World Geographic System 1984- map projection system wt% weight percent ZAR South African Rand ZARm Million Rand 2.7 Reliance on Information Provided by Other Experts The QPs for Mineral Resources and Mineral Reserves have sought input from in-house Technical Specialists on aspects of the modifying factors for the disciplines outside their expertise. Kloof is a large operation and it is not possible for any one person to have the required expertise to comment on all aspects of the operation and inputs to the Mineral Resources and Mineral Reserves. Kloof and Sibanye- Stillwater employ a large team of Technical Experts and Specialist Service providers. The QPs consider it reasonable to rely upon the information provided by these experts. A list of the in-house Technical Specialists and their areas of competency are summarized in Table 10. 18 Table 10: Technical Experts/Specialists Supporting the QPs Name Position Area of Competency Academic Qualifications MT Bane VP Processing Mineral Processing ND , NHD Extractive Metallurgy, SAIMM HD0968 G Coetzee Unit Manager Survey Responsible for Survey, Reporting and Historical Mining Factors MSCC, NHD MRM, ND Survey IMSSA 2253 I Mogohlong Unit Manager Social Responsibility Social Sustainability N/A K Opperman Vice President Engineering Engineering Gold Operations and associated logistics; infrastructure management B Eng Mechanical. Pr Eng L Scheepers Manager Rock Engineering Rock Engineering MSc Applied Science, Advanced Rock Eng Certificate, HED (Post Graduate), SANIRE A du Plessis Manager Environmental Engineering Occupational Environment (Hygiene) Certificate in Mine Environmental Control/ Occupational Hygiene No.937 FC Viviers Act. Senior Manager Health and Safety Safety Function NADSAM (National Diploma Safety Management). Global Minerals Industry Risk Management Council Member AMSPSA (Association of Mine Safety Profesionals of South-Africa) T Setshedi Manager Human Resources Human Resources Management B Tech HRM AMHRP M Netshivhazwaulu Acting Vice President and Head of Operations Overall strategic direction, leadership and management of the operation BSc Mining Engineer Graduate, Mine Manager’s Certificate of Competency No. 6947. 3 Property Description 3.1 Location and Operations Overview The Kloof Operations are situated about 50km west of Johannesburg at latitude 26°24’S and longitude 27°30’E, near the town of Westonaria in the Gauteng Province of South Africa (Figure 2). The Kloof MR covers a mining area totalling 20,087 hectares. 19 Figure 2: General Location of the Material Assets as at 31 December 2023 Kloof is surrounded by agricultural land , towns in the north part of the mine and other mines to the east and west (Figure 3). The Sibanye-Stillwater Driefontein Operation is situated to the west of Kloof and the the Ezulwini and Cooke mines, also owned by the Registrant, border Kloof to the east. Kloof consists of three producing shafts, namely the Main Shaft, No. 7 Shaft and No. 8 Shaft. The deposit is accessed from the surface using underground mining methods to 40 Level (the lowest working level) at No. 7 Shaft, approximately 3,200m below the surface. The orebodies mined are the Ventersdorp Contact Reef (VCR), Kloof Reef, Libanon Reef and the Middelvlei Reef. These are gold bearing conglomerates of the upper part of the Central Rand Group and the contact between the Central Rand Group and the overlying Ventersdorp Lavas and sediments. 20 Ore is processed at the Kloof No. 2 Plant, and as from the middle of 2024, Driefontein No. 1 Plant. The capacity of the Kloof plant is 167ktpm and the Driefontein plant is 240ktpm. Kloof No. 2 Plant is situated near No. 7 Shaft and processes underground ore and the Driefontein No.1 Plant, also owned by the Registrant, is approximately 15km away and processes underground ore. Selected Kloof surface material is toll treated at the Driefontein and the Ezulwini Processing Plant, a separate adjacent property to the east and owned by the Registrant.

21 Figure 3: Kloof Operation Overview 22 3.2 Mineral Title The Mining and Prospecting rights referred to in this document are issued in terms of Section 5(1) of the Mineral and Petroleum Resources Development Act 28 of 2002 in South Africa. The principal terms and conditions are not materially different to other similar operations within South Africa. Mineral Rights are obtained through the normal application process mandated by the South Africa Department of Mineral Resources and Energy. Sibanye Gold Proprietary Limited (SGL), a wholly owned subsidiary of Sibanye-Stillwater Limited, is the holder of a converted mining right in respect of the Kloof operation under the Department of Mineral Resources and Energy (DMRE) reference number: GP30/5/1/2/2/66 MR in respect of the Kloof operations (Kloof MR)(Table 11). The Kloof MR is valid until the 29th of January 2027 and will be renewed prior to expiry in 2027. The current LoM plan used to support the Mineral Reserves continues to 2032. The Kloof Mining Right covers a mining area totalling 20,087 hectares located in the Magisterial District of Oberholzer and Westonaria, near the town of Westonaria, in the Gauteng Province, as indicated in Figure 3. The Mining Rights comprise various farms (or portions thereof). The names of the farms for the Kloof Operations are listed in Table 12. The Kloof Operations have sufficient rights and access to land to conduct operations. Sibanye Gold Proprietary Limited was also granted a Prospecting Right (PR) in terms of Section 17 of the Mineral and Petroleum Resources Development Act, 28 of 2002 (MPRDA) under DMRE Reference Number: GP30/5/1/1/2/193 PR (renewal: GP30/5/1/1/2/10096 PR) (Kloof PR). The Kloof PR covered 24.8823 ha on Portion 6 of the farm Rietfontein 349 IQ, in the Westonaria District. The Kloof PR was granted for a period of 5 (five) years, ending 18 July 2011. Prior to the expiry of the Kloof PR an application for renewal of the prospecting right was submitted to the DMRE Gauteng Regional Office, in terms of Section 18 of the MPRDA, so as to renew the mentioned prospecting right for a further three (3) years. This renewal application was granted on 4 March 2014. The Kloof PR area will form a natural extension of the Kloof MR mining activities, as no additional capital is required to gain access for exploitation, except for the continuation of the existing infrastructure. Continuous prospecting activities, such as drilling of surface and underground drillholes, have proven it worthwhile to include the area covered by the Kloof PR into the Kloof MR. SGL subsequently submitted an application in terms of Section 102 of the MPRDA to the DMRE, for Ministerial consent to amend the Kloof MR, to incorporate the Kloof PR area of the Farm Rietfontein 349 IQ. The mentioned Section 102 application was submitted on the 27th of September 2013 and was subsequently granted on 24 April 2023. SGL is attempting to execute the amendment deed to give effect to the amendment of the Kloof MR. SGL submitted a further section 102 application for Ministerial consent to amend the Kloof MR to incorporate, amongst other land portions, the properties over which the Venterspost North and Venterspost South Tailings Storage Facilities (Venterspost TSF’s) is located. The mentioned application was granted on 25 August 2021 and SGL is attempting to execute the amendment deed to give effect to the amendment of the Kloof MR. Although the Venterspost TSF’s will form part of the Kloof MR after execution of the amendment deed, DRDGOLD Limited, as the owner of the Venterspost TSF’s pursuant 23 to a transaction concluded between the parties on 22 November 2017, retains the right to process the material found within the Venterspost TSF’s for its own account. 24 Table 11: Summary of Mineral Rights held for the Kloof Operations Operation /Project Right Holder Right Number/s Size (ha) Minerals Key Permit Conditions Expiry Date Future Requirements Future Intentions Brief Summary of Violations/Fines Kloof Sibanye Gold Proprietary Limited GP30/5/1/2/2/66MR 20,087.00 Gold Ore and Associated Minerals See the summary of permit conditions, general EMP regulatory reporting requirements and SLP regulatory reporting requirements. Annual performance assessment to be conducted on EIA: Record of Decision relating to Operation Diesel Generator and Fridgeplant. 29 January 2027 None Execution of granted Section 102 applications None

25 KEY PERMIT CONDITIONS LIST MINING Mining right renewal applications are to be submitted 60 working days prior to the date of expiry of the right. The holder of the Mining Right must continue with mining operations, failing which the right may be suspended or cancelled. The terms of the right may not be varied or amended without the consent of the Minister of Mineral Resources and Energy. The Holder shall be entitled to abandon or relinquish the right or the area covered by the right entirely or in part. Upon abandonment or relinquishment, the Holder must: o Furnish the Regional Manager with all prospecting and/or mining results and/or information, as well as the general evaluation of the geological, geophysical and borehole data in respect of such abandoned area; and o Apply for a closure certificate in terms of section 43(3) of the MPRDA. The holder shall pay royalties to the State in accordance with section 25(2)g of the MPRDA throughout the duration of the mining right. Mining Operations must be conducted in accordance with the Mining Work Programme (MWP) and any amendment to the MWP and an approved Environmental Management Plan (EMP). The holder shall not trespass or enter into any homestead, house or its curtilage nor interfere with or prejudice the interests of the occupiers and/or owners of the surface of the Mining Area except to the extent to which such interference or prejudice is necessary for the purposes of enabling the Holder to properly exercise the Holder’s rights under the mining right. The holder must dispose of all minerals derived from mining at competitive market prices which shall mean, in all cases, non-discriminatory prices or non-export parity prices. A shareholding, an equity, an interest or participation in the mining right or joint venture, or a controlling interest in a company/JV may not be encumbered, ceded, transferred, mortgaged, let, sublet, assigned, alienated or otherwise disposed of without the written consent of the Minister, except in the case of a change of controlling interest in listed companies. All drillholes, shafts, adits, excavations and openings created by the holder shall be sealed, closed, fenced and made safe in accordance with the approved EMP and the Mine Health and Safety Act 29 of 1996 (MHSA). The holder of the mining right, while carrying out mining operations should safeguard and protect the environment, the mining area and any person who is entitled to use the surface of the mining area for possible damage or injury. The Minister or a person authorized by the Minister shall be entitled to inspect the Mining Area and the execution of the approved mining right conditions. A mining right may be cancelled or suspended subject to Section 47 of the MPRDA if the holder: o Submits inaccurate, incorrect and/or misleading information in connection with any matter required to be submitted under this Act; o Fails to honour or carry out any agreement, arrangement or undertaking, including the undertaking made by the Holder in terms of the Broad-Based Socio-Economic Empowerment Charter and Social and Labour Plan; 26 o Breaches any material term and condition of the mining right; o Conducts mining in contravention of the MPRDA; o Contravenes the requirements of the approved Environmental Management Programme; o Contravenes any provisions of this Act in any other manner. The Holder shall submit monthly returns contemplated in Section 28 (2) (a) of the MPRDA no later than the 15th of every month and maintain all such books, plans and records in regard to mining on the mining area as may be required by the Act. The Holder shall, at the end of each year, following the commencement of this mining right, inform the Regional Manager in writing of any new developments and of the future mining activities planned in connection with the exploitation/mining of the minerals in the mining area. Provisions relating to section 2(d) and section 2(f) of the MPRDA, relating to the Broad Based Socio Economic Empowerment Charter differ in each mining right. The Mining right does not exempt the holder from complying with the MHSA or any Act in South Africa. Annually, no later than three months before the financial year end, submit a detailed implementation plan to give effect to Regulation 46(e)(i), (ii) and (iii) in line with the Social and Labour Plan. Annually, no later than three months after the finalization of its audited annual report submit a detailed report on the implementation of the previous year’s Social and Labour Plan. SOCIAL AND LABOUR PLAN COMPLIANCE REQUIREMENTS New Social and Labour Plan to be submitted and reviewed every 5 years. Social and Labour Plan Implementation Plans to be submitted annually. Social and Labour Plan Annual Report to be submitted annually. ENVIRONMENTAL MANAGEMENT COMPLIANCE REQUIREMENTS Performance assessment relating to the Environmental Management Programme to be conducted bi-annually. Performance assessment relating to Water Use License to be conducted annually. Performance assessment relating to Atmospheric Emission License to be conducted annually. 27 Table 12: Summary of Mineral Title Properties - Kloof Farm Name Portion Kraalkop 147 IQ Portion 21 (a portion of Portion 10), Portion 25 (Blykop) (a portion of Portion 10) Foch 150 IQ Portion 1,7,11,21,39, Remaining Extent of Farm Luipaardsvlei 243 IQ Portion 3, 29, 34, 46 and Remaining Extent of Portion 1, 2, 31, 32, 33, 47 Middelvlei 255 IQ Portion 4 Uitval 280 IQ Portion 11, Remaining Extent of Farm Libanon or Witkleigat 283 IQ Portion 2, 3,4,6,7,8,10,11,12 and Remaining Extent of Farm Venterspos 284 IQ Portion 6, 92 , and Remaining Extent of Portion 31 Nelshoogte 286 IQ Portion 1 Gemspost 288 IQ Portion 3 (Westonaria Ext.2), 4, 5 (a portion of Portion 1), 6,12 ,15-19, 29,34-36, 39, 41, 42, 43 (Bekkersdal), 45-48, 49(Westonaria), 52, 53, Remaining Extent of Portion 38, 40(Westonaria) and Remaining Extent of Farm Gemsbokfontein 290 IQ Portion 5, 10, 12 (a portion of Portion 8), 13, 14 (a portion of Portion 8), 16, 20 (a portion of Portion 6), 23 , Remaining Extent of Portion 6, 8 Panvlakte 291 IQ Portion 2 (Westonaria Ext.1), 3 (Westonaria Ext.6), Remaining Extent of Farm Elandsfontein 346 IQ Portion 5 (a portion of Portion 1), 10 (a portion of Portion 1), 14 (a portion of Portion 3), 15, 16, 25, 30, 46 , Remaining Extent of Portion 1, 3, 4,7, 26, Doornpoort 347 IQ Portion 5, 15, 26-28, Portion of Portion 37, Remaining Extent of Portion 2 Doornkloof 348 IQ Remaining Extent of Portion 1, Remaining Extent of Farm Rietfontein 349 IQ Portion 6, 9, 12-14, 16, 19, 20, 25, 32, 33, 35, 36, 41, 42, 47, 48, (now Glenharvie Ext.1), 59 (now Glenharvie), 60 (now Glenharvie Ext.2), 61, 63-70, 72, 74, 76, Remaining Extent of Portion 2, 3, 5, 7, 10, 11, 15, 21, 22, 28, 34,58, 73 and Remaining Extent(of Farm?) Doornkloof 350 IQ Portion 5, 7, 8, 13, 19-22, 24, 27, 31, 33, 34, 36, 37, 39-41, 43, Remaining Extent of Portion 1,2, 4, 6, 10-12, 16, 23, 25, 29 Leeuwdoorn 351 IQ Portion 1, Remaining Extent of Farm Leeuwpoort 356 IQ Portion 24-26, 57-59, 62, 63, 75, 76, Remaining Extent of Portion 2, 4-8 Weltevreden 357 IQ Portion 3, 7, 9-13, 20,22, 23, 25, 27, 28, 30, 31, 33, Remaining Extent of Portion 5, 19,21, 26 Wildebeestkuil 360 IQ Portion 1, 4, 14, 16, Remaining Extent of Portion 3, 5, 13, and Remaining Extent of Farm Divonia 363 IQ Farm Rietfontein 519 IQ Portion 2, 9, 11-15, 19, 20, 23-25, and Remaining Extent of Portion 3, 7, 22 Rietfontein* 349 IQ Portion 6 (Kloof 193PR) 28 3.3 Royalties Sibanye-Stillwater Kloof Operation is not a royalty company nor receives royalties from any other operation. 3.4 Legal Proceedings and Significant Encumbrances to the Property The QPs have been advised by Sibanye-Stillwater that there are no material legal proceedings in relation to the Kloof Operations. It should, however, be noted that Sibanye-Stillwater may be involved in various non-material legal matters such as employment claims, third-party subpoenas and collection matters on an ongoing basis, which are not material to the Mineral Resources and Mineral Reserves reported for the Kloof Operations in this TRS. From the documentation reviewed and input by the relevant Technical Specialists and Experts, the QPs could not identify any significant encumbrances or any other significant factors or risks with regard to the title permitting, access, surface ownership, environmental and community factors that would prevent the mining or the ability to perform work on the Kloof Operations, and the declaration and disclosure of the Mineral Resources and Mineral Reserves for the Kloof Operations. The Kloof Operations comply with all title and environmental permitting requirements of the RSA. 4 Accessibility, Climate, Local Resources, Infrastructure and Physiography 4.1 Topography, Elevation and Vegetation The Kloof operation is located in the South African high veld (prairie) at an elevation of approximately 1,650m above mean sea level. The area surrounding Kloof is topographically relatively flat, and the vegetation of the area is classified as Bankenveld consisting of grassland. Livestock farming is widespread in the surrounding area. The natural fauna consists of small mammals and avifauna. This area is drained by the Wonderfonteinspruit, Leeuspruit and the Loopspruit. The northern portion of the mining area consists of gently undulating grassland which is dissected by the Wonderfonteinspruit. The majority of the Kloof Mining Right area is comprised of valley bottom wetlands associated with local river systems, including the Middelvleispruit, Wonderfonteinspruit, Leeuspruit and Loopspruit. 4.2 Access, Towns and Regional Infrastructure The Kloof operation is situated in the District Municipality of West Rand (Merafong City Local Municipality) at latitude 26° 24.3’S and longitude 27° 40.1’E near Carletonville in the Gauteng Province of South Africa. The site is accessed via the N12 highway between Johannesburg (50km to the east) and Potchefstroom (75km to the southwest). Gauteng province has a diverse range of airports catering to various needs, including the large-scale OR Tambo and Lanseria international airports. The town of Westonaria is the closest settlement. The closest city is Johannesburg, some 50km to the east of Westonaria.