UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM40-F

[Check one]

|

REGISTRATION STATEMENT PURSUANT TO SECTION 12 OF THE SECURITIES EXCHANGE ACT OF 1934 |

OR

|

ANNUAL REPORT PURSUANT TO SECTION 13(a) OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year ended December 31, 2024

Commission File Number 001-38336

NUTRIEN LTD.

(Exact name of Registrant as specified in its charter)

Canada

(Province or other jurisdiction of incorporation or organization)

2870

(Primary Standard Industrial Classification Code Number (if applicable))

98-1400416

(I.R.S. Employer Identification Number (if applicable))

|

Suite 1700, 211 19th Street East Saskatoon, Saskatchewan, Canada S7K 5R6 |

(306) 933-8500

(Address and telephone number of Registrant’s principal executive offices)

CT Corporation System

28 Liberty St.

New York, NY 10005

(212) 894-8940

(Name, address (including zip code) and telephone number (including area code)

of agent for service in the United States)

Securities registered or to be registered pursuant to Section 12(b) of the Act:

Title of each class |

Trading Symbol(s) |

Name of each exchange on which registered |

Common Shares |

NTR |

New York Stock Exchange |

Securities registered or to be registered pursuant to Section 12(g) of the Act:

Not Applicable

(Title of Class)

Securities for which there is a reporting obligation pursuant to Section 15(d) of the Act:

Not Applicable

(Title of Class)

For annual reports, indicate by check mark the information filed with this Form:

Annual information form |

|

Audited annual financial statements |

Indicate the number of outstanding shares of each of the issuer’s classes of capital or common stock as of the close of the period covered by the annual report.

491,025,446 Common Shares outstanding as of December 31, 2024

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Exchange Act during the preceding 12 months (or for such shorter period that the registrant was required to file such reports) and (2) has been subject to such filing requirements for the past 90 days.

Yes No |

Indicate by check mark whether the registrant has submitted electronically every Interactive Data File required to be submitted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit such files).

Yes No

Indicate by check mark whether the registrant is an emerging growth company as defined in Rule 12b-2 of the Exchange Act.

Emerging growth company

If an emerging growth company that prepares its financial statements in accordance with U.S. GAAP, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards† provided pursuant to Section 13(a) of the Exchange Act.

† The term “new or revised financial accounting standard” refers to any update issued by the Financial Accounting Standards Board to its Accounting Standards Codification after April 5, 2012.

Indicate by check mark whether the registrant has filed a report on and attestation to its management’s assessment of the effectiveness of its internal control over financial reporting under Section 404(b) of the Sarbanes-Oxley Act (15 U.S.C. 7262(b)) by the registered public accounting firm that prepared or issued its audit report.

If securities are registered pursuant to Section 12(b) of the Act, indicate by check mark whether the financial statements of the registrant included in the filing reflect the correction of an error to previously issued financial statements.

Indicate by check mark whether any of those error corrections are restatements that required a recovery analysis of incentive-based compensation received by any of the registrant’s executive officers during the relevant recovery period pursuant to §240.10D-1(b). The following documents have been filed as part of this Annual Report:

This Annual Report on Form 40-F shall be incorporated by reference into the Registration Statements on Form S-8 (File Nos. 333-222384, 333-222385 and 333-226295) of the registrant. In addition, the registrant’s Annual Information Form; Management’s Discussion and Analysis; Audited Annual Consolidated Financial Statements for the fiscal year ended December 31, 2024, including Management’s Annual Report on Internal Control over Financial Reporting; Consent of KPMG LLP, Independent Registered Public Accounting Firm; Consent of Craig Funk, B.Sc., M.Sc., P.Eng., P.Geo., and Consent of Jodi Derkach, B.Sc.,P.Geo., included as Exhibits 99.1, 99.2, 99.3, 99.4, 99.8 and 99.9, respectively, to this Annual Report on Form 40-F, are incorporated by reference into and as an exhibit to the registrant’s Registration Statement on Form F-10 (File No. 333-278180).

PRINCIPAL DOCUMENTS

CONTROLS AND PROCEDURES

A. Certifications

The required disclosure is included in Exhibits 99.5, 99.6 and 99.7 to this Annual Report, and is incorporated herein by reference.

B. Evaluation of Disclosure Controls and Procedures

The required disclosure is included in “Controls and Procedures—Disclosure Controls and Procedures” in the 2024 MD&A, filed as Exhibit 99.2 to this Annual Report, and is incorporated herein by reference.

C. Management’s Annual Report on Internal Control over Financial Reporting

Management is responsible for establishing and maintaining an adequate system of internal control over financial reporting as defined in Rules 13a-15(f) and 15d-15(f) under the Securities Exchange Act of 1934, as amended. The required disclosure is included in “Management’s Responsibility—Management’s Annual Report on Internal Control Over Financial Reporting” that accompanies the 2024 Audited Annual Financial Statements, filed as Exhibit 99.3 to this Annual Report, and is incorporated herein by reference.

D. Attestation Report of the Independent Registered Public Accounting Firm

The required disclosure is included in the “Report of Independent Registered Public Accounting Firm” that accompanies the 2024 Audited Annual Financial Statements, filed as Exhibit 99.3 to this Annual Report, and is incorporated herein by reference.

E. Changes in Internal Control over Financial Reporting

During the period covered by this report, other than in connection with the previously disclosed material weakness as at June 30, 2024 and September 30, 2024 related to controls over derivative contract authorization in Brazil and the subsequent remediation, there was no change in Nutrien’s internal control over financial reporting that has materially affected, or is reasonably likely to materially affect, its internal control over financial reporting. For further information on such material weakness and subsequent remediation, see “Controls and Procedures—Internal Control over Financial Reporting” in the 2024 MD&A, filed as Exhibit 99.2 to this Annual Report and incorporated herein by reference.

IDENTIFICATION OF THE AUDIT COMMITTEE

The Board has a separately-designated standing audit committee established in accordance with section 3(a)(58)(A) of the Exchange Act. The members of the Audit Committee are Christopher M. Burley, Michael J. Hennigan, Julie A. Lagacy, Consuelo E. Madere, and Aaron W. Regent.

AUDIT COMMITTEE FINANCIAL EXPERT

The Nutrien Board of Directors (the “Board”) has determined that it has at least one “audit committee financial expert” (as such term is defined in paragraph 8(b) of General Instruction B to Form 40-F) serving on its Audit Committee. Mr. Christopher M. Burley has been determined to be such audit committee financial expert and was “independent” as such term is defined under the Canadian Securities Administrators’ National Instrument 52-110—Audit Committees and the standards of the U.S. Securities and Exchange Commission (the “SEC”) and the New York Stock Exchange (the “NYSE”) relating to the independence of audit committee members.

The Board’s designation of Mr. Christopher M. Burley as an audit committee financial expert does not impose on him any duties, obligations or liability that are greater than the duties, obligations and liability imposed on him as a member of the Audit Committee and Board in the absence of such designation or identification. In addition, the designation of Mr. Christopher M. Burley as an audit committee financial expert does not affect the duties, obligations or liability of any other member of the Audit Committee or Board. See also “17—Audit Committee” of Nutrien’s 2024 AIF, filed as Exhibit 99.1 to this Annual Report, and incorporated herein by reference.

COMPLIANCE WITH NYSE LISTING STANDARDS ON CORPORATE

GOVERNANCE

Our common shares are listed on the NYSE, but as a listed foreign private issuer, the NYSE does not require us to comply with all of its listing standards regarding corporate governance. Notwithstanding this exemption, we are in compliance in all material respects with the NYSE listing standards and we intend to continue to comply with such standards so as to ensure that there are no significant differences between our corporate governance practices and those practices required by the NYSE of other publicly listed companies.

CODE OF CONDUCT AND ETHICS

Nutrien has adopted a “code of ethics” (as that term is defined in Form 40-F), entitled the Nutrien Code of Conduct that applies to all directors, officers, employees and representatives of Nutrien and its subsidiaries (the “Nutrien Code”). A copy of the Nutrien Code is posted on Nutrien’s website at https://www.nutrien.com/what-we-do/governance. Copies may be obtained, free of charge, by contacting Nutrien in writing at 211 19th Street East, Suite 1700, Saskatoon, Saskatchewan, Canada S7K 5R6, by telephone at (306) 933-8500 or on Nutrien’s website at www.nutrien.com. Nutrien intends to post any amendments to and waivers from the Nutrien Code on its website as identified above.

NOTICES PURSUANT TO REGULATION BTR

Not applicable.

PRINCIPAL ACCOUNTANT FEES AND SERVICES

The following table sets out the fees billed to Nutrien by KPMG LLP (PCAOB ID: 85; Calgary, AB, Canada) and its affiliates for professional services rendered during the years ended December 31, 2024 and 2023. During these years, KPMG LLP was the Company’s only external auditor.

Category |

Years Ended December 31 (US$) |

||||||

|

|

2024 |

|

2023 |

|||

Audit Fees 1 |

9,877,400 |

|

9,481,000 |

||||

Audit-Related Fees 2 |

73,700 |

|

26,600 |

||||

Tax Fees 3 |

44,500 |

|

74,900 |

||||

All Other Fees 4 |

226,400 |

|

305,100 |

||||

Total |

10,222,000 |

|

9,887,600 |

||||

AUDIT COMMITTEE’S PRE-APPROVAL POLICIES AND PROCEDURES

The required disclosure is included in “17—Audit Committee-17.4—Pre-approval Policies and Procedures” of Nutrien’s 2024 AIF, filed as Exhibit 99.1 to this Annual Report, and incorporated herein by reference.

OFF-BALANCE SHEET ARRANGEMENTS

The information included in “Other Financial Information—Off-Balance Sheet Arrangements” of the 2024 MD&A, filed as Exhibit 99.2 to this Annual Report, is incorporated herein by reference.

TABULAR DISCLOSURE OF CONTRACTUAL OBLIGATIONS

The information included in “Liquidity and Capital Resources—Cash Requirements” of the 2024 MD&A, filed as Exhibit 99.2 to this Annual Report, is incorporated herein by reference.

RESERVE AND RESOURCE ESTIMATES

The disclosure included in or incorporated by reference in this Annual Report uses mineral reserves and mineral resources classification terms that comply with reporting standards in Canada and are made in accordance with National Instrument 43-101—Standards of Disclosure for Mineral Projects (“NI 43-101”), which references the Canadian Institute of Mining, Metallurgy and Petroleum Definition Standards on Mineral Resources and Mineral Reserves. NI 43-101 is a rule developed by the Canadian Securities Administrators that establishes standards for all public disclosure an issuer makes of scientific and technical information concerning mineral projects.

These standards differ from the requirements of the SEC that are applicable to domestic United States reporting companies. Any mineral reserves and mineral resources reported by the Company in accordance with NI 43-101

may not qualify as such under SEC standards. Accordingly, information included in this Annual Report and the documents incorporated by reference herein that describes the Company’s mineral reserves and mineral resources estimates may not be comparable with information made public by United States companies subject to the SEC’s reporting and disclosure requirements.

MINE SAFETY DISCLOSURE

The information concerning mine safety violations or other regulatory matters required by Section 1503(a) of the Dodd-Frank Wall Street Reform and Consumer Protection Act and Item 16 of General Instruction B to Form 40-F is included in Exhibit 99.10 to this Annual Report.

DISCLOSURE REGARDING FOREIGN JURISDICTIONS THAT PREVENT INSPECTIONS

Not applicable.

RECOVERY OF ERRONEOUSLY AWARDED COMPENSATION

Not applicable.

WEBSITE INFORMATION

Notwithstanding any reference to Nutrien’s website or other websites on the World Wide Web in this Annual Report or in the documents attached as exhibits hereto, the information contained in Nutrien’s website or any other website on the World Wide Web referred to in this Annual Report or in the documents attached as exhibits hereto, or referred to in Nutrien’s website, is not a part of this Annual Report and, therefore, is not filed with the SEC.

UNDERTAKING AND CONSENT TO SERVICE OF PROCESS

The Registrant undertakes to make available, in person or by telephone, representatives to respond to inquiries made by the SEC staff, and to furnish promptly, when requested to do so by the SEC staff, information relating to: the securities registered pursuant to Form 40-F; the securities in relation to which the obligation to file an annual report on Form 40-F arises; or transactions in said securities.

The Registrant has previously filed an Appointment of Agent for Service of Process and Undertaking on Form F-X with respect to the class of securities in relation to which the obligation to file the Form 40-F arises. Any change to the name or address of the Registrant’s agent for service of process shall be communicated promptly to the SEC by amendment to the Form F-X referencing the file number of the Registrant.

SIGNATURES

Pursuant to the requirements of the Exchange Act, the Registrant certifies that it meets all of the requirements for filing on Form 40-F and has duly caused this annual report to be signed on its behalf by the undersigned, thereto duly authorized.

|

NUTRIEN LTD.

|

|

By: |

/s/ Noralee Bradley |

|

Name: Title: |

Noralee Bradley Executive Vice President External Affairs and Chief Sustainability and Legal Officer |

Date: February 28, 2025

EXHIBIT INDEX

Exhibit Number |

Description |

97.1 |

|

99.1 |

Annual Information Form for the fiscal year ended December 31, 2024 |

99.2 |

Management’s Discussion and Analysis for the fiscal year ended December 31, 2024 |

99.3 |

Audited Annual Consolidated Financial Statements for the fiscal year ended December 31, 2024 |

99.4 |

Consent of KPMG LLP, Independent Registered Public Accounting Firm |

99.5 |

Certification of Chief Executive Officer pursuant to Section 302 of the Sarbanes-Oxley Act of 2002 |

99.6 |

Certification of Chief Financial Officer pursuant to Section 302 of the Sarbanes-Oxley Act of 2002 |

99.7 |

Certifications pursuant to Section 906 of the Sarbanes-Oxley Act of 2002 |

99.8 |

|

99.9 |

|

99.10 |

|

101 |

Interactive Data File (formatted as Inline XBRL) |

104 |

Cover Page Interactive Data File (formatted as Inline XBRL and contained in Exhibit 101) |

Exhibit 99.1

Nutrien Ltd.

Annual Information Form

Year Ended December 31, 2024

1 – Table of Contents

Following is the table of contents of this Annual Information Form (“AIF”) referencing the applicable requirements of Form 51-102F2 – Annual Information Form of the Canadian Securities Administrators. Certain information required to be disclosed in this AIF is contained in Nutrien Ltd.’s management’s discussion and analysis (“2024 MD&A”), and Consolidated Financial Statements for the years ended December 31, 2024 and 2023 (“2024 Consolidated Financial Statements”) and is incorporated by reference herein to the extent noted below and throughout this AIF; these documents are available under Nutrien’s corporate profile on the Canadian Securities Administrators’ SEDAR+ website at sedarplus.ca and on the EDGAR section of the United States (“US”) Securities and Exchange Commission’s (“SEC”) website at sec.gov.

| Annual Information Page Reference |

Incorporated by Reference from the 2024 Consolidated Financial Statements |

|||||||

| 1 Table of Contents |

2-3 | |||||||

| 2 Advisories |

4-6 | |||||||

| 2.1 Forward-Looking Information |

4 | |||||||

| 2.2 Basis of Presentation |

6 | |||||||

| 3 Corporate Structure |

6-7 | |||||||

| 3.1 Name, Address and Incorporation |

6 | |||||||

| 3.2 Intercorporate Relationships |

7 | |||||||

| 4 General Development of the Business |

7-9 | |||||||

| 4.1 Three-Year History |

7 | Notes 14, 15, 19 and 23 | ||||||

| 5 Description of the Business |

9-34 | Notes 3 and 26 | ||||||

| 5.1 Upstream |

10 |

|||||||

| 5.1A Potash Segment |

10 | |||||||

| 5.1B Nitrogen Segment |

11 | |||||||

| 5.1C Phosphate Segment |

13 | |||||||

| 5.2 Midstream |

14 | |||||||

| 5.3 Downstream - Retail Segment |

15 | |||||||

| 5.4 Specialized Skill and Knowledge |

17 | |||||||

| 5.5 Intangible Properties |

17 | Note 15 | ||||||

| 5.6 Seasonality |

17 | |||||||

| 5.7 Environmental Matters |

17 | Notes 22 and 27 | ||||||

| 5.8 Employees |

20 | |||||||

| 5.9 Social and Environmental Policies |

21 | |||||||

| 5.10 Risk Factors |

24 | |||||||

| 5.11 Mineral Projects |

34 | |||||||

| 6 Dividends |

34 | |||||||

| 7 Description of Capital Structure |

35-37 | |||||||

| 7.1 General Description of Capital Structure |

35 | Notes 4, 19 and 23 | ||||||

| 7.2 Constraints |

36 | |||||||

| 7.3 Debt Ratings |

36 | |||||||

| 8 Market for Securities |

37 | |||||||

| 8.1 Trading Price and Volume |

37 | |||||||

| 8.2 Prior Sales |

37 | Notes 7 and 23 | ||||||

| 9 Escrowed Securities and Securities Subject to Contractual Restriction on Transfer

|

37

|

|||||||

2

| Annual Information Page Reference |

Incorporated by Reference from the 2024 Consolidated Financial Statements |

|||||||||

| 10 Directors and Officers |

37-41 | |||||||||

| 10.1 Name, Occupation and Security Holding |

37 | |||||||||

| 10.2 Cease Trade Orders, Bankruptcies, Penalties or Sanctions |

40 | |||||||||

| 10.3 Conflicts of Interest |

41 | |||||||||

| 11 Promoters |

41 | |||||||||

| 12 Legal Proceedings and Regulatory Actions |

41 | Note 27 | ||||||||

| 13 Interest of Management and Others in Material Transactions |

41 | |||||||||

| 14 Transfer Agent, Registrar and Trustees |

41 | |||||||||

| 15 Material Contracts |

41 | |||||||||

| 16 Interests of Experts |

41 | |||||||||

| 17 Audit Committee |

42-43 | |||||||||

| 17.1 Audit Committee Charter |

42 | |||||||||

| 17.2 Composition of the Audit Committee |

42 | |||||||||

| 17.3 Relevant Education and Experience of Members of the Audit Committee |

42 | |||||||||

| 17.4 Pre-approval Policies and Procedures |

43 | |||||||||

| 17.5 External Auditor Service Fees (by Category) |

43 | |||||||||

| 18 Additional Information |

43 |

|||||||||

| Schedule A Audit Committee Charter |

44-50 |

|||||||||

| Schedule B Mineral Projects |

51-74 |

|||||||||

| a. Material Potash Operations |

51 |

|||||||||

| b. Allan Potash Operations |

63 |

|||||||||

| c. Cory Potash Operations |

65 |

|||||||||

| d. Lanigan Potash Operations |

67 |

|||||||||

| e. Rocanville Potash Operations |

70 |

|||||||||

| f. Vanscoy Potash Operations |

72

|

|||||||||

3

2 – Advisories

2.1 Forward-Looking Information

Certain statements and other information included in this AIF, including within the documents incorporated by reference, constitute “forward-looking information” or “forward-looking statements” (collectively, “forward-looking statements”) under applicable securities laws (such statements are often accompanied by words such as “anticipate”, “forecast”, “expect”, “believe”, “may”, “will”, “should”, “estimate”, “project”, “intend” or other similar words). All statements in this document, other than those relating to historical information or current conditions, are forward-looking statements, including, but not limited to:

| • | our business strategies, plans, prospects and opportunities, and our sustainability, climate change and Environmental, Social and Governance (“ESG”) initiatives and proposed responses to climate change and ESG policies and regulations; |

| • | expectations regarding performance of our operating segments; |

| • | our projections for cash from operations and expectations regarding our capital allocation intentions and strategies; |

| • | our advancement of strategic and growth initiatives; |

| • | capital spending expectations; |

| • | our market outlook for 2025 and our expectations for market conditions and fundamentals, including crop nutrient markets, anticipated supply and demand for our products and services, expected market and industry and growing conditions with respect to crop nutrient application rates, planted acres, farmer crop investment, crop mix, including the need to replenish soil nutrient levels, production volumes and expenses, shipments, natural gas costs and availability, consumption, prices, operating rates and the impact of seasonality, import and export volumes, economic sanctions, tariffs and other trade or export restrictions, inventories, crop development and natural gas curtailments; |

| • | expectations concerning future product offerings; |

| • | expectations regarding changes in the agriculture space, including continued farm consolidation in the US and other developed markets and the continued advancement and adoption of technology and digital innovations, including the use and anticipated effects of more efficient mining, including automation, new crop input technologies and agronomic capabilities; |

| • | expectations regarding acquisitions and divestitures; |

| • | expectations regarding environmental compliance requirements and costs, including estimates of asset retirement obligations, federal and provincial carbon pricing, permits, approvals and site assessment and remediation costs; |

| • | expectations regarding our sustainability, climate change and greenhouse gas (“GHG”) emissions reduction strategy and related programs and initiatives, including our various sustainability performance goals, targets, costs, capital expenditures, commitments and aspirations; |

| • | the negotiation of sales and other contracts, including the anticipated renegotiation and expiry of existing contracts; |

| • | initiatives to promote innovative and productive agriculture; |

| • | expectations regarding future changes in our credit ratings; and |

| • | expectations regarding our mineral reserve and resource estimates, and the annual nameplate capacity and annual operational capability of our mines and associated mine life estimates. |

These forward-looking statements are subject to a number of assumptions, risks and uncertainties, many of which are beyond our control, which could cause actual results to differ materially from such forward-looking statements. As such, undue reliance should not be placed on these forward-looking statements.

All of the forward-looking statements are qualified by the assumptions that are stated or inherent in such forward-looking statements, including the assumptions referred to below and elsewhere in this document. Although we believe that these assumptions are reasonable, having regard to our experience and our perception of historical trends, such assumptions are not exhaustive of the factors that may affect any of the forward-looking statements and the reader should not place undue reliance on these assumptions and such forward-looking statements. Current conditions, economic and otherwise, render assumptions, although reasonable when made, subject to greater uncertainty.

4

Additional key assumptions that have been made in relation to the operation of our business as currently planned and our ability to achieve our business objectives include, among other things:

| • | assumptions with respect to our ability to successfully complete, integrate and realize the anticipated benefits of our already completed and future acquisitions and divestitures, and that we will be able to implement our standards, controls, procedures and policies in respect of any acquired businesses and realize the expected synergies on the anticipated timeline or at all; |

| • | that future business, regulatory and industry conditions will be within the parameters expected by us, including with respect to prices, expenses, margins, demand, supply, product availability, shipments, consumption, weather conditions, supplier agreements, product distribution agreements, inventory levels, exports, crop development and cost of labor and interest, exchange and effective tax rates; |

| • | assumptions with respect to global economic conditions and the accuracy of our market outlook expectations for 2025 and in the future; |

| • | assumptions related to our calculation of the Retail – South America and Brazil asset impairments and Nitrogen and Phosphate asset impairments; |

| • | assumptions with respect to our intention to complete share repurchases under our normal course issuer bid (“NCIB”) programs, including Toronto Stock Exchange (“TSX”) approval, the funding of such share repurchases, existing and future market conditions, including with respect to the price of our common shares, and compliance with respect to applicable limitations under securities laws and regulations and stock exchange policies; |

| • | assumptions related to our ability to fund our dividends at the current level; |

| • | our expectations regarding the impacts, direct and indirect, of certain geopolitical conflicts, including the war in Eastern Europe and the conflict in the Middle East on, among other things, global supply and demand, including for crop nutrients, energy and commodity prices, global interest rates, supply chains and the global macroeconomic environment, including inflation; |

| • | assumption regarding future markets for clean ammonia; |

| • | the adequacy of our cash generated from operations and our ability to access our credit facilities or capital markets for additional sources of financing; |

| • | our ability to identify suitable candidates for acquisitions and divestitures and negotiate acceptable terms; |

| • | availability of investment opportunities that align with our strategic priorities and growth strategy; |

| • | our ability to maintain investment grade ratings and achieve our performance targets; |

| • | our ability to successfully negotiate sales and other contracts; and |

| • | our ability to successfully implement new initiatives and programs. |

Events or circumstances could cause actual results to differ materially from those in the forward-looking statements.

With respect to our business generally and our ability to meet the other targets, commitments, goals, strategies and related milestones and schedules disclosed in this document, such events or circumstances include, but are not limited to:

| • | general global economic, market and business conditions; |

| • | failure to achieve expected results of our business strategy, capital allocation initiatives or results of operations; |

| • | failure to complete announced and future acquisitions or divestitures at all or on the expected terms and within the expected timeline; |

| • | seasonality; |

| • | climate change and weather conditions, including impacts from regional flooding and/or drought conditions; |

| • | failure to execute on our strategies related to ESG matters, and achieve related expectations, targets and commitments; |

| • | crop planted acreage, yield and prices; |

| • | the supply and demand and price levels for our products; |

| • | governmental and regulatory requirements and actions by governmental authorities, including changes in government policy (including in respect of tariffs, trade restrictions and climate change initiatives), government ownership requirements, and changes in environmental, tax, antitrust, and other laws or regulations and the interpretation thereof; |

| • | trade restrictions, including the imposition of any tariffs, or other changes to international trade agreements; |

| • | the effects of current and future international trade agreements or other developments affecting global trade; |

| • | political or military risks, including civil unrest, actions by armed groups or conflict and malicious acts, including terrorism and industrial espionage; |

| • | our ability to access sufficient, cost-effective and timely transportation, distribution and storage of products (including potential rail transportation or port disruptions due to labor strikes and/or work stoppages or other similar actions); |

| • | the occurrence of a major environmental or safety incident or becoming subject to legal or regulatory proceedings; |

| • | innovation and cybersecurity risks related to our systems, including our costs of addressing or mitigating such risks; |

| • | counterparty and sovereign risk; |

| • | delays in completion of turnarounds at our major facilities or challenges related to our major facilities that are outside of our control; |

5

| • | interruptions of or constraints in availability of key inputs, including natural gas and sulfur; |

| • | any significant impairment of the carrying amount of certain assets; |

| • | the risk that rising interest rates and/or deterioration of business operating results may result in the further impairment of assets or goodwill attributed to certain of our cash generating units; |

| • | risks related to reputational loss; |

| • | certain complications that may arise in our mining processes; |

| • | the ability to attract, engage and retain skilled employees, and strikes or other forms of work stoppages; |

| • | geopolitical conflicts, including the war in Eastern Europe and the conflict in the Middle East, and their potential impact on, among other things, global market conditions and supply and demand, including for crop nutrients, energy and commodity prices, interest rates, supply chains and the global economy generally; and |

| • | other risk factors detailed from time to time in Nutrien reports filed with the Canadian securities regulators and the SEC in the US. |

For additional details regarding the risks listed above, see “Risk Factors” discussed in this AIF for a description of other risk factors affecting forward-looking statements.

The forward-looking statements in this document are made as of the date hereof and we disclaim any intention or obligation to update or revise any forward-looking statements in this AIF as a result of new information or future events, except as may be required under applicable Canadian securities legislation or applicable US federal securities laws.

2.2 Basis of Presentation

Nutrien’s consolidated financial information for 2024, 2023 and 2022 presented and discussed in this AIF is prepared in accordance with International Financial Reporting Standards (“IFRS”) as issued by the International Accounting Standards Board. This AIF is dated February 20, 2025, and the information contained herein is current as of such date, unless otherwise specified.

Unless expressly stated, the information contained on, or accessible from, our website or any other website or any other report or document we file with or furnish to applicable Canadian or US securities regulatory authorities is not incorporated by reference into this AIF.

3 – Corporate Structure

In this AIF, unless otherwise specified, the term “Nutrien” refers to Nutrien Ltd. and, unless the context requires otherwise, the terms “we”, “us”, “our”, “Nutrien” and the “Company” refer to Nutrien and its direct and indirect subsidiaries, individually or in any combination, as applicable. Financial information in this AIF is presented in US dollars and references to “dollars”, “$” and “US$” are to US dollars and references to “CAD$” are to Canadian dollars.

3.1 Name, Address and Incorporation

Nutrien is a corporation incorporated under the Canada Business Corporations Act (“CBCA”).

Nutrien’s registered head office is Suite 1700, 211 19th Street East, Saskatoon, Saskatchewan, Canada S7K 5R6. We also have corporate offices at 13131 Lake Fraser Drive SE, Calgary, Alberta, Canada T2J 7E8 and 5296 Harvest Lake Drive, Loveland, Colorado, US 80538.

6

3.2 Intercorporate Relationships

| Principal Subsidiaries 1 | Jurisdiction of Incorporation, Formation or Organization |

Ownership | ||

| Potash Corporation of Saskatchewan Inc. (“PotashCorp”) |

Canada |

100% |

||

| Nutrien (Canada) Holdings ULC (“Agrium”) |

British Columbia, Canada |

100% |

||

| Agrium Canada Partnership |

Alberta, Canada |

100% |

||

| Agrium Potash Ltd. |

Canada |

100% |

||

| Cominco Fertilizer Partnership |

Texas, US |

100% |

||

| Loveland Products Inc. |

Colorado, US |

100% |

||

| Nutrien Ag Solutions (Canada) Inc. |

Canada |

100% |

||

| Nutrien Ag Solutions, Inc. |

Delaware, US |

100% |

||

| Nutrien Ag Solutions Limited |

Western Australia, Australia |

100% |

||

| PCS Nitrogen Fertilizer, L.P. |

Delaware, US |

100% |

||

| PCS Nitrogen Trinidad Limited |

Trinidad |

100% |

||

| PCS Phosphate Company, Inc. |

Delaware, US |

100% |

||

| PCS Sales (USA), Inc. |

Delaware, US |

100% |

||

| Nutrien Financial US LLC |

Delaware, US |

100% |

1 In aggregate, our remaining subsidiaries not listed herein accounted for less than 20 percent of our consolidated assets and less than 20 percent of our consolidated sales as at and for the year ended December 31, 2024.

4 – General Development of the Business

4.1 Three-Year History

Acquisitions and Divestitures

In October 2022, we acquired 100% of the issued and outstanding stock of Casa do Adubo S.A., an agriculture retailer in Brazil with 39 retail locations and 10 distribution centers for a purchase price of $268 million, net of cash and cash equivalents acquired.

In 2024, we announced an update to our strategy, with the intent of simplifying our business and focusing on business activities that are core to our long-term vision while pursuing opportunities to exit non-core activities. As a result, in 2024, we pursued the divestiture of non-core Retail assets in South America, including the closure of more than 50 locations and suspension of operations at all five blending facilities in Brazil, to reduce our fixed costs and improve asset efficiency. Additionally, in 2024, we announced a review of strategic options related to our investment in Profertil S.A., which is located in Argentina.

Asset Impairment and Reversals

| Year | Non-cash (US$ millions) |

Description | ||

| 2024 |

335 | Impairment of Retail – Brazil property, plant and equipment and intangible assets due to ongoing market instability resulting in more moderate margin expectations |

||

| 2024 |

195 | Impairment of the property, plant and equipment related to the Geismar Clean Ammonia project at our Geismar, Louisiana facility as we are no longer pursuing the project |

||

| 2023 |

233 | Impairment of Phosphate White Springs property, plant and equipment due to the volatility of forecasted phosphate margins |

||

| 2023 |

465 | Impairment of Retail – South America goodwill and intangible assets mainly due to the impact of crop input price volatility, more moderate long-term growth assumptions and higher interest rates |

||

| 2023 |

76 | Impairment of Nitrogen Trinidad property, plant and equipment due to a new natural gas contract and the resulting outlook for higher expected natural gas costs and constrained near-term availability |

||

| 2022 |

(780) | Impairment reversal of Phosphate Aurora and White Springs property, plant and equipment due to the volatility of forecasted phosphate margins |

7

NCIB Programs

| Commencement Date |

Expiry | Maximum Shares for Repurchase |

Number of Shares Repurchased |

|||||

| 2025 NCIB 1 |

March 3, 2025 | March 2, 2026 | 24,462,941 | nil | ||||

| 2024 NCIB |

March 1, 2024 | February 28, 2025 | 24,728,159 | 5,832,440 2 | ||||

| 2023 NCIB |

March 1, 2023 | February 29, 2024 | 24,962,194 | 5,375,397 | ||||

| 2022 NCIB 3 |

March 1, 2022 | February 7, 2023 | 55,111,110 | 55,111,110 | ||||

| 2021 NCIB |

March 1, 2021 | February 28, 2022 | 28,468,448 | 22,186,395 |

1 On February 19, 2025, our Board of Directors (the “Board”) approved a share repurchase program for up to 5 percent of our outstanding common shares (the “2025 NCIB”). The 2025 NCIB, which is subject to acceptance by the TSX, will expire earlier than the date above if we acquire the maximum number of common shares allowable or otherwise decide not to make any further repurchases.

2 Includes common shares repurchased to February 18, 2025. Subsequent to December 31, 2024, an additional 1,887,537 common shares were repurchased for cancellation at an aggregate cost of $96 million and an average price per share of $50.82.

3 The original expiry date of the 2022 NCIB was February 28, 2023, but we acquired the maximum aggregate number of common shares allowable thereunder on February 7, 2023.

The table below sets forth the number of common shares we have repurchased during the last three fiscal years, in each case, under the applicable NCIB through open market purchases at market prices.

| Common Shares Repurchased | 2024 | 2023 | 2022 | |||

| Total amount, inclusive of tax (US$ millions) |

190 | 1,000 | 4,496 | |||

| Number of shares |

3,944,903 | 13,378,189 | 53,312,559 |

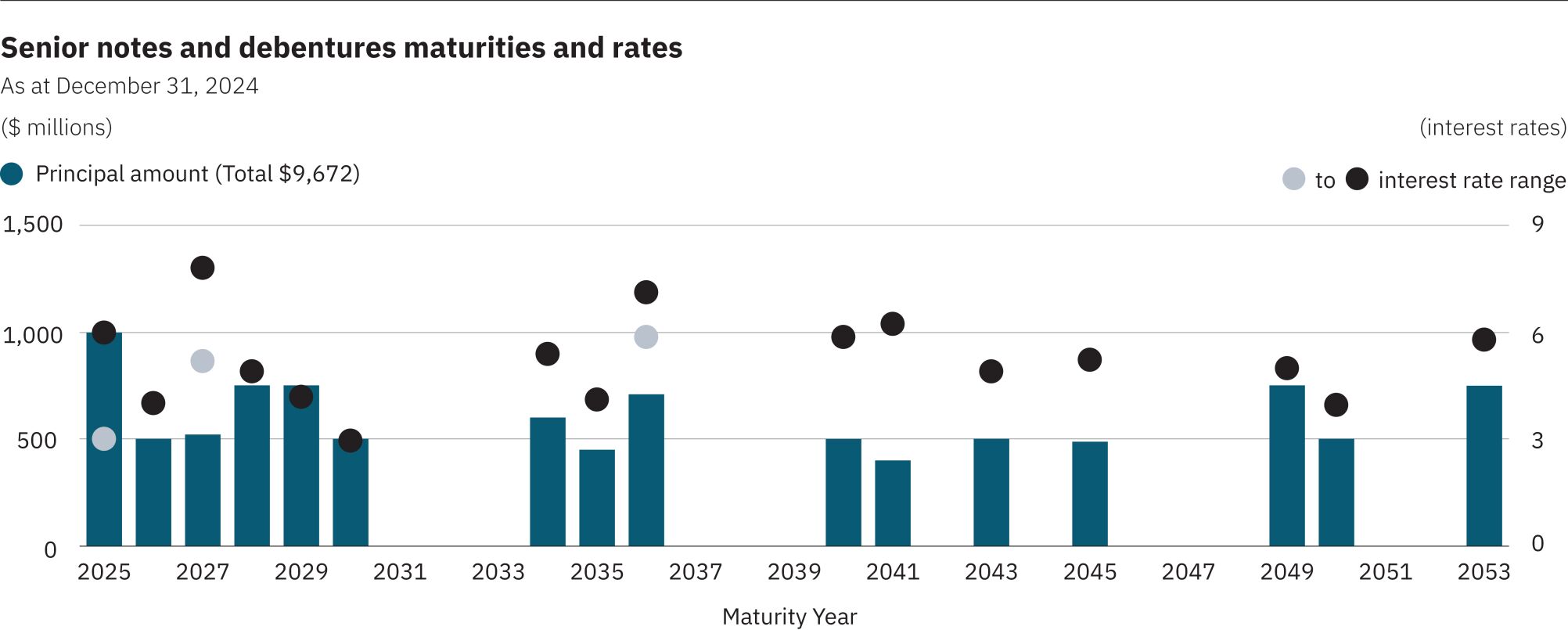

Senior Notes Issuances and Repayments

In 2022, we filed a base shelf prospectus in Canada and the US qualifying the issuance of up to $5.0 billion of common shares, debt securities and other securities during a period of 25 months from March 11, 2022. On March 27, 2023, we issued $1.5 billion of senior notes and on November 7, 2022, we issued $1.0 billion of senior notes each as described below, each such offering pursuant to the base shelf prospectus and the applicable prospectus supplement.

In 2024, we filed a base shelf prospectus in Canada and the US qualifying the issuance of common shares, debt securities and other securities during a period of 25 months from March 22, 2024. On June 21, 2024, we issued $1.0 billion of senior notes as described below, pursuant to the base shelf prospectus and a prospectus supplement.

The senior notes issued, as listed below, are unsecured, rank equally with our existing unsecured debt and have no sinking fund requirements prior to maturity.

The following tables summarize our long-term debt issuances and repayment activities during the last three fiscal years.

| Issuances and Repayments (US$ millions) | 2022 | 2023 | 2024 | |||||||||

| Senior Note Issuances: |

||||||||||||

| 5.900%, due November 7, 2024 |

500 | |||||||||||

| 5.950%, due November 7, 2025 |

500 | |||||||||||

| 4.900%, due March 27, 2028 |

750 | |||||||||||

| 5.800%, due March 27, 2053 |

750 | |||||||||||

| 5.200%, due June 21, 2027 |

400 | |||||||||||

| 5.400%, due June 21, 2034 |

600 | |||||||||||

| 1,000 | 1,500 | 1,000 | ||||||||||

| Senior Note Repayments: |

||||||||||||

| 3.150%, matured October 1, 2022 |

(500) | |||||||||||

| 1.900%, matured May 13, 2023 |

(500) | |||||||||||

| 5.900%, matured November 7, 2024 |

(500) | |||||||||||

| (500) | (500) | (500) | ||||||||||

8

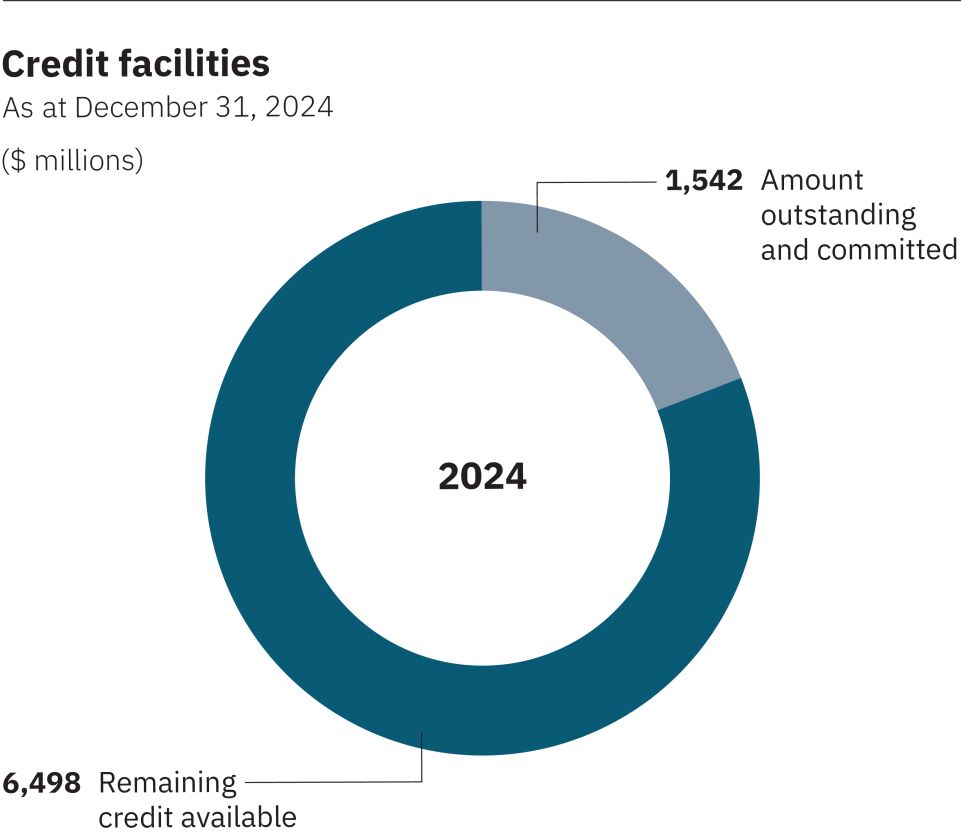

Credit Facilities

| Credit Facilities |

2022 | 2023 | 2024 | |||

| Unsecured revolving term facility | Credit facility limit - $4.5 billion

Maturity date extended from June 4, 2026, to September 14, 2027. |

No change. |

Maturity date extended from September 14, 2027, to September 4, 2029. |

|||

| Uncommitted revolving demand facility |

We increased our uncommitted revolving demand facility limit from $500 million to $1 billion. |

No change. |

No change. |

|||

| Unsecured revolving term facility |

In 2022, we entered into a new $2 billion unsecured revolving term credit facility, with the same principal covenants as our existing $4.5 billion facility. |

Extended the term of the facility from September 13, 2023, to September 10, 2024, and reduced the facility limit to $1.5 billion. |

Extended the term of the facility from September 10, 2024, to September 3, 2025, and reduced the facility limit to $750 million. |

|||

| Unsecured non-revolving term facilities |

To help temporarily manage normal seasonal working capital swings, we entered into non-revolving term credit facilities with an aggregate principal amount of $2.0 billion. Drawdowns on the facilities were fully repaid and subsequently terminated in 2022. |

n/a |

n/a |

|||

| Accounts receivable purchase facility (“repurchase facility”) |

n/a |

n/a |

In 2024, we entered into an uncommitted $500 million repurchase facility, where we may sell certain receivables from customers to a financial institution and agree to repurchase those receivables at a future date. |

5 – Description of the Business

We are a leading global provider of crop inputs and services. We operate a world-class network of production, distribution and agriculture retail facilities that positions us to efficiently serve the needs of farmers. We focus on creating long-term value by prioritizing investments that strengthen the advantages of our business across the agriculture value chain and by maintaining access to the resources and the relationships with stakeholders needed to achieve our goals.

We report our results in four operating segments: Nutrien Ag Solutions (”Retail”), Potash, Nitrogen and Phosphate. Our reporting structure reflects how we manage our business. Sales classified by operating segment and applicable category of products and services are provided in Note 3 of the 2024 Consolidated Financial Statements. Material sales or transfers to certain entities in which the Company has an investment that is accounted for under the equity method are provided in Note 3 of the 2024 Consolidated Financial Statements.

Our business operations are further categorized as upstream, midstream and downstream through our involvement across the agriculture value chain. Our upstream Potash, Nitrogen and Phosphate segments are differentiated by the chemical nutrient contained in the products that each segment produces, and are supported by midstream activities, which include the global sales, freight, transportation and distribution of our products that are reported within these segments. Our downstream Retail segment distributes crop nutrients, crop protection products, seed and merchandise, and provides agronomic application services and solutions, including services offered through Nutrien Financial. Retail also manufactures and distributes proprietary products and provides services directly to farmers through a network of retail locations in North America, South America and Australia.

9

5.1 Upstream

Our upstream operations are focused on our low-cost production assets, including mining, processing and manufacturing of three essential crop nutrients needed for fertilizer production, potash, nitrogen and phosphate. Our fertilizer manufacturing assets are primarily located in North America, which provides access to high-quality resources, lower cost inputs and an extensive distribution network to efficiently supply our customers. We sold approximately 27 million metric tonnes of manufactured fertilizer in 2024 from our production facilities in Canada, the US and Trinidad. As of December 31, 2024, we estimate our Potash segment represented 20 percent of global potash nameplate capacity, our Nitrogen segment represented three percent of global nitrogen nameplate capacity, and our Phosphate segment represented approximately three percent of global phosphate nameplate capacity.

5.1A Potash Segment

Overview

Our Potash segment includes the mining and processing of potash, which is predominantly used as fertilizer, at our six Saskatchewan potash mines. The Saskatchewan Ministry of Energy and Resources has granted Nutrien the exclusive right to mine potash on approximately 383,000 hectares (or approximately 947,000 acres) of Crown land pursuant to subsurface mineral leases. Of the 383,000 hectares leased from the Crown, approximately 282,000 hectares comprise our Potash operations at the Allan, Cory, Lanigan, Patience Lake, Rocanville and Vanscoy mines. Leases also exist with freehold mineral rights owners within the Crown subsurface mineral lease areas and elsewhere in Saskatchewan.

Subsurface mineral leases with the Province of Saskatchewan are for 21-year terms, renewable at our option, at each of our producing mines. Our subsurface mineral leases with other parties are also for 21-year terms, which are renewable at our option, provided generally that production is continuing and that there is continuation of the applicable lease with the Province of Saskatchewan.

In 2024, our nameplate capacity represented 53 percent of the North American total nameplate capacity, and our potash production represented 57 percent of North American production. We allocate production among our mines on the basis of various factors, including cost efficiency and the grades of product that can be produced.

Our total Potash sales to third parties in 2024 represented 12 percent of our total consolidated sales (2023 – 14 percent). Our total offshore sales in 2024 represented 49 percent of our total Potash sales (2023 – 50 percent).

Production Methods

We produce potash primarily using conventional mining methods, except for our Patience Lake mine, which was originally a conventional underground mine, but began employing a solution mining method in 1989. In conventional operations, shafts are sunk to the ore body, which is approximately one kilometer below the surface. Mining machines cut the ore, which is then hoisted to the surface for processing. The ore is a mixture of potassium chloride, salt and insoluble particles. In solution mining, the potash is dissolved in warm brine and pumped to the surface for processing. Saleable potash is produced by removing salt and insoluble particles through a milling process. Six grades of potash (standard, granular, fine standard, white granular, soluble and chicklets) are produced to suit different preferences of the agricultural, industrial and feed markets that we serve.

The mining of potash is a capital-intensive business, which is subject to the normal risks and capital expenditure requirements typically associated with mining operations. The production and processing of ore may be subject to delays and costs resulting from mechanical failures, physical hazards such as fires, and other hazards such as: unusual or unexpected geological conditions, significant subsidence, brine inflows and gas seepages of varying degrees, and other conditions associated with any potash mining operation.

Sources of Raw Materials

The production of potash requires a sustained fresh water supply for the milling process, which comes from nearby sources, including subsurface aquifers, reservoirs and the Saskatchewan River.

10

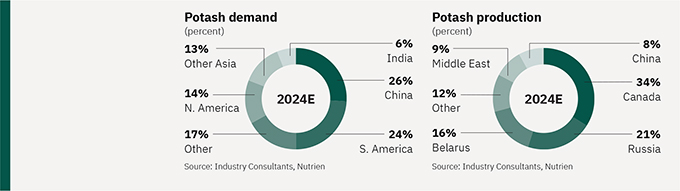

Competitive Position

We are the leading global producer of potash with annual production of 14.2 million tonnes in 2024, representing 19% of annual global production. Potash is a commodity, characterized by minimal product differentiation, and, consequently, producers compete based on price, quality, availability and service. We price competitively, sell high-quality products and provide availability and high-quality service to our customers. Our service includes maintaining warehouses, leasing railcars and chartering vessels to enhance our delivery capabilities. The high cost of transporting potash affects competition in various geographic areas.

5.1B Nitrogen Segment

Overview

We own and operate ammonia production facilities at which we produce and, where applicable, upgrade the following nitrogen products:

| Plant Locations | Nitrogen Products Produced | |

| Augusta, Georgia | Ammonia, urea, urea ammonium nitrate (“UAN”), urea solutions, nitric acid and ammonium nitrate | |

| Borger, Texas | Ammonia, urea and urea solutions | |

| Carseland, Alberta | Ammonia, urea and Environmentally Smart Nitrogen® (“ESN®”) | |

| Fort Saskatchewan, Alberta | Ammonia and urea | |

| Geismar, Louisiana | Ammonia, urea, UAN, urea solutions and nitric acid | |

| Joffre, Alberta | Ammonia | |

| Lima, Ohio | Ammonia, urea, UAN, urea solutions, nitric acid and ammonium nitrate | |

| Point Lisas, Trinidad | Ammonia and urea | |

| Redwater, Alberta | Ammonia, urea, urea solutions, nitric acid, ammonium nitrate, UAN and ammonium sulfate |

We also operate a number of facilities that upgrade ammonia and urea to other products such as UAN, ammonium nitrate, nitric acid and ESN®.

| Plant Locations | Nitrogen Products Produced | |

| Granum, Alberta | UAN | |

| Kennewick, Washington | UAN, ammonium nitrate, nitric acid and calcium ammonium nitrate (“CAN”) | |

| New Madrid, Missouri | ESN® | |

| Standard, Alberta | UAN |

Our owned and operated facilities have a combined annual gross ammonia nameplate capacity of approximately 7.3 million tonnes.

In 2024, our total Nitrogen sales to third parties represented 13 percent of our total consolidated sales (2023 – 13 percent).

We also have a 50 percent joint venture ownership in Profertil S.A. (“Profertil”), a joint venture that owns a nitrogen facility in Bahia Blanca, Argentina. We are currently reviewing our investment in Profertil as part of our strategic priorities announced in 2024.

Production Methods

Ammonia is produced by taking nitrogen from the air and reacting it with a hydrogen source, usually natural gas reformed with steam. CO2 is produced as a result of ammonia production in two primary ways – first, as a product of the chemical reactions involved and, second, as a product of burning fuels that generate the heat required to make those chemical reactions occur. In most plants, the CO2 produced as a chemical byproduct is captured and used as an input to urea production.

Ammonia is the feedstock used to produce a full line of upgraded products, including urea, ammonium nitrate, nitric acid, urea solutions including UAN and diesel exhaust fluid (“DEF”), ammonium sulfate and ESN®. Urea is produced by combining ammonia with CO2 and forming liquid urea, which can be further processed into a solid form. UAN solutions are liquid fertilizers that are produced by combining urea, liquid ammonium nitrate and water. Urea liquor is a urea liquid solution sold into the DEF market. When combined with diesel in larger vehicles and machinery, it can improve fuel efficiency and reduce emissions. Urea liquid solutions are produced by combining liquid urea with water. Ammonium sulfate is produced by reacting ammonia and sulfuric acid, which is then granulated to form a solid granular product. We produce sulfuric acid from purchased sulfur at our Redwater facility. ESN® is a patented coated-fertilizer product that is made by coating the urea substrate with layers of polymers, allowing for more efficient delivery of nitrogen to the plant.

11

Ammonia, urea and nitrogen solutions are sold as fertilizers to agricultural and industrial customers for various applications. Nitric acid and ammonium nitrate are sold to industrial customers for various applications. Urea is also sold for feed applications. ESN® is sold to agricultural customers. Urea solution is sold to industrial and agricultural customers.

Sources of Raw Materials

Natural gas is the primary raw material used for producing ammonia, which is the base for substantially all manufactured nitrogen products. Our Joffre, Alberta facility uses hydrogen as its raw material to produce ammonia.

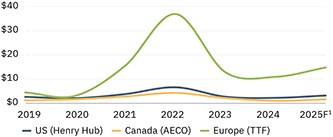

In North America, we may from time to time enter into natural gas hedging transactions with the goal of minimizing risk from potential volatility of natural gas prices. We purchase most of our natural gas from producers or marketers at the point of delivery of the natural gas into the pipeline system, then pay the pipeline company and, where applicable, the local distribution company to transport the natural gas to our nitrogen facilities. Over 90 percent of our North American consumption of natural gas by our Nitrogen segment is delivered pursuant to firm transportation contracts, which do not permit the pipeline or local distribution company to interrupt service to, or divert natural gas from, the plant.

| Trinidad natural gas contracts |

- Renewed in 2023 - Natural gas supply contract using a pricing formula based on benchmark ammonia pricing - Minimum take or pay arrangement providing for approximately 75 percent of the expected requirements of the Trinidad ammonia complex - 2022 and 2023 – force majeure notices received which resulted in reduced operating rates - 2024 – increased operating rates achieved as natural gas availability improved |

|

| Profertil natural gas contracts |

- 70 percent of the natural gas contracts are with YPF S.A., our joint venture partner in Profertil, which were renewed in 2024 and are expiring in 2028 - 30 percent of the natural gas sourced by other suppliers was renewed in 2023 and is expiring in 2028 |

|

| Carseland power cogeneration agreement |

- Expiring on December 31, 2026 - Provides 60 megawatt-hours of power per hour - Based on a fixed charge adjusted for inflation and a variable charge based on the cost of natural gas provided to the facility for power generation |

|

| Geismar natural gas pipeline transportation contracts |

- Entered in 2023 for various terms up to 10 years - Take or pay arrangement providing for approximately 80 percent of the expected natural gas requirements of Geismar as well as other production sites in Eastern US |

Competitive Position

We are one of the top three global producers of nitrogen, with a diverse portfolio of nitrogen products and have flexibility to optimize product mix in changing market conditions. Nitrogen-based fertilizer is a global commodity, and customers, including end-users, dealers, and other fertilizer producers and distributors, base their purchasing decisions principally on the delivered price and availability of the product. The relative cost of, and availability of transportation for, raw materials and finished products to manufacturing facilities are also important competitive factors. Nitrogen is also an input into industrial production of a wide range of products. Many manufacturers want consistent quality and just-in-time delivery to keep their plants running. Our North American plants are geographically well positioned to service agriculture, industrial and feed customers across Canada and the US. Our robust North American distribution network provides in-market support during seasonal peak demand, ensuring timely product availability. Trinidad mainly supplies our international fertilizer and industrial customers.

Our US nitrogen production has continued to benefit from the low relative cost of natural gas and, to a greater extent, our Western Canadian production, which utilizes natural gas indexed to the Alberta Energy Company (“AECO”) benchmark natural gas price, has also benefited from the low relative cost of natural gas. In Trinidad, the price at which we purchase natural gas is linked to benchmark ammonia pricing, and annual escalating floor prices. Ammonia and urea predominate our offshore sales of nitrogen and originate primarily from Trinidad, with other sales coming from purchased product locations.

12

5.1C Phosphate Segment

Overview

Our Phosphate segment includes the manufacture and sale of solid and liquid phosphate fertilizers, phosphate feed and purified phosphoric acid, which is used in feed and industrial products. We have phosphate mines and mineral processing plant complexes in Aurora, North Carolina and White Springs, Florida. We also have three phosphate feed plants in the US.

Our Phosphate properties include:

| Plant Locations | Primary Products Produced 1 | |

| Aurora, North Carolina |

MAP, purified acid, merchant grade phosphoric acid (“MGA”), low magnesium SPA (“LOMAG”) and ammonium polyphosphate (“POLY”) |

|

| Cincinnati, Ohio |

Blended purified acid products |

|

| Joplin, Missouri |

Animal feed |

|

| Marseilles, Illinois |

Animal feed |

|

| Weeping Water, Nebraska |

Animal feed |

|

| White Springs, Florida |

MAP and MAP+MST, MGA 2, SPA, LOMAG and POLY |

1 The following scientific terms have the following meanings:

MAP monoammonium phosphate, 52 percent P2O5 (solid)

MAP+MST sulfur enhanced MAP

SPA superphosphoric acid, 70 percent P2O5 (liquid)

2 All of the MGA from White Springs is consumed internally in the production of additional products.

In 2024, our Phosphate sales to third parties represented six percent of our total consolidated sales (2023 – seven percent).

Production Methods

We extract phosphate ore using surface mining techniques. At each mine site, the ore is mixed with recycled water to form a slurry, which is pumped from the mine site to our processing facilities. The ore is then screened to remove coarse materials, washed to remove clay and floated to remove sand to produce phosphate “rock”. The annual production capacity of our mines is currently 7.4 million tonnes of phosphate rock. During 2024, the Aurora facility’s total production of phosphate rock was 3.99 million tonnes and the White Springs facility’s total production of phosphate rock was 1.20 million tonnes. The sequence for mining portions of the Aurora property was identified in the permit issued by the US Army Corps of Engineers in June 2009. The permit authorizes mining in excess of 20 years, although the mine life has been estimated at 17 years at current production rates. Phosphate rock is the major input in our phosphate processing operations. Substantially all the phosphate rock produced is used internally for the production of phosphoric acid, SPA, chemical fertilizers, purified phosphoric acid and animal feed products.

We produce sulfuric acid at the Aurora and White Springs facilities from purchased sulfur. We produce MGA at our Aurora and White Springs facilities. Some MGA from the Aurora facility is sold to foreign and domestic fertilizer producers and industrial customers. We further process the balance of the MGA to make solid fertilizers (MAP), liquid fertilizers, animal feed supplements for the poultry and livestock markets, and purified phosphoric acid for use in a wide variety of food, technical and industrial applications.

Sources of Raw Materials

Phosphate rock is the major input in our phosphate processing operations and is mined at our Aurora and White Springs facilities. In addition to phosphate ore, the other principal raw materials we require are sulfur and ammonia. The production of phosphoric acid requires substantial quantities of sulfur, which we purchase from third parties. Agreements for the purchase of sulfur for use in production of phosphoric acid provide for specified purchase quantities and prices based on market rates at the time of delivery. Any significant disruption in our sulfur supply to the phosphate facilities could adversely impact our Phosphate financial results.

Our Phosphate segment purchases substantially all of its ammonia at market rates from or through our Nitrogen sales subsidiaries. Phosphoric acid is reacted with ammonia to produce MAP and MAP+MST as well as liquid fertilizers. We produce sulfuric acid at the Aurora and White Springs facilities from purchased sulfur. Ammonia for our Aurora facility is primarily supplied by rail and truck from our nitrogen production facilities in Lima, Ohio and Augusta, Georgia. Ammonia for our White Springs facility is primarily supplied by truck from our nitrogen production facility in Augusta, Georgia.

13

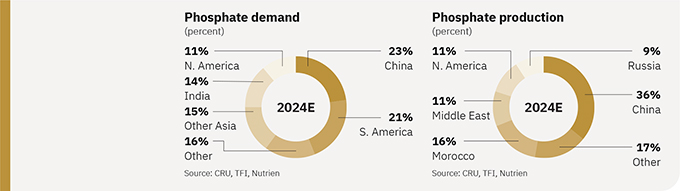

Competitive Position

In 2024, we were the second largest producer of phosphate in North America, consistent with 2023. Markets for phosphate fertilizer products are highly competitive and based largely on price, service and availability. Low-cost capacity has been commissioned over the past few years, most notably in Morocco and Saudi Arabia. The additional capacity is needed to keep pace with steadily growing phosphate demand, both in agricultural and industrial sectors, and is helping to partially offset lost phosphate fertilizer exports from Chinese producers driven by domestic Chinese policy shifts. Our principal advantages at the Aurora and White Springs facilities are that we produce higher-value, diversified products and that we operate integrated phosphate mine and phosphate processing complexes. Our in-market distribution network supports product supply during peak demand periods.

In 2021, the US Department of Commerce issued countervailing duty (“CVD”) orders on imports of phosphate fertilizers from Morocco and Russia, which will remain in place for at least five years. In November 2024, the Department of Commerce published the final results of its CVD administrative review for entries from 2022. The revised CVD rate for imports from Morocco is 16.81 percent (previously 14.21 percent) while imports that are produced/exported from Russia by JSC Apatit, a producer/exporter of phosphate fertilizers, and affiliates are subject to a CVD rate of 18.21 percent (previously 28.5 percent). Further rate adjustments may be made upon completion of the next administrative reviews, which are expected in November 2025.

Within the animal feed supplement business in the Phosphate segment, opportunities exist to differentiate products based on nutritional content. We have a significant presence in the domestic feed supplement market segments.

Industrial products are the least commodity-like of the phosphate products as product quality is a more significant consideration for customer buying decisions. We market industrial phosphate products principally in the US.

5.2 Midstream

Established in late 2022, our Commercial organization supports the global sales of our potash, nitrogen and phosphate products, transportation, distribution and logistics, market research and product management functions. This organizational function helps maximize performance across our supply chain and generates incremental value by delivering customer service, driving supply chain efficiencies, and leading margin optimization opportunities across our integrated network. It achieves this through optimizing our logistics infrastructure, leveraging our distribution network and customer relationships, and increasing internal sourcing of our upstream manufactured fertilizer sales volumes.

Transportation, Storage and Distribution

We operate a sophisticated logistics network to transport our products from production facilities to retail and wholesale customers, ensuring timely and efficient delivery. Transportation costs can be a significant component of the total delivered cost of our products. Producers may have an advantage in serving markets close to their sources of supply depending on prevailing transportation costs. International shipping cost variances permit offshore producers to effectively compete with our production in many geographies.

Potash Segment

We use an extensive transportation and distribution network to transport our potash products. Most of our potash for North American customers is shipped by rail, along with significant volumes shipped by truck and barge. We believe we have a strategic advantage in this market with approximately 330 owned or leased potash distribution points and a fleet of approximately 5,800 owned or leased railcars as at December 31, 2024. Shipments are also made by rail from each of our Saskatchewan mines to Thunder Bay, Ontario for shipment by lake vessel to our warehouses and storage facilities in Canada and the US. In 2024, we expanded our midstream distribution network with the opening of a new potash terminal, providing additional storage capacity for multiple products and shortening delivery lead times for our customers.

The potash we produce in Canada for sale to destinations outside the US and Canada is sold exclusively to Canpotex Limited (“Canpotex”). Canpotex is owned in equal shares by Nutrien and another potash producer in Canada. Canpotex, which was incorporated in 1970 and commenced operations in 1972, acts as an export company providing integrated sales, marketing and distribution for all Canadian potash produced by its shareholders/producers that is exported to destinations outside the US and Canada. Each shareholder of Canpotex has an equal voting interest as a shareholder and a right to equal representation on the Canpotex board of directors. In general, Canpotex sales volumes are allocated among Canpotex producers based on production capacity. In 2024, Nutrien supplied approximately 66 percent of Canpotex’s product supply requirements (2023 – approximately 64 percent). Canpotex sells potash to buyers in export markets pursuant to term and spot contracts at agreed-upon prices. Canpotex has a long history of being a reliable supplier of potash to international markets and of proven logistics and marketing capabilities. Other major potash exporting countries include Russia, Belarus, Israel and Germany.

14

In the case of our sales to Canpotex, Canpotex is responsible for managing and directing all aspects of its logistics infrastructure platform, including the transportation of its potash by way of rail to marine facilities where it is handled, stored and loaded onto ocean-going vessels. We have an equity interest in Canpotex Bulk Terminals Limited, which is a part owner of the marine facilities utilized by Canpotex in Vancouver, British Columbia. We also provide a lease to Canpotex for the utilization of a marine facility in Saint John, New Brunswick. Canpotex also utilizes marine facilities in Portland, Oregon and Thunder Bay, Ontario. Other facilities may be utilized as required.

Nitrogen Segment

We distribute our nitrogen products by vessel, barge, pipeline, railcar and truck to our customers and, in high-consumption areas, through our strategically located storage terminals. In North America, as at December 31, 2024, we owned or leased approximately 200 nitrogen distribution points, as well as a fleet of approximately 5,700 owned or leased railcars. We also lease dry and liquid storage capacity in Europe. These locations provide a network of field and production site storage capacity sufficient to serve local dealers during the peak seasonal demand period and are also used to provide off-season storage.

We also distribute nitrogen products from Trinidad primarily to markets in the US, South America and Europe. We employ five long-term chartered ocean-going vessels and utilize short-term and spot charters as necessary for the transportation of ammonia for our marine distribution operations in Trinidad. All bulk urea production from Trinidad is shipped through third-party carriers. In addition, Profertil’s terminal on the Paraná River includes a dedicated berth and two 100,000 tonne dry storage buildings in a key agricultural region of Argentina.

Phosphate Segment

As at December 31, 2024, we had approximately 130 owned or leased phosphate distribution points and a fleet of approximately 5,400 owned or leased railcars. We have access to ocean-based shipping terminal capacity in North Carolina through which we internationally ship a portion of the Aurora facility’s finished product. Most of our offshore Phosphate sales are shipped through the terminal at Morehead City, North Carolina. We use barges and tugboats to transport solid products and phosphoric acid between the Aurora facility and the Morehead City terminal. Raw materials and products, including sulfur, are also transported to and from the Aurora facility by rail and truck. Sulfur is delivered to the White Springs facility by rail and truck from Canada and the US. Most of the phosphoric acid and chemical fertilizers produced at the White Springs facility are shipped to North American destinations by rail. Ammonia for the Aurora and White Springs facilities is supplied by rail and truck from our production facilities in Lima, Ohio and Augusta, Georgia.

5.3 Downstream – Retail Segment

Our Retail segment markets crop nutrients, crop protection products, seed and merchandise, and provides agronomic application services and solutions, including the services offered through Nutrien Financial, through more than 1,900 retail locations across North America, Australia and South America. Over 4,500 crop consultants support farmers in crop planning, seed selection, soil sampling, variable rate fertilizer application and crop monitoring.

15

In 2024, our total Retail sales represented 69 percent of our total consolidated sales (2023 – 67 percent). Retail’s products and services are as follows:

|

Product

|

% of Retail Sales

|

Description

|

||

| Crop nutrients | 2024 – 41 2023 – 43 |

- Dry and liquid macronutrient and micronutrient products, which include potash, nitrogen and phosphate, specialty fertilizers and proprietary plant nutrition and biostimulant products. |

||

| Crop protection products | 2024 – 35 2023 – 34 |

- Third-party supplier and proprietary products, primarily through our Loveland Products Inc. brands across North America, South America and Australia, designed to enhance crop quality and manage diseases, weeds, and other pests. |

||

| Seed | 2024 – 13 2023 – 12 |

- Third-party supplier and proprietary seed product lines, including Dyna-Gro®, Proven™, and Sementes Goiás, and seed treatments applied to seeds prior to planting, designed to protect them from pests and disease |

||

| Services and other | 2024 – 5 2023 – 4 |

- Product application, soil and leaf testing, crop scouting and precision agriculture services, water services and brokerage agency services. |

||

| Merchandise | 2024 – 5 2023 – 5 |

- Livestock-related merchandise including fencing, feed supplements, animal identification merchandise and various animal health products and services. - storage and irrigation equipment and other products. |

||

| Nutrien Financial | 2024 – 1 2023 – 2 |

- Financing solutions offered to US and Australia Retail branches and customers in support of Nutrien’s agricultural product and service sales. |

We have an extensive infrastructure system to store and transport our Retail products, strategically located across distribution points in regions where we operate to serve our customers across the US, Canada, Australia and South America.

|

Approximate Number (as at December 31, 2024) |

Nature | Description | ||

| 90 | Terminals |

- Receive large quantities of crop nutrients for redistribution to Retail centers and to farmers directly |

||

| 50 | Distribution centers |

- Distribute crop protection products and seed - Coordinate product supply to Retail centers and allow us to efficiently manage inventory levels across our distribution network |

||

| 1,800 | Branches, satellites, plants, storage and franchises |

- Retail locations provide farmers with complete agriculture solutions, including crop and soil nutrients, crop protection, seed, services and digital tools - Manufacturing plants used for production of crop inputs |

||

| 31,700 | On-farm and on-road vehicles and application equipment |

- Distribute, support and apply crop inputs |

Supply chain management, utilizing our extensive storage and distribution network and transportation capabilities, allows us to efficiently deliver crop nutrients and seed products to our customers. As farmers have a short application and planting window, the precise timing of such deliveries is unpredictable due to both the seasonal nature of crop planting and the impact of weather. We regularly review and manage our suppliers to maintain critical feedstocks, and we believe we can leverage our diverse retail distribution network and expansive fertilizer terminal network to effectively manage product logistic challenges.

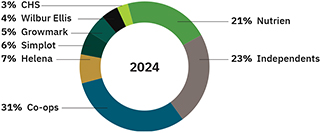

Competitive Position

Nutrien is the largest global agriculture retailer. Our Retail segment serves farmers in key agricultural markets in North America, South America and Australia. The market for Nutrien’s Retail products and services is highly competitive in the countries in which we operate. The principal competitors in the retail distribution of crop inputs include agricultural cooperatives, other major agriculture retailers, and smaller independent retailers and distributors. Retail produces a range of high-quality proprietary crop protection, crop nutrient and seed products that generate higher margins for our Retail segment compared to non-proprietary products. Our digital platform supports our core business offering, enhances the customer experience, and includes access to services such as crop planning, customer account management, invoice payment and financing, dependent on geography.

16

5.4 Specialized Skill and Knowledge

We believe our success is dependent on the performance of our management and key operational employees, many of whom have specialized skills and knowledge relating to the agricultural retail, potash, nitrogen and phosphate industries, and to the conduct of the agricultural Retail, Potash, Nitrogen and Phosphate operations. We believe that we have adequate personnel with the specialized skills and knowledge to successfully carry out our business and operations.

5.5 Intangible Properties

We have registered and pending trademarks and patents in Canada, the US and other countries where our products are sold. In addition, it has been our practice to seek patent protection for inventions and improvements that are likely to be incorporated into our products, where appropriate, and to protect the freedom to use our inventions in our manufacturing processes. We consider several factors in assessing the materiality of our patents including, but not limited to, scope and breadth of claims, sales volumes of products incorporating the technology, strategic importance and patent duration.

While these trademarks and patents constitute valuable assets, we do not regard any single trademark or patent as being material to our operations as a whole. See Note 15 of the 2024 Consolidated Financial Statements for disclosure on estimated useful lives of intangible assets.

5.6 Seasonality

Seasonality in our business results from increased demand for products during planting season. Crop input sales are generally higher in spring and fall application seasons. Crop input inventories are normally accumulated leading up to each application season. The results of this seasonality have a corresponding effect on receivables from customers and rebates receivables, inventories, prepaid expenses and other current assets and trade payables. Our short-term debt also fluctuates during the year to meet working capital requirements. Our cash collections generally occur after the application season is complete, while customer prepayments made to us are typically concentrated in December and January and inventory prepayments paid to our suppliers are typically concentrated in the period from November to January. Feed and industrial sales are more evenly distributed throughout the year. See “Risk Factors” below for a description of the risks related to seasonality.

5.7 Environmental Matters

Environmental Requirements, Permits, and Regulatory Approvals