UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, DC 20549

FORM 6-K

Report of Foreign Private Issuer

Pursuant to Rule 13a-16 or 15d-16

Under the Securities Exchange Act of 1934

For the month of March, 2024

Cameco Corporation

(Commission file No. 1-14228)

2121-11th Street West

Saskatoon, Saskatchewan, Canada S7M 1J3

(Address of Principal Executive Offices)

Indicate by check mark whether the registrant files or will file annual reports under cover Form 20-F or Form 40-F.

Form 20-F ☐ Form 40-F ☒

Indicate by check mark whether the registrant by furnishing the information contained in this Form is also thereby furnishing the information to the Commission pursuant to Rule 12g3-2(b) under the Securities Exchange Act of 1934.

Yes ☐ No ☒

If “Yes” is marked, indicate below the file number assigned to the registrant in connection with Rule 12g3-2(b):

Exhibit Index

| Exhibit No. |

Description |

|

| 99.1 | Press Release dated March 22, 2024 | |

| 99.2 | Cigar Lake Technical Report dated March 22, 2024 | |

SIGNATURE

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| Date: March 22, 2024 | Cameco Corporation | |||||

| By: | /s/ Sean A. Quinn |

|||||

| Sean A. Quinn | ||||||

| Senior Vice-President, Chief Legal Officer and Corporate Secretary | ||||||

Exhibit 99.1

| TSX: CCO |

|

website: cameco.com | ||

| NYSE: CCJ | currency: Cdn (unless noted) |

2121 – 11th Street West, Saskatoon, Saskatchewan, S7M 1J3 Canada

Tel: 306-956-6200 Fax: 306-956-6201

Cameco Reports Document Filings

Saskatoon, Saskatchewan, Canada, March 22, 2024 . . . . . . . . . . . . .

Cameco (TSX: CCO; NYSE: CCJ) reported today that it filed its annual report on Form 40-F with the US Securities and Exchange Commission. The document includes Cameco’s audited annual financial statements for the year ended December 31, 2023, its management’s discussion and analysis (MD&A), and its Canadian annual information form (AIF).

In addition, Cameco filed with Canadian securities regulatory authorities its AIF. Its audited annual financial statements for the year ended December 31, 2023, and its MD&A were filed with Canadian securities regulatory authorities in February 2024.

Cameco also filed a technical report for the Cigar Lake operation under Canadian Securities Administrators’ National Instrument 43-101.

All of these documents are posted on our website. Shareholders may obtain hard copies of these documents, including the financial statements, free of charge by contacting:

Cameco Investor Relations

2121 11th Street West

Saskatoon, SK S7M 1J3

Phone: 306-956-6294

On April 5, 2024, Cameco plans to post on its website the management proxy circular that is being distributed to shareholders of record as of March 11, 2024, for its annual meeting of shareholders on

May 9, 2024. Cameco, on behalf of itself and certain subsidiaries (collectively, “Cameco”), will also post its Modern Slavey Report in accordance with the Fighting Against Forced Labour and Child Labour in Supply Chains Act (Canada) (the “Act”). This is Cameco’s first Modern Slavery Report pursuant to the Act.

Profile

Cameco is one of the largest global providers of the uranium fuel needed to energize a clean-air world. Our competitive position is based on our controlling ownership of the world’s largest high-grade reserves and low-cost operations, as well as significant investments across the nuclear fuel cycle, including ownership interests in Westinghouse Electric Company and Global Laser Enrichment. Utilities around the world rely on Cameco to provide global nuclear fuel solutions for the generation of safe, reliable, carbon-free nuclear power. Our shares trade on the Toronto and New York stock exchanges. Our head office is in Saskatoon, Saskatchewan, Canada.

- End –

Investor inquiries:

Cory Kos

306-716-6782

cory_kos@cameco.com

Media inquiries:

Veronica Baker

306-385-5541

veronica_baker@cameco.com

Exhibit 99.2

Cigar Lake Operation

Northern Saskatchewan, Canada

National Instrument 43-101

Technical Report

Effective Date: December 31, 2023

Date of Technical Report: March 22, 2024

PREPARED FOR CAMECO CORPORATION BY:

BIMAN BHARADWAJ, P. ENG.

C. SCOTT BISHOP, P. ENG.

ALAIN D. RENAUD, P. GEO.

LLOYD ROWSON, P. ENG.

Table of Contents

| 1 SUMMARY |

1 | |||

| 1.1 Preamble |

1 | |||

| 1.2 Introduction |

1 | |||

| 1.3 Property tenure |

2 | |||

| 1.4 Location and site description |

2 | |||

| 1.5 Geology and mineralization |

3 | |||

| 1.6 Exploration of Cigar Lake deposit |

4 | |||

| 1.7 Mineral resources and mineral reserves |

4 | |||

| 1.8 Mining |

7 | |||

| 1.9 Processing |

9 | |||

| 1.10 Environmental assessment and licensing |

10 | |||

| 1.11 Cigar Lake water inflow incidents and remediation |

11 | |||

| 1.12 Current status of development |

11 | |||

| 1.13 Production plan |

12 | |||

| 1.14 Economic analysis and costs |

13 | |||

| 1.15 Mining and milling risks |

14 | |||

| 1.16 Conclusions and recommendations |

14 | |||

| 2 INTRODUCTION |

17 | |||

| 2.1 Introduction and purpose |

17 | |||

| 2.2 Report basis |

18 | |||

| 3 RELIANCE ON OTHER EXPERTS |

19 | |||

| 4 PROPERTY DESCRIPTION AND LOCATION |

20 | |||

| 4.1 Location |

20 | |||

| 4.2 Mineral tenure |

21 | |||

| 4.3 Surface tenure |

25 | |||

| 4.4 Royalties |

28 | |||

| 4.5 Known environmental liabilities |

28 | |||

| 4.6 Permitting |

28 | |||

| 5 ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

29 | |||

| 5.1 Access |

29 | |||

| 5.2 Climate |

31 | |||

| 5.3 Physiography |

31 | |||

| 5.4 Local resources |

31 | |||

i

| 5.5 Mine and infrastructure |

32 | |||

| 6 HISTORY |

35 | |||

| 6.1 Ownership |

35 | |||

| 6.2 Exploration and development history |

36 | |||

| 6.3 Historical mineral resource and mineral reserve estimates |

38 | |||

| 6.4 Historical production |

38 | |||

| 7 GEOLOGICAL SETTING AND MINERALIZATION |

39 | |||

| 7.1 Regional geology |

39 | |||

| 7.2 Local geology |

39 | |||

| 7.3 Property geology |

42 | |||

| 7.4 Mineralization |

46 | |||

| 8 DEPOSIT TYPES |

48 | |||

| 9 EXPLORATION |

49 | |||

| 9.1 ORANO 1980 – present |

49 | |||

| 9.2 Cameco 2007 – present |

54 | |||

| 10 DRILLING |

55 | |||

| 10.1 Surface drilling |

55 | |||

| 10.2 Underground drilling |

60 | |||

| 10.3 Factors that could materially affect the accuracy of the results |

62 | |||

| 11 SAMPLE PREPARATION, ANALYSES AND SECURITY |

63 | |||

| 11.1 Sample density and sampling methods |

63 | |||

| 11.2 Core recovery |

63 | |||

| 11.3 Sample quality and representativeness |

64 | |||

| 11.4 Sample preparation by Cameco employees |

64 | |||

| 11.5 Sample preparation |

64 | |||

| 11.6 Assaying |

65 | |||

| 11.7 Radiometric surveying |

65 | |||

| 11.8 Density sampling |

67 | |||

| 11.9 Quality assurance/quality control |

67 | |||

| 11.10 Adequacy of sample preparation, assaying, QA/QC and security |

70 | |||

| 12 DATA VERIFICATION |

72 | |||

| 13 MINERAL PROCESSING AND METALLURGICAL TESTING |

73 | |||

| 13.1 Cigar Lake processing metallurgical test work |

73 | |||

| 13.2 McClean Lake processing metallurgical test work |

73 | |||

| 14 MINERAL RESOURCE ESTIMATES |

76 | |||

ii

| 14.1 Definitions |

76 | |||

| 14.2 Key assumptions, parameters and methods |

76 | |||

| 14.3 Geological modelling |

79 | |||

| 14.4 Compositing |

81 | |||

| 14.5 Block modelling |

85 | |||

| 14.6 Validation |

86 | |||

| 14.7 Mineral resource classification |

87 | |||

| 14.8 Factors that could materially affect the mineral resource estimate |

89 | |||

| 15 MINERAL RESERVE ESTIMATES |

91 | |||

| 15.1 Definitions |

91 | |||

| 15.2 Key assumptions, parameters and methods |

91 | |||

| 15.3 Mineral reserves estimation and classification |

95 | |||

| 15.4 Factors that could materially affect the mineral reserves estimate |

96 | |||

| 16 MINING METHODS |

98 | |||

| 16.1 Design parameters |

98 | |||

| 16.2 Mine design |

105 | |||

| 16.3 Mine production |

117 | |||

| 17 RECOVERY METHODS |

123 | |||

| 17.1 Overview |

123 | |||

| 17.2 Cigar Lake flowsheet |

123 | |||

| 17.3 Processing at McClean Lake |

124 | |||

| 17.4 McClean Lake mill flowsheet |

124 | |||

| 18 PROJECT INFRASTRUCTURE |

126 | |||

| 18.1 Cigar Lake infrastructure |

126 | |||

| 18.2 McClean Lake infrastructure |

126 | |||

| 19 MARKET STUDIES AND CONTRACTS |

128 | |||

| 19.1 Markets |

128 | |||

| 19.2 Material contracts for property development |

129 | |||

| 19.3 Uranium price assumptions used for economic analysis |

130 | |||

| 20 ENVIRONMENTAL STUDIES, PERMITTING AND SOCIAL OR COMMUNITY IMPACT |

133 | |||

| 20.1 Regulatory framework |

133 | |||

| 20.2 Licences and permits |

133 | |||

| 20.3 Environmental assessment |

134 | |||

iii

| 20.4 Environmental aspects |

135 | |||

| 20.5 Decommissioning and reclamation |

137 | |||

| 20.6 Known environmental liabilities |

138 | |||

| 20.7 Social and community factors |

139 | |||

| 21 CAPITAL AND OPERATING COSTS |

141 | |||

| 21.1 Capital and other costs |

141 | |||

| 21.2 Operating cost estimates |

143 | |||

| 22 ECONOMIC ANALYSIS |

145 | |||

| 22.1 Economic analysis |

145 | |||

| 22.2 Sensitivities |

147 | |||

| 22.3 Payback |

147 | |||

| 22.4 Mine life |

147 | |||

| 22.5 Taxes |

148 | |||

| 22.6 Royalties |

148 | |||

| 23 ADJACENT PROPERTIES |

149 | |||

| 24 OTHER RELEVANT DATA AND INFORMATION |

150 | |||

| 24.1 Cigar Lake water inflow incidents |

150 | |||

| 24.2 Mining and milling risks |

150 | |||

| 24.3 Caution about forward-looking information |

153 | |||

| 25 INTERPRETATION AND CONCLUSIONS |

155 | |||

| 26 RECOMMENDATIONS |

157 | |||

| 27 REFERENCES |

158 | |||

| 28 DATE AND SIGNATURE PAGE |

161 | |||

iv

Tables

| TABLE 1-1: CIGAR LAKE MINERAL RESOURCES – DECEMBER 31, 2023 |

5 | |||

| TABLE 1-2: CIGAR LAKE MINERAL RESERVES – DECEMBER 31, 2023 |

6 | |||

| TABLE 3-1: RELIANCE ON OTHER EXPERTS |

19 | |||

| TABLE 4-1: CIGAR LAKE OPERATION - MINERAL CLAIMS STATUS |

24 | |||

| TABLE 6-1: CIGAR LAKE HISTORICAL PRODUCTION (100% BASIS) |

38 | |||

| TABLE 9-1: SUMMARY OF EXPLORATION OUTSIDE OF ML 5521 |

52 | |||

| TABLE 13-1: McCLEAN LAKE OVERALL MILL RECOVERY (2014 TO 2023) |

75 | |||

| TABLE 14-1: GENERAL SUMMARY OF CL MAIN SEARCH PARAMETERS FOR ORDINARY KRIGING MODEL (U3O8 and DENSITY) |

85 | |||

| TABLE 14-2: GENERAL SUMMARY OF CLEXT SEARCH PARAMETERS |

86 | |||

| TABLE 14-3: RECONCILIATION OF PRODUCTION AND MODEL |

87 | |||

| TABLE 14-4: CIGAR LAKE MINERAL RESOURCES – DECEMBER 31, 2023 |

89 | |||

| TABLE 15-1: CIGAR LAKE MINERAL RESERVES – DECEMBER 31, 2023 |

95 | |||

| TABLE 16-1: UNDERGROUND MINING EQUIPMENT |

115 | |||

| TABLE 16-2: CAVITY DILUTION FACTORS |

119 | |||

| TABLE 16-3: CIGAR LAKE 2024 – 2036 PLANNED PRODUCTION SCHEDULE SUMMARY |

121 | |||

| TABLE 19-1: EXPECTED AVERAGE REALIZED URANIUM PRICES BY YEAR |

132 | |||

| TABLE 21-1: CLJV CAPITAL AND OTHER COSTS FORECAST BY YEAR |

142 | |||

| TABLE 21-2: CLJV OPERATING COST FORECAST BY YEAR |

144 | |||

| TABLE 22-1: CLJV ECONOMIC ANALYSIS – CAMECO’S SHARE |

146 |

v

Figures

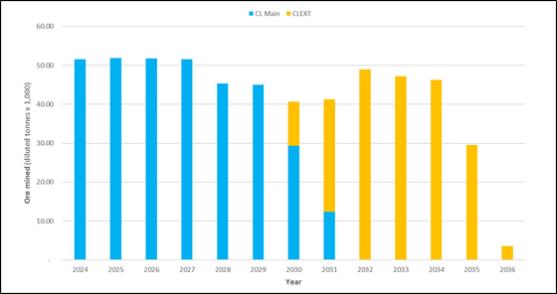

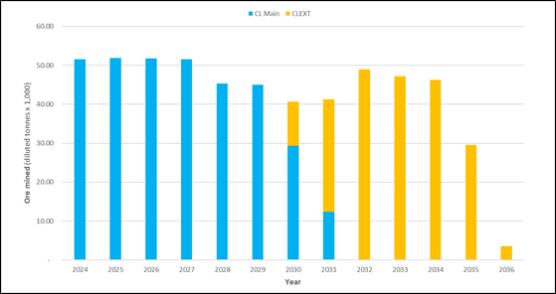

| FIGURE 1-1: MINE PRODUCTION |

13 | |||

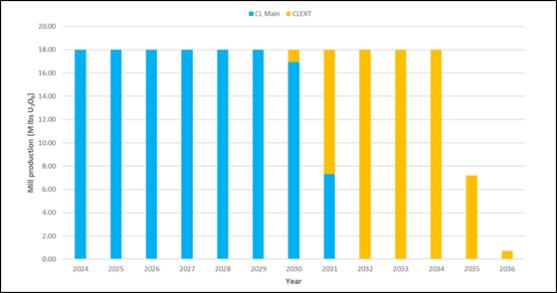

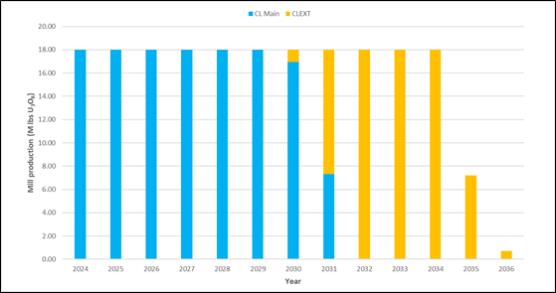

| FIGURE 1-2: MILL PRODUCTION |

13 | |||

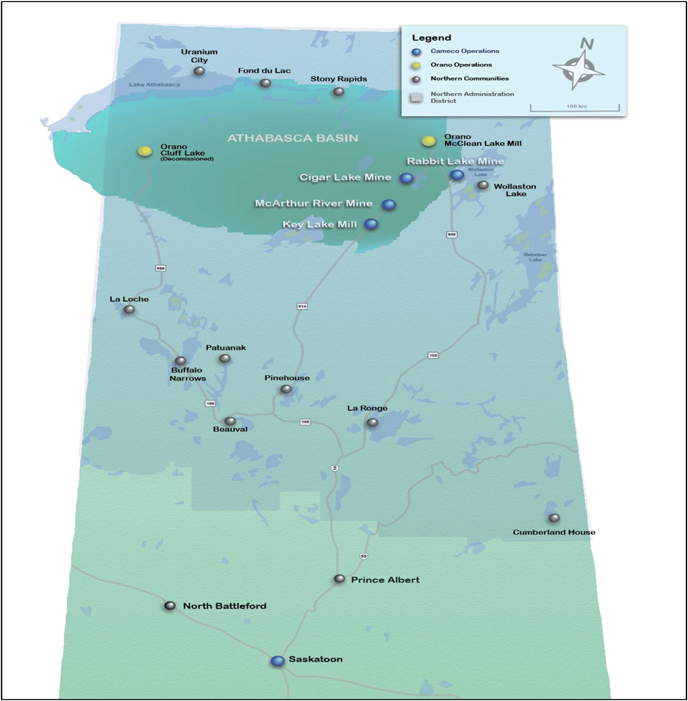

| FIGURE 4-1: CIGAR LAKE MINERAL PROPERTY LOCATION |

21 | |||

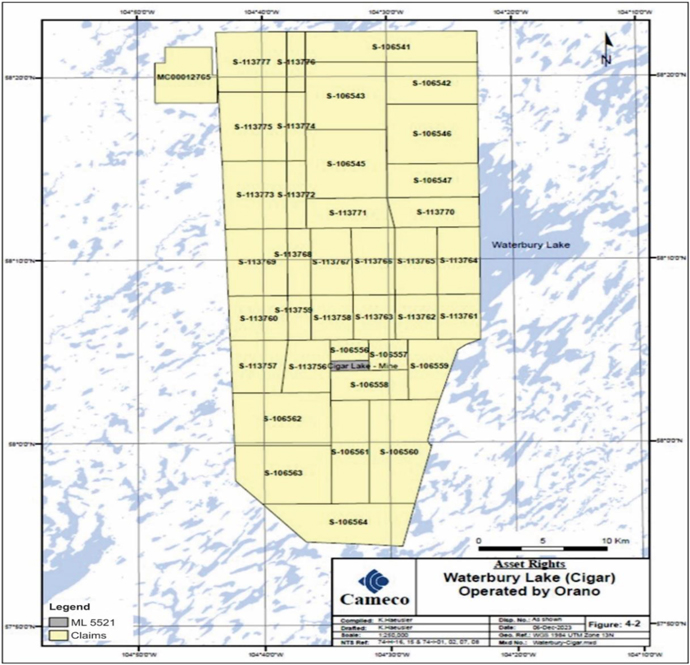

| FIGURE 4-2: MINERAL LEASE AND MINERAL CLAIMS |

23 | |||

| FIGURE 4-3: SURFACE LEASE, MINERAL LEASE AND MINERAL CLAIMS |

25 | |||

| FIGURE 4-4: MAP OF MINE FACILITIES AND SURFACE LEASE BOUNDARY |

27 | |||

| FIGURE 5-1: CIGAR LAKE SITE - REGIONAL LOCATION AND ROADS |

30 | |||

| FIGURE 5-2: SITE PLAN OF EXISTING AND PLANNED SURFACE FACILITIES |

34 | |||

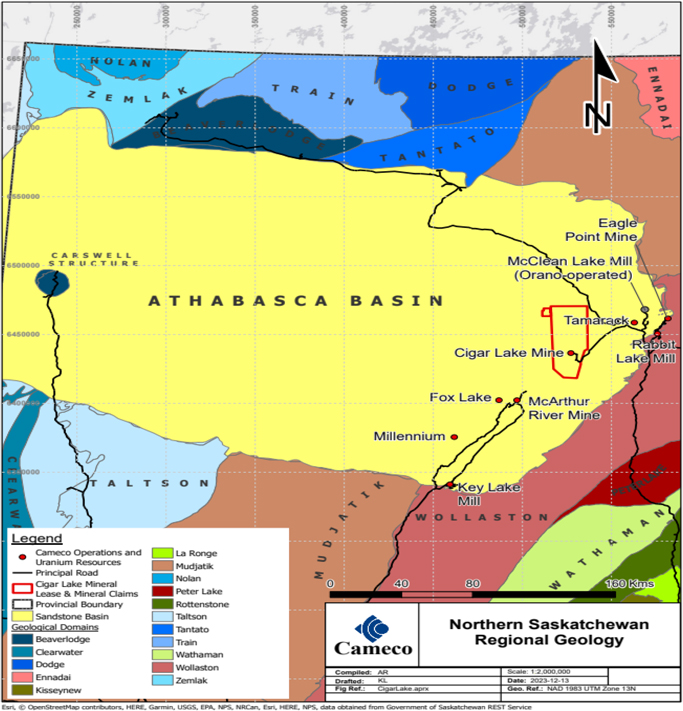

| FIGURE 7-1: GEOLOGICAL MAP OF NORTHERN SASKATCHEWAN |

40 | |||

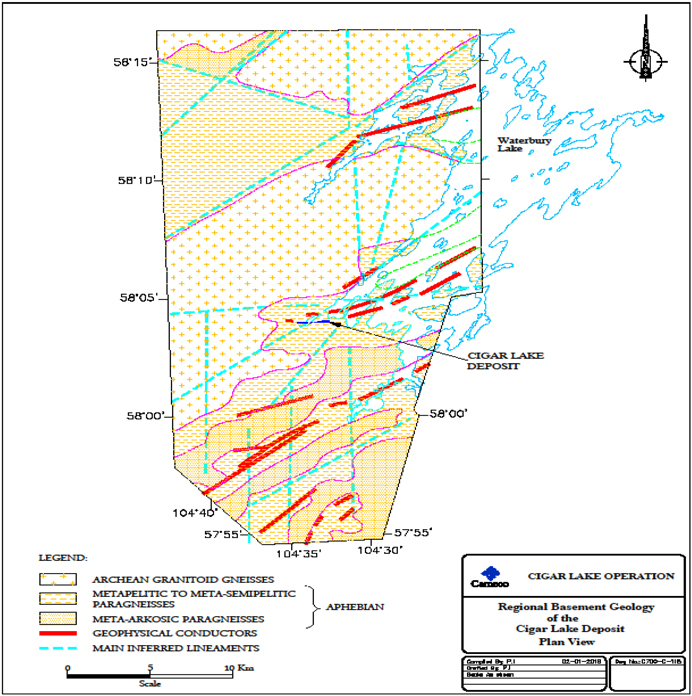

| FIGURE 7-2: CIGAR LAKE - REGIONAL BASEMENT GEOLOGY |

42 | |||

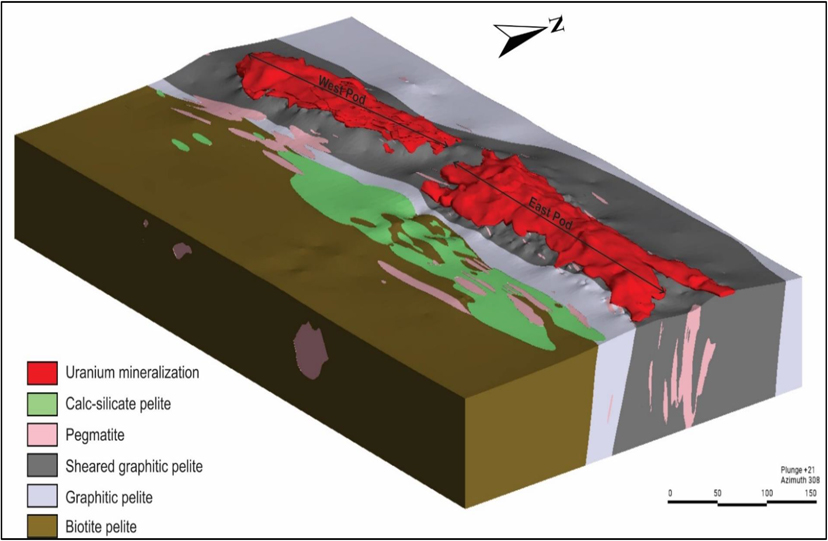

| FIGURE 7-3: BASEMENT GEOLOGY OF THE CL MAIN AREA RELATIVE TO MINERALIZATION |

44 | |||

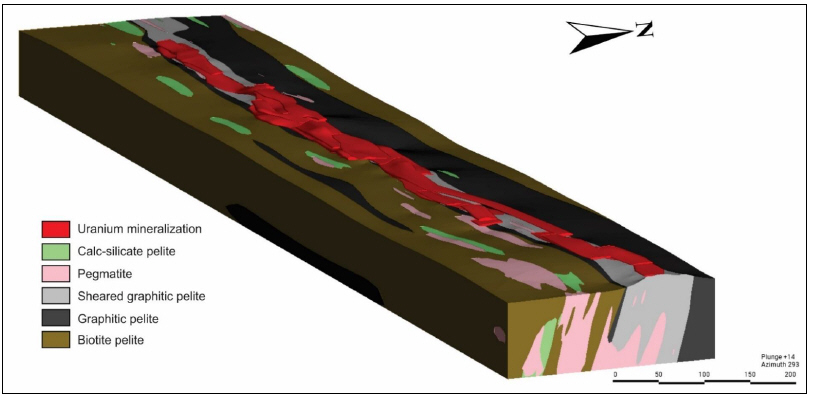

| FIGURE 7-4: BASEMENT GEOLOGY OF THE CLEXT AREA RELATIVE TO MINERALIZATION |

45 | |||

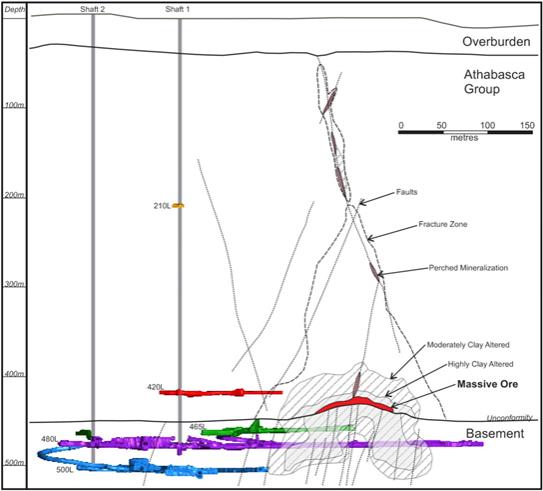

| FIGURE 7-5: CL MAIN DEPOSIT - SCHEMATIC CROSS SECTION LOOKING WEST |

46 | |||

| FIGURE 9-1: EXPLORATION WORK AREAS OUTSIDE OF ML 5521 |

51 | |||

| FIGURE 10-1: CIGAR LAKE DEPOSIT - SURFACE EXPLORATION AND DELINEATION DRILLHOLE LOCATIONS |

57 | |||

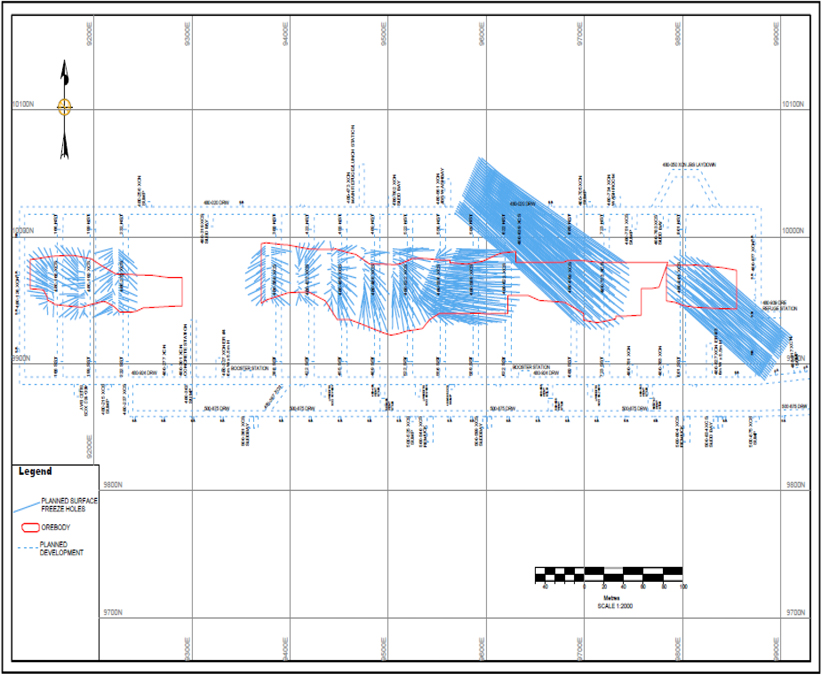

| FIGURE 10-2: CIGAR LAKE DEPOSIT - SURFACE FREEZE HOLE LOCATIONS (CL MAIN) |

58 | |||

| FIGURE 10-3: CL MAIN GEOLOGICAL CROSS SECTION AT 10781E – LOOKING WEST (±3 m) |

59 | |||

| FIGURE 10-4: UNDERGROUND GEOTECHNICAL DIAMOND DRILLHOLE LOCATION MAP - CL MAIN |

61 | |||

| FIGURE 11-1: GT COMPARISON OF eU3O8 CORRELATION AGAINST CHEMICAL ASSAY |

66 | |||

| FIGURE 11-2: CIGAR LAKE STANDARDS (CL MAIN AND CLEXT): BL4A, BL2A, CL-1, BL5, CL-2, CL-3, CL-4, AND CL-5 |

68 | |||

| FIGURE 11-3: CIGAR LAKE (CL MAIN AND CLEXT) PULP DUPLICATE AR-ICP RESULTS |

70 | |||

| FIGURE 14-1: MINERAL RESOURCE AND RESERVE ESTIMATES - DECEMBER 31, 2023 |

78 | |||

| FIGURE 14-2: ISOMETRIC VIEW OF CL MAIN MINERALIZED PODS AND LENSES |

79 | |||

| FIGURE 14-3: CL MAIN INTERNAL HIGH-GRADE DOMAINS |

80 | |||

| FIGURE 14-4: SECTION 10749E (±1 m) SHOWING HIGH-GRADE DOMAIN (MAGENTA) WITHIN EAST POD (GREEN) RELATIVE TO DRILL COMPOSITE GRADES – LOOKING WEST |

80 | |||

| FIGURE 14-5: ISOMETRIC VIEW OF CLEXT MINERALIZED LENSES |

81 | |||

| FIGURE 14-6: SECTION 9170E (±8 m) SHOWING LENSES AND DRILL COMPOSITES - LOOKING WEST |

81 | |||

| FIGURE 14-7: HISTOGRAM AND SUMMARY STATISTICS OF ALL CL MAIN %U3O8 AND DENSITY COMPOSITES |

83 |

vi

| FIGURE 14-8: HISTOGRAM AND SUMMARY STATISTICS OF ALL CLEXT %U3O8 AND DENSITY COMPOSITES |

84 | |||

| FIGURE 14-9: CL MAIN MINERAL RESOURCE CLASSIFICATION INCLUDING MINERALIZED POTENTIAL |

88 | |||

| FIGURE 14-10: CLEXT MINERAL RESOURCE CLASSIFICATION INCLUDING MINERALIZED POTENTIAL |

88 | |||

| FIGURE 15-1: CL MAIN MINERAL RESERVES - ESTIMATED JBS CAVITY GRADE DISTRIBUTION – PLAN VIEW |

93 | |||

| FIGURE 15-2: CLEXT MINERAL RESERVES - ESTIMATED JBS CAVITY GRADE DISTRIBUTION – PLAN VIEW |

94 | |||

| FIGURE 16-1: GEOTECHNICAL DOMAINS OF THE 480L OF CL MAIN WITH INTERPRETED FAULT ZONES |

100 | |||

| FIGURE 16-2: GEOTECHNICAL DOMAINS OF THE 480L OF CLEXT WITH INTERPRETED FAULT ZONES |

101 | |||

| FIGURE 16-3: CL MAIN GEOTECHNICAL SCHEMATIC CROSS SECTION AT 10783E – LOOKING WEST |

102 | |||

| FIGURE 16-4: CLEXT GEOTECHNICAL SCHEMATIC CROSS SECTION AT 9580E – LOOKING WEST |

103 | |||

| FIGURE 16-5: THREE-DIMENSIONAL GENERAL MINE LAYOUT OF CL MAIN AND CLEXT – LOOKING NORTHWEST |

106 | |||

| FIGURE 16-6: CL MAIN FREEZE HOLE LAYOUT |

112 | |||

| FIGURE 16-7: CLEXT FREEZE HOLE LAYOUT |

113 | |||

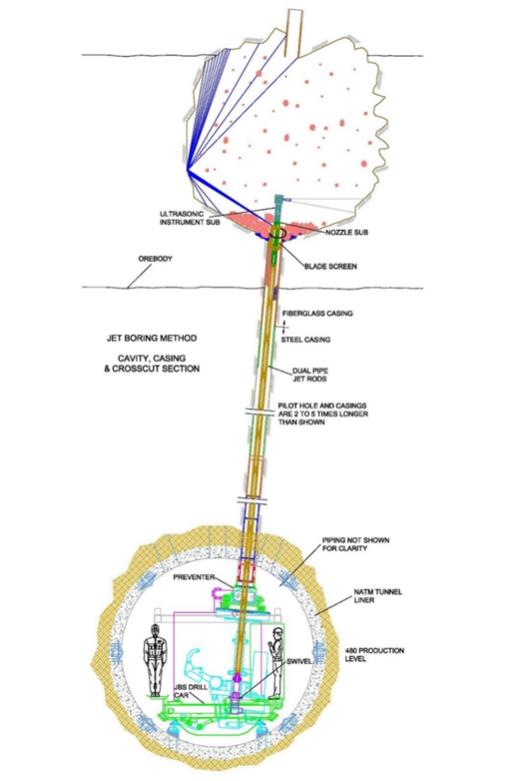

| FIGURE 16-8: SCHEMATIC VERTICAL SECTION OF THE JBS MINING METHOD |

118 | |||

| FIGURE 16-9: MINE PRODUCTION |

122 | |||

| FIGURE 16-10: MILL PRODUCTION |

122 | |||

| FIGURE 17-1: CIGAR LAKE ORE PROCESSING ACTIVITIES – BLOCK DIAGRAM |

124 | |||

| FIGURE 22-1: CIGAR LAKE OPERATION SENSITIVITY ANALYSIS |

147 |

vii

Units of measure and abbreviations

| 3D | three-dimensional | |

| % | percent | |

| ° | degrees | |

| °C | degrees Celsius | |

| CCD | counter current decantation | |

| CLJV | Cigar Lake Joint Venture | |

| eU3O8 | equivalent uranium oxide | |

| g | grams | |

| h | hour(s) | |

| ha | hectares (10,000 square metres) | |

| hp | horsepower | |

| Hwy | highway | |

| IRR | internal rate of return | |

| JBS | jet boring system | |

| km | kilometres | |

| km2 | square kilometres | |

| kV | kilovolts | |

| kW | kilowatts | |

| L | litre | |

| lbs | pounds | |

| M | million | |

| m | metres | |

| m3 | cubic metres | |

| m3/h | cubic metres per hour | |

| m3/s | cubic metres per second | |

| MASL | metres above sea level (elevation) | |

| MLJV | McClean Lake Joint Venture | |

| mm | millimetres | |

| MW | megawatts | |

| NPV | net present value | |

| SX | solvent extraction | |

| t | tonnes (metric) | |

| U | uranium | |

| % U | percent uranium (% U x 1.179 = % U3O8) | |

| U3O8 | uranium oxide (yellowcake) | |

| % U3O8 | percent uranium oxide (% U3O8 x 0.848 = % U) | |

| $Cdn | Canadian dollars | |

| $US | US dollars | |

| $/t | Canadian dollars per tonne | |

| US$/lb | US dollars per pound | |

| > | greater than | |

| < | less than | |

viii

| 1 | Summary |

| 1.1 | Preamble |

This technical report replaces the previous Cigar Lake Operation technical report, filed in March of 2016 (2016 Technical Report). This report is based on new technical and scientific information, and reflects experience gained since 2016.

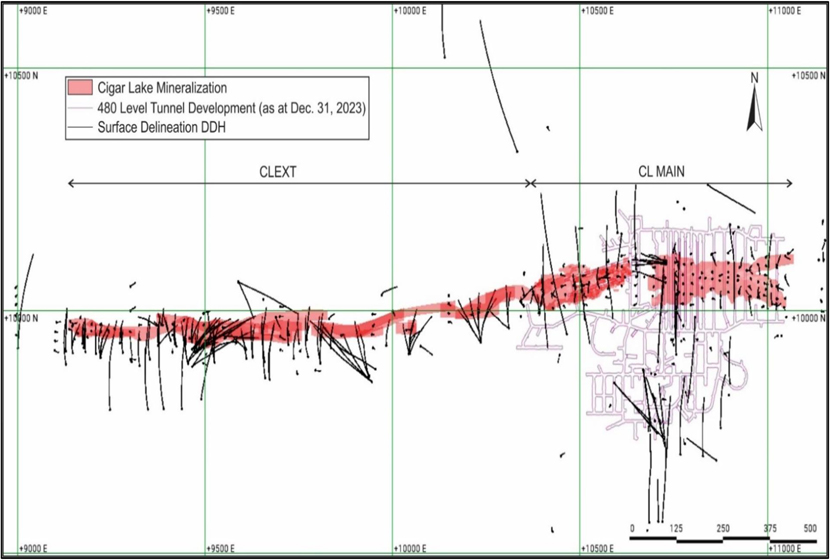

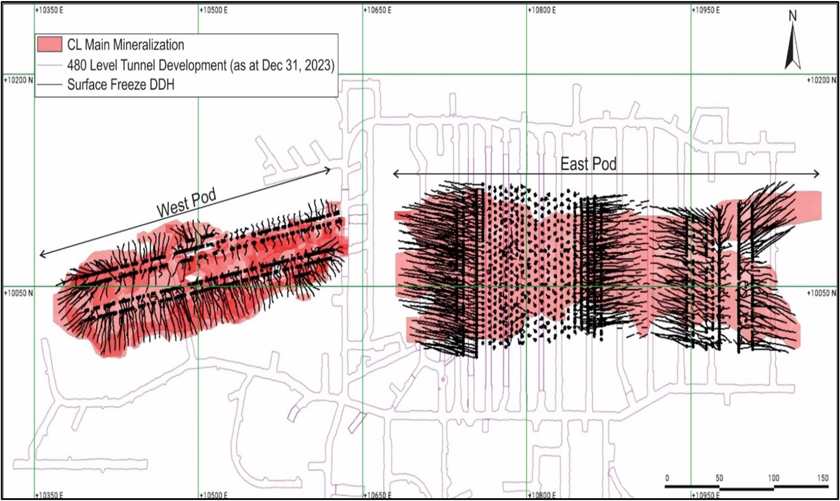

The Cigar Lake deposit has historically been divided into two parts. The eastern portion, previously referred to as Phase 1, is now referred to as the Cigar Lake Main (CL Main) portion of the deposit, whereas the western portion, previously referred to as Phase 2, is now referred to as the Cigar Lake Extension (CLEXT).

Key highlights of this report include:

| • | extension of the mine life to 2036 subject to receipt of all regulatory approvals |

| • | an increase in Cameco’s ownership interest in the Cigar Lake Joint Venture (CLJV) to 54.547% with the 2023 acquisition of a 4.522% interest from Idemitsu Canada Resources Ltd. |

| • | estimated pre-tax net present value (NPV) at an 8% discount rate to Cameco of $2.5 billion for its share of current mineral reserves |

| • | estimated pre-tax internal rate of return (IRR) of 8.3%, using Cameco’s share of the total capital invested to date, along with the operating and capital cost estimates for the remainder of the mineral reserves |

| • | on an undiscounted pre-tax basis, payback for Cameco, including total capital invested to date, is expected to be achieved in 2024 |

| • | increase in estimated average cash operating costs per pound—from $18.75 to $20.58 |

| • | total estimated Cigar Lake mine capital and McClean Lake mill capital to bring the remaining mineral reserves (CL Main and CLEXT) into production is approximately $1.2 billion (Cameco’s share – $680 million) |

| • | mine development and capital expenditures for CLEXT are expected to be approximately $895 million (Cameco’s share – $487 million), including approximately $520 million (Cameco’s share – $284 million) required in advance of first ore from CLEXT in 2030 |

| • | conversion of 73.4 million pounds of CLEXT mineral resources into mineral reserves based on information from 235 holes totaling approximately 99,000 metres of diamond drilling |

| • | expected total packaged production of 205.9 million pounds U3O8, based on remaining mineral reserves and an overall milling recovery of 98.7% |

| • | a plan to develop and mine CLEXT utilizing the same methods and approach as used for CL Main, including utilizing existing infrastructure for mine access, ventilation, dewatering, processing and jet bore mining support activities |

| • | completion of modifications to the McClean Lake mill to increase capacity in the front-end circuits (leaching, CCD) from a nominal 45 kt ore/year to 59 kt ore/year plus regulatory approval for the continued expansion of the tailings management facility (TMF) at Orano’s McClean Lake mill to allow processing of all Cigar Lake’s current mineral reserves |

| 1.2 | Introduction |

PROFILE

Located in northern Saskatchewan’s Athabasca Basin, Cigar Lake is the world’s highest grade uranium mine.

2024 CIGAR LAKE TECHNICAL REPORT 1

Cigar Lake is owned by the CLJV participants:

| • | Cameco Corporation (Cameco) (54.547%) |

| • | Orano Canada Inc. (40.453%) |

| • | TEPCO Resources Inc. (TEPCO) (5.000%) |

Cameco has been the operator of Cigar Lake since January 2002.

BACKGROUND

In December 2004, the CLJV decided to proceed with development of the Cigar Lake mine and received a construction licence from the Canadian Nuclear Safety Commission (CNSC) that same month. Construction began in January 2005, but development was delayed due to water inflows in April and October 2006, and an additional water inflow in August 2008.

In October 2009, Cameco successfully sealed the August 2008 inflow, and the underground workings were dewatered in February 2010. Safe access to the 480-metre (480L) and 500-metre (500L) levels was restored and the restoration of underground mine systems and infrastructure was completed in 2011.

With the mine re-entry and remediation milestone attained, construction of the permanent underground infrastructure began and was substantially complete in 2013. Staged commissioning of the JBS machine and supporting underground circuits began shortly thereafter, with the first commissioning cavity mined in barren rock in October 2013, and first ore cavity mined in December 2013.

The first shipment of ore slurry to McClean Lake occurred in March 2014, and the first yellowcake was packaged in October 2014. With the completion of commissioning of all circuits attained and sustainable, and acceptable performance demonstrated, commercial production was declared in May 2015. Since that time, mine operation has achieved full nameplate capacity.

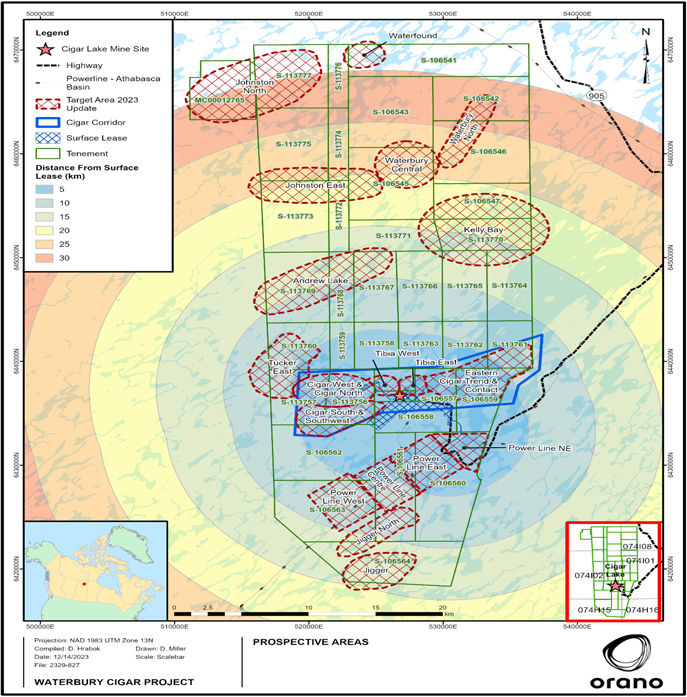

| 1.3 | Property tenure |

The mineral property consists of one mineral lease (ML 5521) and 38 mineral claims totaling 95,601 hectares. The mineral lease and mineral claims are contiguous.

The Cigar Lake deposit is located in the area subject to the mineral lease, totaling 308 hectares. The right to mine this uranium deposit was acquired under this mineral lease. The current mineral lease expires November 30, 2031, with the right to renew for successive 10-year terms, absent a default by the CLJV.

A mineral claim grants the holder the right to explore for minerals within the claim lands and to apply for a mineral lease.

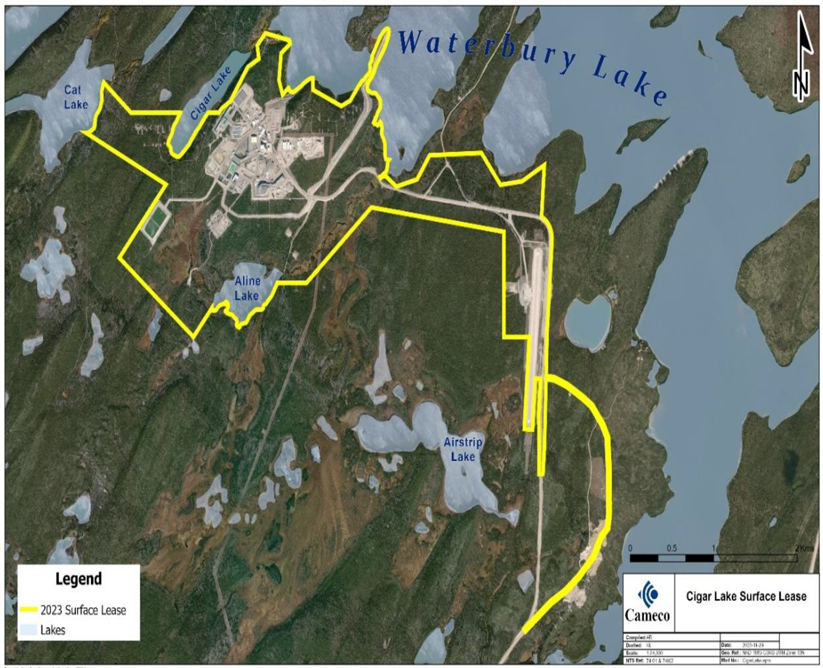

The surface facilities and mine shafts for the Cigar Lake operation are located on lands owned by the Province of Saskatchewan. The CLJV acquired the right to use and occupy the lands under a surface lease agreement with the Province. The term of the surface lease expires May 31, 2044. The Cigar Lake surface lease covers a total area of 715 hectares of Crown land.

See Section 4.2 and 4.3 for further detail.

| 1.4 | Location and site description |

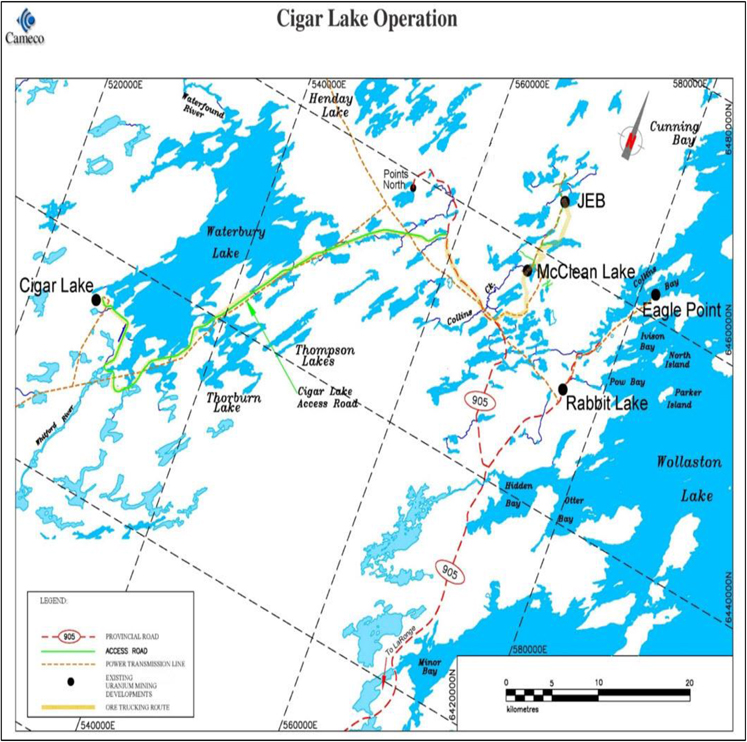

The Cigar Lake mine site is located near Waterbury Lake, approximately 660 kilometres north of Saskatoon. The McClean Lake mill is located 69 kilometres northeast of the mine site by road.

The property is accessible by an all-weather road and by air. Site activities occur year-round, including supply deliveries.

2024 CIGAR LAKE TECHNICAL REPORT 2

The topography and the environment are typical of the taiga forested lands common to the Athabasca Basin area of northern Saskatchewan. The area is covered with 30 to 50 metres of overburden. The surface facilities are at an elevation of approximately 490 metres above sea level.

The site is connected to the provincial electricity grid with a 138-kilovolt overhead power line. There are standby generators in case of grid power interruption.

Personnel are recruited on a preferential basis from northern Saskatchewan. Development and construction work is tendered to a number of contractors.

More information is available in Section 4.

| 1.5 | Geology and mineralization |

The Cigar Lake deposit is located approximately 40 kilometres west of the eastern margin of the Athabasca Basin. It is an unconformity related uranium deposit occurring at the unconformity contact between rock of the Athabasca Group and underlying lower Proterozoic Wollaston Group metasedimentary gneiss and plutonic rocks. In this way, it is similar to the Key Lake, McClean Lake, Collins Bay and McArthur River deposits. As a result, Cigar Lake shares many geological similarities with these deposits, including general structural setting, mineralogy, geochemistry, host rock association and the age of the mineralization. However, the Cigar Lake deposit is distinguished from other similar deposits by its size, high grade, the intensity of its alteration process, and the high degree of associated hydrothermal clay alteration.

The Cigar Lake deposit is similar to the McArthur River deposit in that sandstone overlies the basement rock and contains large volumes of water at significant pressure, but unlike McArthur River, this deposit is flat-lying.

The Cigar Lake deposit is approximately 1,950 metres long, 20 to 100 metres wide, and ranges up to 13.5 metres thick, with an average thickness of about 5.4 metres. It occurs at depths ranging between 410 and 450 metres below surface.

Two distinct styles of mineralization occur within the Cigar Lake deposit:

| • | high-grade mineralization at or proximal to the unconformity (“unconformity” mineralization), which includes almost all of the mineral resources and mineral reserves |

| • | low-grade, fracture controlled, vein-like mineralization which is located either higher up in the sandstone (“perched” mineralization) or in the basement rock mass |

The high-grade mineralization located in proximity to the unconformity contains the bulk of the total uranium metal in the deposit and currently represents the only economically viable style of mineralization, in the context of the selected mining method and ground conditions. It is characterized by the occurrence of massive clays and very high-grade uranium concentrations.

The unconformity mineralization consists primarily of three dominant rock and mineral facies occurring in varying proportions: quartz, clay (primarily chlorite with lesser illite) and metallic minerals (oxides, arsenides, sulphides). In the relatively higher grade eastern CL Main zone, the ore consists of approximately 50% clay matrix, 20% quartz and 30% metallic minerals, visually estimated by volume. In this area, the unconformity mineralization is overlain by a weakly mineralized contiguous clay cap 1 to 10 metres thick. In the western CLEXT zone, the proportions change to approximately 20% clay, 60% quartz and 20% metallic minerals.

See Section 7 for further detail.

2024 CIGAR LAKE TECHNICAL REPORT 3

| 1.6 | Exploration of Cigar Lake deposit |

The Cigar Lake uranium deposit was discovered in 1981 on lands now covered by ML 5521. The discovery was a result of initial airborne and ground geophysical surveys followed by a regional program of diamond drill testing.

The deposit was subsequently delineated by surface diamond drilling during the period 1982 to 1986 and was followed by several small campaigns of geotechnical and infill drilling to the end of 2007. Additional drilling campaigns were conducted by Cameco after 2007 which targeted a broad range of technical objectives, including geotechnical, geophysical, delineation and ground freezing.

Since 2012, diamond drilling managed by Cameco has mainly focused on underground geotechnical and surface ground freezing programs on CL Main along with continued delineation drilling on CLEXT.

The CL Main zone was discovered in 1983. Drilling was initially done at a nominal drillhole grid spacing of 50 metres east-west by 20 metres north-south. A surface drill program was conducted from 2010 to 2012 to tighten up the spacing in areas with gaps in coverage. Similarly, a small program of six holes was completed on mineralized zones situated between East Pod and West Pod in 2023. Apart from this area, CL Main has been fully delineated by surface freeze holes on a nominal 7 x 7 metre pattern.

The CLEXT zone had been outlined through several exploration drilling campaigns conducted between 1981 and 2012. Since 2016, Cameco has completed additional surface delineation drilling to confirm and upgrade the mineral resources contained in CLEXT and to collect metallurgical, hydrogeological and geotechnical information used to support the prefeasibility study for CLEXT. Drillholes are variably spaced 12 to 25 metres apart in the western portion and 20 to 50 metres in its eastern portion.

Diamond core drilling from underground locations has been done primarily to ascertain rock mass characteristics in advance of development and mining. Underground geotechnical drilling has occurred since 1989.

More information on exploration and drilling can be found in Sections 9 and 10.

| 1.7 | Mineral resources and mineral reserves |

The known mineralization at Cigar Lake is divided into two zones, the western CLEXT zone and the eastern CL Main zone. The CL Main mineral resource and mineral reserve estimates are based on 1,284 mineralized surface drillholes while the CLEXT mineral resource estimate is based on 135 mineralized surface drillholes. The vast majority of drillholes were drilled perpendicular to the mineralization and their intercepts approximate the true thickness of the mineralization.

The Cigar Lake mineral resources, exclusive of mineral reserves, with an effective date of December 31, 2023, are presented in Table 1-1. Al Renaud, P. Geo. with Cameco, is the qualified person within the meaning of National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101) for the purpose of the mineral resource estimates.

The Cigar Lake mineral reserves estimates, with an effective date of December 31, 2023, are shown in Table 1-2. B. Bharadwaj, P. Eng., C. Scott Bishop, P. Eng., Al Renaud, P. Geo., and Lloyd Rowson, P. Eng., each with Cameco, are the qualified persons within the meaning of NI 43-101 for the purpose of the mineral reserve estimates.

2024 CIGAR LAKE TECHNICAL REPORT 4

TABLE 1-1: CIGAR LAKE MINERAL RESOURCES – DECEMBER 31, 2023

| Category |

Area |

Total tonnes (x 1,000) |

Grade % U3O8 |

Total M lbs U3O8 |

Cameco’s share M lbs U3O8 |

|||||||||||||

| Measured and Indicated |

||||||||||||||||||

| Measured |

CL Main | 86.3 | 5.32 | 10.1 | 5.5 | |||||||||||||

| Indicated |

CL Main | 30.6 | 6.61 | 4.5 | 2.4 | |||||||||||||

| Indicated |

CLEXT | 113.0 | 4.98 | 12.4 | 6.8 | |||||||||||||

| Total Measured and Indicated |

229.9 | 5.32 | 27.0 | 14.7 | ||||||||||||||

| Inferred |

||||||||||||||||||

| Inferred |

CL Main | 6.2 | 4.41 | 0.6 | 0.3 | |||||||||||||

| Inferred |

CLEXT | 157.1 | 5.60 | 19.4 | 10.6 | |||||||||||||

| Total Inferred |

163.4 | 5.55 | 20.0 | 10.9 | ||||||||||||||

| Notes: |

(1) | Cameco reports mineral reserves and mineral resources separately. Reported mineral resources do not include amounts identified as mineral reserves. Totals may not add up due to rounding. |

| (2) | Mineral resources that are not mineral reserves do not have demonstrated economic viability. |

| (3) | Cameco’s share is 54.547% of total mineral resources. |

| (4) | Inferred mineral resources are estimated using limited geological evidence and sampling information. We do not have enough confidence to evaluate their economic viability in a meaningful way. You should not assume that all or any part of an inferred mineral resource will be upgraded to an indicated or measured mineral resource, but it is reasonably expected that the majority of inferred mineral resources could be upgraded to indicated mineral resources with continued exploration. |

| (5) | Reasonable expectation for eventual economic extraction of the mineral resources is based on a constant dollar average uranium price of $62.00 (US) per pound U3O8 with a $1.00 US = $1.26 Cdn fixed exchange rate, mining and process recoveries, production costs, royalties and mineralized area tonnage, grade, and spatial continuity considerations. |

| (6) | Mineral resources have been estimated with a minimum mineralization thickness of one metre and a cut-off grade of 1.0% U3O8 for CL Main and 0.8% U3O8 for CLEXT based on the use of the JBS method combined with bulk freezing of the orebody. |

| (7) | The mineralized lenses have been interpreted from drillhole information on vertical cross-sections or with 3D implicit modelling and validated on plan views and in 3D. |

| (8) | Mineral resources have been estimated with no allowance for mining dilution and mining recovery. |

| (9) | Mineral resources were estimated using 3D block models. |

| (10) | There are no known environmental, permitting, legal, title, taxation, socio-economic, political, marketing or other relevant factors that could materially affect the above estimate of mineral resources. |

2024 CIGAR LAKE TECHNICAL REPORT 5

TABLE 1-2: CIGAR LAKE MINERAL RESERVES – DECEMBER 31, 2023

| Category |

Area |

Total tonnes (x 1,000) |

Grade % U3O8 |

Total M lbs U3O8 |

Cameco’s share M lbs U3O8 |

|||||||||||||

| Proven |

Broken CL Main |

|

1.1 337.0 |

|

|

27.55 18.07 |

|

|

0.7 134.3 |

|

|

0.4 73.3 |

|

|||||

| Total proven |

338.1 | 18.11 | 135.0 | 73.6 | ||||||||||||||

| Probable |

CL Main CLEXT |

|

1.7 215.8 |

|

|

7.17 15.42 |

|

|

0.3 73.4 |

|

|

0.1 40.0 |

|

|||||

| Total probable |

217.5 | 15.36 | 73.7 | 40.2 | ||||||||||||||

| Total mineral reserves |

555.6 | 17.03 | 208.6 | 113.8 | ||||||||||||||

| Notes: |

(1) | Cameco reports mineral reserves and mineral resources separately. Totals may not add up due to rounding. |

| (2) | Total pounds U3O8 are those contained in mineral reserves and are not adjusted for the estimated mill recovery of 98.8% for CL Main and 98.5% for CLEXT. |

| (3) | Cameco’s share is 54.547% of total mineral reserves. |

| (4) | Mineral reserves have been estimated on the basis of designed JBS cavities having greater revenue than the cost to mine and process. |

| (5) | Mineral reserves have been estimated with an average allowance of 34% dilution at 0% U3O8, inclusive of dilution material above and below the planned cavity and include dilution from the JBS pilot hole and from adjacent backfill. |

| (6) | Mineral reserves have been estimated based on 86% mining recovery. |

| (7) | Mineral reserves were estimated based on the use of the JBS mining method combined with bulk freezing of the orebody. Mining rate assumed to vary between 115 and 160 tonnes per day, and a full mill production rate of approximately 18 million pounds U3O8 per year. The reference point at which mineral reserves are defined is when the ore is delivered to the McClean Lake mill. |

| (8) | An average uranium price of $54.00 (US) per pound U3O8 with a $1.00 US = $1.26 Cdn fixed exchange rate was used to estimate the mineral reserves. |

| (9) | Broken ore is defined as ore that has been mined with the JBS but not yet processed at McClean Lake. This includes all in-circuit inventory at Cigar Lake plus the ore slurry stored in the ore storage pachucas at McClean Lake. |

| (10) | Other than the challenges related to water inflows, jet boring and geotechnical issues described in Section 15.4, there are no known mining, metallurgical, infrastructure, permitting, or other relevant factors that could materially affect the above estimate of mineral reserves. |

CHANGES TO MINERAL RESOURCE AND RESERVE ESTIMATES

The updated mineral resource and mineral reserve estimates (December 31, 2023) reflect changes from the 2022 year-end estimates that are mainly due to:

| • | addition of 98 surface freeze holes in portions of CL Main |

| • | addition of six delineation holes in the Central lenses |

| • | addition of 12 surface delineation holes in CLEXT |

| • | reinterpretation of the mineralized envelope of CL Main and CLEXT |

2024 CIGAR LAKE TECHNICAL REPORT 6

| • | an adjustment to the correlation to convert corrected probe count rates into equivalent %U3O8 applied to address a slight eU3O8 overestimation bias |

| • | reclassification of the mineral resources and mineral reserves based on drillhole spacing, geological and grade continuity, estimation confidence and reconciliation of mined production to the end of 2023 |

| • | updated operating cost estimates, metal price and exchange rate assumptions |

| • | conversion of 73.4 million pounds (100% basis) of CLEXT mineral resources into mineral reserves based on information from 235 holes totaling approximately 99,000 metres of diamond drilling, with a corresponding decrease in mineral resources |

| • | removal of the reserve estimates for the mined cavities contributing to the mill feed to December 31, 2023 |

More information on mineral reserves and mineral resources is available in Sections 14 and 15.

| 1.8 | Mining |

JET BORING MINING SYSTEM

The jet boring mining system, a non-entry mining method, has been selected to mine the Cigar Lake deposit because of the challenges associated with mining the deposit, including control of groundwater, weak rock formations, radiation protection, and relatively thin, flat-lying mineralization. This method was selected after many years of exploration and test mining activities following the discovery of the deposit in 1981.

The JBS mining method consists of cutting cavities out of frozen ore using a high-pressure water jet. Access to the orebody is achieved by drilling boreholes upwards from the production crosscuts below and then inserting specialized jetting tools to the ore horizon. Jetting begins at the top of a cavity and retreats vertically downward in thin slices, resulting in a cylindrical void with a height corresponding to the thickness of the orebody (up to 13.5 metres) and a diameter of 4.5 to 6 metres. The resulting void is tightly backfilled with concrete, and the cycle is repeated to recover adjacent ore.

This non-entry method was developed and adapted specifically for the Cigar Lake deposit, and does not directly expose personnel to the ore. The mining process is controlled from headings located in barren basement rock below the orebody, where the levels of radiation exposure to workers are very low. Radiation protection is further enhanced through the containment of the ore cuttings within cuttings collection and hydraulic conveyance systems, and via the application of ground freezing which limits the mobility of potentially radon-bearing water. These unique properties of the mining method have proven very effective at minimizing workers’ exposure to radiation.

The mine production fleet is currently comprised of three JBS units and supporting infrastructure and ancillary equipment. This fleet size is sufficient for the remainder of the mine life, including CLEXT.

MINE DEVELOPMENT

Mine development for construction and operation uses two basic approaches: for good quality, competent rock mass, drill and blast with conventional ground support is applied; for poor quality, weak rock mass, the New Austrian Tunnelling Method (NATM) is applied. Most permanent areas of the mine, which contain the majority of the installed equipment and infrastructure, are hosted in competent rock mass and are excavated and supported conventionally. The production tunnels immediately below the orebody are primarily in poor, weak rock mass and are excavated and supported following NATM principles.

2024 CIGAR LAKE TECHNICAL REPORT 7

NATM, as applied at Cigar Lake, involves a multi-stage sequential mechanical excavation, extensive external ground support and a specialized shotcrete liner. The liner system incorporates yielding elements which permit controlled deformation required to accommodate additive pressure from mining and ground freezing activities. The production tunnels have an inside diameter of five metres and are circular in profile.

Cameco plans its mine development to take place away from known groundwater sources whenever possible. In addition, Cameco assesses all planned mine development for relative risk and applies extensive additional technical and operating controls for all higher risk development.

MINE ACCESS

The main access to the mine is via Shaft No. 1, a circular concrete-lined shaft, 4.9 metres in diameter which extends to a depth of 500 metres below the surface and provides direct access to the working level on the 480L. Shaft No. 1 is used as the main access and services shaft, and as a route for delivery of fresh ventilation underground.

Shaft No. 2 is a circular lined shaft, 6.1 metres in diameter, also sunk to a depth of 500 metres. This shaft is located 90 metres south of Shaft No. 1 and provides access to 480L. It is divided into two compartments by a central airtight partition: one compartment serves as the main path for exhaust air from the mine; the second compartment is used to downcast additional fresh ventilation air, as well as provide secondary egress and a number of additional services. The primary ventilation system has been designed to supply a volume of up to 240 m3/s of fresh air to the mine.

MINE LEVELS – 480L AND 500L

There are two main levels in the mine: the 480L and the 500L. Both levels are located in the basement rocks below the unconformity. Mining is conducted from the 480L, which is located about 40 metres below the ore zone. The main underground processing and infrastructure facilities are also located on this level. The 500L is accessed via a ramp from the 480L. The main ventilation exhaust drift for the mine, the mine dewatering sump and additional processing facilities are located on 500L.

ARTIFICIAL GROUND FREEZING

Cameco bulk freezes the ore zone and surrounding ground prior to mining an area. This system freezes the deposit and underlying basement rock in two to four years, depending on water content and geological conditions.

Freezing is key to the success of mining the deposit, and results in several enhancements to mining conditions, including: (1) increasing the stability of the area being mined; (2) minimizing the risk of water inflows into the mine from the water-bearing rock above the unconformity; and (3) reducing the radiation resulting from radon dissolved in the water.

In 2015, the CLJV decided to pursue a strategy of freezing exclusively from surface. This strategy has resulted in the following benefits:

| • | reducing risk to mine development |

| • | allowing ground freezing to start before development of underground production tunnels |

| • | simplifying mining operations, since ground freezing infrastructure and activities are located on surface |

Artificial ground freezing for mining of CLEXT mineral reserves will follow a similar strategy of freezing exclusively from surface.

Artificial ground freezing is accomplished by drilling a systematic grid of boreholes through the orebody from surface. A network of supply and return pipes on surface convey a calcium chloride

2024 CIGAR LAKE TECHNICAL REPORT 8

brine to and from each hole. The warmed brine returning from each hole is chilled to a temperature of approximately -30ºC at the surface freeze plant and recirculated.

The Cigar Lake production schedule relies upon the ground being sufficiently frozen prior to the start of JBS mining.

WATER MANAGEMENT

A mine water handling strategy was developed which includes increasing the mine’s water-handling capabilities for routine and potential non-routine inflows above the existing capability previously assessed by Cameco in its 2004 environmental assessment. In addition to treating all routine water inflows (both seepage and process water) prior to releasing to the environment, water from any non-routine inflow will also be treated prior to releasing to the environment until such time as the inflow can be mitigated at the source.

As of early 2012, the installed mine dewatering capacity has been increased to 2,500 m3/h. Mine water treatment capacity has been increased to 2,550 m3/h, of which a minimum operational capacity of 1,740 m3/h is maintained at all times. Regulatory approval to discharge routine and non-routine treated water to Seru Bay is in place. See Sections 1.10, 16.2 and 20.4 for more details.

Cameco believes it has sufficient pumping, water treatment and surface storage capacity to handle the estimated maximum inflow.

The Cigar Lake orebody contains elements of concern with respect to water quality and the receiving environment. The distribution of elements such as arsenic, molybdenum, selenium and others is non-uniform throughout the orebody, and this could result in complications in attaining the effluent concentrations included in the licensing basis. Cameco continues to optimize the water treatment process to attain effluent quality consistent with the licensing basis.

Further information on mining at Cigar Lake is available in Section 16.

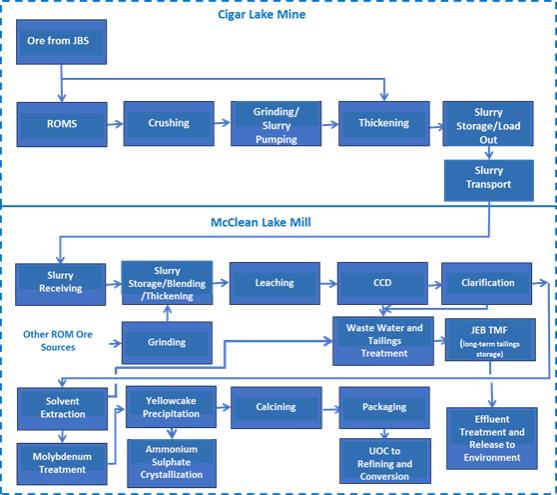

| 1.9 | Processing |

Cigar Lake ore is processed at two locations. Comminution is conducted underground at Cigar Lake, while leaching, purification and final yellowcake production and packaging occurs at the McClean Lake mill. The ore is trucked as a finely ground slurry from Cigar Lake to the McClean Lake mill in purpose-built containers identical to those used to transport McArthur River ore slurry to the Key Lake mill.

The McClean Lake mill is owned by the McClean Lake Joint Venture (MLJV) and operated by Orano Canada Inc. (Orano). The MLJV owners are:

| • | Orano (77.5%) |

| • | Denison Mines Inc. (22.5%) |

The milling arrangements are subject to the terms and conditions of a toll milling agreement made effective January 1, 2002 between the CLJV and the MLJV, and amended and restated effective November 30, 2011 (JEB Toll Milling Agreement).

In accordance with the JEB Toll Milling Agreement, the McClean Lake mill was expanded to process and package all of Cigar Lake’s mineral reserves. Originally, the mill had a production capacity of 12 million pounds U3O8 per year. In order to process all of Cigar Lake’s mineral reserves and other ores at McClean Lake, projects were identified to increase the total production capacity at the mill to 24 million pounds U3O8 per year. Construction of the expanded facility began in 2012 and was completed in 2016. Further changes were completed in 2021 to increase the capacity in the front-end circuits (leaching, CCD) from a nominal 45 kt ore/year to 59 kt ore/year.

2024 CIGAR LAKE TECHNICAL REPORT 9

No additional changes are required to the McClean Lake circuit to process the CLEXT mineral reserves.

During processing at McClean Lake mill, tailings are generated. The residue is treated in the upgraded McClean Lake mill tailings neutralisation circuit. Neutralised tailings are pumped to the existing TMF.

In 2022, Orano received regulatory approval for the continued expansion of the JEB TMF to allow the disposal of tailings up to a consolidated tailings elevation of 462 MASL, which is the approximate high point of the natural ground elevation. The expansion will be achieved by the continued construction of an engineered embankment and placement of the bentonite amended liner to an elevation of 468 MASL.

With these extensions, the JEB TMF will have the capacity to receive tailings from processing all of Cigar Lake’s current mineral reserves.

See Section 20.4 for a discussion of the TMF and the related licensing, and Section 19.2 for a discussion of the JEB Toll Milling Agreement. See Section 17 for information on processing at the McClean Lake mill.

| 1.10 | Environmental assessment and licensing |

The Cigar Lake operation has regulatory obligations to both the federal and provincial governments. Classified as a nuclear facility, primary regulatory authority resides with the federal government and its agency, the CNSC. The main regulatory agencies that issue permits / approvals and inspect the Cigar Lake operation are: the CNSC (federal), Fisheries and Oceans Canada (federal), Environment and Climate Change Canada (federal), Transport Canada (federal), Saskatchewan Ministry of Labour Relations and Workplace Safety (provincial), and Saskatchewan Ministry of Environment (provincial) (SMOE). Environment and Climate Change Canada, specifically, is responsible for administering the federal Metal and Diamond Mining Effluent Regulations (MDMER) and approves environmental effects monitoring programs required under the MDMER.

There are three key permits that are required to operate the mine. Federally, Cigar Lake holds a “Uranium Mine Licence” from the CNSC with a corresponding Licence Conditions Handbook (LCH). Provincially, Cigar Lake holds an “Approval to Operate Pollutant Control Facilities” from the SMOE and a “Water Rights Licence to Use Surface Water and Approval to Operate Works” from the Saskatchewan Water Security Agency (SWA). These documents are current.

The CNSC licence was issued for a ten-year term in June 2021, authorizing Cameco to mine, process and ship uranium ore to McClean Lake. Valid until June 30, 2031, this licence and associated LCH, authorizes an average annual production rate of 18 million pounds U3O8.

The SMOE Approval to Operate Pollutant Control Facilities was renewed in 2024 and expires on October 31, 2030. The SWA water rights licence was amended in 2023 and expires November 30, 2028. The SWA Approval to Operate Works was issued in January 2020 and is valid for an indefinite period of time.

The CNSC licence and LCH for the McClean Lake operation, issued by the CNSC in 2017, authorizes the production of up to 24 million pounds U3O8 annually. The licence and LCH were amended in 2022 to authorize the expansion of the JEB TMF. See Section 20.4 for a discussion of the TMF and related licensing.

Previous environmental assessments (EAs) completed for Cigar Lake form the basis for the current CNSC licence, LCH, and SMOE approval to operate. Approvals, issued by SMOE pursuant to the Saskatchewan Environmental Assessment Act, for Cigar Lake are based on estimated annual

2024 CIGAR LAKE TECHNICAL REPORT 10

production rates of 18 million pounds U3O8 for CL Main and 6 million pounds U3O8 for CLEXT. As such, it is anticipated that the planned annual production rate of 18 million pounds U3O8 for CLEXT represents a change to the approved development that will require Ministerial Approval. Cameco plans to submit the information required to obtain this approval in 2025.

A detailed history of Cigar Lake EAs is provided in Section 20.3.

| 1.11 | Cigar Lake water inflow incidents and remediation |

Over the period 2006 through 2008, Cigar Lake suffered setbacks as a result of three water inflows.

The first occurred in April of 2006, resulting in the flooding of the then partially completed Shaft No. 2. The two subsequent incidents involved inflows in the mine workings connected to Shaft No. 1 and resulted in flooding of the mine workings completed to that point in time.

Cameco developed and successfully executed recovery and remediation plans for all three inflows.

Through 2010 and 2011, Cameco developed a comprehensive plan and successfully proceeded with remediation to restore the underground workings at Cigar Lake.

Successful re-entry into the main mine workings was achieved in early 2010 and work to secure the mine was completed in 2011.

The mine is fully remediated, and entered commercial production in 2015. Lessons learned from the inflows have been applied to the subsequent mine plan and development in order to reduce the risk of future inflows and improve Cameco’s ability to manage water inflows. These improvements are detailed in sections throughout the report.

| 1.12 | Current status of development |

Construction of all major permanent underground development and process facilities required for the duration of the mine life is complete. A number of underground access drifts and production crosscuts remain to be driven as part of ongoing mine development to sustain production, most notably in the western CLEXT areas.

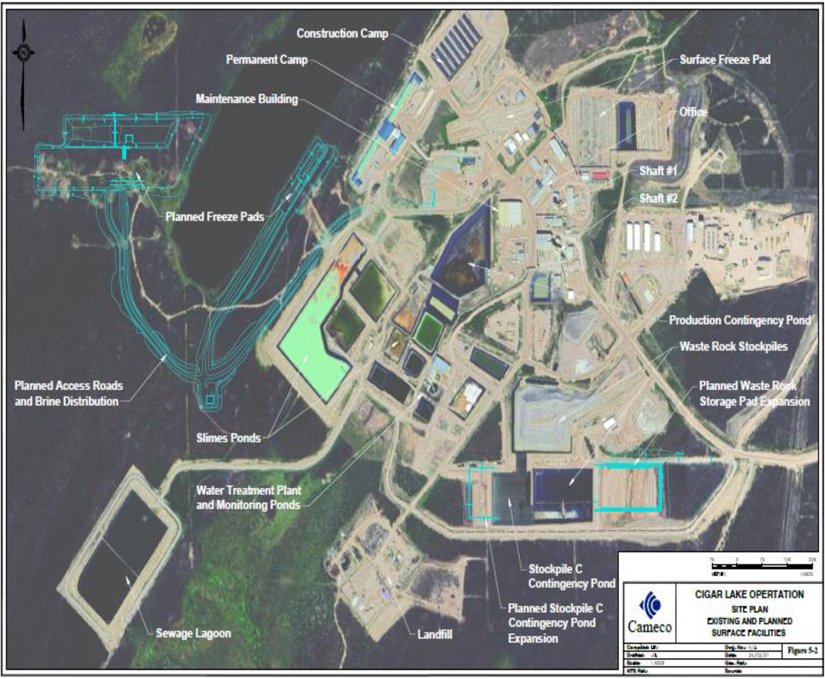

On surface, construction of all permanent infrastructure required to achieve nameplate capacity has been completed. As CLEXT progresses, new or expanded surface infrastructure will be required including:

| • | access road and adjacent pipe bench construction |

| • | construction of surface freeze pads to the west and east of Cigar Lake, including runoff ponds for each pad |

| • | freeze hole drilling, outfitting, activation and ongoing operation to facilitate ongoing bulk freezing of the orebody from surface |

| • | construction of a new brine booster station and routing of additional brine supply/return and distribution piping for the freeze systems on the freeze pads |

| • | routing of other required services to support surface freeze hole drilling and ongoing freeze system operation (e.g., drill fresh water supply, runoff pond water return, electrical and instrumentation) |

| • | expansion of the waste rock crushing pad |

| • | a minor expansion of the freeze plant capacity |

McClean Lake has all major permanent infrastructure in place to process the remaining Cigar Lake mineral reserves.

2024 CIGAR LAKE TECHNICAL REPORT 11

| 1.13 | Production plan |

The remaining mine life based on current mineral reserves will be approximately 13 years, with estimated full annual production of 18 million pounds U3O8 recovered from the mill for 11 years followed by a two-year ramp down until depletion.

The following is a general summary of the Cigar Lake production schedule, based on current remaining mineral reserves:

| • | total mill production of 205.9 million pounds U3O8, based on an overall milling recovery of 98.7% |

| • | total remaining mine production of 554,500 tonnes of ore (excluding mineral reserves already mined) |

| • | average mill feed grade of 17.0% U3O8 |

| • | remaining mine operating life of approximately 13 years |

| • | variable mining rate to achieve a constant production level of U3O8 (the average mine production varies annually from 115 to 160 tonnes per day, depending on the grade of ore being mined) |

The mine and mill production schedules for Cigar Lake are shown in Figures 1-1 and 1-2, respectively.

See Section 16 for more information on the production plan.

2024 CIGAR LAKE TECHNICAL REPORT 12

FIGURE 1-1: MINE PRODUCTION

FIGURE 1-2: MILL PRODUCTION

| 1.14 | Economic analysis and costs |

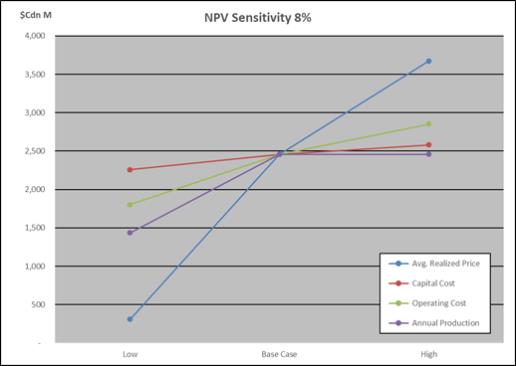

The economic analysis results in an estimated pre-tax NPV (at a discount rate of 8%) to Cameco, for net cash flows from January 1, 2024 forward, of $2.5 billion for its share of the Cigar Lake mineral reserves. Using the total capital invested to date, along with the operating and capital cost estimates for the remaining mineral reserves, the pre-tax IRR has been estimated to be 8.3%.

Sensitivity analysis shows changes in uranium price and production can have a significant impact on the size of the positive NPV. On an undiscounted pre-tax basis, payback for Cameco, including

2024 CIGAR LAKE TECHNICAL REPORT 13

total capital invested to date, is expected to be achieved in 2024. All future capital expenditures are forecasted to be covered by operating cash flow.

The CLJV’s estimated capital cost to bring the remaining mineral reserves into production is approximately $1.2 billion and includes sustaining capital for the Cigar Lake mine and McClean Lake mill, as well as underground development at Cigar Lake.

The total capital cost estimate as of December 31, 2023 for the CLJV is discussed further in Section 21 and summarized in Table 21-1.

Operating costs for the Cigar Lake operation are estimated to be $20.58 per pound U3O8 over the remaining life of the current mineral reserves. The current operating cost projections are based on operational experience to date and assumes the throughput described in Section 1.13 and in more detail in Section 16.3.

The total operating cost estimate as of December 31, 2023 for the CLJV is discussed further in Section 21 and summarized in Table 21-2.

| 1.15 | Mining and milling risks |

Cigar Lake is a challenging deposit to develop and mine. These challenges include, but are not limited to, variable or unanticipated ground conditions, ground movement and cave-ins, water inflows, performance of the water treatment system, variable dilution, recovery values, mining productivity, equipment reliability and other mining-related challenges. Additionally, the realization of risks associated with processing the ore at Orano’s McClean Lake mill would adversely affect production at Cigar Lake.

Specific mining and milling risks are described in more detail in Section 24.2.

| 1.16 | Conclusions and recommendations |

Conclusions

The Cigar Lake operation outlined in this report represents a significant economic source of feed material for the McClean Lake mill. With an estimated remaining operating mine life of approximately 13 years, Cigar Lake is expected to produce approximately 205.9 million pounds U3O8. At the forecast average realized uranium price over this 13-year period, it is estimated that Cameco will receive substantial positive net cash flows from its share of Cigar Lake production.

Since the previous technical report was issued, the following has been achieved:

| • | commissioned all circuits, demonstrating acceptable performance at both the mine and the mill |

| • | achieved mine production rampup to full nameplate capacity of 18 million pounds U3O8 per year and produced 138.4 million pounds U3O8 to December 31, 2023 |

| • | completed JBS production from seven crosscuts excavated using the NATM technique |

| • | completed the surface drilling program for bulk ground freezing of CL Main |

| • | received 10-year Cigar Lake licence renewal from CNSC in 2021 |

| • | regulatory approval for the continued expansion of Orano’s JEB TMF to allow the disposal of tailings up to a consolidated tailings elevation of 462 MASL |

| • | finalized a prefeasibility study for the CLEXT portion of the deposit, leading to a production decision and declaration of mineral reserves |

| • | increased Cameco’s ownership interest in the CLJV to 54.547% with the 2023 acquisition of a 4.522% interest from Idemitsu Canada Resources Ltd. |

| • | constructed a waste rock crushing pad to enable processing of waste rock into backfill aggregate |

2024 CIGAR LAKE TECHNICAL REPORT 14

ECONOMIC ANALYSIS AND COSTS (100% BASIS)

Cameco’s estimated pre-tax NPV (at a discount rate of 8%) of $2.5 billion for its share of the Cigar Lake mineral reserves supports the decision to extend the mine life to 2036. Economic sensitivity to factors such as average realized price, production rates and annual costs show that the reserves present a robust economic outlook in several scenarios.

MINE PLAN

Mine design changes and refinements since 2012 achieved their objective. Application of the NATM tunnel excavation technique has proven to be effective and reliable in reducing tunnel rehabilitation requirements. Lateral mine development is largely complete at CL Main.

The ground freezing system has seen a number of improvements, including optimizing of freezing capacity, drilling patterns and freeze hole installations.

The CLEXT mine plan is largely based on the design criteria, processes and experience gained during mining of the CL Main portion of the deposit. Application of the same mining methods and techniques are expected to continue to increase the reliability of development, production and cost forecasts.

JBS MINING METHOD

Since 2012, comprehensive JBS testing and commissioning was completed to advance three JBS units to full production. This mining method has been successfully demonstrated through the mining of 572 cavities and extraction of 358,000 tonnes of ore.

MINE WATER TREATMENT

Adjustments to our circuits have been successful in reducing the amount of water requiring treatment and release and increasing the amount of water that can be recycled.

MCCLEAN LAKE MILL

The McClean Lake mill was successfully restarted in 2014, and ongoing process improvement projects have been implemented in the mill to achieve required production rates.

With Orano’s receipt of regulatory approval for the continued expansion of the JEB TMF, Cigar Lake has access to sufficient tailings capacity to allow mining of the current Cigar Lake mineral reserves.

MINERAL RESOURCES AND MINERAL RESERVES

The CL Main zone is now fully delineated and CL Main mineral reserves are largely in the proven category. Additional surface delineation drilling programs at CLEXT since 2016 were conducted in order to better define the mineral resource, gather metallurgical, hydrogeological and geotechnical information and used to support a prefeasibility study for CLEXT.

Mineral reserves in CLEXT are entirely in the probable category due to the sparser drilling density and are located in its western portion. The eastern portion of CLEXT is mostly in the inferred mineral resource category.

As of December 31st, 2023, total proven and probable mineral reserves at Cigar Lake amount to 555,600 tonnes at a grade of 17.03% U3O8 and 208.6 million pounds. Mineral resources total 132,900 tonnes at a grade of 2.65% U3O8 and 7.8 million pounds in the measured and indicated category. Inferred mineral resources total 80,500 tonnes at a grade of 2.25% U3O8 for 4.0 million pounds.

Other than the challenges related to water inflows, jet boring and geotechnical issues described in Section 15.4, there are no known issues with respect to mining, metallurgical, infrastructure,

2024 CIGAR LAKE TECHNICAL REPORT 15

permitting, or other relevant factors that could materially affect the mineral resource or reserve estimates.

Recommendations

The Cigar Lake operation outlined in this report represents a significant economic source of feed material for the McClean Lake mill. To realize the economic benefits from this operation and to mitigate risk, the authors of this technical report make the following recommendations:

OPERATIONAL EXCELLENCE/RELIABILITY

| • | continue process and equipment optimization initiatives related to tooling, leveraging instrumentation and operational technology for improved cavity excavation control to increase recovery and reduce dilution |

| • | continue to advance industry best practices related to asset management to improve equipment reliability for the life of mine |

| • | investigate options for sustainable life of mine aggregate sources |

| • | continue investigation of opportunities to optimize the leach circuit at McClean Lake to manage a wider range of arsenic to uranium slurry feed ratios to reduce potential throughput limitations in leaching while also providing positive effects in downstream unit operations |

| • | continue monitoring the reliability of the arsenic block model to improve short-term forecasting |

ENVIRONMENTAL PERFORMANCE

| • | continue to monitor and review the process water balance related to effluent generation and effluent concentrations that form part of the licensing basis |

| • | investigate opportunities to reduce environmental liabilities during operations and decrease decommissioning costs associated with waste rock management |

FREEZE INFRASTRUCTURE OPTIMISATION

| • | complete trade-off studies to determine optimal capital spending on freeze projects to sustain production for the life of the mine |

GEOTECHNICAL DRILLING

| • | undertake geotechnical drilling ahead of the two main access drifts for CLEXT to allow for the collection of information to support excavation and ground support plans |

MINERAL RESOURCES AND RESERVES

| • | focus exploration efforts mainly on the relatively sparsely drilled, eastern portion of CLEXT, given the current proven and probable mineral reserve inventory, the forecast rate of production and the 13-year mine life |

| • | continue to invest in further exploration on the Waterbury Lake lands, subject to annual reviews of ongoing exploration results, to allow for the extended timelines associated with exploring, designing, permitting and developing new uranium deposits |

2024 CIGAR LAKE TECHNICAL REPORT 16

| 2 | Introduction |

| 2.1 | Introduction and purpose |

The Cigar Lake Operation is a material property for Cameco under Canadian securities laws.

This technical report has been prepared for Cameco by, or under supervision of, internal qualified persons in support of disclosure of new scientific and technical information about the Cigar Lake operation as contained in Cameco’s annual Management’s Discussion and Analysis for the year ended December 31, 2023, Cameco’s Annual Information Form and 40-F for the year ended December 31, 2023, and Cameco’s press release dated February 8, 2024. This new information is the result of progress at Cigar Lake, combined with experience gained since the 2016 Technical Report.

This report has an effective date of December 31, 2023, and has been prepared in accordance with NI 43-101 by the following individuals:

| • | Biman Bharadwaj, P. Eng., Principal Metallurgist, Technical Services, Cameco Corporation |

| • | C. Scott Bishop, P. Eng., Director, Technical Services, Cameco Corporation |

| • | Alain D. Renaud, P. Geo., Principal Resource Geologist, Technical Services, Cameco Corporation |

| • | Lloyd Rowson, P. Eng., General Manager, Cigar Lake Operation, Cameco Corporation |

These individuals are the qualified persons responsible for the content of this report. All four qualified persons have visited the Cigar Lake site.

Mr. Bharadwaj has been a process engineer/metallurgist and operations manager in the mining/milling industry for over thirty years and has in-depth knowledge of the process unit operations associated with the Cigar Lake Operation and the McClean Lake Mill. Over the years Mr. Bharadwaj has been directly involved in several studies and projects related to the processing of the Cigar Lake ore and water treatment systems. Recently Mr. Bharadwaj was directly involved in the modelling of the CL Main and CLEXT outputs from a processing perspective. Mr. Bharadwaj’s last visit to both the Cigar Lake Operation and the ore slurry receiving mill were in 2016, which included an end-to-end tour of both operations.

Mr. Bishop, from October 2004 to September 2010, was the Chief Mine Engineer of the Cigar Lake project and was present at the site at least several times a month for periods extending up to seven days. Since 2010, Mr. Bishop has been directly and indirectly involved in a number of studies, projects and technical reviews of specific Cigar Lake mine design and operational practices, including the prefeasibility study of the CLEXT. Mr. Bishop’s last personal inspection of the Cigar Lake operation occurred from May 9-10, 2023, and included inspections of both the surface and underground facilities.

Mr. Renaud has been involved with the Cigar Lake Operation since 2016 and has visited the site on several occasions. Mr. Renaud’s last personal inspection of the Cigar Lake Operation occurred from March 13-15, 2023, and included a review of drilling, core handling, radiometric probing, logging, sampling facilities, sampling and data verification procedures in place. Mr. Renaud was involved with the 2023 CL Main and CLEXT mineral resource updates as well as the year-end mineral reserves and resources compilation and review.

Mr. Rowson has been continuously involved in the Cigar Lake Operation since 2012 and is regularly present on site currently overseeing all aspects of the operation as General Manager. During this time, Mr. Rowson has held various site-based leadership roles initially focused on mine development and jet boring system commissioning and operations, followed by a focus on

2024 CIGAR LAKE TECHNICAL REPORT 17

Technical Services including Mine Engineering, Geology and Metallurgical Engineering functions. Mr. Rowson also visits the McClean Lake Mill one to two times per year, with the most recent personal inspection occurring February 14, 2024.

| 2.2 | Report basis |

This report has been prepared with available internal Cameco data and information, and data and information prepared for the CLJV. Technical and certain financial information for processing Cigar Lake ore at the McClean Lake mill was provided to Cameco by Orano.

The principal technical documents and files relating to the Cigar Lake operation and the McClean Lake mill that were used in preparation of this report are listed in Section 27.

All monetary references in this technical report are expressed in Canadian dollars, unless otherwise indicated. Illustrations (Figures) in this report are from Cameco, and are dated December 31, 2023, unless otherwise specified.

Within this technical report, three different coordinate systems are used: latitudes/longitudes, Universal Transverse Mercator (UTM) coordinates and mine grid. The UTM coordinates are calculated using the latest World Geodetic System (WGS) standard WGS 84. The conversion from mine grid to UTM coordinates is as follows:

| UTM Northing = | Mine Northing + 6426697.9 | |

| UTM Easting = | Mine Easting + 516518.7 | |

| UTM Elevation = | Mine Elevation + 1000 = MASL + 1000 | |

2024 CIGAR LAKE TECHNICAL REPORT 18

| 3 | Reliance on other experts |

The authors have relied, and believe they have a reasonable basis to rely, upon the following individuals who have contributed the environmental, legal and taxation information stated in this report, as noted below in Table 3-1.

TABLE 3-1: RELIANCE ON OTHER EXPERTS

| Name |

Title |

Section Number (description) |

||

| Kevin Nagy, M.Sc. | Director, Compliance and Licensing, Cameco | 1.10 (description of Environmental assessment and licensing)

4.5 (description of Known environmental liabilities)

4.6 (description of Permitting)

20 (description of Environmental studies, permitting and social or community impact), excluding Section 20.7 |

||

| Candice Murray, JD | Director Legal Services, SHEQ, Regulatory Relations and Corporate Responsibility, Cameco | 1.3 (description of Property tenure)

4.2 (description of Mineral tenure)

4.3 (description of Surface tenure)

6.1 (description of Ownership)

19.2 (description of Material contracts for property development) |

||

| Jill Johnson, MPAcc, CPA, CA | Senior Director, Tax and Treasury, Cameco | 4.4 (description of Royalties)

22.5 (description of Taxes)

22.6 (description of Royalties) |

||

2024 CIGAR LAKE TECHNICAL REPORT 19

| 4 | Property description and location |

| 4.1 | Location |

The Cigar Lake mine site is located near Waterbury Lake, approximately 660 kilometres north of Saskatoon, at latitude 580 04’ 14” north and longitude 1040 32’ 18” west, and about 40 kilometres inside the eastern margin of the Athabasca Basin region in northern Saskatchewan.

See Figure 4-1.

The mine site is in close proximity to two uranium milling operations: McClean Lake is 69 kilometres northeast by road and Rabbit Lake is 87 kilometres east by road. The McArthur River mine is 46 kilometres southwest by air from the mine site.

2024 CIGAR LAKE TECHNICAL REPORT 20

FIGURE 4-1: CIGAR LAKE MINERAL PROPERTY LOCATION

| 4.2 | Mineral tenure |

| • | One mineral lease: ML 5521 |

| • | 38 mineral claims. See Table 4-1 |

| • | Total contiguous area: 95,601 hectares |

2024 CIGAR LAKE TECHNICAL REPORT 21

The Cigar Lake deposit is located in the area subject to the mineral lease, totaling 308 hectares. The right to mine this deposit was granted by the Province of Saskatchewan under the Crown Minerals Act (Saskatchewan) through the mineral lease, effective December 1, 2001. The term of the current mineral lease is for 10 years and expires on November 30, 2031, but is subject to a right to renew for successive ten-year terms, absent a default by the CLJV. The Province of Saskatchewan may only terminate the lease if the CLJV breaches a provision of the lease or fails to satisfy any of its obligations under The Crown Minerals Act (Saskatchewan) or associated regulations, or in the event that any prescribed environmental concerns arise.

Adjoining the mineral lease, there are 38 mineral claims which were also granted by the Province of Saskatchewan under The Crown Minerals Act (Saskatchewan), totaling 95,293 hectares. These mineral claims grant the CLJV the right to explore for minerals within the claim lands, and to convert a mineral claim into a mineral lease if the CLJV remains in good standing. Surface exploration work of a mineral claim requires additional government approval.

There is an annual requirement of $2.4 million, either in work or cash, to retain title to the 38 mineral claims. Based on previous work submitted and approved by the Province of Saskatchewan, title is secured until 2037 or later. The mineral lease has a yearly rental payment of $3,080.00.

Under the Cigar Lake Joint Venture Agreement and related agreements, made effective January 1, 2002 and as amended on November 30, 2011 (CLJV Agreement), the mineral lease and the 38 mineral claims noted above were divided into the Cigar Lake lands, consisting of ML 5521 and claim S-106558, and the Waterbury Lake lands, consisting of the remaining 38 claims. Orano is the operator of the Waterbury Lake lands and is also contract exploration operator of the Cigar Lake lands other than the area on ML 5521 from which the mineral reserves are being mined. Cameco has been the mine operator for the Cigar Lake lands with respect to ML 5521 since 2002.

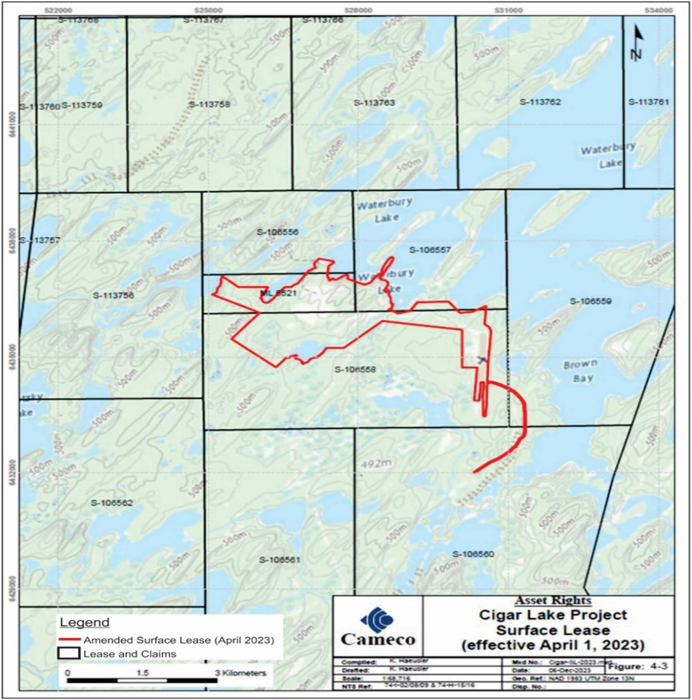

Figure 4-2 shows the Cigar Lake mineral lease and mineral claims as currently registered with the Province of Saskatchewan.

2024 CIGAR LAKE TECHNICAL REPORT 22

FIGURE 4-2: MINERAL LEASE AND MINERAL CLAIMS

2024 CIGAR LAKE TECHNICAL REPORT 23

TABLE 4-1: CIGAR LAKE OPERATION - MINERAL CLAIMS STATUS

| Lease/Claim |

Record Date | Area | Annual | Next Payment | ||||||||||||

| ML 5521 (Lease) |

1981-Dec-01 | 308 | Yearly Rent | 2024-Dec-01 | ||||||||||||

| MC00012765 |

2019-Mar-27 | 2,533 | $ | 38,007 | 2042-Mar-28 | |||||||||||

| S-106541 |

1975-Dec-16 | 4,270 | $ | 106,750 | 2043-Dec-16 | |||||||||||

| S-106542 |

1975-Dec-16 | 3,039 | $ | 75,975 | 2037-Dec-16 | |||||||||||

| S-106543 |

1975-Dec-16 | 4,316 | $ | 107,900 | 2041-Dec-16 | |||||||||||

| S-106545 |

1975-Dec-16 | 4,410 | $ | 110,250 | 2041-Dec-16 | |||||||||||

| S-106546 |

1975-Dec-16 | 4,334 | $ | 108,350 | 2042-Dec-16 | |||||||||||

| S-106547 |

1975-Dec-16 | 2,550 | $ | 63,750 | 2043-Dec-16 | |||||||||||

| S-106556 |

1975-Dec-16 | 635 | $ | 15,875 | 2042-Dec-16 | |||||||||||

| S-106557 |

1975-Dec-16 | 935 | $ | 23,375 | 2042-Dec-16 | |||||||||||

| S-106558 |

1975-Dec-16 | 1,872 | $ | 46,800 | 2042-Dec-16 | |||||||||||

| S-106559 |

1975-Dec-16 | 2,210 | $ | 55,250 | 2042-Dec-16 | |||||||||||

| S-106560 |

1975-Dec-16 | 4,742 | $ | 118,550 | 2042-Dec-16 | |||||||||||

| S-106561 |

1975-Dec-16 | 3,150 | $ | 78,750 | 2042-Dec-16 | |||||||||||

| S-106562 |

1975-Dec-16 | 4,175 | $ | 104,375 | 2041-Dec-16 | |||||||||||

| S-106563 |

1975-Dec-16 | 4,149 | $ | 103,725 | 2042-Dec-16 | |||||||||||

| S-106564 |

1975-Dec-16 | 3,945 | $ | 98,625 | 2041-Dec-16 | |||||||||||

| S-113756 |

1975-Dec-16 | 1,900 | $ | 47,510 | 2043-Dec-16 | |||||||||||

| S-113757 |

1975-Dec-16 | 2,223 | $ | 55,568 | 2042-Dec-16 | |||||||||||

| S-113758 |

1975-Dec-16 | 1,484 | $ | 37,108 | 2042-Dec-16 | |||||||||||

| S-113759 |

1975-Dec-16 | 823 | $ | 20,565 | 2041-Dec-16 | |||||||||||

| S-113760 |

1975-Dec-16 | 2,076 | $ | 51,910 | 2042-Dec-16 | |||||||||||

| S-113761 |

1975-Dec-16 | 1,523 | $ | 38,081 | 2042-Dec-16 | |||||||||||

| S-113762 |

1975-Dec-16 | 1,510 | $ | 37,740 | 2042-Dec-16 | |||||||||||

| S-113763 |

1975-Dec-16 | 1,489 | $ | 37,213 | 2042-Dec-16 | |||||||||||

| S-113764 |

1975-Dec-16 | 2,273 | $ | 56,826 | 2042-Dec-16 | |||||||||||

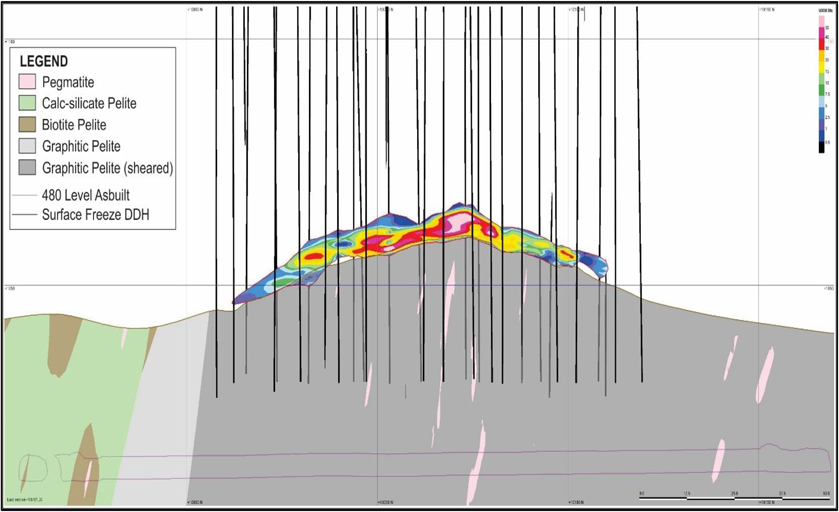

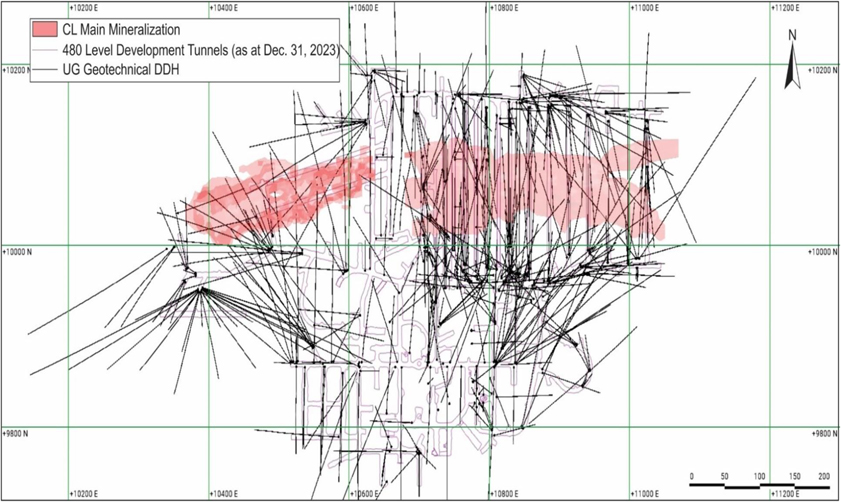

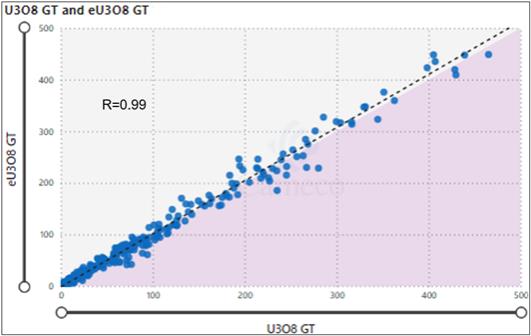

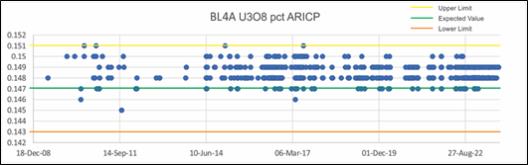

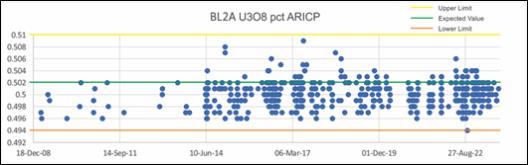

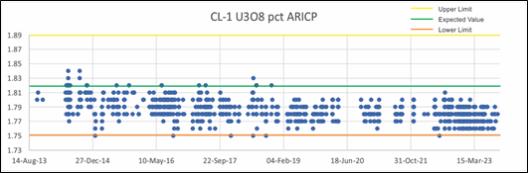

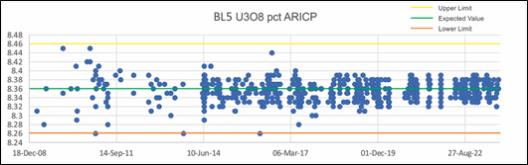

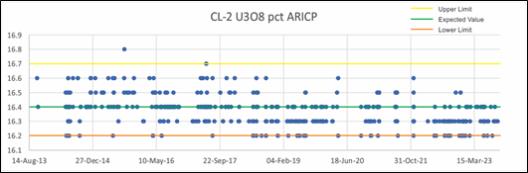

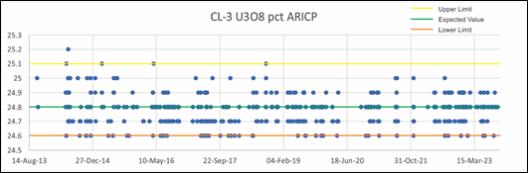

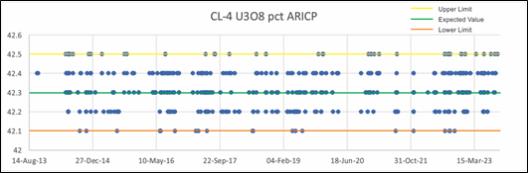

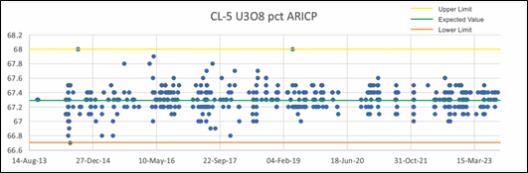

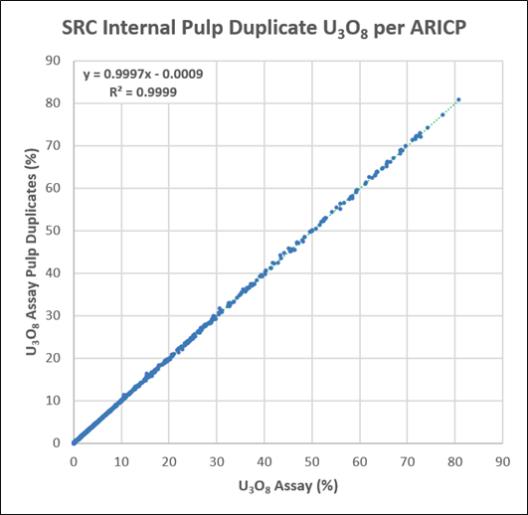

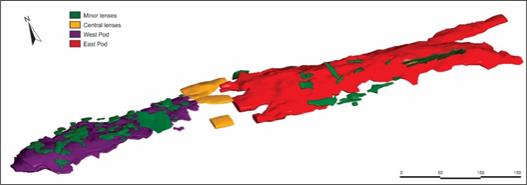

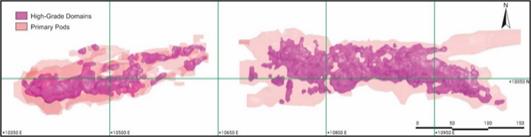

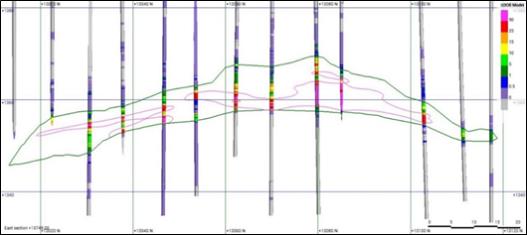

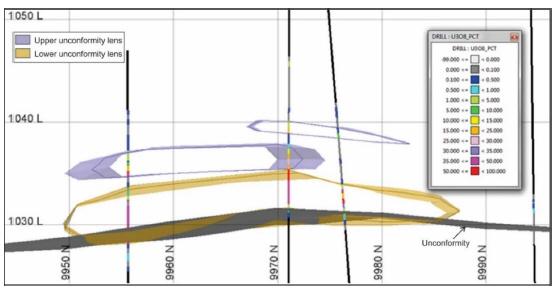

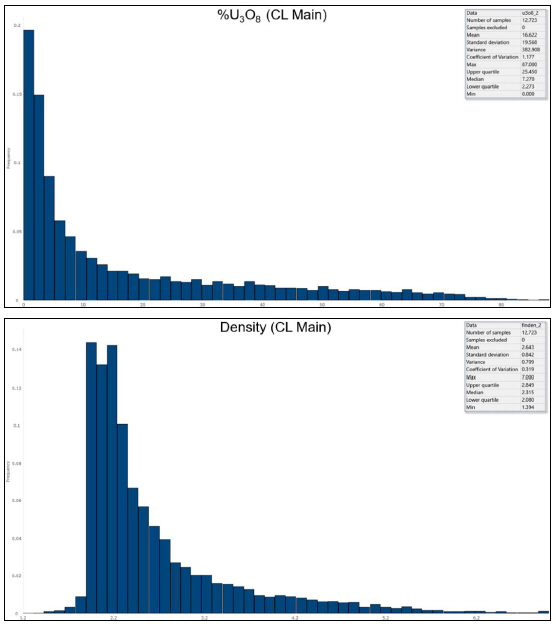

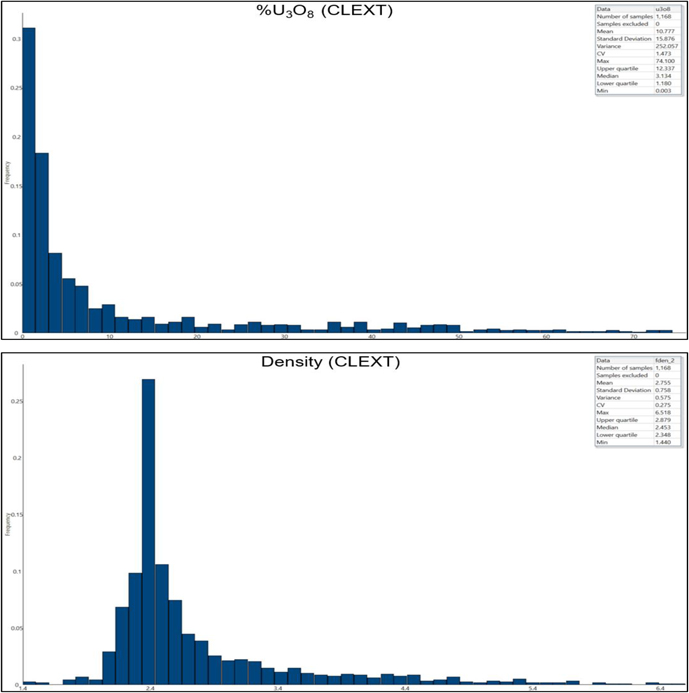

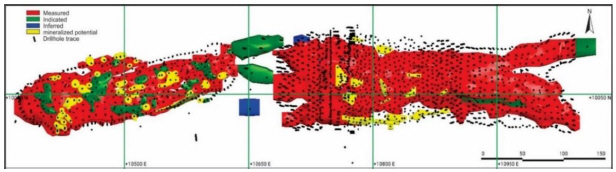

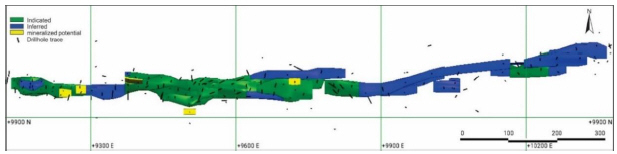

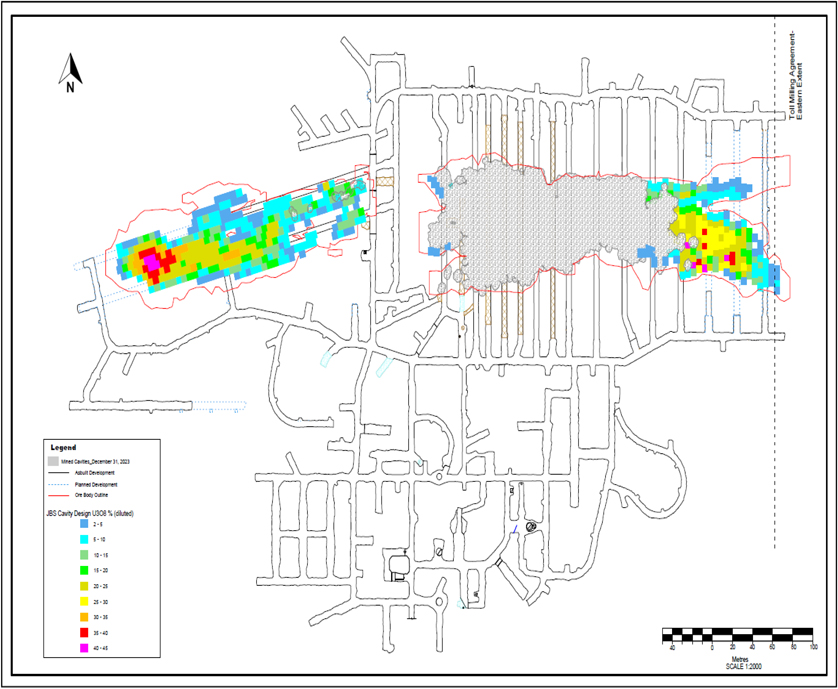

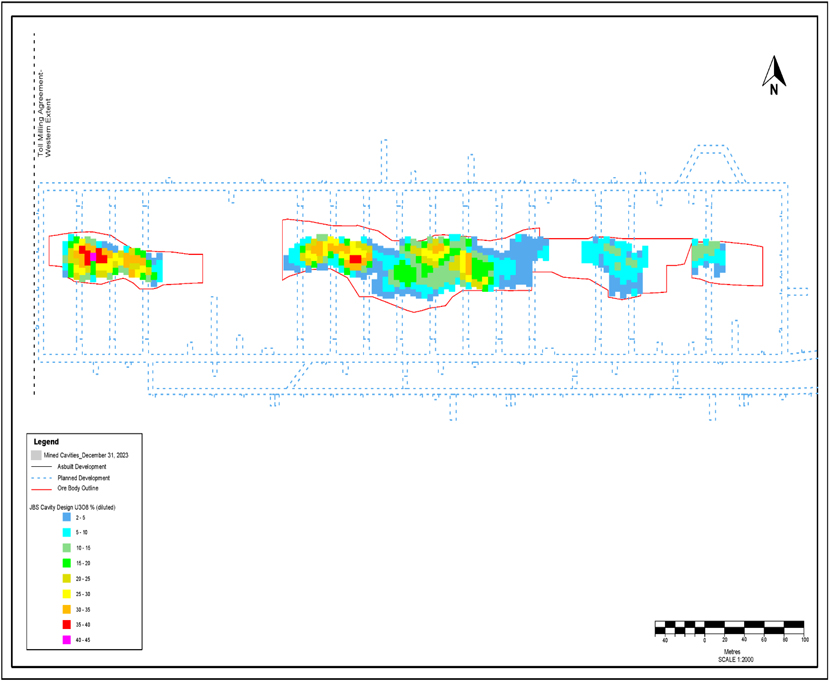

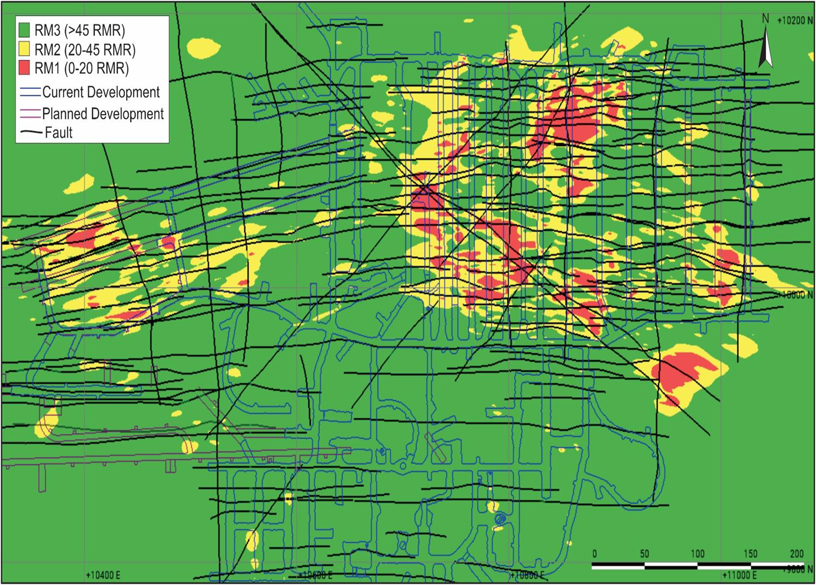

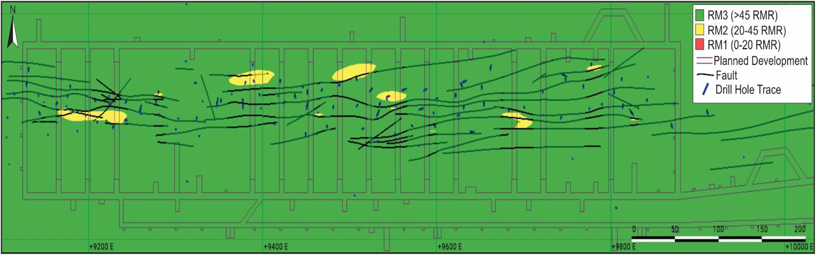

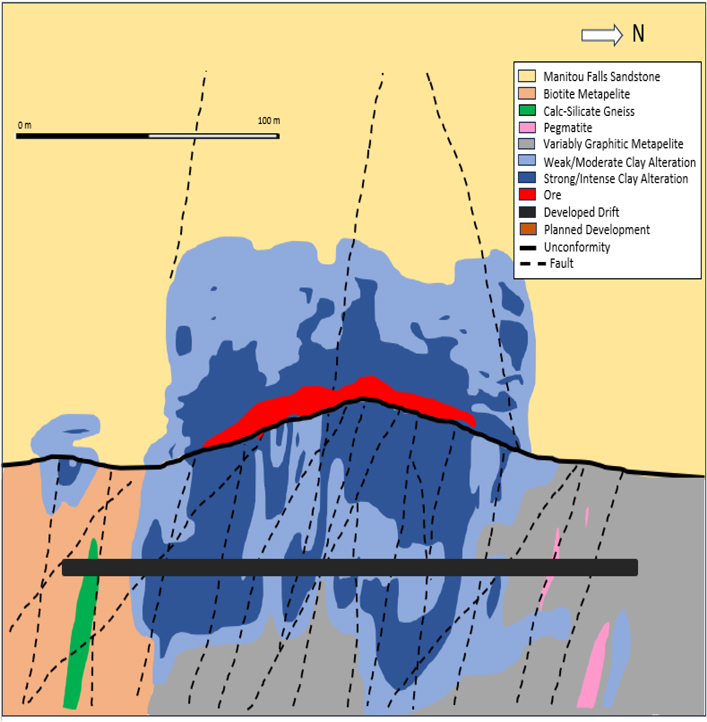

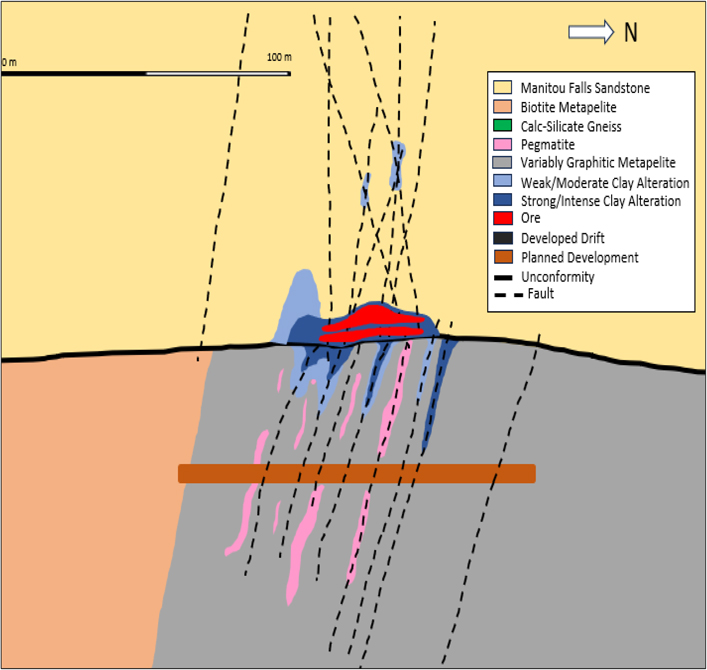

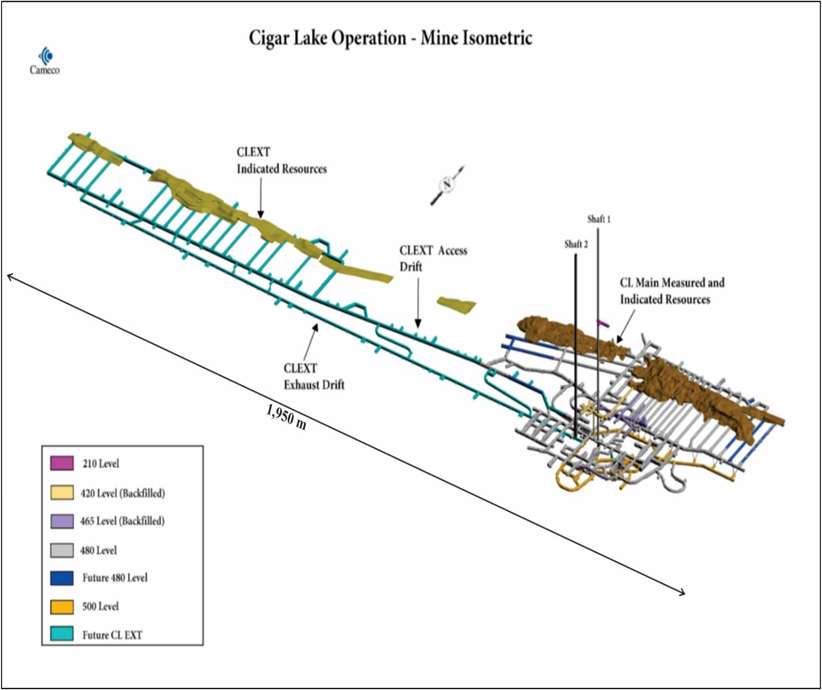

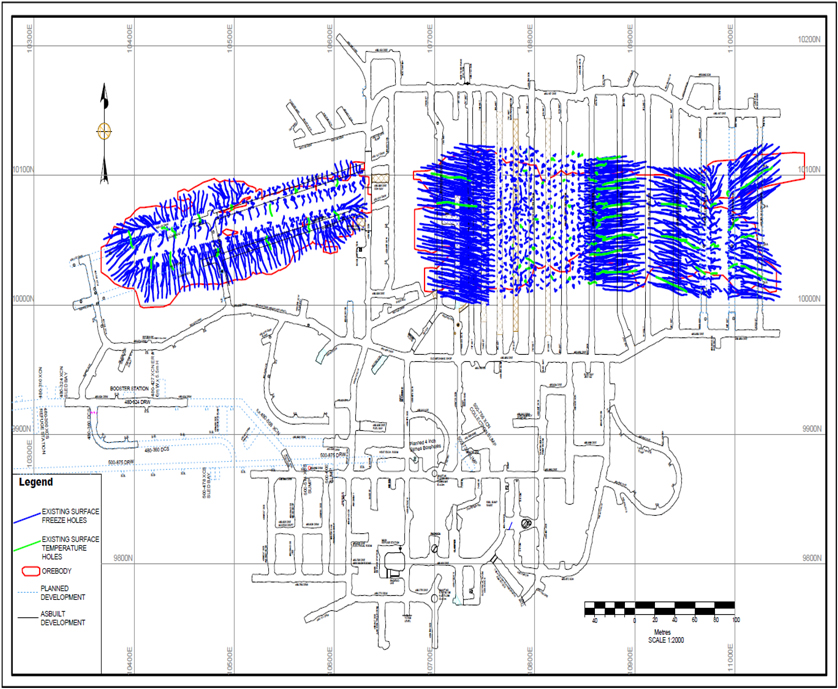

| S-113765 |