UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 6-K

Report of Foreign Private Issuer

Pursuant to Rule 13a-16 or 15d-16

Under the Securities Exchange Act of 1934

For the month of February, 2025

Commission File Number: 001-38336

NUTRIEN LTD.

(Name of registrant)

Suite 1700, 211 19th Street East

Saskatoon, Saskatchewan, Canada

S7K 5R6

(Address of principal executive office)

Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40-F.

Form 20-F ☐ Form 40-F ☒

SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| NUTRIEN LTD. | ||||||

| Date: February 28, 2025 | By: | /s/ Noralee Bradley |

||||

| Name: | Noralee Bradley | |||||

| Title: | Executive Vice President, External Affairs and Chief Sustainability and Legal Officer | |||||

EXHIBIT INDEX

Exhibit 99.1

NUTRIEN LTD.

ALLAN

NATIONAL INSTRUMENT 43-101 TECHNICAL REPORT ON

ALLAN POTASH DEPOSIT (KL 112R C),

SASKATCHEWAN, CANADA

FEBRUARY 20, 2025

PREPARED BY: JODI DERKACH, P. GEO.

| CRAIG FUNK, P. ENG., P. GEO. |

NUTRIEN LTD.

GEOSERVICES & LAND—ENGINEERING, TECHNOLOGY & CAPITAL

SUITE 1700, 211 19TH STREET EAST

SASKATOON, SASKATCHEWAN, CANADA

S7K 5R6

QUALIFIED PERSONS: JODI DERKACH, P. GEO. AND CRAIG FUNK, P. ENG., P. GEO.

DATE AND SIGNATURE PAGE

The scientific and technical information included in this report has been prepared under the supervision of persons who are ‘‘qualified persons’’ under Canadian National Instrument 43-101. Jodi Derkach, P. Geo. and Craig Funk, P. Eng., P. Geo. are the qualified persons who supervised the preparation of the information presented in this report and who verified the data disclosed herein.

| /s/ “Jodi Derkach” | ||||||||

| Signature | Jodi Derkach P. Geo. | |||||||

| Senior Manager, Land & Resource Nutrien Ltd. |

||||||||

| Date | February 20, 2025 | |||||||

| /s/ “Craig Funk” | ||||||||

| Signature | Craig Funk, P. Eng., P. Geo. | |||||||

| Director, GeoServices & Land Nutrien Ltd. |

||||||||

| Date | February 20, 2025 | |||||||

2

AUTHOR PAGE

The scientific and technical information included in this report has been prepared by, or under the supervision of, persons who are ‘‘qualified persons’’ under Canadian National Instrument 43-101.

Jodi Derkach, B. Sc., Cert. GIS, P. Geo. (APEGS Member # 14897)

| • | Senior Manager, Land & Resource—Engineering, Technology & Capital |

| • | B. Sc. (Geology), University of Saskatchewan, Saskatoon, Saskatchewan, Canada, 2007 |

| • | Geographic Information Science for Resource Management Certificate, Saskatchewan Polytechnic, Prince Albert, Saskatchewan, Canada, 2010 |

| • | with Nutrien or its subsidiaries since 2010 |

Craig Funk, B. Sc., M. Sc., P. Eng., P. Geo. (APEGS Member # 16034)

| • | Director, GeoServices & Land—Engineering, Technology & Capital |

| • | B. Sc. (Geological Engineering – Geophysics), University of Saskatchewan, Saskatoon, Saskatchewan, Canada, 1989 |

| • | M. Sc. (Geophysics), University of Saskatchewan, Saskatoon, Saskatchewan, Canada, 1992 |

| • | with Nutrien or its subsidiaries since 2008 |

are the qualified persons who supervised the preparation of all information presented in this report and who verified the data disclosed herein.

The team of persons who conducted the work presented within this report consists of:

Lisa MacKenzie, Cert. GIS

| • | Senior Advisor, Land—Engineering, Technology & Capital |

| • | Geographic Information Science for Resource Management Certificate, Saskatchewan Polytechnic, Prince Albert, Saskatchewan, Canada, 2012 |

| • | with Nutrien or its subsidiaries since 2012 |

Jennifer Nicolay Lawlor, B. Sc., P. Geo. (APEGS Member # 16167)

| • | Senior Advisor, Land & Resource – Engineering, Technology & Capital |

| • | B. Sc. (Geology), University of Regina, Regina, Saskatchewan, Canada, 2008 |

| • | with Nutrien or its subsidiaries since 2013 |

The authors would like to acknowledge the many staff who provided information and expert reviews on portions of this report, as well as past contributions of former (retired) staff Terrance Danyluk and Arnfinn Prugger.

3

TABLE OF CONTENTS

| DATE AND SIGNATURE PAGE | 2 | |||||

| AUTHOR PAGE | 3 | |||||

| TABLE OF CONTENTS |

4 | |||||

| LIST OF FIGURES |

6 | |||||

| LIST OF TABLES |

7 | |||||

| 1.0 |

SUMMARY | 8 | ||||

| 2.0 |

INTRODUCTION | 10 | ||||

| 3.0 |

RELIANCE ON OTHER EXPERTS | 11 | ||||

| 4.0 |

PROPERTY DESCRIPTION AND LOCATION | 11 | ||||

| 4.1 |

GENERAL | 11 | ||||

| 4.2 |

MINERAL RIGHTS | 12 | ||||

| 5.0 |

ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY | 13 | ||||

| 6.0 |

HISTORY | 14 | ||||

| 7.0 |

GEOLOGICAL SETTING AND MINERALIZATION | 15 | ||||

| 8.0 |

DEPOSIT TYPE | 17 | ||||

| 9.0 |

EXPLORATION | 18 | ||||

| 10.0 |

DRILLING | 20 | ||||

| 11.0 |

SAMPLING PREPARATION, ANALYSES AND SECURITY | 22 | ||||

| 11.1 |

BASIC APPROACH | 22 | ||||

| 11.2 |

MEAN POTASH MINERAL GRADE FROM IN-MINE SAMPLES | 24 | ||||

| 11.3 |

POTASH ORE DENSITY FROM IN-MINE MINERAL GRADE MEASUREMENTS | 25 | ||||

| 12.0 |

DATA VERIFICATION | 26 | ||||

| 12.1 |

ASSAY DATA | 26 | ||||

| 12.2 |

EXPLORATION DATA | 26 | ||||

| 13.0 |

MINERAL PROCESSING AND METALLURGICAL TESTING | 27 | ||||

| 14.0 |

MINERAL RESOURCE ESTIMATES | 27 | ||||

| 14.1 |

DEFINITIONS OF MINERAL RESOURCE | 27 | ||||

4

| 14.2 |

ALLAN POTASH RESOURCE CALCULATIONS | 28 | ||||

| 15.0 |

MINERAL RESERVE ESTIMATES | 29 | ||||

| 15.1 |

DEFINITIONS OF MINERAL RESERVE | 29 | ||||

| 15.2 |

ALLAN POTASH RESERVE CALCULATIONS | 30 | ||||

| 16.0 |

MINING METHOD | 31 | ||||

| 16.1 |

MINING OPERATIONS | 31 | ||||

| 16.2 |

RISKS TO POTASH MINING OPERATIONS, WITH EMPHASIS ON WATER INFLOWS | 34 | ||||

| 17.0 |

RECOVERY METHODS | 34 | ||||

| 18.0 |

PROJECT INFRASTRUCTURE | 36 | ||||

| 19.0 |

MARKET STUDIES AND CONTRACTS | 36 | ||||

| 20.0 |

ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT | 39 | ||||

| 21.0 |

CAPITAL AND OPERATING COSTS | 41 | ||||

| 22.0 |

ECONOMIC ANALYSIS | 41 | ||||

| 22.1 |

FUNDAMENTALS | 41 | ||||

| 22.2 |

TAXES | 42 | ||||

| 23.0 |

ADJACENT PROPERTIES | 42 | ||||

| 24.0 |

OTHER RELEVANT DATA AND INFORMATION | 42 | ||||

| 25.0 |

INTERPRETATION AND CONCLUSIONS | 42 | ||||

| 26.0 |

RECOMMENDATIONS | 42 | ||||

| 27.0 |

REFERENCES | 43 | ||||

5

LIST OF FIGURES

Unless otherwise noted, figures for which a source and / or date are not provided are current as of the effective date of this report and were prepared by the Company.

| Figure 1: Aerial photo of Allan surface operations, 2012 |

8 | |||

| Figure 2: Actual finished potash products production from the Allan mine over the past 10 years (in million tonnes per year) |

9 | |||

| Figure 3: Map showing location of Nutrien Operations, including Allan |

11 | |||

| Figure 4: Nutrien’s potash operations, including Allan, relative to potash mineralization (pink) in Saskatchewan |

12 | |||

| Figure 5: Map showing Allan Crown Lease KL 112R C (blue) |

13 | |||

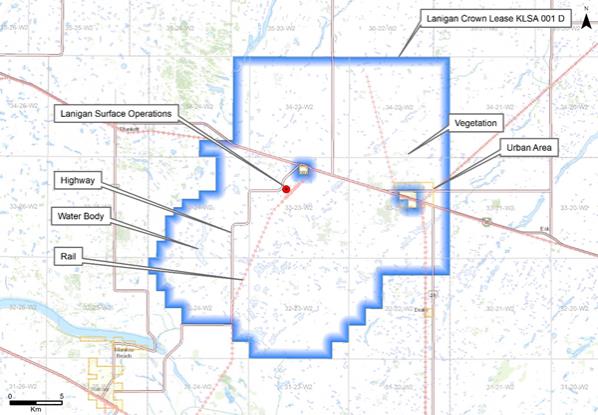

| Figure 6: Map showing infrastructure near Allan. Allan surface operations shown as red dot |

14 | |||

| Figure 7: Vertical section showing basic layered-Earth stratigraphy in a typical Saskatchewan potash region |

16 | |||

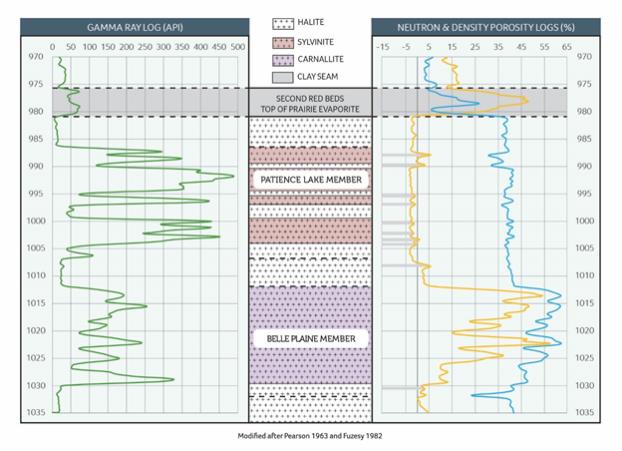

| Figure 8: Geophysical wireline logs showing basic stratigraphy of the Prairie Evaporite Formation in the Saskatoon area |

17 | |||

| Figure 9: Cross-section of the Prairie Evaporite Formation across southern Saskatchewan showing relative position of potash members |

18 | |||

| Figure 10: Potash exploration at Allan including 3D seismic (purple), 2D seismic infill (orange lines), and potash drillholes (black dots) |

19 | |||

| Figure 11: A seismic section showing relative rock velocities and major geological units at Nutrien’s conventional potash operations |

20 | |||

| Figure 12: Stratigraphic section showing local nomenclature at, and adjacent to, the mining horizon |

21 | |||

| Figure 13: Potash assay plot for PCS Allan 09-27-034-01 W3 indicating the best 3.35 m (11’) mining interval |

23 | |||

| Figure 14: Histogram of potash ore grade from Allan in-mine grade samples (data from 1968 through to the end of 2024) |

24 | |||

| Figure 15: Map showing Allan Mineral Resource as of December 2024 |

29 | |||

| Figure 16: Map showing Allan Mineral Reserve to December 2024 |

31 | |||

| Figure 17: Schematic cross-section through the Prairie Evaporite Formation, illustrating mining horizons at each of Nutrien’s conventional potash operations |

32 | |||

| Figure 18: Mined tonnes, product tonnes, and concentration ratio for the Allan mine over the past 10 years |

34 | |||

| Figure 19: Simplified flow diagram for potash flotation and crystallization milling methods used at Allan |

35 | |||

| Figure 20: Allan mill recovery rate over the past 10 years |

35 | |||

| Figure 21: Historical Company potash sales 2015 to 2024 in million tonnes / year* |

37 | |||

| Figure 22: Historical Company potash net sales 2015 to 2024 in million USD $ / year* |

37 | |||

| Figure 23: World potash production and demand for 2024E |

38 | |||

| Figure 24: World potash shipments and consumption, 2019-2024E |

39 | |||

| Figure 25: Aerial photo showing the Allan surface operations, disposal wells, and Tailings Management Area |

40 | |||

| Figure 26: Historic annual average realized potash price in USD / tonne* |

41 |

6

LIST OF TABLES

| Table 1: Potash Mineral Resources and Reserves for Allan, as of December 31, 2024 |

10 | |||

| Table 2: Assay results for all potash test holes within Allan Lease KL 112R C |

22 | |||

| Table 3: Values for potash assay plot in Figure 13 |

23 | |||

| Table 4: Primary Potash Market Profile |

38 |

7

EFFECTIVE DATE OF REPORT

The effective date of this report is December 31, 2024, other than where otherwise noted.

| 1.0 | SUMMARY |

Effective January 1, 2018, Potash Corporation of Saskatchewan Inc. (“PotashCorp”) and Agrium Inc. (“Agrium”) completed a court-approved plan of arrangement (the “Arrangement”), involving, among others, PotashCorp, Agrium and Nutrien Ltd. (“Nutrien”) the new parent company of PotashCorp and Agrium. As a result of completing the Arrangement, PotashCorp and Agrium are wholly-owned subsidiaries of Nutrien. References to “the Company” means Nutrien, indirectly through PotashCorp, or, for references prior to the completion of the Arrangement, PotashCorp, as the context requires.

Nutrien is a leading global provider of crop inputs and services. We operate a world-class network of production, distribution and agriculture retail facilities that positions us to efficiently serve the needs of farmers.

Nutrien is a corporation organized under the Canada Business Corporations Act, the common shares of which are listed and publicly traded on the Toronto and New York stock exchanges (symbol NTR).

The Company owns and operates a potash mine at Allan, Saskatchewan, Canada (“Allan mine” or “Allan”). An aerial view of the Allan surface operations is shown in Figure 1. The Allan Crown Subsurface Mineral Lease is numbered KL 112R C (the “Allan Crown Lease”) and was last amended in January 2021. Production of potash from the Allan mine began in 1968.

Figure 1: Aerial photo of Allan surface operations, 2012.

In 2024, annual nameplate capacity for Allan was 4.0 million tonnes and annual operational capability was 2.4 million tonnes of finished potash products (concentrated KCl). Estimates of nameplate capacity are based on capacity as per design specifications or Canpotex entitlements once these have been determined. Operational capability is the estimated annual achievable production level at current staffing and operational readiness (estimated at beginning of year), not including any inventory-related shutdowns and unplanned downtime and may vary during the year and year-to-year including as between our potash operations. While the term potash refers to a wide variety of potassium bearing minerals, in the Allan region of Saskatchewan, the predominant potash mineralization is sylvinite, which is comprised mainly of the minerals sylvite (KCl / potassium-salt) and halite (NaCl / rock salt), with minor amounts water insolubles.

8

Carnallite (KMgCl3 · 6H2O) occurs only in trace amounts at Allan. Potash fertilizer is concentrated, nearly pure KCl (i.e. greater than 95% pure KCl), but ore grade is traditionally reported on a % K2O equivalent basis. The “% K2O equivalent” gives a standard measurement of the nutrient value of different potassium-bearing rocks and minerals. To convert from % K2O equivalent tonnes to actual KCl tonnes, multiply by 1.58.

The Allan mine is a conventional underground mining operation whereby continuous mining machines are used to excavate the potash ore by the stress-relief mining method, with continuous conveyor belt transport of ore from the mining face to the bottom of the production shaft. In addition to hoisting potash ore to surface, the production shaft also provides fresh air ventilation to the mine and serves as a secondary egress. The Service Shaft is used for service access, and exhaust ventilation from the mine. Raw potash ore is processed and concentrated on surface and concentrated finished potash products (near-pure KCl) are sold and shipped to markets in North America and offshore.

Virtually all Allan underground mining rooms are in the potash mineralized zone situated approximately 12 m below the top of the host evaporite salt, the Prairie Evaporite Formation. More specifically, the Allan mine is located within the Patience Lake Member of the Prairie Evaporite Formation. In this Member, there are two potash seams named A Zone (the upper seam) and B Zone (the lower seam); at present, only the A Zone is being mined at Allan. Mine elevations range from approximately 980 m to 1,120 m depth below surface. These depths to A Zone potash mineralization are anticipated over most of the Allan lease area. Mine workings are protected from aquifers in overlying formations by salt which overlies the mineralized zone. Conservative local extraction ratios (never exceeding 45% in any mining block) are employed at Allan to minimize potential detrimental effects of mining on overlying strata; this is common practice in flat-lying, tabular ore bodies overlain by water-bearing layers.

Part of the normal surface infrastructure associated with operating the potash mine in Saskatchewan includes waste disposal on the land and disposal of salt brine into deep subsurface aquifers. The Company stows salt tailings within an engineered and licensed Tailings Management Area (TMA) and operates two brine disposal wells near the surface plant of the Allan mine.

Since opening in 1968, 192.352 million tonnes of potash ore have been mined and hoisted at Allan to produce 67.990 million tonnes of finished potash products. The life-of-mine average concentration ratio (raw ore / finished potash products) is 2.83 and the overall extraction ratio over this period is 28%. Actual production of finished potash products at Allan for the last 10 years is shown in Figure 2.

Figure 2: Actual finished potash products production from the Allan mine over the past 10 years (in million tonnes per year).

Over the past three years (2022, 2023, 2024), actual potash production at Allan has totaled:

| • | 20.368 million tonnes of ore mined and hoisted (6.789 million tonnes per year, on average) |

| • | 7.290 million tonnes of finished potash products produced (2.430 million tonnes per year, on average) |

| • | Average mill feed ore grade was 25.0% K2O equivalent |

| • | Average concentration ratio (ore mined / potash produced) was 2.79 |

9

The Canadian Institute of Mining and Metallurgy and Petroleum (CIM) has defined Mineral Resources and Reserves in The CIM Definition Standards for Mineral Resources and Reserves (2014). Based on these guidelines, all mineral rights owned or leased by the Company at Allan can be assigned to Mineral Resource categories (Inferred, Indicated, and Measured) and Mineral Reserve categories (Probable and Proven). Mineral Resources (reported as in-place tonnes) and Mineral Reserves (reported as recoverable ore tonnes) for Allan as of December 31, 2024, are outlined in Table 1. Mineral Resources reported are exclusive of Mineral Reserves.

Table 1: Potash Mineral Resources and Reserves for Allan, as of December 31, 2024.

| Proven Mineral Reserve (millions of tonnes recoverable ore) |

99 | |||

| Probable Mineral Reserve (millions of tonnes recoverable ore) |

260 | |||

|

|

|

|||

| Total Mineral Reserve (millions of tonnes recoverable ore) |

359 | |||

| Measured Mineral Resource - A Zone (millions of tonnes in-place) |

1,625 | |||

| Measured Mineral Resource - B Zone (millions of tonnes in-place) |

2,168 | |||

| Indicated Mineral Resource - A Zone (millions of tonnes in-place) |

2,157 | |||

| Indicated Mineral Resource - B Zone (millions of tonnes in-place) |

2,157 | |||

| Inferred Mineral Resource - A Zone (millions of tonnes in-place) |

1,197 | |||

| Inferred Mineral Resource - B Zone (millions of tonnes in-place) |

1,197 | |||

|

|

|

|||

| Total Mineral Resource (millions of tonnes in-place) |

10,501 | |||

| Average % K2O Grade - A Zone (from Allan in-mine samples) |

24.5 | % | ||

| Average % K2O Grade - B Zone (from Lanigan in-mine samples) |

20.2 | % | ||

|

|

|

|||

| Years of Remaining Mine Life |

53 | |||

The average mineral grade of the Allan Mineral Resource and Mineral Reserve is estimated to be 24.5% K2O equivalent and was determined from thousands of in-mine samples at Allan to the end of December 2024 (discussed further in Section 11.2).

Potash production in any given year at the Allan potash mine is a function of many variables, so actual production in any given year can vary dramatically from tonnages produced in previous years. The Mineral Reserve tonnage and historic average production are used to estimate the remaining mine life. If the average mining rate seen over the past three years (6.789 million tonnes of potash ore mined and hoisted per year) is sustained, and if Mineral Reserves remain unchanged, then the Allan mine life is 53 years from December 31, 2024.

The mining of potash is a capital-intensive business subject to the normal risks and capital expenditure requirements associated with mining operations. The production and processing of ore may be subject to delays and costs resulting from mechanical failures, physical hazards such as fires, and other hazards such as: unusual or unexpected geological conditions, significant subsidence, brine inflows and gas seepages of varying degree, and other situations associated with any potash mining operation.

| 2.0 | INTRODUCTION |

The purpose of this document is to give a formal reporting of potash Mineral Resource and Reserve for Allan, and to provide a description of the method used to compute Mineral Resource and Reserve tonnages. Sources of geological and geotechnical information analysed from this study include:

| • | Publicly available geological maps, reports, and publications (listed in Section 27.0) |

| • | Data and internal reports on exploration drillholes |

| • | Hydrogeological analysis conducted in exploration drillholes |

| • | Geological studies conducted at the Allan mine over the past 50+ years |

| • | In-mine geophysical studies conducted at the Allan mine over the past 50+ years |

| • | Geotechnical studies conducted for the Allan mine over the past 50+ years |

| • | 2D & 3D surface seismic exploration data |

All data and reports are archived at the Nutrien corporate office in Saskatoon, the Allan mine site, or secure offsite commercial document storage facilities. In addition, drillhole data (well-log data, drilling reports, drill-stem test results, etc.) are archived with the Saskatchewan Ministry of Energy & Resources, Integrated Resource Information System (IRIS), and surface seismic data (shot records and stack) are archived through an offsite commercial data storage service.

10

All geological and geophysical data and information presented in this report were personally reviewed and inspected by qualified geoscience staff at Nutrien who are registered with the Association of Professional Engineers and Geoscientists of Saskatchewan (APEGS) under the supervision of Jodi Derkach, P. Geo. and Craig Funk, P. Eng., P. Geo. Jodi Derkach last visited Allan on November 14, 2024. Craig Funk last visited Allan on March 19, 2024. All reserve and resource estimates and mineral rights data presented in this report were personally evaluated and reviewed by the authors of this report. Each of these staff collaborates with Allan personnel multiple times per year.

The authors would like to acknowledge the many staff who provided information and expert reviews on portions of this report.

| 3.0 | RELIANCE ON OTHER EXPERTS |

Responsibility for the accuracy of the technical data presented in this report is assumed by the authors. Outside experts were not used in the preparation of this report.

| 4.0 | PROPERTY DESCRIPTION AND LOCATION |

| 4.1 | GENERAL |

The Allan mine is located in central Saskatchewan, approximately 45 km east of the city of Saskatoon, Saskatchewan. The general location is shown on the map in Figure 3.

Figure 3: Map showing location of Nutrien Operations, including Allan.

The legal land description (Saskatchewan Township / Range) of the Allan surface plant is Section 22 Township 34 Range 01 West of 3rd Meridian. More precisely, the Allan Shaft #2 collar is located at:

| – |

Latitude: |

51 degrees 55 minutes 55.56 seconds North | ||

| – |

Longitude: |

106 degrees 04 minutes 18.84 seconds West | ||

| – |

Elevation: |

524.26 metres above mean Sea Level (SL) | ||

| – |

Easting: |

426,303.225 m |

11

| – |

Northing: |

5,754,028.978 m | ||

| – |

Projection: |

UTM | ||

| – |

Datum: |

NAD83 | ||

| – |

Zone: |

13 |

The Company owns approximately 3,431 hectares (8,478 acres) of surface rights required for current Allan mine operations, including areas covered by the existing surface plant and TMA, and surface lands required for anticipated future Allan mine and expanded milling operations.

All permits and approvals required for the operation of a potash mine in Saskatchewan are in place at Allan.

Figure 4 is a more detailed map showing the location of Allan relative to the potash deposits in Saskatchewan (modified from Yang, 2009).

Figure 4: Nutrien’s potash operations, including Allan, relative to potash mineralization (pink) in Saskatchewan.

| 4.2 | MINERAL RIGHTS |

Mineral rights at Allan are mined pursuant to subsurface mineral leases with the Province of Saskatchewan, Canada (the Crown), and with non-Crown (Freehold) mineral rights owners. Crown mineral rights are governed by The Subsurface Mineral Tenure Regulations, 2015, and Crown Leases are approved and issued by the Saskatchewan Ministry of Energy & Resources.

The original Allan Crown Subsurface Mineral Lease, numbered KL 112, was made effective in September 1962. In the following years various amendments were made whereby certain lands were added, removed, or transferred between Company dispositions for realized synergies between mining operations. The last amendment was executed in January 2021, resulting in Crown Subsurface Mineral Lease KL 112R C (the “Allan Crown Lease” or simply “KL 112 C”).

12

KL 112 C covers an area of approximately 80,950 hectares (200,032 acres) as shown in Figure 5. At Allan, the Company has leased potash mineral rights for 50,690 hectares (125,257 acres) of Crown Land and owns or has leased approximately 27,071 hectares (66,893 acres) of Freehold Land within the lease boundary. The Allan Crown Lease term is for a period of 21 years and is renewable in accordance with The Subsurface Mineral Tenure Regulations, 2015 for successive 21-year periods. Freehold Lands also remain under lease providing, generally, that production is continuing and that there is a continuation of the Crown Lease.

Within the Allan Crown Lease area, 67,198 hectares (166,049 acres) are mined pursuant to unitization agreements with mineral rights holders (Crown and Freehold) within four unitized areas.

When underground workings of a potash mine are designed, there are inevitably regions that are mined with higher mining extraction (e.g. production panels) and other regions where mining extraction is lower (e.g. conveyor-belt development rooms). To treat mineral rights holders in both low extraction and high extraction areas fairly, and to promote good mining practices, a unitization agreement is the preferred method for determining royalty payouts. Under a unitization agreement, each mineral rights holder is paid a royalty based on their proportional share of the entire Unit Area regardless of whether their lands are mined. For example, if one mineral rights holder owns rights to 4,000 hectares within a 40,000-hectare Unit Area, they would be paid 10% of the total monthly royalty payout from that Unit Area.

Figure 5: Map showing Allan Crown Lease KL 112R C (blue).

| 5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

The Allan mine surface facilities are accessed by an existing paved road that is part of the Saskatchewan Provincial Highway System. All potash product is shipped by rail over existing track. Location of Allan with respect to the features described in this section (major road and rail infrastructure, as well as nearby river systems) is shown in Figure 6.

The Allan mine is served by a number of villages within 50 km of the mine site. The nearest city is Saskatoon (45 km distant).

13

Allan is situated near the northern extent of the Great Plains of North America. Topography is relatively flat, with gently rolling hills and occasional valleys. There are no rivers or other major watercourse channels near the Allan mine site. Climate at the Allan mine is typical for an inland prairie location at latitude 52º North (often characterized as “mid-latitude steppe” climate).

Part of the normal surface infrastructure associated with operating the potash mine in Saskatchewan includes waste disposal on the land and disposal of salt brine into deep subsurface aquifers. Facilities to carry out all aspects of these tasks are in place at Allan (see Section 20.0).

Figure 6: Map showing infrastructure near Allan. Allan surface operations shown as red dot.

| 6.0 | HISTORY |

Ten potash mines were brought into production in Saskatchewan between 1962 and 1970. Until 2017, no new mine had been commissioned following the original ten. Most current potash production comes from conventional underground mines, while just three operate using solution mining methods. Generally, potash mines have contracted or expanded production over the years in response to the demand for potash.

Exploration drilling for potash in the Allan area was carried out in the 1950s and 1960s. The Allan mine was built by a consortium of companies (U. S. Borax, Homestake Potash Company, and Swift Canadian Company) in the 1960s. Potash production began at Allan in April 1968 and the mine has run on a continuous basis since then other than short-term shutdowns taken for inventory management purposes, occasional plant maintenance and construction work, or other outages that are typical for operations of this nature.

PotashCorp acquired a 60% ownership of the Allan mine in 1978 (through purchase of the U. S. Borax and Swift Canadian interests) and became the operator of the mine in 1981. In 1990, PotashCorp purchased the remaining 40% interest.

14

Effective January 1, 2018, PotashCorp and Agrium completed the Arrangement. As a result of completing the Arrangement, PotashCorp and Agrium are wholly-owned subsidiaries of Nutrien.

Both flotation and crystallization methods are used at Allan to produce potash products for agricultural and industrial application. Debottlenecking and compaction expansion projects were completed at Allan during two phases of construction in 2005 and 2007. A major refurbishment and expansion of the Allan mine was completed in 2013, increasing nameplate capacity to 4.0 million tonnes of finished potash products per year.

| 7.0 | GEOLOGICAL SETTING AND MINERALIZATION |

Much of southern Saskatchewan is underlain by the Prairie Evaporite Formation, a layered sequence of salts and anhydrite which contains one of the world’s largest deposits of potash. The potash extracted from the predominantly sylvinite ore has its main use as a fertilizer. A map showing the extent of the potash deposits in Saskatchewan is shown in Figure 4.

The 100 m to 200 m thick Prairie Evaporite Formation is overlain by between 400 and 500 m of Devonian carbonates, followed by approximately 100 m of Cretaceous sandstone, and between 400 and 500 m of Cretaceous shales and more recent Pleistocene glacial tills to surface; it is underlain by Devonian carbonates (Fuzesy, 1982). The Phanerozoic stratigraphy of Saskatchewan is remarkable in that units are flat-lying and relatively undisturbed over very large areas. A geological section representing Saskatchewan stratigraphy is shown in Figure 7 (modified from Fuzesy, 1982). A geological section representing the Prairie Evaporite Formation stratigraphy in the Saskatoon area is shown in Figure 8 (modified from Fuzesy, 1982).

15

Figure 7: Vertical section showing basic layered-Earth stratigraphy in a typical Saskatchewan potash region.

Potash mineralization in this region of Saskatchewan is predominantly sylvinite, which is comprised mainly of the minerals sylvite (KCl) and halite or rock salt (NaCl), with trace carnallite (KMgCl3 · 6H2O) and minor water insolubles. Potash fertilizer is concentrated, nearly pure KCl (i.e. greater than 95% pure KCl), but ore grade is traditionally reported on a % K2O equivalent basis. The “% K2O equivalent” gives a standard measurement of the nutrient value of different potassium-bearing rocks and minerals. To convert from % K2O equivalent tonnes to actual KCl tonnes, multiply by 1.58.

Over the past three years (2022, 2023, 2024), the average, measured potash ore grade of the mill feed at Allan was 25.0% K2O equivalent. The average ore grade reported from surface drillhole intersections, all within Allan Subsurface Mineral Lease KL 112R C, is 26.8% K2O equivalent (discussed further in Section 10.0). The average ore grade observed from thousands of in-mine samples collected to the end of 2024 is 24.5% K2O equivalent (discussed further in Section 11.2).

16

Figure 8: Geophysical wireline logs showing basic stratigraphy of the Prairie Evaporite Formation in the Saskatoon area.

| 8.0 | DEPOSIT TYPE |

There are three mineable potash members within the Prairie Evaporite Formation of Saskatchewan. Stratigraphically highest to lowest, these members are: Patience Lake, Belle Plaine, and Esterhazy. A geological section showing potash members that occur in Saskatchewan is shown in Figure 9.

The Allan potash deposit lies within the Patience Lake Member of Prairie Evaporite Formation. There are two potash seams named A Zone and B Zone within this member; at present, only the A Zone is being mined at Allan. Some test mining has been carried out in the B Zone, but no mining is done in this layer at present. The Belle Plaine Member and the Esterhazy Member are present but not necessarily well-developed in the Allan area.

Allan potash mineralization occurs at about 1,000 m depth below surface. The A Zone is approximately 3.35 m thick and occurs near the top of the Prairie Evaporite Formation salts. Salt cover from the ore zone to overlying units is approximately 12 m. The Allan mine operates as a conventional, underground potash mine.

17

Figure 9: Cross-section of the Prairie Evaporite Formation across southern Saskatchewan showing relative position of potash members.

| 9.0 | EXPLORATION |

Before the Allan mine was established in 1968, all exploration consisted of drilling from surface and analysis of core from these drillholes; drilling results are discussed in Section 10.0. Since mining began in 1968, exploration drilling has been infrequent. Now, drilling is most often used to derisk mining. A map showing potash exploration coverage at Allan (drillholes, 2D and 3D seismic coverage) is shown in Figure 10.

In most of southern Saskatchewan, potash mineralization is in place wherever Prairie Evaporite Formation salts exist, are flat-lying, and are undisturbed. Since the surface seismic exploration method is an excellent tool for mapping the top and bottom of Prairie Evaporite salts, this has become the main potash exploration tool in any existing Saskatchewan Subsurface (potash) Mineral Lease. Historically, 2D seismic, and now the more accurate and full coverage 3D seismic methods are used to infer continuity and extent of potash beds in flat-lying potash deposits. Seismic data are relied upon to identify collapse structures that must be avoided in the process of mine development since these structures can act as conduits for water ingress to the mine. As a result, isolation pillars or mining buffer zones are left around these anomalous features. This practice reduces the overall mining extraction ratio, but the risk of inflow to mine workings are effectively mitigated. Occasional, small-scale salt anomalies that are not mapped by seismic data do occur. When they do, they are dealt with in the normal course of mining and extraction through these areas is typically minimized. Where there is uncertainty in seismic interpretations, drilling is often used to confirm or improve refine the seismic interpretation.

Within the Allan Crown Lease, a total of 357 linear kilometres of 2D seismic lines, and 585 square kilometres of 3D seismic has been acquired to the end of December 2024.

18

Figure 10: Potash exploration at Allan including 3D seismic (purple), 2D seismic infill (orange lines), and potash drillholes (black dots).

A typical seismic section from Nutrien’s conventional seismic operations is shown in Figure 11. This is a cross-section extracted from a multi-program 3D seismic volume (earliest program was 2002). The vertical scale is in metres relative to sea level (SL). The seismic section is coloured by rock velocities computed from the seismic data and represents different rock types. Note that the Prairie Evaporite (salt) is continuous. This indicates an undisturbed, flat-lying salt within which potash is likely to be found based on over 50 years of mining experience at Allan.

Experience has shown that the potash mining horizon is continuous when seismic data are undisturbed and flat-lying, as shown in Figure 11. It is now Nutrien’s policy to collect detailed 3D seismic data ahead of mining. Any areas recognized as seismically unusual are identified early, and mine plans are adjusted as needed.

19

Figure 11: A seismic section showing relative rock velocities and major geological units at Nutrien’s conventional potash operations.

| 10.0 | DRILLING |

For the original Allan potash test holes drilled in the 1950s and 1960s, the primary objective was to sample potash horizons to establish basic mining parameters. The seismic method was still novel and crude at that time and as such, 2D seismic surveys were done sparingly, so the drillhole information was relied upon heavily to evaluate potash deposits. Test holes would penetrate the evaporite section with a hydrocarbon-based drilling mud (oil-based or diesel fuel) to protect the potash mineralization from dissolution. Basic geophysical well-logs were acquired, and in many cases, drill stem tests were run on the Dawson Bay Formation to help assess water-make potential of the caprock. Core samples from the targeted potash intersections were split or quartered (cut with a masonry saw), crushed and analysed to establish potash grades.

Relatively thin interbeds or seams of insoluble material, referred to as clay seams in the potash industry, are an ever-present component of the A Zone and B Zone at Allan. Figure 12 shows the basic stratigraphic relationships. These seams, along with the clay and other detrital minerals disseminated throughout the potash rock matrix, make up the water insoluble portion of the ore. The same sequences of clay seams can be correlated for many kilometres across the central Saskatchewan potash mining district.

At Allan, a particular sequence of three clay seams marks the top of the A Zone, as illustrated in Figure 12 (modified from Robertson, 1978). These seams are used to guide the vertical positioning of the mining machine. The uppermost portion of the sequence of three seams is maintained at the top of the mining cut to keep the mining machines “on grade”. Cutting too high above this upper seam or top marker results in dilution, as halite (rather than sylvinite) immediately overlies the production zone. In practice though, the top marker seam is slightly overcut (between 10 cm to 20 cm) to prevent an unstable condition from being created. Clay seams are often planes of weakness, and if they are undercut, material immediately below the clay seam becomes a hazard as it may separate and fall. Since the hazard must be remediated prior to proceeding, thus slowing production, the moderately diluted mineral grade that results from the overcutting is preferable from a safety point of view.

20

The A Zone mining interval was historically fixed at 3.35 m (11’). These mining heights allow for comfortable working headroom and efficient extraction of potash ore.

Figure 12: Stratigraphic section showing local nomenclature at, and adjacent to, the mining horizon.

The original exploration area was explored with several test holes spaced at intervals of 1.6 km to 6.4 km (1 – 4 miles). Assays from most of these original test holes were studied by independent consultant David S. Robertson and Associates (1978) and are found in Table 2. Drillholes following the original test holes were analysed by Nutrien staff and are listed in Table 2 below. All drilling and sampling were carried out following the regulations in place at the time.

In each case, the best 3.35 m (11’) mining interval intersected in each drillhole was determined from the assay values, using clay marker seams as a guide. Note that five test holes were omitted from the assay calculation for one of the following reasons: a section of missing core in the ore zone, erroneous assay data which could not be resolved, or anomalous ore grade of less than 15% K2O. Another drillhole was missing insoluble analytical results. With over 50 years of mining experience at Allan, it is the opinion of the authors that areas of low grade (i.e. <15% K2O) are localized with a relatively small lateral extent.

Drillhole assay data for the A Zone at Allan gives an estimated mean grade of 26.8% K2O with 4.9% water insolubles.

21

B Zone mineralization is indicated by gamma ray geophysical log response in each of the exploration drillholes listed in Table 2 indicating a potash Mineral Resource. Some test mining of the B Zone has been done. However, sustained production from that zone has not been established. Assay results for the B Zone are not presented here.

Table 2: Assay results for all potash test holes within Allan Lease KL 112R C.

| Average in 3.35 m (11’) mining interval (undiluted) |

||||||

| Drillhole |

Year Drilled |

% K2O |

% Water Insolubles |

|||

| 04-10-033-01 W3 |

1954 | * | * | |||

| 12-32-034-02 W3 |

1956 | 28.7 | 5.8 | |||

| 16-11-033-01W3 |

1956 | * | * | |||

| 04-29-034-01 W3 |

1957 | 25.8 | 4.7 | |||

| 01-25-034-01 W3 |

1957 | 28.1 | 4.7 | |||

| 16-11-034-02 W3 |

1957 | 29.1 | 3.4 | |||

| 13-11-034-01 W3 |

1957 | 28.8 | 4.5 | |||

| 13-11-034-03 W3 |

1957 | 22.0 | 1.7 | |||

| 16-09-035-01 W3 |

1957 | 25.0 | 5.1 | |||

| 05-26-035-01 W3 |

1957 | 16.8 | * | |||

| 09-29-033-02 W3 |

1957 | * | * | |||

| 09-28-034-01 W3 |

1961 | 29.5 | 5.3 | |||

| 09-27-034-01 W3 |

1961 | 30.6 | 4.5 | |||

| 09-26-034-01 W3 |

1961 | 27.7 | 6.3 | |||

| 09-33-034-01 W3 |

1961 | 24.0 | 5.39 | |||

| 08-34-034-01 W3 |

1961 | 26.3 | 5.8 | |||

| 09-35-034-01 W3 |

1961 | 25.9 | 8.6 | |||

| 05-22A-034-01 W3 |

1961 | 26.5 | 3.2 | |||

| 16-14-034-01 W3 |

1962 | 26.8 | 5.3 | |||

| 01-17-034-01 W3 |

1962 | 28.6 | 5.3 | |||

| 01-12-034-01 W3 |

1962 | * | * | |||

| 14-23-034-03 W3 |

1969 | 29.6 | 4.2 | |||

| 14-23-035-02 W3 |

2021 | 28.0 | 4.6 | |||

| 15-31-034-28 W2 |

2022 | 28.3 | 4.6 | |||

| 04-08-035-28 W2 |

2023 | 26.8 | 4.7 | |||

|

|

|

|||||

| Average (from 21 usable values): |

26.8 | 4.9 | ||||

|

|

|

|||||

Due to the remarkably consistent mineralogy and continuity of the resource, as experienced through decades of mine production, very little potash exploration drilling has been done at Allan since production began. Instead of exploration drillholes, seismic surveying has been relied upon to explore ahead of mine development. Where normal Prairie Evaporite sequences are mapped in the seismic data, potash beds have unfailingly been present. Occasional, small-scale salt anomalies not mapped by seismic data do occur. When they do, they are dealt with in the normal course of mining, and extraction through these areas is typically minimized. Anomalies associated with possible water inflow problems, which are mapped in the seismic data, are avoided.

| 11.0 | SAMPLING PREPARATION, ANALYSES AND SECURITY |

| 11.1 | BASIC APPROACH |

Exploration drilling in the Allan area was conducted in the 1950s and 1960s. Sampling and assaying of potash core samples was done using methods considered consistent with standard procedures for potash exploration at these times.

Drillhole sampling methods have remained essentially the same over the years. Potash core samples are acquired as described in earlier sections of this report. Short segments of core usually about 0.3 m (1’) in length are labeled based on visible changes in mineralization, and sometimes based on fixed intervals. Each segment of core is then split using some type of rock or masonry saw. The split portion of core is then bagged and labeled and sent to a laboratory for chemical analysis. Historical potash samples remain stored at the Subsurface Geological Laboratory (Regina, Saskatchewan) of the Saskatchewan Ministry of Energy & Resources.

22

Figure 13: Potash assay plot for PCS Allan 09-27-034-01 W3 indicating the best 3.35 m (11’) mining interval.

An assay plot for drillhole PCS Allan 09-27-034-01 W3 is shown above in Figure 13. Similar data were compiled for all historical potash test holes. The best 3.35 m (11’) mining interval intersected in each drillhole, as discussed in Section 10.0, is determined from the assay values, using clay seams as a guide. Table 3 lists the assay values plotted in Figure 13.

Table 3: Values for potash assay plot in Figure 13.

All new drilling efforts have targeted areas of geological uncertainty. Although normal ore zone conditions may occur in the tested areas, they are not targeted specifically. For this reason, and because ore grade is known to be locally variable, assays from drilling are not relied upon for ore grade estimation. Instead, grade determined from routinely collected in-mine ore zone samples are found to be most reliable. The long-term average from in-mine tends to best represent the larger ore zone as it normalizes local variability.

23

Thousands of in-mine ore grade samples were collected at Allan to the end of December 2024 (discussed further in section 11.2). All in-mine samples were analysed in the Allan mill laboratory using analysis techniques that were up-to-date for the era in which the sample was collected.

Regarding quality assurance for analytical results, the Company participates in the Canpotex Producer Sample Exchange Program using methods developed by the Saskatchewan Potash Producers Association (SPPA). The Sample Exchange Program monitors the accuracy of analytical procedures used in its labs. In the early 1970s, the SPPA initiated a round-robin Sample Exchange Program, the purpose of which was to assist the potash laboratories in developing a high level of confidence in analytical results. This program, now named the Canpotex Producer Sample Exchange Program using SPPA Methods (CPSEP), has continued up to the present. Current participants include all Canpotex member potash mine site labs, the Nutrien Pilot Plant Lab, and independent third-party surveyor labs. The CPSEP provides participants with three unknown potash samples for analysis quarterly. Results for the unknown sample analysis are correlated by an independent agency that distributes statistical analysis and a summary report to all participants. Completed exchange program samples can be used for control standards as required in QA/QC sections of standard analytical procedures.

The Nutrien Pilot Plant is secured in the same way as modern office buildings are secured. Authorized personnel have access and visitors are accompanied by staff. No special security measures are taken beyond that. Currently, no external laboratory certification is held by the Nutrien Pilot Plant. On occasion, product quality check samples are sent to the Saskatchewan Research Council (SRC), a fully certified analytical facility.

In the opinion of the authors, the sample preparation, security, and analytical procedures are acceptable, are consistent with industry-standard practices, and are adequate for Mineral Resource and Reserve estimation purposes.

| 11.2 | MEAN POTASH MINERAL GRADE FROM IN-MINE SAMPLES |

At Allan, in-mine grade samples are taken by collecting fine “muck” from the floor of the mine (i.e. grab sampling) approximately once per week per active mining face. This is roughly equivalent to a sample taken every 68 m to 74 m in production panels, and a sample taken every 85 m to 128 m in development panels. Since start-up in 1968 through to the end of 2024, a total of 7,967 in-mine potash mineral grade samples were collected from the Allan A Zone, the main potash horizon at Allan. All samples were analysed in the Allan mill laboratory using analysis techniques that were up-to-date for the era in which the sample was collected. Figure 14 shows a histogram of A Zone in-mine grade sample results from the Allan mine.

Figure 14: Histogram of potash ore grade from Allan in-mine grade samples (data from 1968 through to the end of 2024).

The median ore grade for this family of in-mine samples is 25.3% K2O equivalent and the mean ore grade is 24.5%. The five-year (2020 – 2024) mean ore grade is 21.9% K2O equivalent and was determined from 692 samples.

This is considered to be a more representative estimate of expected potash ore grade at Allan than drillhole assay results presented in Section 10.0.

For the B Zone at Allan, mineral grade is reported to be 20.2% K2O equivalent, the grade observed from thousands of in-mine samples at the Lanigan mine where the B Zone has been extensively mined.

24

Even though Allan mine is some distance from Lanigan, this is considered the best estimate of expected mineral grade for this potash layer because the deposit is known to be regionally continuous from west of Vanscoy to east of Lanigan (Fuzesy, 1982 and references therein). Although it is possible that once mining proceeds into the B Zone the reported grade could change from what is reported, it is expected that any such change would be minimal.

| 11.3 | POTASH ORE DENSITY FROM IN-MINE MINERAL GRADE MEASUREMENTS |

An estimate of in-situ rock density is used to calculate potash mineralization volumes in Mineral Resource and Reserve assessments. A common approach, and the one used by Nutrien, is to determine in-place Mineral Resource and Reserve volumes (m3), then multiply this number by in-situ bulk-rock density (tonnes / m3) to give in-place Mineral Resource and Reserve tonnes.

Well-log data from drillholes can be used to calculate bulk density if accurate and calibrated well-logs are acquired during exploration drilling. In practical terms, modern well-logs tend to meet these criteria, but historic well-logs (collected before the 1990s) do not. In Saskatchewan, almost all potash exploration drilling took place in the 1950s and 1960s, well before density logs were accurate and reliable.

Another approach, and the one used by Nutrien, is to look up density values for the minerals which constitute potash rock – values determined in a laboratory to a high degree of accuracy and published in reliable scientific journals / textbooks – then apply these densities to the bulk rock. Given that the density of each pure mineral is quantified and known, the only variable is what proportion of each mineral makes up the bulk rock. An obvious benefit of this approach is that a mean value computed on the in-mine samples shown in Figure 14 has a much greater confidence interval than a mean value computed from just a few drillhole assays.

The four main mineralogical components of the ore zones of Saskatchewan’s Prairie Evaporite Formation with their respective mineral densities are:

| Mineral |

Density (kg / m3) |

Components |

||||

| Halite | 2,170 | NaCl | ||||

| Sylvite | 1,990 | KCl | ||||

| Carnallite | 1,600 | KMgCl3 · 6(H2O) | ||||

| Insolubles | 2,510 | Anhydrite, dolomite, quartz, muscovite, and other minor mineral components (Nutrien Pilot Plant, 2018) |

All Nutrien potash mines measure and record the in-mine % K2O grade and insoluble content of the mined rock. The magnesium content is not measured at Allan since carnallite is a negligible component of the ore here. From this set of measurements, density of the ore can be calculated.

The value for insoluble density is based on known densities of the constituent parts of the insoluble components of the mineralization and the average occurrence of these insoluble components, which is known from over 50 years of mining experience at Allan. Assuming the lowest plausible density of insolubles known for Saskatchewan potash deposits of this nature, the effect upon overall bulk-rock ore density and Mineral Resource and Reserve calculations would be negligible.

From thousands of in-mine samples taken at Allan, bulk density has been determined to be:

= (halite density * % halite) + (sylvite density * % sylvite) + (insolubles density * % insolubles)

= (2,170 kg / m3 * 56.1%) + (1,990 kg / m3 * 38.8%) + (2,510 kg / m3 * 5.1%)

= 2,117 kg / m3

RHObulk-rock (Allan A Zone) = 2,117 kg / m3 = 2.12 tonnes / m3

This method is as accurate as the ore grade measurements and mineral density estimates.

Not enough test mining of the B Zone has been conducted at Allan to permit a bulk density calculation based on Allan in-mine grade samples. If test mining of the B Zone at Allan is conducted in future, there may be enough samples with all constituent minerals measured to warrant a change from what is reported. It is expected that any such change would have only a minimal effect on bulk-rock density used in tonnage calculations.

Instead, the potash bulk-rock density is calculated using thousands of in-mine grade samples from Lanigan B Zone:

25

RHObulk-rock (Allan B Zone) = RHObulk-rock (Lanigan B Zone) = 2,120 kg / m3 = 2.12 tonnes / m3

This estimate is considered acceptable since both Allan B Zone and Lanigan B Zone are the same potash seam. Should the Allan B Zone bulk density change from the predicted value of 2,120 kg / m3, the later defined Allan B Zone Mineral Resources and Reserves in Sections 14.2 and 15.2 will also change, albeit, insignificantly.

| 12.0 | DATA VERIFICATION |

| 12.1 | ASSAY DATA |

Most of the original drillhole assays were studied by independent consultant David S. Robertson and Associates (1978). Recently, drillhole core is prepared for sampling by Nutrien staff and, generally, sent to SRC Geoanalytical Laboratory for independent analyses.

The original assay results for core samples from historical drillholes were taken as accurate in these studies, as there is no way to reliably reanalyse these samples. Most of the remaining samples in storage have long since deteriorated to the point where they are not usable.

Ore grades of in-mine samples are measured in-house at the Allan mine laboratory by Company staff using modern, standard chemical analysis tools and procedures; an independent agency does not verify these results. However, check sampling through the CPSEP, discussed in Section 11.1, does occur.

It should be noted that assay results from historical drillholes match in-mine sample results reasonably well even though drillhole sample spacing is much greater. This correlation is further validation of the in-mine sampling methodology. Mean mineral grade determined from in-mine samples taken over decades of mining at Allan is thought to provide the most accurate measurement of potash grade for the Allan mine, also providing a good basis for estimating ore grade in areas of future mining at Allan.

| 12.2 | EXPLORATION DATA |

The purpose of any mineral exploration program is to determine extent, continuity, and grade of mineralization to a certain level of confidence and accuracy. For potash exploration, it is important to minimize the amount of cross-formational drilling, since each drillhole is a potential conduit for subsurface groundwater from overlying (or underlying) water-bearing formations into future mine workings. Every potash test drillhole from surface sterilizes potash mineralization as a safety pillar is required around every surface drillhole once underground mining commences.

Initial sampling and assaying of cores were done during potash exploration at Allan in the 1950s and 1960s. Methods were consistent with standard procedures for that era. The mine began production in 1968 and test drilling conducted after that was largely for the purpose of better understanding the caprock rather than potash mineralization. This approach to potash sampling is in accordance with widely accepted industry practice for areas adjacent and contiguous to an existing operating potash mine.

Assay of physical samples (drillhole cores and/or in-mine samples) is the only way to gain information about mineral grade, but extent and continuity of mineralization are correctly determined using data collected from seismic surveys correlated with drilling information. To date, surface seismic data at Allan have been collected, analysed, and verified by Company staff, at times, in cooperation with independent consultants.

Data for the Mineral Resource and Reserve estimates for Allan mine reported in Sections 14.0 and 15.0 were verified by Company staff as follows:

| • | Review of potash assay sample information (drillholes and in-mine grade samples), |

| • | Review and verify procedures used for in-mine grade sampling and laboratory analysis, |

| • | Review of surface geophysical exploration results (3D and 2D seismic data), |

| • | Crosscheck of mined tonnages reported by mine site technical staff with tonnages estimated from mine survey information, and |

| • | Crosscheck of Mineral Resource and Mineral Reserve calculations carried out by corporate technical staff. |

In the opinion of the authors, this approach to data verification of potash mineral grade and surface seismic information is in accordance with generally accepted industry practice for areas adjacent and contiguous to an existing operating potash mine.

26

| 13.0 | MINERAL PROCESSING AND METALLURGICAL TESTING |

At Allan, potash ore has been mined and concentrated using flotation and crystallization methods to produce saleable quantities of high-grade finished potash products since 1968.

Since opening in 1968, 192.352 million tonnes of potash ore have been mined and hoisted at Allan to produce 67.990 million tonnes of finished potash products. Given this level of sustained production over several decades, basic mineralogical processing and prospective metallurgical testing of Allan potash is not considered relevant.

See also Section 17.0.

| 14.0 | MINERAL RESOURCE ESTIMATES |

| 14.1 | DEFINITIONS OF MINERAL RESOURCE |

The CIM has defined Mineral Resource in The CIM Definition Standards for Mineral Resources and Reserves (2014) as:

| 1) | Inferred Mineral Resource: that part of a Mineral Resource for which quantity and grade or quality are estimated on the basis of limited geological evidence and sampling. Geological evidence is sufficient to imply but not verify geological and grade or quality continuity. |

| 2) | Indicated Mineral Resource: that part of a Mineral Resource for which quantity, grade or quality, densities, shape, and physical characteristics are estimated with sufficient confidence to allow the application of Modifying Factors in sufficient detail to support mine planning and evaluation of the economic viability of the deposit. Geological evidence is derived from adequately detailed and reliable exploration, sampling and testing and is sufficient to assume geological and grade quality continuity between points of observation. |

| 3) | Measured Mineral Resource: that part of a Mineral Resource for which quantity, grade or quality, densities, shape, and physical characteristics are estimated with confidence sufficient to allow the application of Modifying Factors to support detailed mine planning and final evaluation of the economic viability of the deposit. Geological evidence is derived from detailed and reliable exploration, sampling and testing and is sufficient to confirm geological and grade or quality continuity between points of observation. |

CIM defines Modifying Factors as “considerations used to convert Mineral Resources into Mineral Reserves. These include, but are not restricted to, mining, processing, metallurgical, infrastructure, economic, marketing, legal, environmental, social and governmental factors.”

In south-central Saskatchewan, where geological correlations are straightforward, and within a (potash) subsurface mineral lease at an operating potash mine, Mineral Resource categories are generally characterized by Nutrien as follows:

| 1) | Inferred Mineral Resource: areas of limited exploration, such as areas that have been investigated through regional geological studies, or areas with 2D regional surface seismic coverage, little or no drilling, at some distance from underground workings, and within Crown Subsurface Mineral Lease KL 112R C. |

| 2) | Indicated Mineral Resource: areas of adequate exploration, such as areas with 3D surface seismic coverage, little or no drilling, at some distance from underground workings, and within Crown Subsurface Mineral Lease KL 112R C. |

| 3) | Measured Mineral Resource: areas of detailed, physical exploration through actual drilling or mine sampling, near existing underground workings, and within Crown Subsurface Mineral Lease KL 112R C. |

The mine began production in 1968 and test drilling conducted after that was largely for the purpose of better understanding the caprock rather than potash mineralization. Instead, exploration involved collecting surface seismic data, which became better in quality over the years. Exploration drilling has demonstrated the presence of the potash horizon, and seismic coverage shows the continuity of the Prairie Evaporite Formation within which the potash horizon occurs.

27

Along with this approach, analysis of in-mine samples for potash grade has provided an observation-based understanding of the potash mineralized zone at Allan that is far superior to the level of understanding provided by any surface drilling-based exploration program. The authors believe that this approach provides a body of information that guides and constrains exploration inferences in a much better way than could be achieved from any conventional exploration investigation in areas immediately surrounding, and contiguous to, the Allan potash mine.

| 14.2 | ALLAN POTASH RESOURCE CALCULATIONS |

Exploration information used to calculate reported Mineral Resource tonnages at Allan consist of both physical sampling (drillhole and in-mine) and surface seismic (2D and 3D) as discussed in earlier sections. Based on the definitions and guidelines in Section 14.1, all mineral rights leased or owned by the Company, and within Crown Subsurface Mineral Lease KL 112R C, are assigned to one of the three Mineral Resource categories.

Mineral Resources are reported as mineralization in-place and are exclusive of Mineral Reserves. In-place tonnes were calculated for each of the Mineral Resource categories using the following parameters:

| Mining Height: | 3.35 m (11 feet) | |

| Ore Density: | 2.12 tonnes / m3 (A Zone) | |

| Ore Density: | 2.12 tonnes / m3 (B Zone) |

The Mineral Resources for Allan, as of December 31, 2024, are as follows:

Allan A Zone:

| Inferred Resource |

1,197 | millions of tonnes | ||||||

| Indicated Resource |

2,157 | millions of tonnes | ||||||

| Measured Resource |

1,625 | millions of tonnes | ||||||

|

|

||||||||

| Total A Zone Resource |

4,979 | millions of tonnes | ||||||

Allan B Zone:

| Inferred Resource |

1,197 | millions of tonnes | ||||

| Indicated Resource |

2,157 | millions of tonnes | ||||

| Measured Resource |

2,168 | millions of tonnes | ||||

|

|

||||||

| Total B Zone Resource |

5,522 | millions of tonnes | ||||

Total for Allan (A Zone + B Zone):

| Inferred Resource |

2,394 | millions of tonnes | ||||

| Indicated Resource |

4,314 | millions of tonnes | ||||

| Measured Resource |

3,793 | millions of tonnes | ||||

|

|

||||||

| Total A Zone + B Zone Resource |

10,501 | millions of tonnes | ||||

Allan Mineral Resources are plotted in Figure 15.

The average mineral grade of the Allan A Zone Mineral Resource is 24.5% K2O equivalent and was determined from thousands of in-mine samples at Allan. The average mineral grade of the Allan B Zone Mineral Resource is 20.2% K2O equivalent and was determined from thousands of in-mine samples at Lanigan mine where the B Zone has been extensively mined. See Section 11.2 for more detail.

The tonnage reported in the Allan A Zone Measured Resource is comprised of the potash that is within 1.6 km (1 mile) of a physically sampled location (i.e. drillholes or mine workings). Also included as Measured Resource is the potash in the pillars of mined-out areas of the Allan mine that is not already accounted for in the Proven Reserve estimation as there is the possibility of retrieving ore from the remnant mining pillars at some point in the future.

Portions of the B Zone that are immediately underlying the Proven and Probable A Zone Mineral Reserve as well as portions of the B Zone that are immediately underlying drillholes and the 1.6 km (1 mile) buffer placed around drillholes have been classified as Measured Resource.

28

Figure 15: Map showing Allan Mineral Resource as of December 2024.

| 15.0 | MINERAL RESERVE ESTIMATES |

| 15.1 | DEFINITIONS OF MINERAL RESERVE |

The CIM has defined Mineral Reserve in The CIM Definition Standards for Mineral Resources and Reserves (2014) as:

| 1) | Probable Mineral Reserve: the economically mineable part of an Indicated, and in some circumstances, a Measured Mineral Resource. The confidence in the Modifying Factors applying to a Probable Mineral Reserve is lower than that applying to a Proven Mineral Reserve. |

| 2) | Proven Mineral Reserve: the economically mineable part of a Measured Mineral Resource. A Proven Mineral Reserve implies a high degree of confidence in the Modifying Factors. |

CIM defines Modifying Factors as “considerations used to convert Mineral Resources into Mineral Reserves. These include, but are not restricted to, mining, processing, metallurgical, infrastructure, economic, marketing, legal, environmental, social and governmental factors.”

For Saskatchewan, in regions adjacent and contiguous to an operating potash mine and within a (potash) subsurface mineral lease, Mineral Reserve categories are characterized by Nutrien as follows:

| 1) | Probable Mineral Reserve: identified recoverable potash mineralization classified as a Measured Resource, within a 1.6 km (1 mile) radius of a sampled mine entry or exploration drillhole contiguous to mine workings, |

29

| and within Crown Subsurface Mineral Lease KL 112R C. |

| 2) | Proven Mineral Reserve: identified recoverable potash mineralization classified as a Measured Resource, delineated on at least three sides by sampled mined entries or exploration drillholes to a maximum of 3.2 km (2 miles) apart, and within Crown Subsurface Mineral Lease KL 112R C. |

Along with this approach, analysis of in-mine samples for potash grade has provided an observation-based understanding of the potash mineralized zone at Allan that is far superior to the level of understanding provided by any surface drilling-based exploration program. An understanding of the amount of ore that can be conventionally mined from the Measured Resource category using current mining practices comes from over 50 years of potash mining experience at Allan.

| 15.2 | ALLAN POTASH RESERVE CALCULATIONS |

Using the definitions outlined in Section 15.1, a portion of the Allan A Zone Measured Resource has been converted to Mineral Reserve. The assigned Mineral Reserve category is dependent on proximity to sampled mine entries also described in Section 15.1. An overall extraction ratio for the Allan mine has been applied to the qualifying areas outlined as Measured Resource in Figure 15. This extraction ratio is significantly lower than the local extraction ratio described in Section 16.1, as it takes into account areas which cannot be mined due to unfavorable geology.

The overall extraction ratio at the Allan mine is 28%. It was derived by dividing the total ore tonnes mined to date by the tonnage equivalent of the total area of the mine workings (i.e. the perimeter around the mine workings) less future mining blocks. This extraction ratio has been applied to the Probable Reserve, an area where no mining has occurred to date. To remain conservative in our estimations, and because a considerable amount of mining has already occurred in the Proven Reserve area, this extraction ratio has been applied only to the portion of the Proven Reserve that is anticipated to be mined in future. Future mining blocks within the Proven Reserve area vary from year-to-year as production continues. Pillars remaining that are not planned for mining remain a Measured Resource. Since an extraction ratio has been applied, Mineral Reserves are considered recoverable ore, and are reported as such. Note that only drillholes whose 1.6 km radii are contiguous to mine workings or the 1.6 km radius placed around mine workings are used to compute probable mineral reserve. The remaining non-contiguous drillholes remain in the Measured Resource category.

At times, irregular mining which resembles development mining occurs to support operational requirements (e.g. egress) or as geological conditions necessitate. While irregular mining increases confidence in the Mineral Resource by way of physical sampling, it can add considerable Mineral Reserve to broad areas not otherwise covered (or planned to be covered) by mine workings. Again, to remain conservative in our estimations, certain irregular mining may not have been converted from Measured Resource to Proven Reserve.

The Mineral Reserves for Allan as of December 31, 2024, are as follows:

Allan A Zone:

| Probable Reserve |

260 | millions of tonnes | ||||

| Proven Reserve |

99 | millions of tonnes | ||||

|

|

||||||

| Total A Zone Reserve |

359 | millions of tonnes | ||||

Allan B Zone:

| Probable Reserve |

nil | |||

| Proven Reserve |

nil | |||

|

|

||||

| Total B Zone Reserve |

nil | |||

Total for Allan (A Zone + B Zone):

| Probable Reserve |

260 | millions of tonnes | ||||

| Proven Reserve |

99 | millions of tonnes | ||||

|

|

||||||

| Total A Zone and B Zone Reserve |

359 | millions of tonnes | ||||

Allan Mineral Reserves are plotted in Figure 16.

The average mineral grade of the Allan A Zone Mineral Reserve is 24.5% K2O equivalent and was determined from thousands of in-mine samples at Allan.

30

Figure 16: Map showing Allan Mineral Reserve to December 2024.

| 16.0 | MINING METHOD |

| 16.1 | MINING OPERATIONS |

All conventional potash mines in Saskatchewan operate at 900 m to 1,200 m below surface within 9 m to 30 m of the top of the Prairie Evaporite Formation. Over the scale of any typical Saskatchewan potash mine, potash beds are tabular and regionally flat-lying, with only moderate local variations in dip. At Allan, potash ore is mined using conventional mining methods, whereby:

| • | Shafts are sunk to the potash ore body; |

| • | Continuous mining machines cut out the ore, which is hoisted to surface through the production shaft; |

| • | Raw potash is processed and concentrated in a mill on surface; and |

| • | Concentrated finished potash products (near-pure KCl) are sold and shipped to markets in North America and offshore. |

Sinking of the two original shafts (Shaft #1 and Shaft #2) from surface to the potash zone was completed in early 1968, and the first potash ore was hoisted in April of that year. The Allan mine has run on a continuous basis since the first ore was hoisted in 1968, other than short-term shutdowns taken for inventory management purposes or occasional plant maintenance and construction work, or other outages that are typical for operations of this nature.

In recent years, the Allan mine underwent a major expansion which brought the nameplate capacity up to 4.0 million tonnes of finished potash products per year. The operational capability at the Allan facility in 2024, was 2.4 million tonnes per year.

31

Virtually all Allan underground mining rooms are in one potash mineralized zone, the upper layer (or A Zone) of the Patience Lake Member of the Prairie Evaporite Formation (the host evaporite salt). Saskatchewan potash geology is illustrated in Figure 17. At Allan, mine elevations range from approximately 980 m to 1,120 m depth below surface. These depths to A Zone potash mineralization are anticipated over most of the Allan lease area. Mine workings are protected from aquifers in overlying formations by approximately 12 m of overlying salt and potash beds, along with salt plugged porosity in the Dawson Bay Formation, a carbonate layer lying immediately above potash hosting salt beds.

The Allan mine is a conventional underground mining operation whereby mining machines are used to excavate the potash ore by the stress-relief mining method. Continuous conveyor belts transport ore from the mining face to the bottom of the production shaft. Mining methods employed in Saskatchewan are discussed in Jones and Prugger (1982) and in Gebhardt (1993). The highest mineral grade section of the Allan potash seam is approximately 3.35 m (11’) thick, with gradations to lower grade salts immediately above and below the mining horizon. The actual mining thickness at Allan is dictated by the height of mining machines used to cut the ore. There are two types of mining machines at Allan; nine which are designed to cut at a thickness of 3.35 m (11’) and six which are designed to cut 3.65 m (12’).

As discussed in Section 10.0, Allan cuts to a marker (clay) seam that is slightly above the high-grade mineralized zone to establish a safe and stable mine roof. The top marker seam is slightly overcut by 10 cm to 20 cm. Clay seams are often planes of weakness, and if they are undercut, material immediately below the clay seam becomes a hazard as it may separate and fall. Since the hazard must be remediated prior to proceeding, thus slowing production, the moderately diluted mineral grade that results from the overcutting is preferable from a safety point of view.

Figure 17: Schematic cross-section through the Prairie Evaporite Formation, illustrating mining horizons at each of Nutrien’s conventional potash operations.

Conservative local extraction ratios (never exceeding 45% in any mining block) are employed at all Saskatchewan mines, including Allan, to minimize potential detrimental effects of mining on overlying strata; this is common practice in flat-lying, tabular ore bodies overlain by water-bearing layers.

From the shaft-bottom, potash ore is hoisted approximately 1,000 m from the potash level through the vertical shafts to a surface mill. In addition to hoisting potash ore to surface, the production shaft also provides fresh air ventilation to the mine and serves as a secondary egress. The Service Shaft is used for service access, and exhaust ventilation from the mine.

32

Since production began in 1968, 192.352 million tonnes of potash ore have been mined and hoisted at Allan to produce 67.990 million tonnes of finished potash products. The life-of-mine average concentration ratio (raw ore / finished potash products) is 2.83 and the overall extraction ratio over this period is 28%.

Actual potash production tonnages for the Allan mine, along with concentration ratios (tonnes mined / tonnes product), are plotted for the past decade in Figure 18.

33

| Figure | 18 |

Figure 18: Mined tonnes, product tonnes, and concentration ratio for the Allan mine over the past 10 years.

| 16.2 | RISKS TO POTASH MINING OPERATIONS, WITH EMPHASIS ON WATER INFLOWS |

The mining of potash is a capital-intensive business, subject to the normal risks and capital expenditure requirements associated with mining operations. The production and processing of ore may be subject to delays and costs resulting from mechanical failures, physical hazards such as fires, and other hazards such as: unusual or unexpected geological conditions, significant subsidence, brine inflows and gas seepages of varying degree, and other situations associated with any potash mining operation.

Potash beds in all regions of Saskatchewan are overlain by a number of water-bearing formations, and there are water zones underlying the potash beds as well. A water inflow into mine workings is generally significant in a potash mine since salt dissolves in water; an inflow can lead to anything from increased costs at best to closure of the mine at worst (e.g. see Prugger and Prugger, 1991).

When sinking of the Allan Shaft #1 was near the bottom of the Blairmore Formation at approximately 570 m depth, a breach developed in the ice wall and the shaft was flooded (Prugger and Prugger, 1991). A concrete plug was installed in the shaft bottom (underwater), and two additional freeze holes were drilled to seal the area of the breach and allow recovery of the shaft. The shaft was completed in 1968. In the mid-1990s the concrete shaft liner in an area of the Allan production shaft had deteriorated to the point where it required replacement. The concrete in the 671 m to 750m (2,203’ to 2,463’) level was replaced with iron tubbing segments in 1999, successfully repairing the shaft through this area. Small scale shaft liner repairs have since occurred in both the production and service shafts as part of an ongoing maintenance program. At present, inflow into the existing shafts is estimated at 23 litres / minute (6 US gallons / minute) for the Service Shaft and 117 litres / minute (31 US gallons / minute) for the Production Shaft.

There has not been any significant water ingress into underground workings at Allan since production began in 1968, other than several temporary nuisance connate brine inflows. At present, brine ingress into underground mine workings at Allan is negligible.

In 2022, a gas seepage developed in an active mining panel where gas was found to be coming out of cracks in the floor. The composition of the inert gas is dominated by nitrogen (which is harmless). To ensure ongoing workplace safety, the panel was abandoned. Given this occurrence, and a smaller gas seepage nearby in 2020, the decision was made to curtail mining in the area until the source of the gas is characterized, and controls are established for degassing should further seepages develop. To date, the mine ventilation system continues to function normally, and these gas seepages have had no impact on production at the Allan mine.

| 17.0 | RECOVERY METHODS |