UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

Form 6-K

REPORT OF FOREIGN PRIVATE ISSUER

PURSUANT TO RULE 13a-16 OR 15d-16

UNDER THE SECURITIES EXCHANGE ACT OF 1934

For the month of March 2024

Commission File Number: 1-9059

Barrick Gold Corporation

(Registrant’s name)

Brookfield Place, TD Canada Trust Tower, Suite 3700

161 Bay Street, P.O. Box 212

Toronto, Ontario M5J 2S1 Canada

(Address of principal executive offices)

Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40-F.

Form 20-F ☐ Form 40-F ☒

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| Date: March 15, 2024 | BARRICK GOLD CORPORATION | |||||

| By: | /s/ Poupak Bahamin |

|||||

| Name: | Poupak Bahamin | |||||

| Title: | General Counsel | |||||

EXHIBIT INDEX

| Exhibit |

Description |

|

| 99.1 | Technical Report on the Turquoise Ridge Complex, Humboldt County, Nevada, USA | |

Exhibit 99.1

NI 43-101 Technical Report on the

Turquoise Ridge Complex

Humboldt County, Nevada, USA

March 15, 2024

Effective Date: December 31, 2023

Prepared for Barrick Gold Corporation

Prepared by:

Craig Fiddes, SME (RM)

John Langhans, MMSA (QP)

Paul Schmiesing, SME (RM)

Joseph Becker, SME (RM)

Timothy Webber, SME (RM)

Simon Bottoms, CGeol, MGeol, FGS, FAusIMM

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

Cautionary Statement on Forward-Looking Information

This Technical Report contains forward-looking statements. All statements, other than statements of historical fact regarding Nevada Gold Mines LLC, Barrick Gold Corporation, Newmont Corporation or the Turquoise Ridge Complex, are forward-looking statements. The words “believe”, “expect”, “anticipate”, “contemplate”, “target”, “plan”, “intend”, “project”, “continue”, “budget”, “estimate”, “potential”, “may”, “will”, “can”, “could” and similar expressions identify forward-looking statements. In particular, this Technical Report contains forward-looking statements with respect to cash flow forecasts, projected capital, operating and exploration expenditure, targeted cost reductions, mine life and production rates, potential mineralization and metal or mineral recoveries, and information pertaining to potential improvements to financial and operating performance and mine life at the Turquoise Ridge Complex. All forward-looking statements in this Technical Report are necessarily based on opinions and estimates made as of the date such statements are made and are subject to important risk factors and uncertainties, many of which cannot be controlled or predicted. Material assumptions regarding forward-looking statements are discussed in this Technical Report, where applicable. In addition to such assumptions, the forward-looking statements are inherently subject to significant business, economic and competitive uncertainties, and contingencies. Known and unknown factors could cause actual results to differ materially from those projected in the forward-looking statements. Such factors include, but are not limited to: fluctuations in the spot and forward price of commodities (including gold, diesel fuel, natural gas and electricity); the speculative nature of mineral exploration and development; changes in mineral production performance, exploitation and exploration successes; diminishing quantities or grades of reserves; increased costs, delays, suspensions, and technical challenges associated with the construction of capital projects; operating or technical difficulties in connection with mining or development activities, including disruptions in the maintenance or provision of required infrastructure and information technology systems; damage to Nevada Gold Mines LLC’s, Barrick Gold Corporation’s, or Newmont Corporation’s reputation due to the actual or perceived occurrence of any number of events, including negative publicity with respect to the handling of environmental matters or dealings with community groups, whether true or not; risk of loss due to acts of war, terrorism, sabotage and civil disturbances; uncertainty whether the Turquoise Ridge Complex will meet Nevada Gold Mines LLC’s or Barrick Gold Corporation’s capital allocation objectives; the impact of global liquidity and credit availability on the timing of cash flows and the values of assets and liabilities based on projected future cash flows; the impact of inflation; fluctuations in the currency markets; changes in interest rates; changes in national and local government legislation, taxation, controls or regulations and/or changes in the administration of laws, policies and practices, expropriation or nationalization of property and political or economic developments in the United States; failure to comply with environmental and health and safety laws and regulations; timing of receipt of, or failure to comply with, necessary permits and approvals; litigation; contests over title to properties or over access to water, power and other required infrastructure; increased costs and physical risks including extreme weather events and resource shortages, related to climate change; and availability and increased costs associated with mining inputs and labour. In addition, there are risks and hazards associated with the business of mineral exploration, development, and mining, including environmental hazards, industrial accidents, unusual or unexpected formations, ground conditions, pressures, cave-ins, flooding and gold ore losses (and the risk of inadequate insurance, or inability to obtain insurance, to cover these risks).

Many of these uncertainties and contingencies can affect Nevada Gold Mines LLC’s actual results and could cause actual results to differ materially from those expressed or implied in any forward-looking statements made by, or on behalf of, Nevada Gold Mines LLC. All of the forward-looking statements made in this Technical Report are qualified by these cautionary statements. None of Nevada Gold Mines LLC, Barrick Gold Corporation, Newmont Corporation, and the Qualified Persons who authored this Technical Report undertake no obligation to update publicly or otherwise revise any forward-looking statements whether as a result of new information or future events or otherwise, except as may be required by law.

| March 15, 2024 |

Page i |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

Table of Contents

| 1 |

Summary | 18 | ||||

| 1.1 | Description, Location, and Ownership | 18 | ||||

| 1.2 | Geology and Mineralization | 18 | ||||

| 1.3 | Exploration Status | 19 | ||||

| 1.4 | Mineral Resource Estimate | 20 | ||||

| 1.5 | Mineral Reserve Estimate | 22 | ||||

| 1.6 | Mining Methods | 24 | ||||

| 1.7 | Mineral Processing | 24 | ||||

| 1.8 | Project Infrastructure | 25 | ||||

| 1.9 | Environmental, Permitting, and Social Considerations | 25 | ||||

| 1.10 | Capital and Operating Costs | 25 | ||||

| 1.11 | Interpretations and Conclusions | 26 | ||||

| 1.11.1 | Mineral Tenure, Rights, Royalties and Agreements | 26 | ||||

| 1.11.2 | Geology and Mineral Resources | 26 | ||||

| 1.11.3 | Mining and Mineral Reserves | 28 | ||||

| 1.11.4 | Mineral Processing | 29 | ||||

| 1.11.5 | Infrastructure | 30 | ||||

| 1.11.6 | Environmental, Permitting and Social Considerations | 30 | ||||

| 1.11.7 | Project Economics | 31 | ||||

| 1.12 | Recommendations | 32 | ||||

| 1.12.1 | Geology and Mineral Resources | 32 | ||||

| 1.12.2 | Mining and Mineral Reserves | 33 | ||||

| 1.12.3 | Mineral Processing | 33 | ||||

| 1.12.4 | Infrastructure | 34 | ||||

| 1.12.5 | Environment, Permitting, and Social and Community | 34 | ||||

| 2 |

Introduction | 35 | ||||

| 2.1 | Effective Date | 38 | ||||

| 2.2 | Qualified Persons | 38 | ||||

| 2.3 | Site Visits of Qualified Persons | 40 | ||||

| 2.4 | Information Sources | 41 | ||||

| March 15, 2024 |

Page ii |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 2.5 | List of Abbreviations | 41 | ||||

| 3 |

Reliance on Other Experts | 43 | ||||

| 4 |

Property Description and Location | 44 | ||||

| 4.1 | Property and Title in Nevada | 44 | ||||

| 4.1.1 | Mineral Title | 44 | ||||

| 4.1.2 | Surface Rights | 46 | ||||

| 4.1.3 | Water Rights | 46 | ||||

| 4.2 | Project Ownership | 47 | ||||

| 4.3 | Mineral Tenure | 47 | ||||

| 4.3.1 | Unpatented Mining and Mill Site Claims | 49 | ||||

| 4.3.2 | Fee Property | 64 | ||||

| 4.4 | Surface Rights and Plans of Operations | 65 | ||||

| 4.5 | Agreements | 65 | ||||

| 4.6 | Royalties, Taxes, and Levies | 66 | ||||

| 4.6.1 | Government Mining Taxes, Levies, and Royalties | 66 | ||||

| 4.6.2 | NGM Royalty | 67 | ||||

| 4.6.3 | Claims Royalties | 67 | ||||

| 4.7 | Permit Considerations | 68 | ||||

| 4.8 | Environmental Liabilities | 68 | ||||

| 4.9 | Comment on Property Description and Location | 68 | ||||

| 5 |

Accessibility, Climate, Local Resources, Infrastructure and Physiography | 69 | ||||

| 5.1 | Accessibility | 69 | ||||

| 5.2 | Climate | 69 | ||||

| 5.3 | Local Resources and Infrastructure | 70 | ||||

| 5.4 | Physiography | 70 | ||||

| 5.5 | Seismicity | 70 | ||||

| 5.6 | Sufficiency of Surface Rights | 70 | ||||

| 6 |

History | 72 | ||||

| 6.1 | Development and Operations | 72 | ||||

| 6.2 | Production History | 74 | ||||

| 7 |

Geological Setting and Mineralization | 76 | ||||

| 7.1 | Regional Geology | 76 | ||||

| March 15, 2024 |

Page iii |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 7.2 | Local Geology | 79 | ||||

| 7.2.1 | Lithologies | 79 | ||||

| 7.2.2 | Structure | 82 | ||||

| 7.2.3 | Alteration | 83 | ||||

| 7.2.4 | Mineralization | 85 | ||||

| 7.3 | Project Geology | 85 | ||||

| 7.3.1 | Turquoise Ridge Underground | 85 | ||||

| 7.3.2 | Turquoise Ridge Surface | 90 | ||||

| 7.3.3 | Vista Underground | 97 | ||||

| 7.4 | Comment on Geological Setting and Mineralization | 101 | ||||

| 8 |

Deposit Types | 102 | ||||

| 8.1 | Summary | 102 | ||||

| 8.2 | Deposit Type | 102 | ||||

| 8.3 | Comment on Deposit Types | 102 | ||||

| 9 |

Exploration | 103 | ||||

| 9.1 | Summary | 103 | ||||

| 9.2 | Grids and Surveys | 103 | ||||

| 9.2.1 | Turquoise Ridge Underground | 103 | ||||

| 9.2.2 | Turquoise Ridge Surface and Vista Underground | 103 | ||||

| 9.3 | Geological Mapping | 103 | ||||

| 9.3.1 | Turquoise Ridge Underground | 104 | ||||

| 9.3.2 | Turquoise Ridge Surface | 104 | ||||

| 9.3.3 | Vista Underground | 104 | ||||

| 9.4 | Geochemical Sampling | 104 | ||||

| 9.5 | Geophysics | 104 | ||||

| 9.6 | Petrology, Mineralogy, and Research Studies | 105 | ||||

| 9.7 | Exploration Potential | 105 | ||||

| 9.7.1 | Near Mine | 105 | ||||

| 9.7.2 | Regional Exploration | 106 | ||||

| 9.8 | Comment on Exploration | 106 | ||||

| 10 |

Drilling | 107 | ||||

| 10.1 | Summary | 107 | ||||

| March 15, 2024 |

Page iv |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 10.2 | Drilling Used to Support Mineral Resource Estimation | 109 | ||||

| 10.3 | Drill Methods | 113 | ||||

| 10.3.1 | Drill Contractors | 113 | ||||

| 10.3.2 | Air and Mud Drilling Methods | 113 | ||||

| 10.3.3 | Reverse Circulation Drilling Methods | 113 | ||||

| 10.3.4 | Core Drilling | 113 | ||||

| 10.4 | Logging Procedures | 114 | ||||

| 10.4.1 | Reverse Circulation | 114 | ||||

| 10.4.2 | Core | 114 | ||||

| 10.5 | Collar Surveys | 115 | ||||

| 10.5.1 | Reverse Circulation | 115 | ||||

| 10.5.2 | Core | 116 | ||||

| 10.6 | Down Hole Surveys | 116 | ||||

| 10.6.1 | Reverse Circulation | 116 | ||||

| 10.6.2 | Core | 116 | ||||

| 10.7 | Recovery | 117 | ||||

| 10.8 | Surface Grade Control Drilling | 117 | ||||

| 10.9 | Underground Grade Control Drilling | 117 | ||||

| 10.10 | Sample Length/True Thickness | 118 | ||||

| 10.11 | Comments on Drilling | 118 | ||||

| 11 |

Sample Preparation, Analyses and Security | 120 | ||||

| 11.1 | Sampling Methods | 120 | ||||

| 11.1.1 | Historic Sampling Methods | 120 | ||||

| 11.1.2 | RC Drill Sampling | 120 | ||||

| 11.1.3 | Core Sampling | 120 | ||||

| 11.1.4 | Production Sampling | 121 | ||||

| 11.2 | Density Determinations | 121 | ||||

| 11.2.1 | Turquoise Ridge Underground | 121 | ||||

| 11.2.2 | Turquoise Ridge Surface | 122 | ||||

| 11.2.3 | Vista Underground | 122 | ||||

| 11.3 | Analytical and Test Laboratories | 122 | ||||

| 11.4 | Sample Preparation | 123 | ||||

| March 15, 2024 |

Page v |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 11.5 | Analysis | 123 | ||||

| 11.6 | Quality Assurance and Quality Control | 125 | ||||

| 11.6.1 | Analytical Procedures | 125 | ||||

| 11.6.2 | Analytical Monitoring | 126 | ||||

| 11.7 | Databases | 128 | ||||

| 11.8 | Sample Security | 129 | ||||

| 11.9 | Sample Storage | 129 | ||||

| 11.10 | Comments on Sample Preparation, Analyses, and Security | 129 | ||||

| 12 |

Data Verification | 130 | ||||

| 12.1 | Summary | 130 | ||||

| 12.2 | External Reviews and Audits | 130 | ||||

| 12.3 | Internal Reviews and Audits | 130 | ||||

| 12.4 | Comments on Data Verification | 131 | ||||

| 13 |

Mineral Processing and Metallurgical Testing | 132 | ||||

| 13.1 | Summary | 132 | ||||

| 13.2 | Metallurgical Testwork | 133 | ||||

| 13.2.1 | Variability of Preg-robbing in Turquoise Ridge Ores | 133 | ||||

| 13.2.2 | Turquoise Ridge Underground | 134 | ||||

| 13.2.3 | Vista Underground | 139 | ||||

| 13.2.4 | Turquoise Ridge Mega Pit Cutback | 139 | ||||

| 13.2.5 | Stockpiles | 142 | ||||

| 13.3 | Metallurgical Variability | 143 | ||||

| 13.4 | Recovery Forecasts | 143 | ||||

| 13.4.1 | Juniper Mill | 144 | ||||

| 13.4.2 | Sage Mill | 144 | ||||

| 13.5 | Blending | 145 | ||||

| 13.6 | Deleterious Elements | 148 | ||||

| 14 |

Mineral Resource Estimates | 149 | ||||

| 14.1 | Summary | 149 | ||||

| 14.2 | Turquoise Ridge Underground | 152 | ||||

| 14.2.1 | Introduction | 152 | ||||

| 14.2.2 | Geological Modelling and Domaining | 152 | ||||

| March 15, 2024 |

Page vi |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

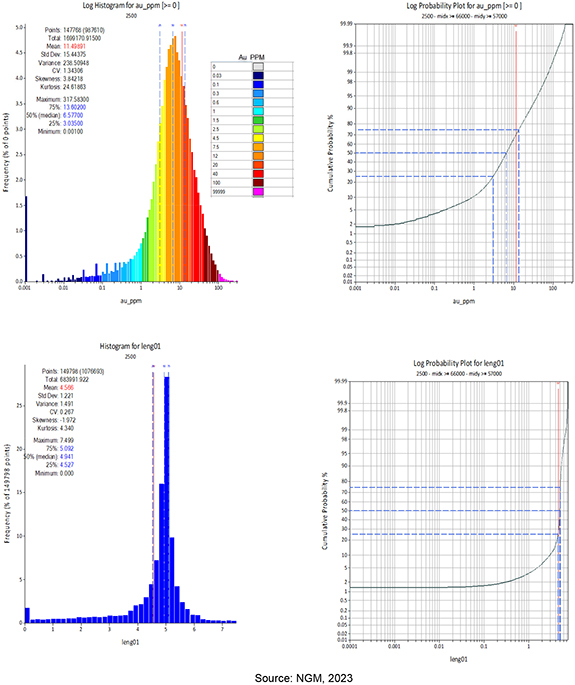

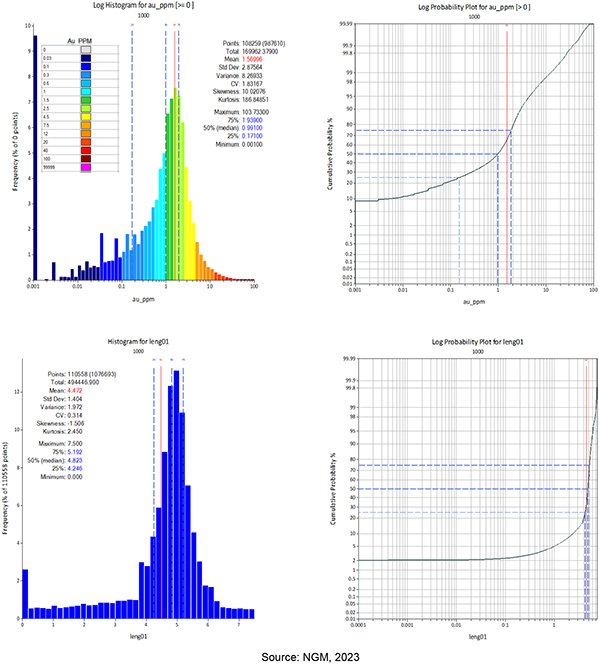

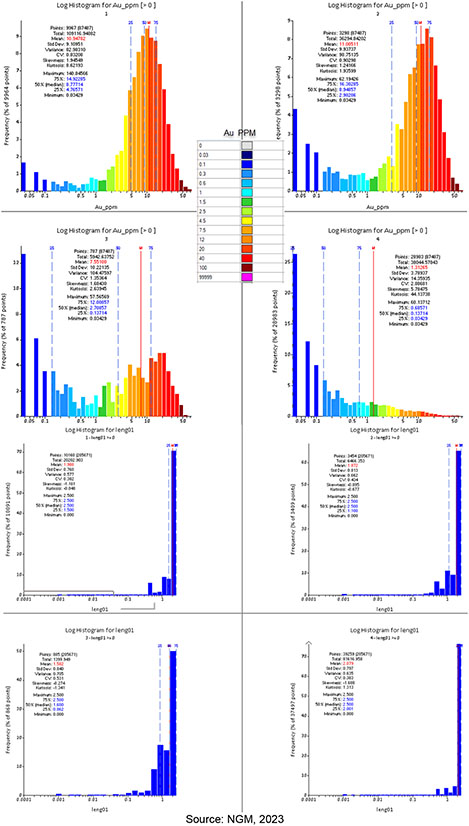

| 14.2.3 | Exploratory Data Analysis | 154 | ||||

| 14.2.4 | Composites | 155 | ||||

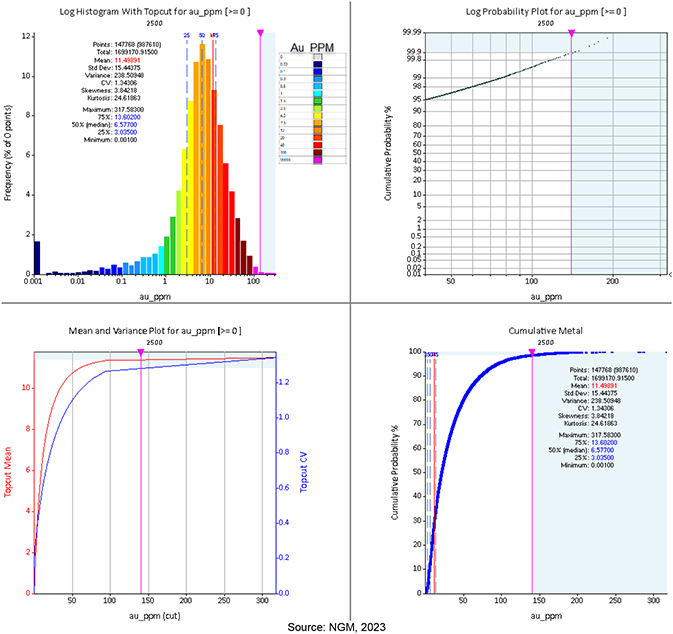

| 14.2.5 | Grade Capping/Outlier Restriction | 157 | ||||

| 14.2.6 | Density Assignment | 160 | ||||

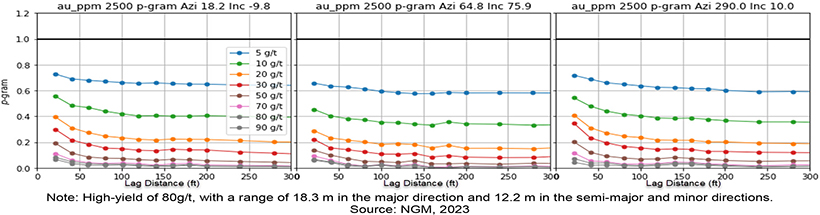

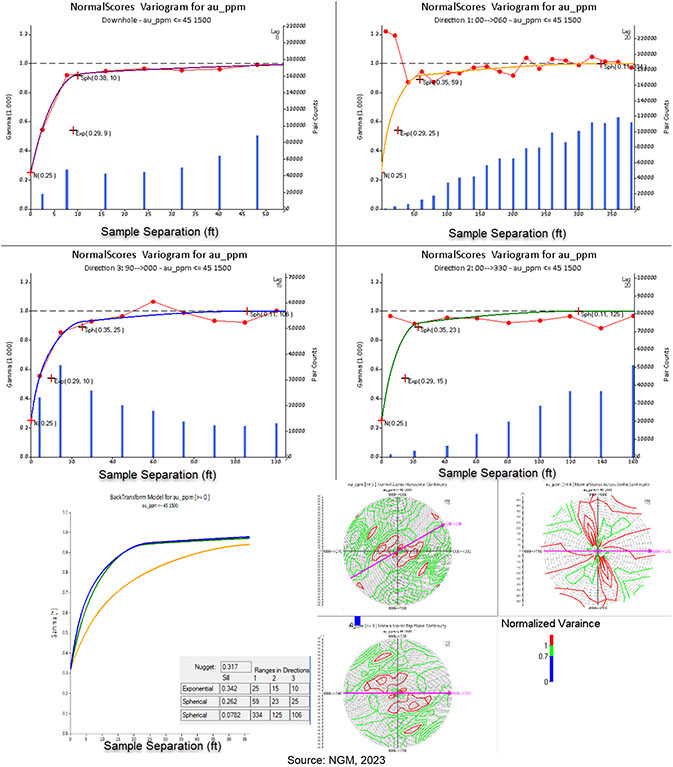

| 14.2.7 | Variography | 160 | ||||

| 14.2.8 | Estimation/Interpolation Methods | 163 | ||||

| 14.2.9 | Block Model Validation | 165 | ||||

| 14.2.10 | Confidence Classifications | 165 | ||||

| 14.2.11 | Reasonable Prospects of Eventual Economic Extraction | 166 | ||||

| 14.3 | Turquoise Ridge Surface | 167 | ||||

| 14.3.1 | Introduction | 167 | ||||

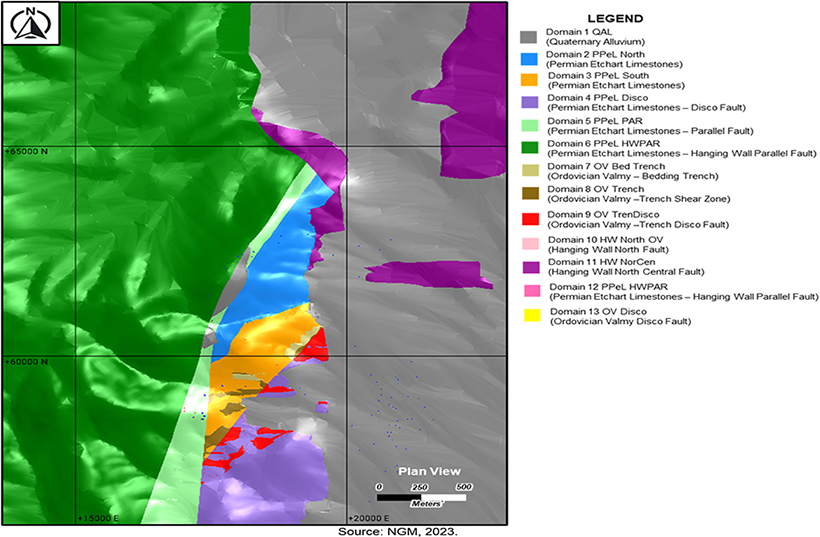

| 14.3.2 | Geological Modelling and Domaining | 168 | ||||

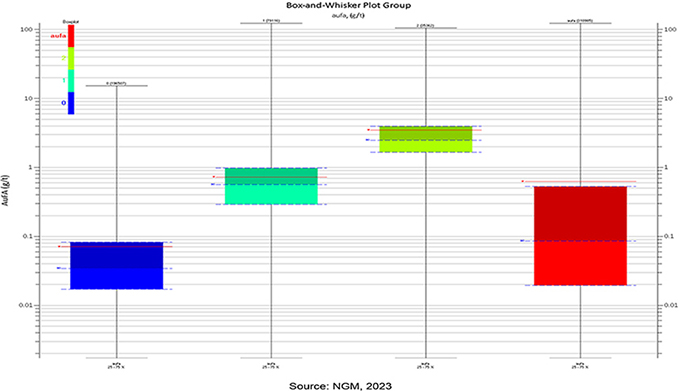

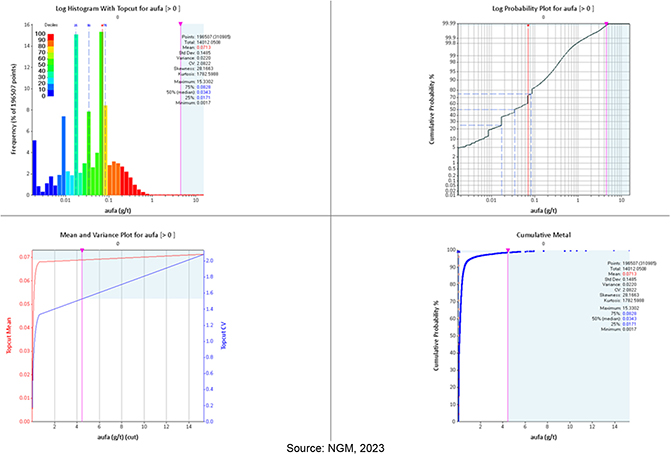

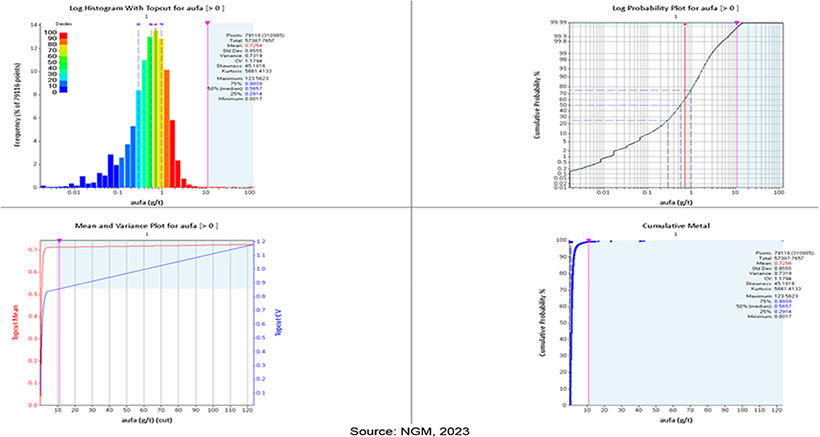

| 14.3.3 | Exploratory Data Analysis | 170 | ||||

| 14.3.4 | Composites | 176 | ||||

| 14.3.5 | Grade Capping/Outlier Restriction | 177 | ||||

| 14.3.6 | Density Assignment | 177 | ||||

| 14.3.7 | Variography | 178 | ||||

| 14.3.8 | Estimation/Interpolation Methods | 178 | ||||

| 14.3.9 | Block Model Validation | 178 | ||||

| 14.3.10 | Confidence Classifications | 179 | ||||

| 14.3.11 | Reasonable Prospects of Eventual Economic Extraction | 180 | ||||

| 14.4 | Vista Underground | 181 | ||||

| 14.4.1 | Introduction | 181 | ||||

| 14.4.2 | Geological Modelling and Domains | 182 | ||||

| 14.4.3 | Exploratory Data Analysis | 184 | ||||

| 14.4.4 | Composites | 184 | ||||

| 14.4.5 | Grade Capping/Outlier Restriction | 186 | ||||

| 14.4.6 | Density Assignment | 186 | ||||

| 14.4.7 | Variography | 186 | ||||

| 14.4.8 | Estimation/Interpolation Methods | 187 | ||||

| 14.4.9 | Block Model Validation | 188 | ||||

| 14.4.10 | Confidence Classifications | 189 | ||||

| 14.4.11 | Reasonable Prospects of Eventual Economic Extraction | 189 | ||||

| March 15, 2024 |

Page vii |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 14.5 | Stockpiles | 190 | ||||

| 14.6 | Royalties | 190 | ||||

| 14.7 | Mineral Resource Statement | 191 | ||||

| 14.8 | Comments on Mineral Resource Estimates | 194 | ||||

| 14.8.1 | External Mineral Resource Audits | 194 | ||||

| 14.8.2 | Relative Accuracy/Confidence of the 2023 Mineral Resource Estimate | 194 | ||||

| 15 |

Mineral Reserve Estimates | 195 | ||||

| 15.1 | Summary | 195 | ||||

| 15.2 | Metal Price Assumptions | 198 | ||||

| 15.3 | Revenue Calculation | 198 | ||||

| 15.4 | Turquoise Ridge Underground | 198 | ||||

| 15.4.1 | Estimation Procedure | 198 | ||||

| 15.4.2 | Dilution and Mining Recovery | 200 | ||||

| 15.4.3 | Processing Recovery | 200 | ||||

| 15.4.4 | Net Value Calculation | 200 | ||||

| 15.4.5 | Sensitivities | 201 | ||||

| 15.5 | Turquoise Ridge Surface | 201 | ||||

| 15.5.1 | Estimation Procedure | 201 | ||||

| 15.5.2 | Dilution and Mining Recovery | 206 | ||||

| 15.5.3 | Net Value Calculation | 206 | ||||

| 15.5.4 | Processing Recovery | 206 | ||||

| 15.5.5 | Royalties | 207 | ||||

| 15.5.6 | Sensitivities | 207 | ||||

| 15.6 | Vista Underground | 207 | ||||

| 15.6.1 | Estimation Procedure | 207 | ||||

| 15.6.2 | Dilution and Mining Recovery | 208 | ||||

| 15.6.3 | Processing Recovery | 208 | ||||

| 15.6.4 | Net Value Calculation | 209 | ||||

| 15.6.5 | Sensitivities | 209 | ||||

| 15.7 | Stockpiles | 210 | ||||

| 15.7.1 | Estimation Procedure | 210 | ||||

| 15.7.2 | Net Value Calculation | 210 | ||||

| March 15, 2024 |

Page viii |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 15.8 | Mineral Reserve Statement | 210 | ||||

| 15.9 | Comments on Mineral Reserve Estimates | 213 | ||||

| 16 |

Mining Methods | 214 | ||||

| 16.1 | Summary | 214 | ||||

| 16.2 | Turquoise Ridge Underground | 214 | ||||

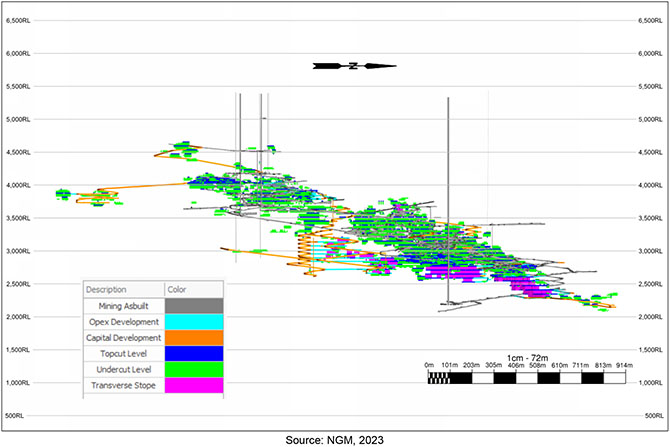

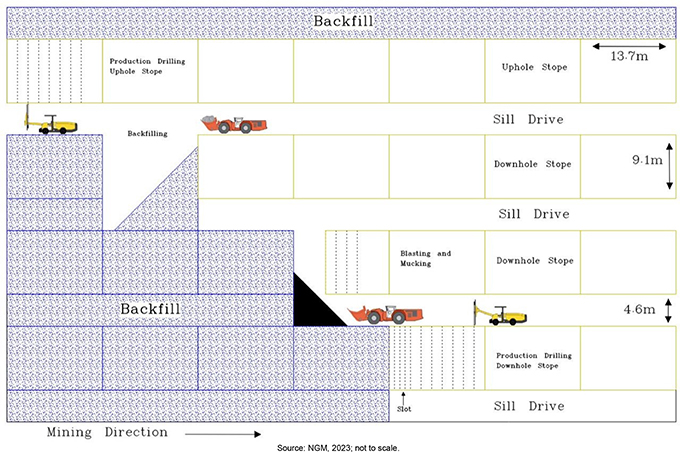

| 16.2.1 | Mining Method and Mine Design | 214 | ||||

| 16.2.2 | Geotechnical Considerations | 216 | ||||

| 16.2.3 | Ground Support | 218 | ||||

| 16.2.4 | Hydrological Considerations | 219 | ||||

| 16.2.5 | Mine Dewatering | 220 | ||||

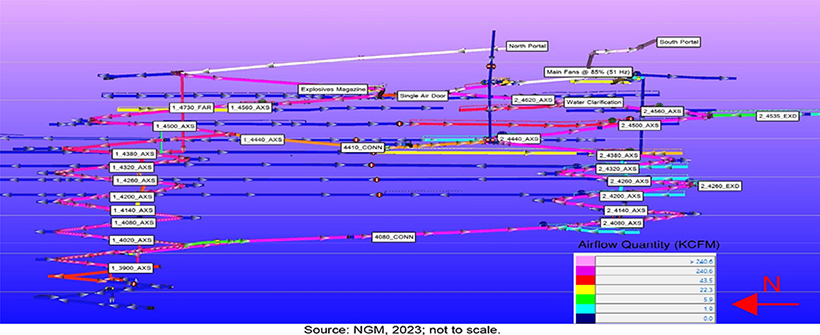

| 16.2.6 | Ventilation | 220 | ||||

| 16.2.7 | Electric Power | 221 | ||||

| 16.2.8 | Main Infrastructure Levels | 221 | ||||

| 16.2.9 | Material Handling | 222 | ||||

| 16.2.10 | Grade Control | 223 | ||||

| 16.2.11 | Backfill | 223 | ||||

| 16.2.12 | Blasting and Explosives | 224 | ||||

| 16.2.13 | Mining Equipment | 224 | ||||

| 16.2.14 | Production Rate | 225 | ||||

| 16.2.15 | Mine Schedule | 226 | ||||

| 16.3 | Turquoise Ridge Surface | 227 | ||||

| 16.3.1 | Mining Method | 227 | ||||

| 16.3.2 | Mine Design | 228 | ||||

| 16.3.3 | Geotechnical Considerations | 228 | ||||

| 16.3.4 | Hydrogeological Considerations | 230 | ||||

| 16.3.5 | Waste Rock Storage Facilities | 231 | ||||

| 16.3.6 | Stockpiles | 231 | ||||

| 16.3.7 | Grade Control | 231 | ||||

| 16.3.8 | Blasting and Explosives | 232 | ||||

| 16.3.9 | Mining Equipment | 232 | ||||

| 16.3.10 | Production Rate | 232 | ||||

| 16.3.11 | Mine Schedule | 233 | ||||

| 16.4 | Vista Underground | 234 | ||||

| March 15, 2024 |

Page ix |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

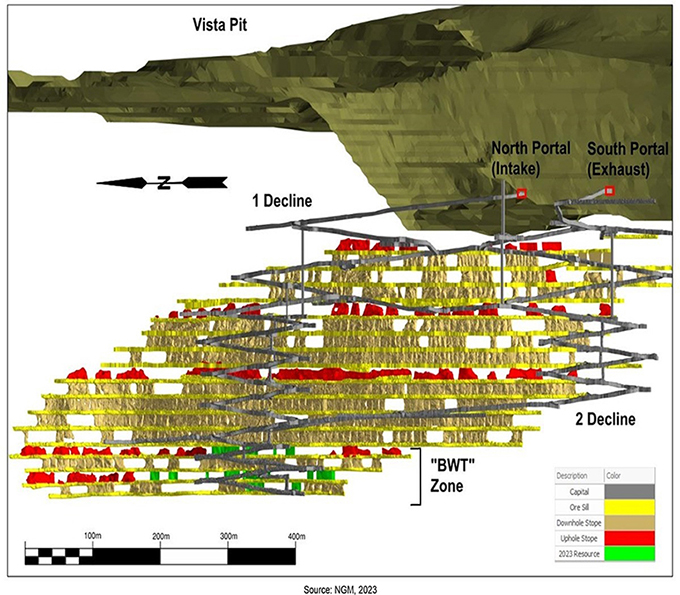

| 16.4.1 | Mining Method and Mine Design | 234 | ||||

| 16.4.2 | Geotechnical Considerations | 238 | ||||

| 16.4.3 | Hydrological Considerations | 239 | ||||

| 16.4.4 | Ventilation | 239 | ||||

| 16.4.5 | Material Handling | 240 | ||||

| 16.4.6 | Backfill | 240 | ||||

| 16.4.7 | Blasting and Explosives | 240 | ||||

| 16.4.8 | Grade Control | 240 | ||||

| 16.4.9 | Mining Equipment | 240 | ||||

| 16.4.10 | Production Rate | 241 | ||||

| 16.4.11 | Mine Schedule | 241 | ||||

| 16.5 | Life of Mine Production Schedule | 242 | ||||

| 16.6 | Comments on Mining Methods | 245 | ||||

| 17 |

Recovery Methods | 246 | ||||

| 17.1 | Summary | 246 | ||||

| 17.2 | Design Basis | 246 | ||||

| 17.3 | Flowsheet | 246 | ||||

| 17.4 | Plant Design | 248 | ||||

| 17.4.1 | Juniper Mill | 248 | ||||

| 17.4.2 | Sage Autoclave | 248 | ||||

| 17.4.3 | Heap Leach | 250 | ||||

| 17.5 | Comments on Recovery Methods | 250 | ||||

| 17.6 | Energy, Water, and Consumables Requirements | 251 | ||||

| 17.6.1 | Energy | 251 | ||||

| 17.6.2 | Water | 251 | ||||

| 17.6.3 | Consumables | 251 | ||||

| 17.7 | Comments on Recovery Methods | 252 | ||||

| 18 |

Project Infrastructure | 253 | ||||

| 18.1 | Summary | 253 | ||||

| 18.1.1 | Turquoise Ridge Underground and Getchell Infrastructure | 254 | ||||

| 18.1.2 | Turquoise Ridge Surface, Vista Underground, and Process Infrastructure | 256 | ||||

| 18.1.3 | Common Purpose Infrastructure | 259 | ||||

| March 15, 2024 |

Page x |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 18.1.4 | Planned Infrastructure and Facility Relocations | 259 | ||||

| 18.2 | Road and Logistics | 259 | ||||

| 18.3 | Stockpiles | 260 | ||||

| 18.4 | Heap Leach Pads | 260 | ||||

| 18.5 | Waste Rock Storage Facilities | 260 | ||||

| 18.6 | Tailings Storage Facilities | 261 | ||||

| 18.7 | Water Management | 262 | ||||

| 18.8 | Power and Electrical | 263 | ||||

| 19 |

Market Studies and Contracts | 264 | ||||

| 19.1 | Market Studies | 264 | ||||

| 19.2 | Commodity Price Assumptions | 264 | ||||

| 19.3 | Contracts | 265 | ||||

| 19.4 | Comment on Market Studies and Contracts | 265 | ||||

| 20 |

Environmental Studies, Permitting, and Social or Community Impact | 266 | ||||

| 20.1 | Environmental Studies | 266 | ||||

| 20.2 | Environmental Considerations | 266 | ||||

| 20.3 | Closure and Reclamation | 267 | ||||

| 20.4 | Permits | 267 | ||||

| 20.4.1 | Current Operations | 267 | ||||

| 20.4.2 | Mega Pit Layback | 268 | ||||

| 20.4.3 | Sage Tailings Facility | 269 | ||||

| 20.5 | Social Considerations | 269 | ||||

| 21 |

Capital and Operating Costs | 271 | ||||

| 21.1 | Summary | 271 | ||||

| 21.2 | Capital Cost Estimates | 271 | ||||

| 21.2.1 | Sustaining Capital | 271 | ||||

| 21.2.2 | Open Pit Stripping | 271 | ||||

| 21.2.3 | Underground Development | 271 | ||||

| 21.2.4 | Capital Drilling | 272 | ||||

| 21.2.5 | Expansion Capital | 272 | ||||

| 21.3 | Operating Cost Estimates | 272 | ||||

| 21.4 | Comments on Capital and Operating Costs | 273 | ||||

| March 15, 2024 |

Page xi |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 22 |

Economic Analysis | 274 | ||||

| 23 |

Adjacent Properties | 275 | ||||

| 24 |

Other Relevant Data and Information | 276 | ||||

| 25 |

Interpretation and Conclusions | 277 | ||||

| 25.1 | Mineral Tenure, Rights, Royalties and Agreements | 277 | ||||

| 25.2 | Geology and Mineral Resources | 277 | ||||

| 25.2.1 | Exploration, Drilling and Analytical Data Collection in Support of Mineral Resource Estimation | 278 | ||||

| 25.2.2 | Mineral Resource Estimates | 278 | ||||

| 25.3 | Mining and Mineral Reserves | 279 | ||||

| 25.3.1 | Mineral Reserve Estimate | 279 | ||||

| 25.3.2 | Mine Plan | 279 | ||||

| 25.4 | Mineral Processing | 280 | ||||

| 25.4.1 | Metallurgical Testwork | 281 | ||||

| 25.5 | Infrastructure | 281 | ||||

| 25.6 | Environmental, Permitting and Social Considerations | 281 | ||||

| 25.7 | Project Economics | 282 | ||||

| 25.7.1 | Capital Cost Estimates | 283 | ||||

| 25.7.2 | Operating Cost Estimates | 283 | ||||

| 25.8 | Risks | 283 | ||||

| 25.8.1 | Risk Analysis Definitions | 283 | ||||

| 25.8.2 | Risk Analysis Table | 284 | ||||

| 26 |

Recommendations | 286 | ||||

| 26.1 | Geology and Mineral Resources | 286 | ||||

| 26.2 | Mining and Mineral Reserves | 286 | ||||

| 26.3 | Mineral Processing | 287 | ||||

| 26.4 | Infrastructure | 287 | ||||

| 26.5 | Environment, Permitting, and Social and Community | 287 | ||||

| 27 |

References | 289 | ||||

| 28 |

Date and Signature Page | 291 | ||||

| 29 |

Certificates of Qualified Persons | 293 | ||||

| 29.1 | Craig Fiddes | 293 | ||||

| March 15, 2024 |

Page xii |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 29.2 | John Langhans | 295 | ||||

| 29.3 | Paul Schmiesing | 297 | ||||

| 29.4 | Joseph Becker | 299 | ||||

| 29.5 | Timothy Webber | 301 | ||||

| 29.6 | Simon P. Bottoms | 303 | ||||

| March 15, 2024 |

Page xiii |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

List of Tables

| Table 1-1 |

Turquoise Ridge Mineral Resources Summary, 100% Basis, as of December 31, 2023 |

21 | ||||

| Table 1-2 |

Turquoise Ridge Mineral Reserves Summary, December 31, 2023 |

23 | ||||

| Table 2-1 |

QP Responsibilities |

39 | ||||

| Table 2-2 |

Table of Abbreviations |

42 | ||||

| Table 4-1 |

Plans of Operations Centroid Location Summary Table |

44 | ||||

| Table 4-2 |

Fee Properties |

64 | ||||

| Table 4-3 |

Agreements |

66 | ||||

| Table 6-1 |

Turquoise Ridge Complex Development History |

72 | ||||

| Table 6-2 |

Operations History |

74 | ||||

| Table 6-3 |

Summary of Gold Production |

75 | ||||

| Table 7-1 |

Local Structure |

83 | ||||

| Table 10-1 |

Turquoise Ridge Complex Drill Summary Table |

107 | ||||

| Table 10-2 |

Turquoise Ridge Underground Drilling Supporting Mineral Resource Estimates |

109 | ||||

| Table 10-3 |

Turquoise Ridge Surface Drilling Supporting Mineral Resource Estimates |

109 | ||||

| Table 10-4 |

Vista Underground Drilling Supporting Mineral Resource Estimates |

109 | ||||

| Table 10-5 |

Cutoff Dates for Drilling Data Supporting Mineral Resource Estimates by Deposit |

110 | ||||

| Table 11-1 |

QA/QC Samples and Insertion Rates |

126 | ||||

| Table 13-1 |

Drill Hole Test Program BTAC Results |

135 | ||||

| Table 13-2 |

TRUG Monthly Composite BTAC vs Plant Results |

136 | ||||

| Table 13-3 |

Turquoise Ridge Surface Ore Control Matrix |

140 | ||||

| Table 13-4 |

Number of Tests Conducted per Metallurgical Type |

141 | ||||

| Table 13-5 |

Turquoise Ridge Surface Refractory Ore Classification |

146 | ||||

| Table 13-6 |

Autoclave Feed Parameter Ranges |

146 | ||||

| Table 13-7 |

Typical Sage Mill Constraints |

147 | ||||

| Table 14-1 |

Turquoise Ridge Mineral Resources Summary, 100% Basis, as of December 31, 2023 |

151 | ||||

| Table 14-2 |

Grade Capping Analysis for Turquoise Ridge Underground |

158 | ||||

| Table 14-3 |

OK Estimation Parameters |

164 | ||||

| Table 14-4 |

Turquoise Ridge Underground Model Mineral Resource Classification Distances |

165 | ||||

| Table 14-5 |

Resources Cut-off Grade Inputs |

167 | ||||

| Table 14-6 |

Mega Leapfrog Grade Shell Cutoffs |

168 | ||||

| Table 14-7 |

Vista Leapfrog Grade Shell Cutoffs |

170 | ||||

| Table 14-8 |

Summary of Mega Modelled Densities |

177 | ||||

| Table 14-9 |

Summary of Vista Modelled Densities |

178 | ||||

| Table 14-10 |

Turquoise Ridge Surface Model Mineral Resource Classification Distances |

179 | ||||

| Table 14-11 |

Turquoise Ridge Surface Resource Cut-Off Grade Parameters |

181 | ||||

| Table 14-12 |

Grade Capping Analysis for Vista Underground |

186 | ||||

| Table 14-13 |

VUG Estimation Parameters |

188 | ||||

| Table 14-14 |

Input Considerations, Mineral Resources CoG, Vista Underground |

190 | ||||

| Table 14-15 |

Turquoise Ridge Mineral Resource Statement, 100% Basis, December 31, 2023 |

192 | ||||

| Table 14-16 |

Turquoise Ridge Mineral Resource Statement, Barrick Attributable Basis, December 31, 2023 |

193 |

| March 15, 2024 |

Page xiv |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| Table 15-1 |

Turquoise Ridge Mineral Reserves Summary, December 31, 2023 |

197 | ||||

| Table 15-2 |

TRUG Mining Dilution and Recovery Assumptions |

200 | ||||

| Table 15-3 |

Input Considerations, Mineral Reserve Net Value, Turquoise Ridge Underground |

201 | ||||

| Table 15-4 |

TRUG Reserves Sensitivity to Gold Price |

201 | ||||

| Table 15-5 |

Summary of Optimisation Input Parameters |

202 | ||||

| Table 15-6 |

Mega Pit Reserves Sensitivity to Gold Price |

207 | ||||

| Table 15-7 |

Input Considerations, Mineral Reserve Net Value, Vista Underground |

209 | ||||

| Table 15-8 |

VUG Reserves Sensitivity to Gold Price |

209 | ||||

| Table 15-9 |

Input Considerations, Mineral Reserve Net Value, Stockpiles |

210 | ||||

| Table 15-10 |

Turquoise Ridge Mineral Reserves Statement, December 31, 2023 |

211 | ||||

| Table 16-1 |

Typical Geotechnical Design Assumptions |

219 | ||||

| Table 16-2 |

Turquoise Ridge Underground Equipment List |

225 | ||||

| Table 16-3 |

Turquoise Ridge Underground LOM Production Schedule Summary |

226 | ||||

| Table 16-4 |

Historical Inter-ramp Slope Angles By Domain |

229 | ||||

| Table 16-5 |

Turquoise Ridge Surface LOM Equipment Requirements |

233 | ||||

| Table 16-6 |

Turquoise Ridge Surface LOM Production Schedule Summary |

234 | ||||

| Table 16-7 |

VUG Stope Design Parameters |

238 | ||||

| Table 16-8 |

Vista Underground Equipment List |

241 | ||||

| Table 16-9 |

Vista Underground LOM Production Schedule Summary |

241 | ||||

| Table 16-10 |

Consolidated LOM Mining Schedule |

243 | ||||

| Table 16-11 |

LOM Processing Schedule |

244 | ||||

| Table 17-1 |

Major Process Equipment, Juniper Mill |

248 | ||||

| Table 17-2 |

Major Process Equipment, Sage Autoclave |

249 | ||||

| Table 17-3 |

Major Process Equipment, Heap Leach Facilities |

250 | ||||

| Table 21-1 |

Capital Cost Summary |

271 | ||||

| Table 21-2 |

LOM Operating Costs Summary |

272 | ||||

| Table 25-1 |

Turquoise Ridge Risk Analysis |

285 |

| March 15, 2024 |

Page xv |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

List of Figures

| Figure 2-1 |

Project Location Map |

37 | ||

| Figure 4-1 |

NGM Area of Interest |

48 | ||

| Figure 4-2 |

PoO Layout Plan (Operations), 2023 |

50 | ||

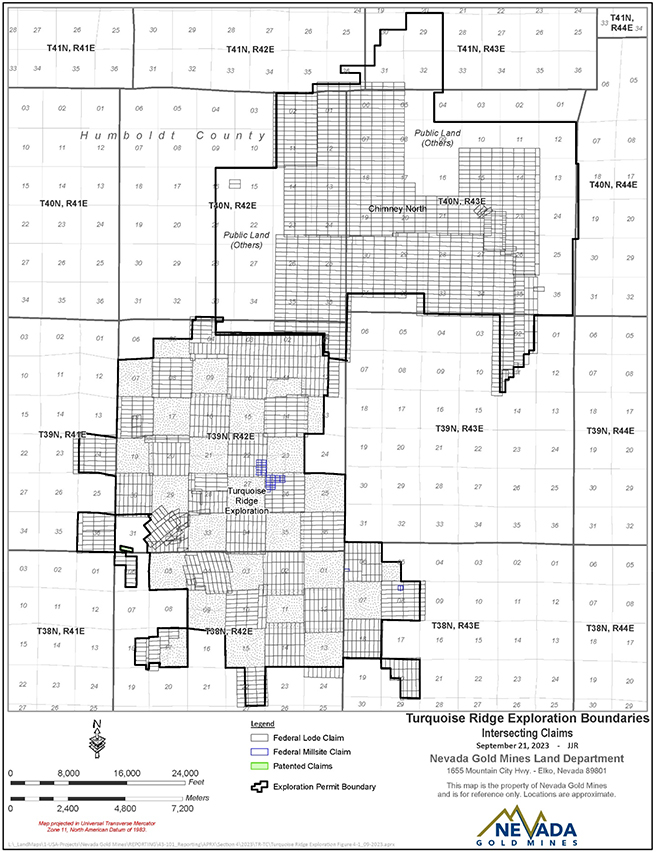

| Figure 4-3 |

PoO Layout Plan (Exploration), 2023 |

51 | ||

| Figure 4-4 |

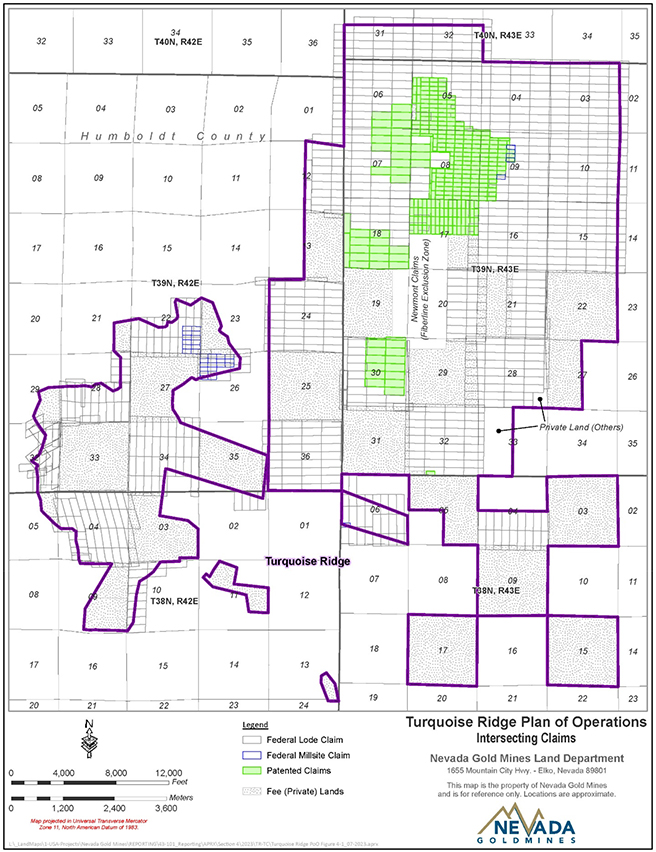

Operations PoO Claims Locations, 2023; Sheet 1 of 4 |

52 | ||

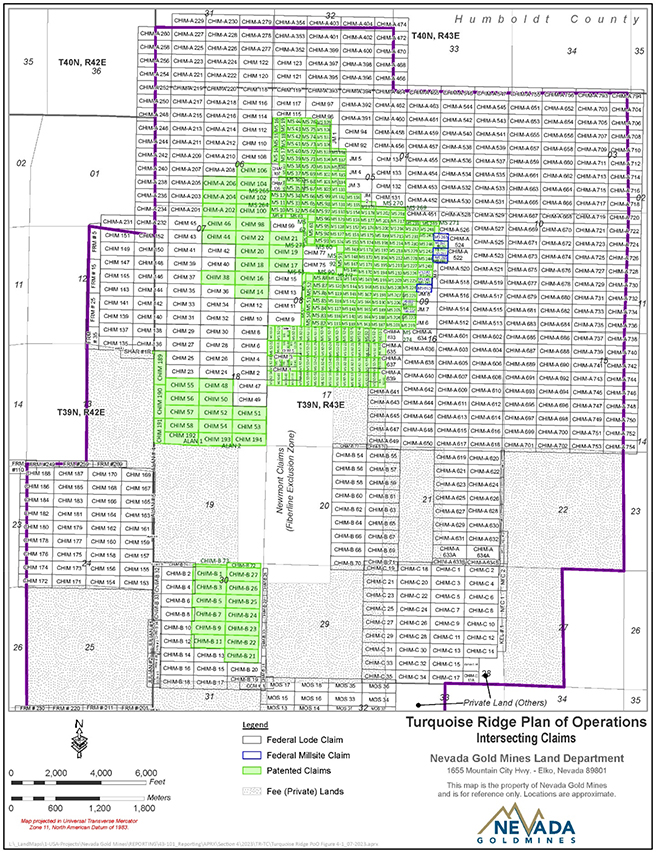

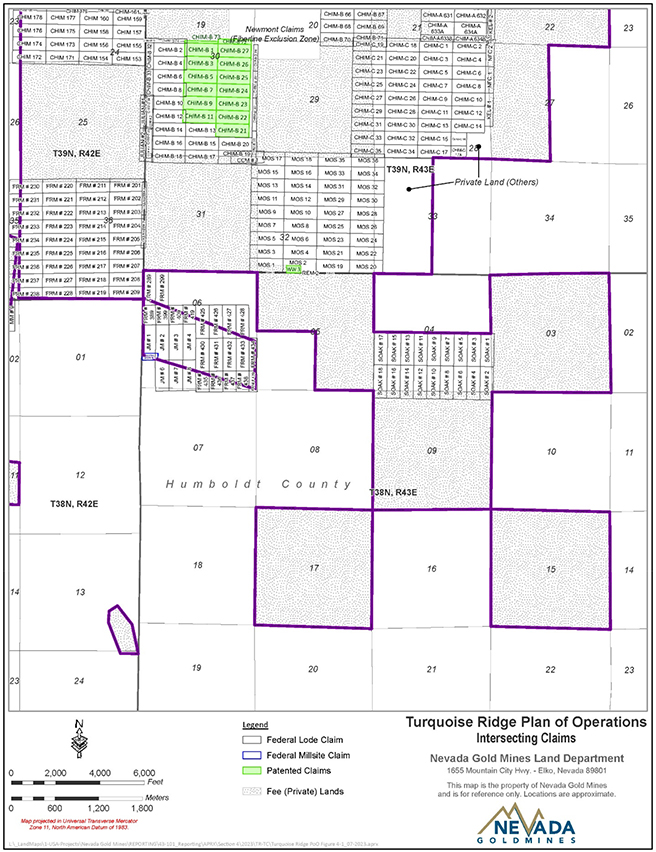

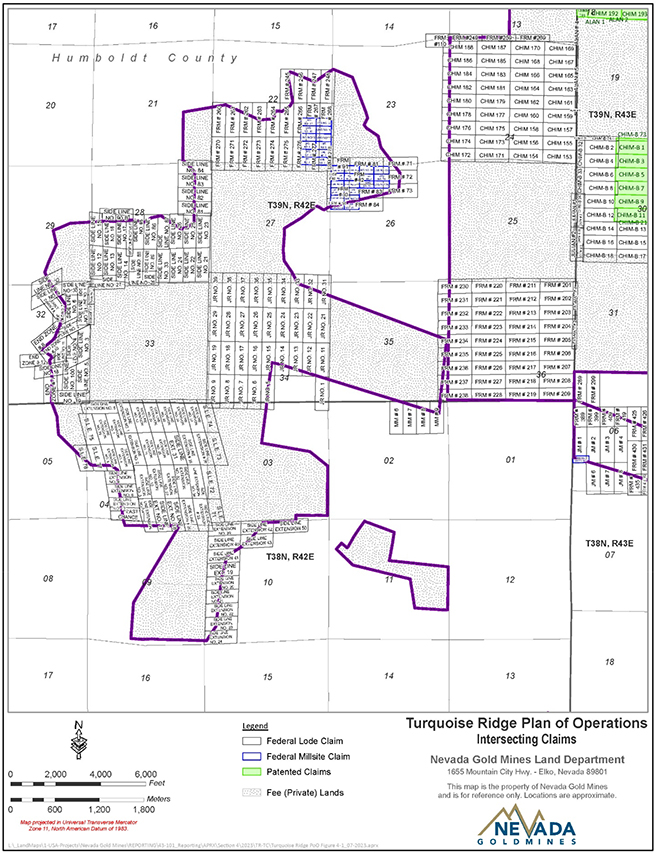

| Figure 4-5 |

Operations PoO Claims Locations; 2023, Sheet 2 of 4 |

53 | ||

| Figure 4-6 |

Operations PoO Claims Locations, 2023; Sheet 3 of 4 |

54 | ||

| Figure 4-7 |

Operations PoO Claims Locations, 2023; Sheet 4 of 4 |

55 | ||

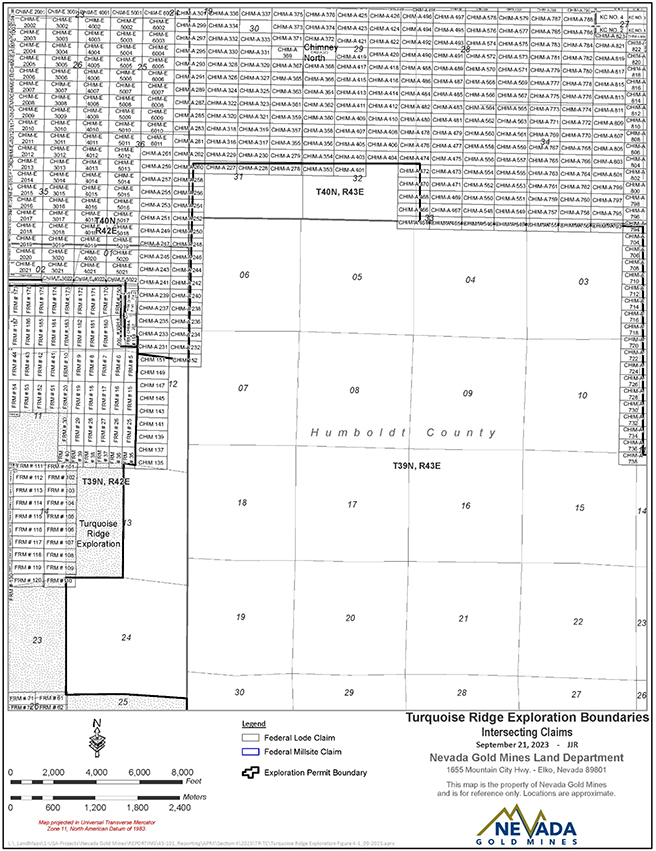

| Figure 4-8 |

Exploration PoO Claims Locations, Sheet 1 of 8 |

56 | ||

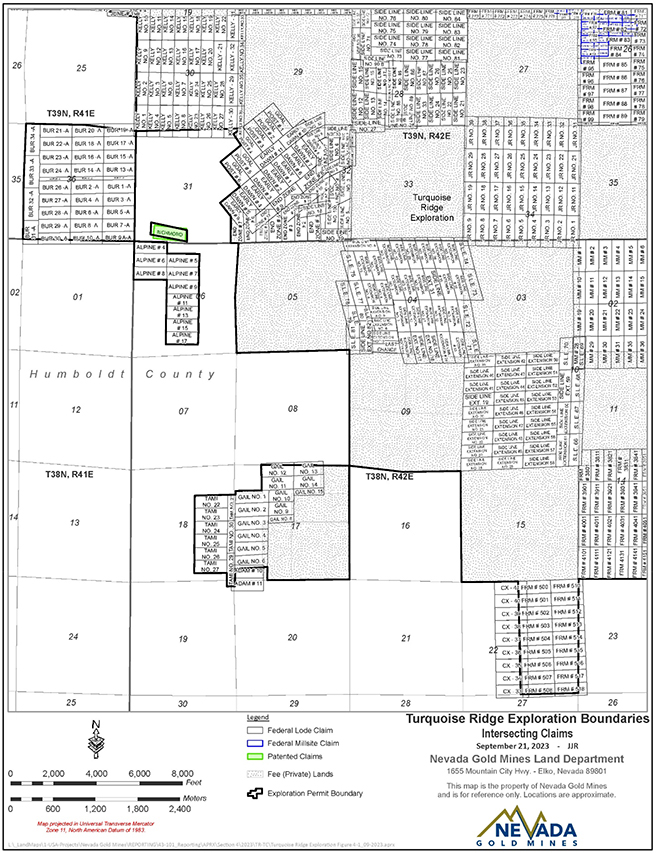

| Figure 4-9 |

Exploration PoO Claims Locations, Sheet 2 of 8 |

57 | ||

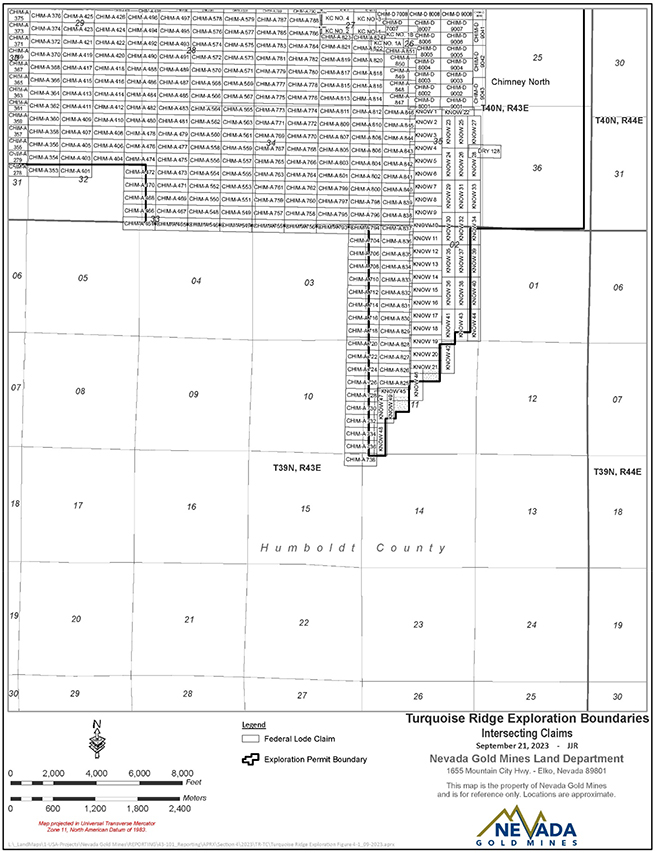

| Figure 4-10 |

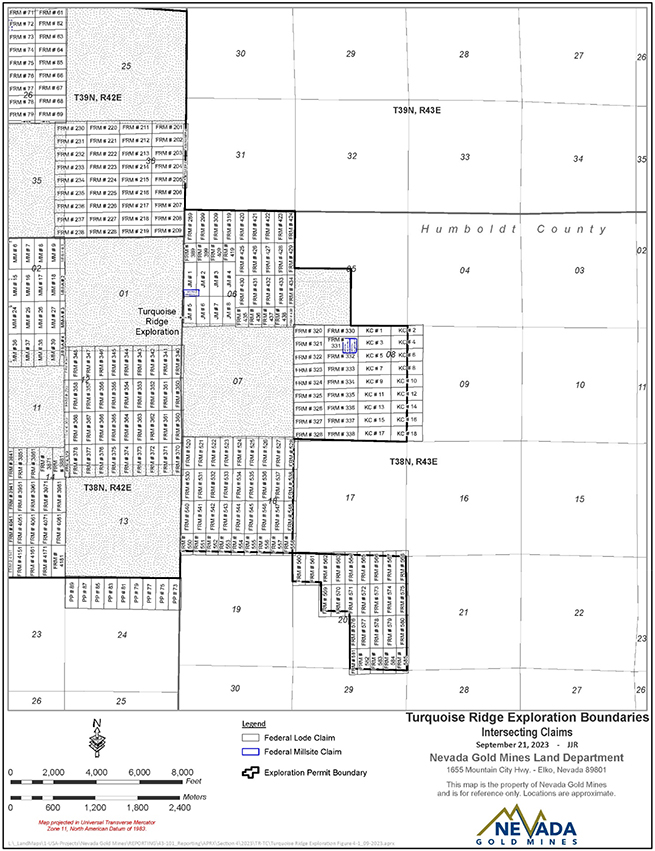

Exploration PoO Claims Locations, Sheet 3 of 8 |

58 | ||

| Figure 4-11 |

Exploration PoO Claims Locations, Sheet 4 of 8 |

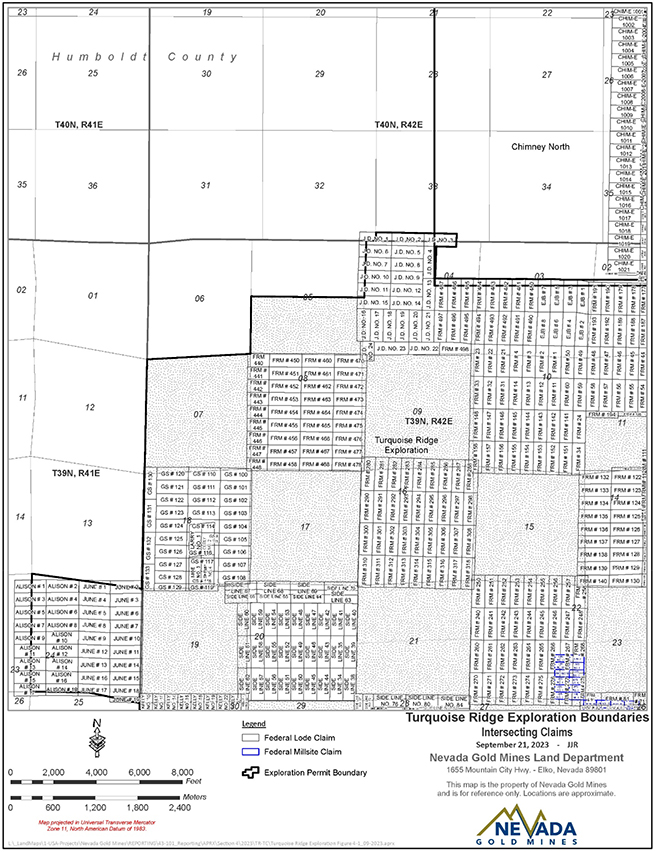

59 | ||

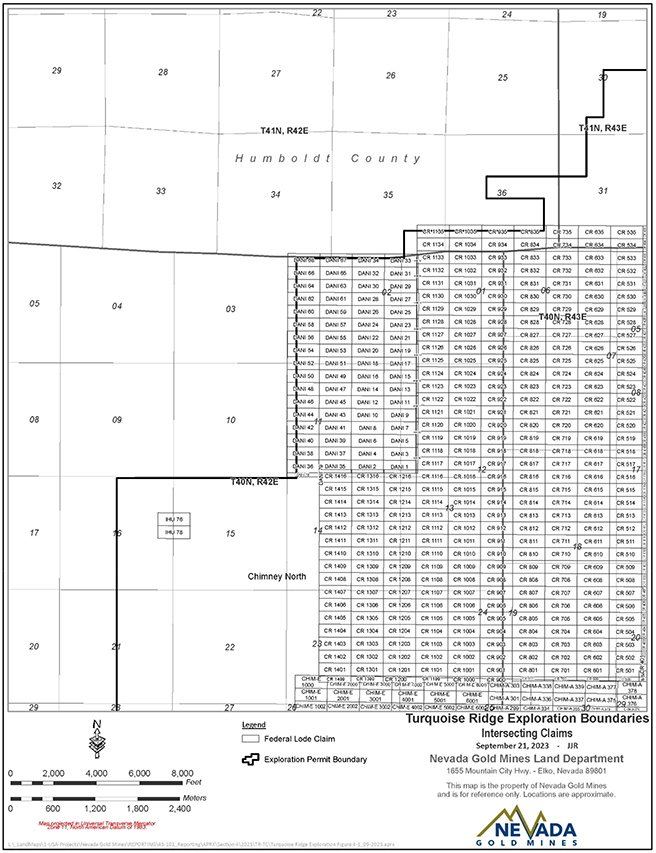

| Figure 4-12 |

Exploration PoO Claims Locations, Sheet 5 of 8 |

60 | ||

| Figure 4-13 |

Exploration PoO Claims Locations, Sheet 6 of 8 |

61 | ||

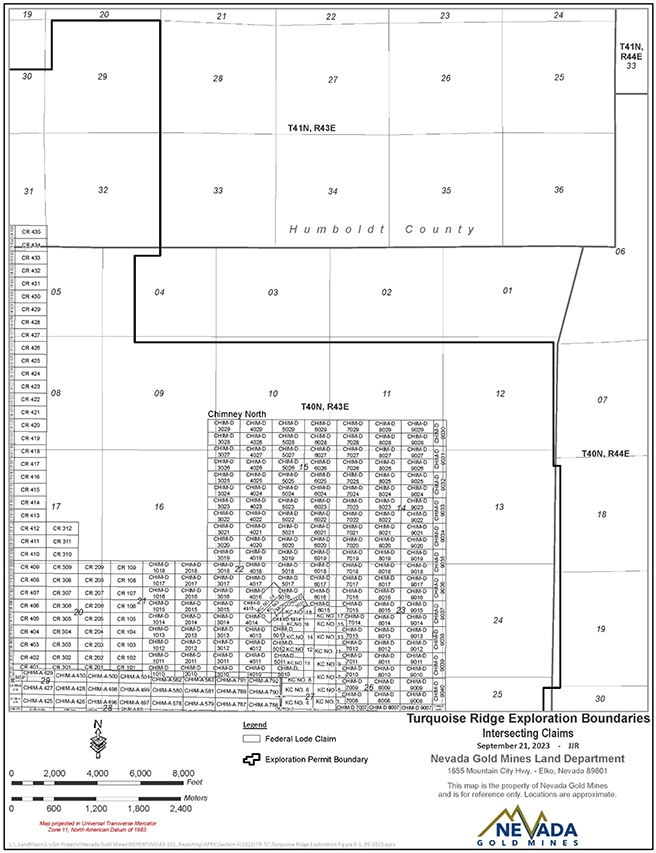

| Figure 4-14 |

Exploration PoO Claims Locations, Sheet 7 of 8 |

62 | ||

| Figure 4-15 |

Exploration PoO Claims Locations, Sheet 8 of 8 |

63 | ||

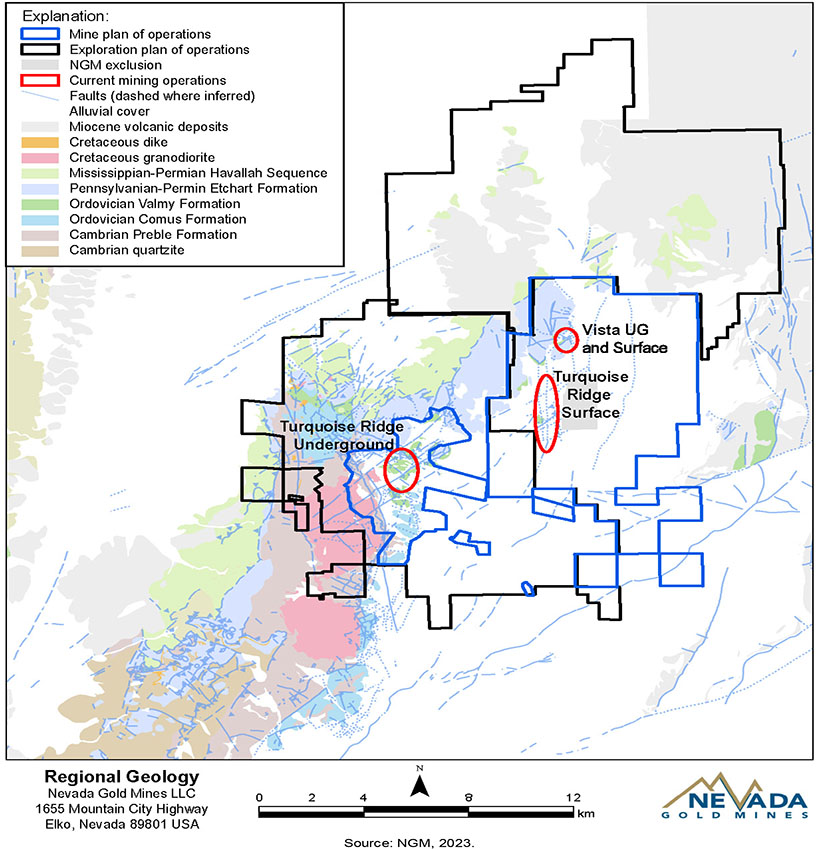

| Figure 7-1 |

Regional Geology Map |

78 | ||

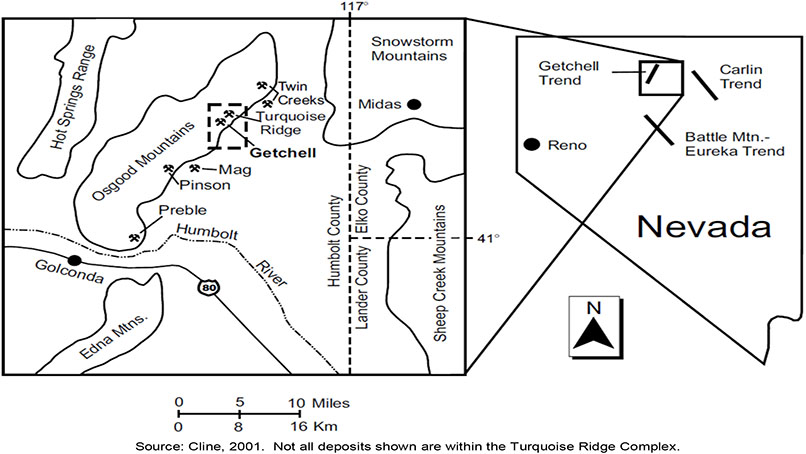

| Figure 7-2 |

Getchell Trend Deposits |

79 | ||

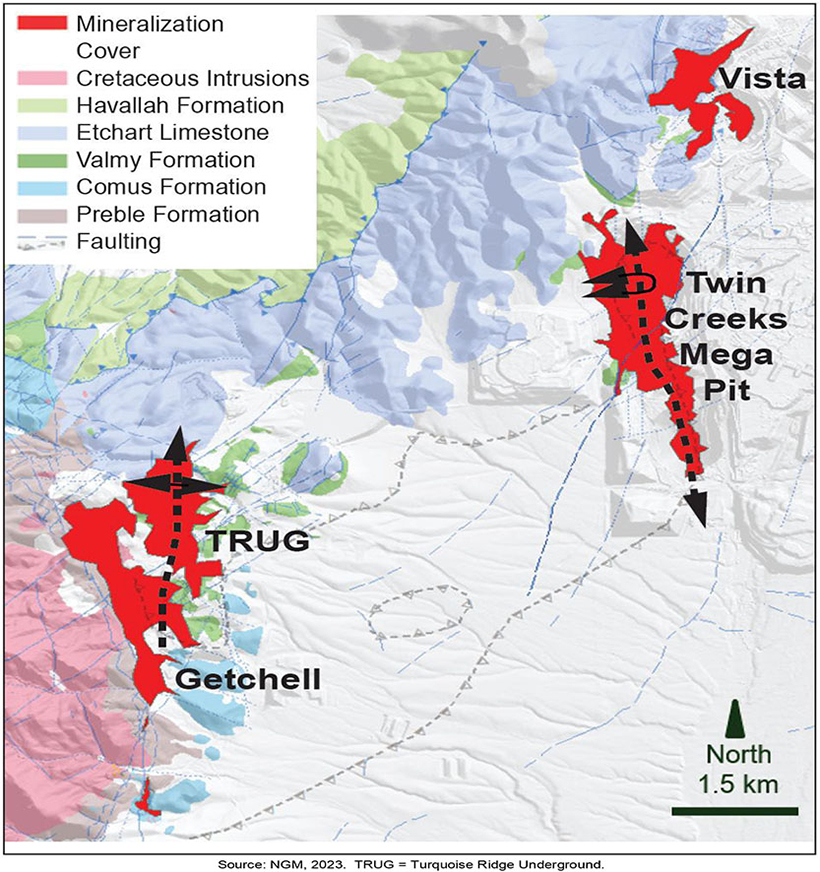

| Figure 7-3 |

Simplified Geology Plan, Turquoise Ridge and Vista Areas |

80 | ||

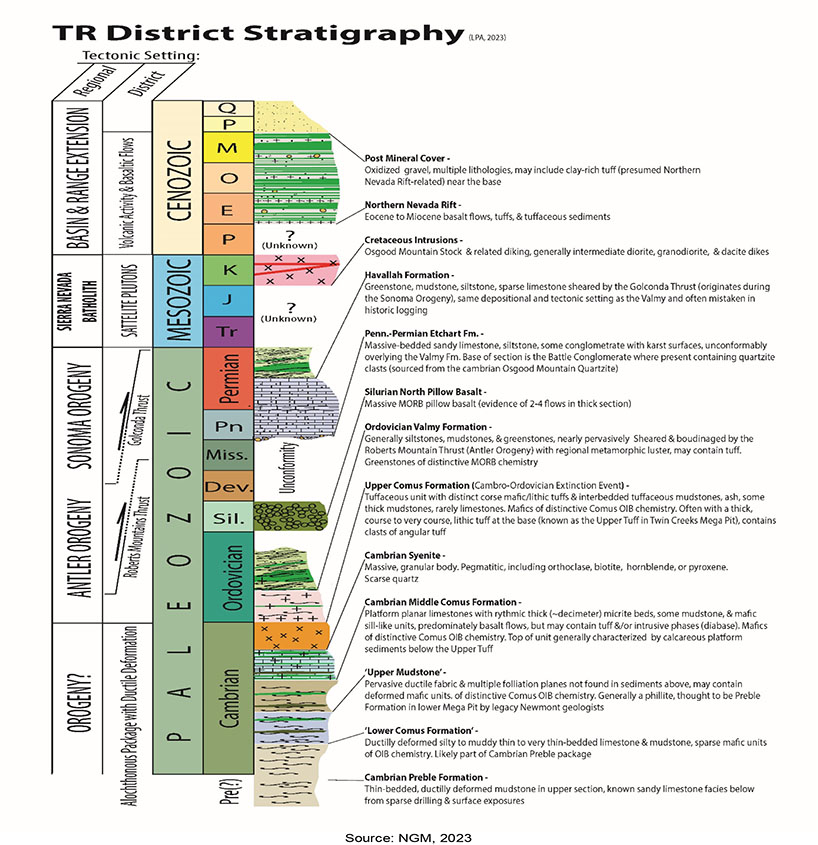

| Figure 7-4: |

Stratigraphic Column |

81 | ||

| Figure 7-5 |

Turquoise Ridge Underground Geological Map |

87 | ||

| Figure 7-6 |

Example Cross-Section, Turquoise Ridge Underground, Showing Drill Intercepts |

88 | ||

| Figure 7-7 |

Example Cross-Section, Turquoise Ridge Underground, Showing Grade Shells |

89 | ||

| Figure 7-8 |

Geological Map, Turquoise Ridge Surface (Mega Pit) |

92 | ||

| Figure 7-9 |

Example Long Section, Turquoise Ridge Surface (Mega Pit), Showing Drill Intercepts |

93 | ||

| Figure 7-10 |

Example Long Section, Turquoise Ridge Surface (Mega Pit), Showing Grade Shells |

94 | ||

| Figure 7-11 |

Geological Map, Turquoise Ridge Surface (Vista 8 Pit) |

95 | ||

| Figure 7-12 |

Example Long Section, Turquoise Ridge Surface (Vista 8 Pit) |

96 | ||

| Figure 7-13 |

Geological Map, Vista Underground |

98 | ||

| Figure 7-14 |

Geological Map, Vista Underground Showing Location of Figure 7-15 |

99 | ||

| Figure 7-15 |

Example Cross Section, Vista Underground |

100 | ||

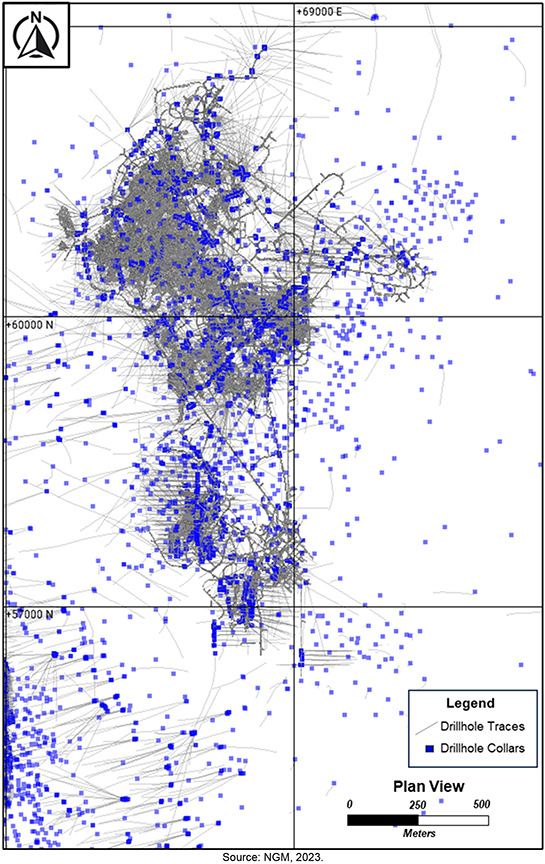

| Figure 10-1 |

Project Drill Collar Location Plan |

108 | ||

| Figure 10-2 |

Drill Collar Location Map Turquoise Ridge Underground Drilling Supporting Mineral Resource Estimates |

111 | ||

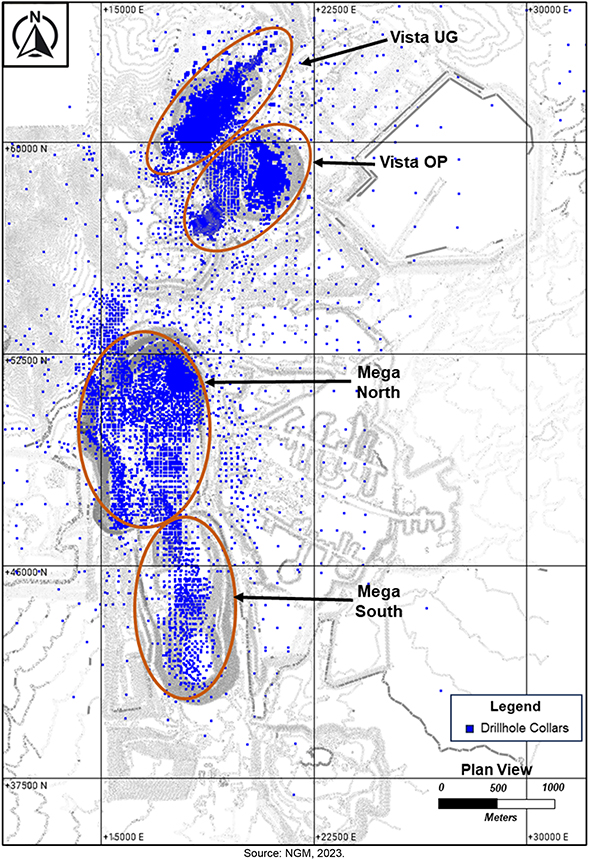

| Figure 10-3 |

Drill Collar Location Plan, Turquoise Ridge Surface and Vista Underground Drilling Supporting Mineral Resource Estimates |

112 | ||

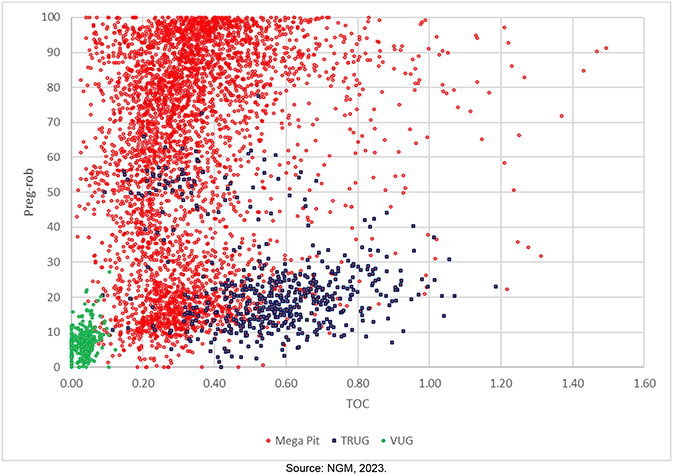

| Figure 13-1 |

Relationship Between Total Organic Carbon (TOC) and the Preg-Rob Index |

134 | ||

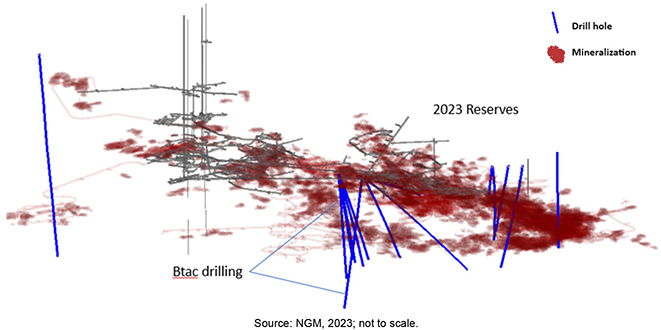

| Figure 13-2 |

View of the TRUG Showing Mineral Reserves and BTAC Drill Holes |

136 | ||

| Figure 13-3 |

TRUG Recovery as a Function of Organic Carbon and Gold Head Grade |

139 | ||

| Figure 13-4 |

Sage Autoclave Recovery Data by shift for the years of 2022 and 2023 |

145 | ||

| Figure 13-5 |

Stockpile Locations at ROM |

147 | ||

| Figure 14-1 |

Geologic and Resource Domains Cross Section, Turquoise Ridge Underground |

153 | ||

| Figure 14-2 |

Box and Whisker Plots for Gold Domain Grades |

154 |

| March 15, 2024 |

Page xvi |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| Figure 14-3 |

Histogram Showing Raw Composite Sample Length and Comparing Raw and Composited Data 2500 Domain |

156 | ||

| Figure 14-4 |

Histogram Showing Raw Composite Sample Length and Comparing Raw and Composited Data 1000 Domain |

157 | ||

| Figure 14-5 |

Domain 2500 Datamine Supervisor Top Cut Analysis for 2500 Domain (140g/t topcut) |

159 | ||

| Figure 14-6 |

2500 Domain r-Grams Used to Help Determine the 2500 Domain |

160 | ||

| Figure 14-7 |

Variograms for Au Domain 2500 |

161 | ||

| Figure 14-8 |

Variograms for the TCM Estimation |

162 | ||

| Figure 14-9 |

Plan Section Example of TRUG Classification with Drilling (Section width 30.5m) |

166 | ||

| Figure 14-10 |

Mega Domains and Main Mafic Map |

168 | ||

| Figure 14-11 |

Vista Domains Plan View |

169 | ||

| Figure 14-12 |

Box and Whisker Plots for Mega aufa, by aufa Grade Shell |

170 | ||

| Figure 14-13 |

aufa Composite Statistics Less Than 0.3 g/t Gold Shell |

171 | ||

| Figure 14-14 |

aufa Composite Statistics Between 0.3 and 1.5 g/t Gold Shell |

172 | ||

| Figure 14-15 |

aufa Composite Statistics Greater Than 1.5 g/t Gold Shell |

173 | ||

| Figure 14-16 |

Vista 6.1m (20 ft) Composites by Domain |

174 | ||

| Figure 14-17 |

Vista 6.1m Composites Inside 111_hwcen Domain, 17.1 g/t (0.50 opt) Cap |

175 | ||

| Figure 14-18 |

Histogram and Probability Plot of the Gold Composites |

176 | ||

| Figure 14-19 |

Vista Open Pit Composite Length Statistics |

177 | ||

| Figure 14-20 |

Mega Section 51000 N, Looking North, Cut 40 Classification Model |

180 | ||

| Figure 14-21 |

Vista Database |

182 | ||

| Figure 14-22 |

VUG OZ domains |

183 | ||

| Figure 14-23 |

Vista Underground Gold Histograms by Domain and Composite Length Histograms by Domain |

185 | ||

| Figure 14-24 |

Vista Underground High Grade Variogram |

187 | ||

| Figure 14-25 |

Mega Pit Royal Gold Royalty Boundary |

191 | ||

| Figure 15-1 |

Turquoise Ridge Underground Cross-Section Showing Mineral Reserves |

199 | ||

| Figure 15-2 |

Mineral Reserves Remaining in Vista Pit |

203 | ||

| Figure 15-3 |

Mineral Reserves Remaining in Mega Pit – Cut 40 |

204 | ||

| Figure 15-4 |

Mineral Reserves Remaining in Turquoise Ridge Open Pit |

205 | ||

| Figure 15-5 |

Vista Underground Cross-Section Showing Mineral Reserves |

208 | ||

| Figure 16-1 |

Underhand Drift and Fill with Cemented Aggregate Backfill Mining Method Schematic |

215 | ||

| Figure 16-2 |

Long-hole Stoping Mining Method Schematic |

216 | ||

| Figure 16-3 |

Turquoise Ridge Underground VentSIM Model Long Section |

221 | ||

| Figure 16-4 |

Turquoise Ridge Underground Shaft Location Schematic |

223 | ||

| Figure 16-5 |

Turquoise Underground Schedule 2024 |

227 | ||

| Figure 16-6 |

VUG LHSR Layout and Mining Activities |

235 | ||

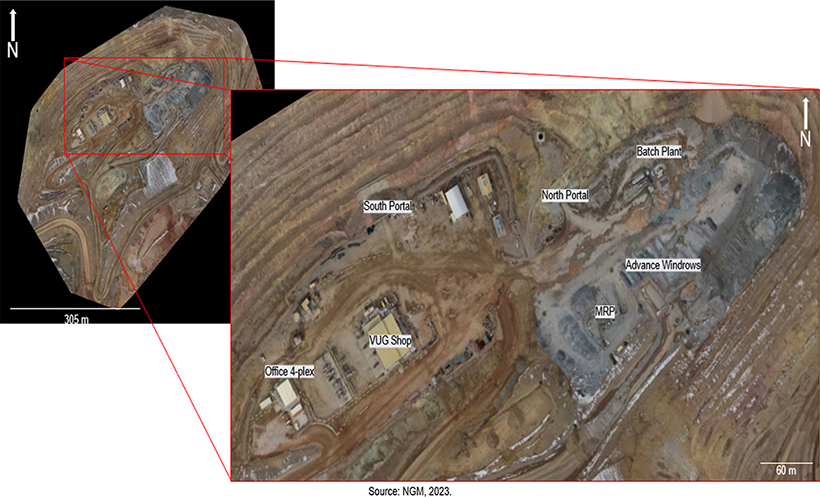

| Figure 16-7 |

VUG Surface Infrastructure Layout Plan |

236 | ||

| Figure 16-8 |

VUG Mine Layout Plan |

237 | ||

| Figure 16-9 |

Ventilation Design, VUG |

239 | ||

| Figure 17-1 |

Process Flow Sheet |

247 | ||

| Figure 18-1 |

Location Plan, Major Operations, Turquoise Ridge Complex |

253 | ||

| Figure 18-2 |

Location Plan, Key Infrastructure, Turquoise Ridge Underground and Getchell |

255 | ||

| Figure 18-3 |

Location Plan, Key Facilities, Turquoise Ridge Surface, Vista Underground, and Process Facilities |

258 |

| March 15, 2024 |

Page xvii |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 1 | Summary |

| 1.1 | Description, Location, and Ownership |

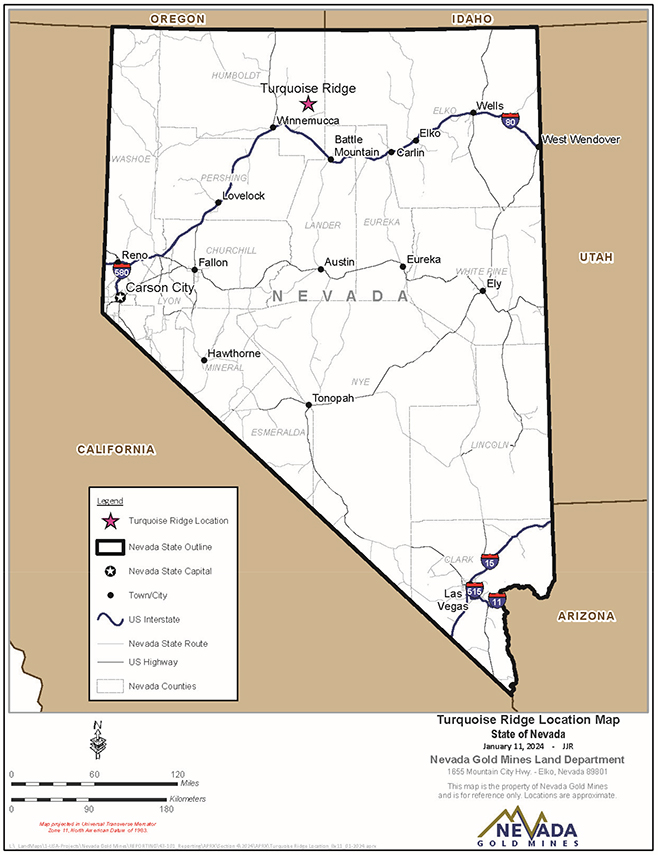

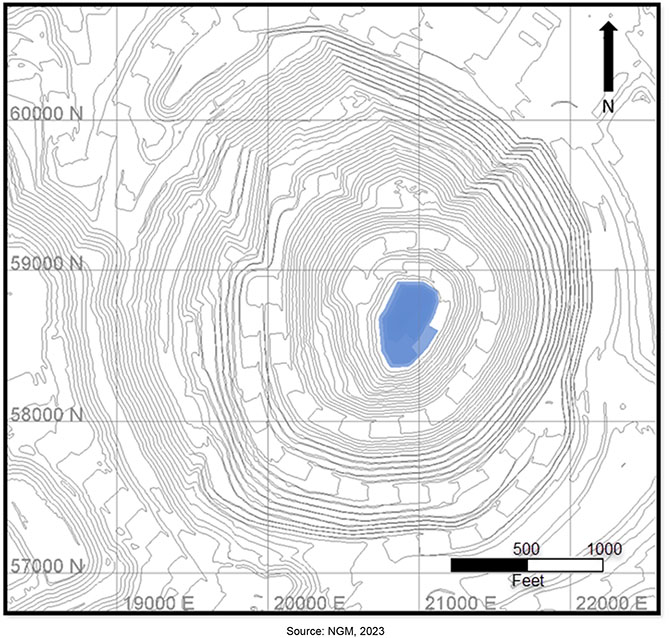

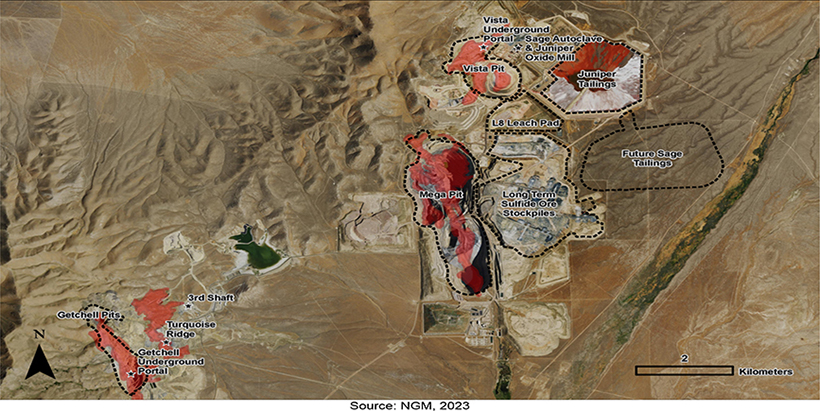

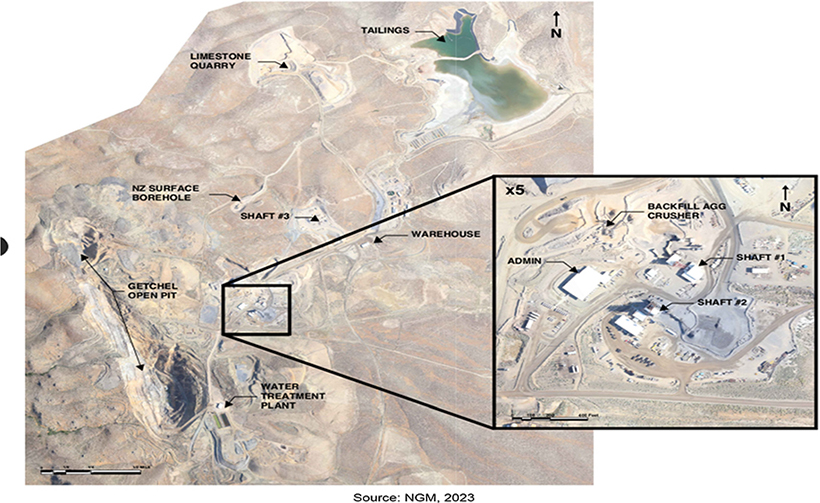

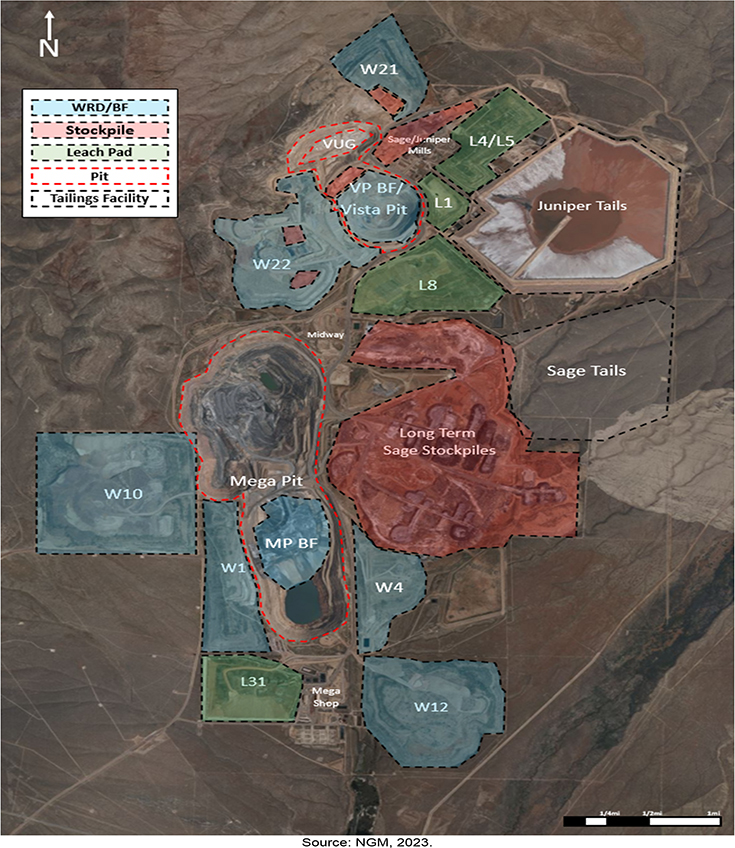

The Turquoise Ridge Complex (the “Project”) is a gold mining operation utilizing both underground and open pit mining methods. It is located in Humboldt County, approximately 64 km northeast of Winnemucca, Nevada, and 40 km northeast of the settlement of Golconda, Nevada.

Since 1883, there has been sporadic mining of various minerals and metals at the property.

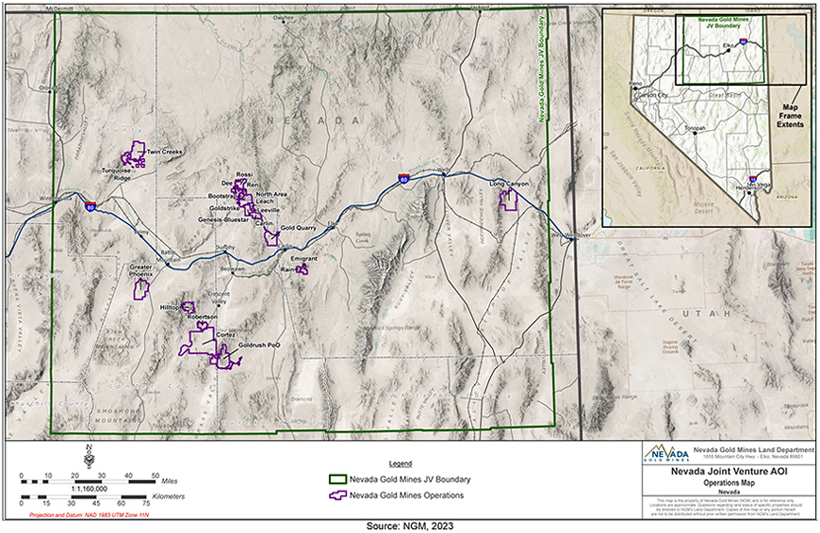

The Project is operated as a joint venture (JV) through Nevada Gold Mines (NGM) which was formed in 2019. Barrick is the JV operator and owns 61.5%, with Newmont owning the remaining 38.5% JV interest.

| 1.2 | Geology and Mineralization |

The Turquoise Ridge Complex deposits are considered examples of Carlin-type or carbonate-hosted disseminated gold–silver deposits. The Carlin deposit forms the type locality.

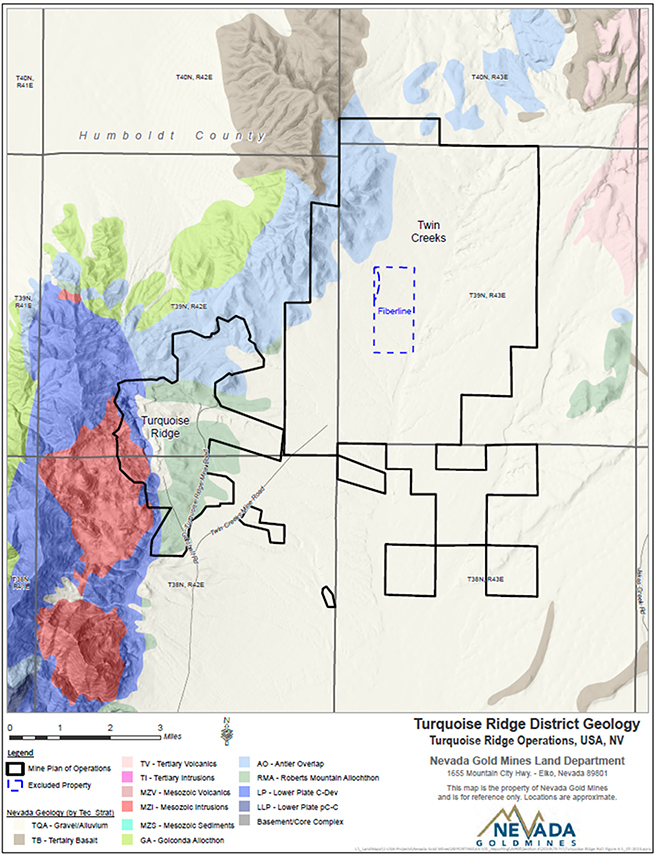

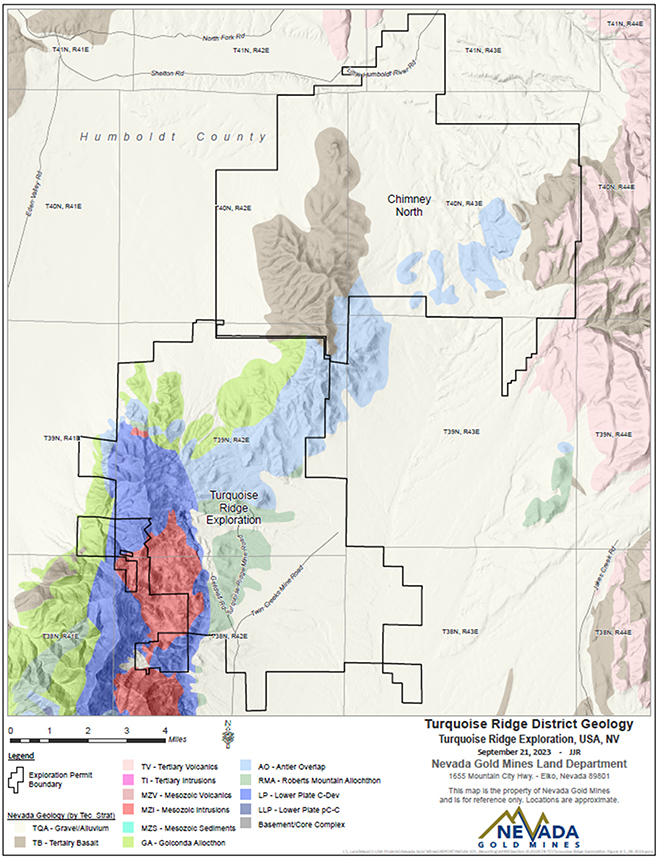

The Project is within the Basin and Range Province between the Osgood Mountains and the Dry Hills in Northern Nevada.

Preferred host lithologies for gold mineralization are the Comus Formation, followed by the Valmy and Etchart Formations.

Host rocks are most commonly thinly bedded silty or argillaceous carbonaceous limestone or dolomite, commonly with carbonaceous shale. Although less mineralized, non-carbonate siliciclastic and rare metavolcanic rocks can locally host gold that reaches economic grades. Felsic plutons and dikes may also be mineralized at some deposits. Deposits typically have a tabular shape, are strata-bound, localized at contacts between contrasting lithologies, but can also be discordant or breccia related.

Mineralization consists primarily of micrometer-sized gold in sulfide grains disseminated in zones of siliciclastic and decarbonated calcareous rocks and are commonly associated with jasperoids. Other associated minerals to mineralization include pyrite, arsenian pyrite, stibnite, realgar, orpiment, cinnabar, fluorite, barite, and rare thallium minerals. Gangue minerals typically comprise fine-grained quartz, barite, clay minerals, carbonaceous matter, and late-stage calcite veins.

| March 15, 2024 |

Page 18 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

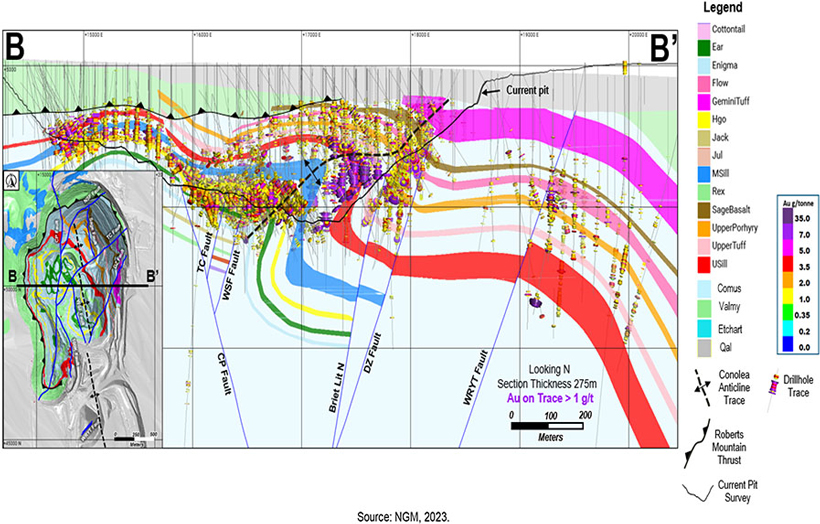

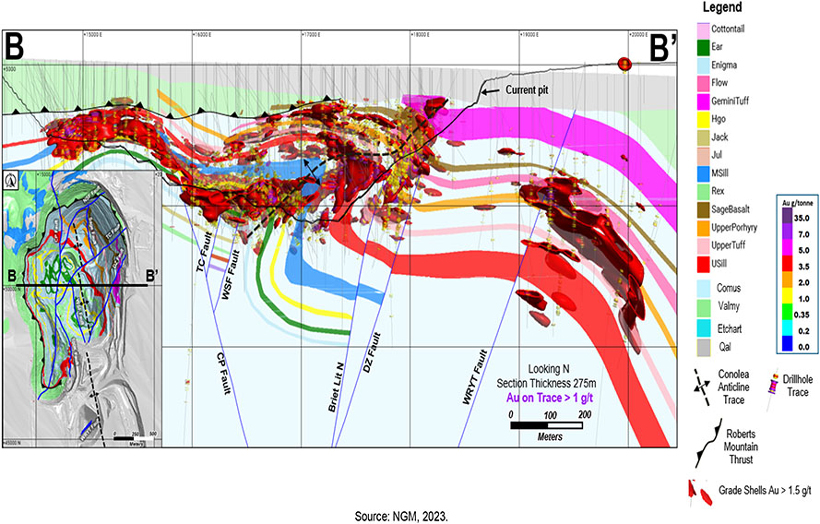

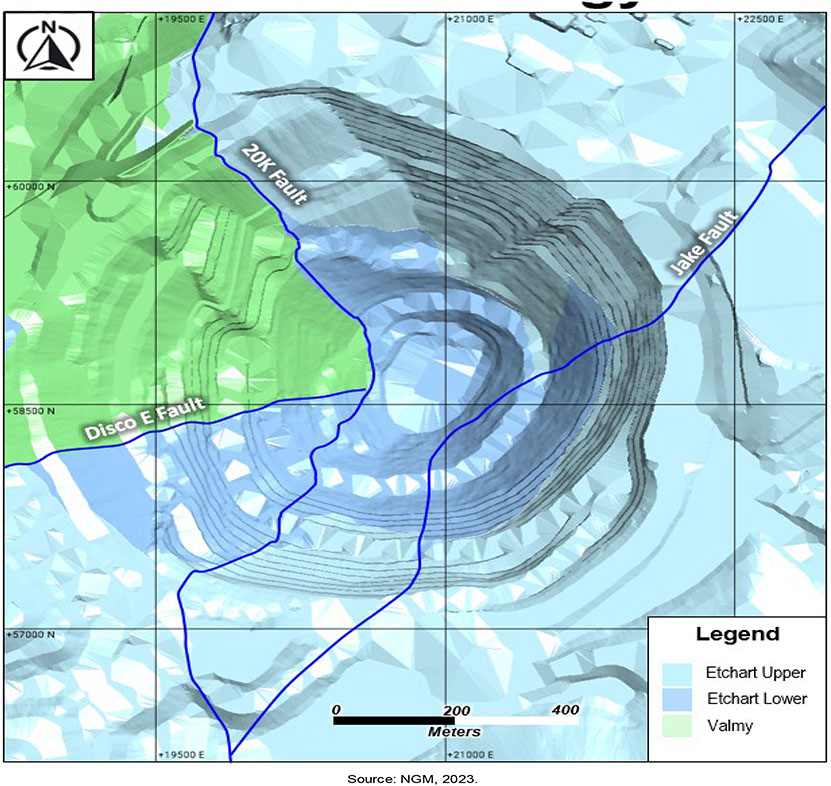

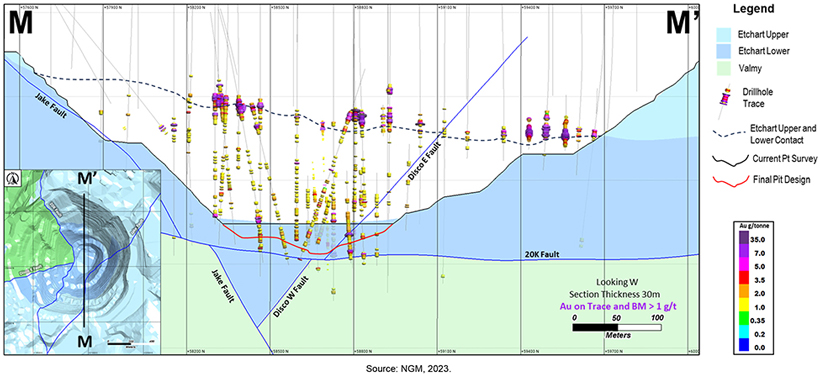

Mineralization is often structurally focused, either related to lithologic contacts, anticlines, fault intersections and fracture sets or unconformities. Sub-microscopic gold mineralization is associated with arsenian pyrite, quartz, calcite, realgar, and orpiment. Gold mineralization is likely Eocene in age, and it is overprinted in some areas by a late stage of realgar, orpiment, and calcite. Gold-bearing zones can be located close to granodiorite and dacite dikes and beneath basaltic sills, evidencing the importance of rheologic contacts to mineralization.

| 1.3 | Exploration Status |

Given the mining history in the Project area, extensive exploration has occurred at various times by numerous operators.

Significant potential remains within the district plan of operations and exploration is actively being conducted at the Project and regionally.

Near mine exploration is focussed on prospectivity at depth, along strike, and down plunge from current operations. Current near mine exploration focus includes:

| ● | Interpreted corridors of high-angle faults and fractures that can act as conduits for mineralizing fluids; |

| ● | Intersections of faults and dikes; |

| ● | Favorable lithofacies that have been fractured and/or brecciated and represent good potential for gold mineralization; and |

| ● | Deformation above and below mafic units that could generate fluid pathways such that gold mineralization may occur between the mafic units or have ponded under the mafic units acting as impermeable barriers. |

Current regional exploration focus includes:

| ● | Geochemistry – using Carlin-type deposit model pathfinder elements as vectors to mineralization. |

| ● | Alteration – using alteration associated with Carlin-type deposit model as vectors to mineralization. |

| ● | Structure – targeting anticlines, fault intersections, dike and sill contacts, and other anomalous structural sites containing deep-seated fractures and rheologic changes that can act as conduits for mineralizing fluids. |

| ● | Facies interpretation – to identify the most favorable mineralization host rocks. |

| March 15, 2024 |

Page 19 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 1.4 | Mineral Resource Estimate |

The Mineral Resource estimates have been prepared according to the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) 2014 Definition Standards for Mineral Resources and Mineral Reserves dated 10 May 2014 (CIM (2014) Standards) as incorporated with National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101). Mineral Resource estimates were also prepared using the guidance outlined in CIM Estimation of Mineral Resources and Mineral Reserves (MRMR) Best Practice Guidelines 2019 (CIM (2019) MRMR Best Practice Guidelines).

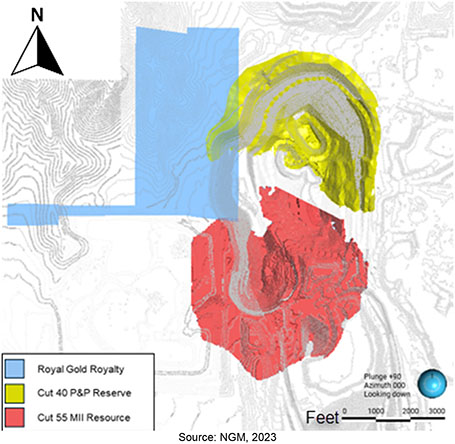

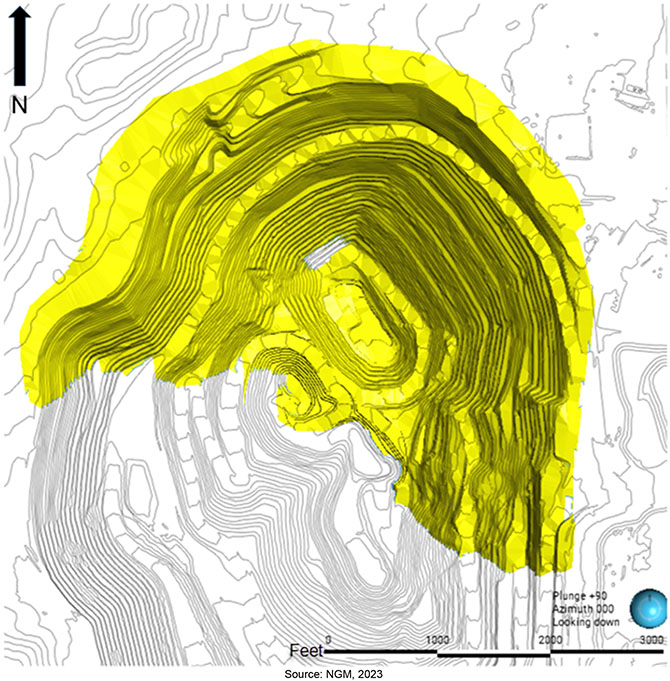

Mineral Resources considered amenable to open pit mining methods were constrained within a Pseudoflow (Lerchs-Grossman algorithm alternative) pit shell that used $1,700/oz gold price. Value-based routing was used in generating the cost and cash value of each block to determine reasonable prospects for eventual economic extraction and are demonstrated as a result of this pit optimisation process.

Mineral Resources for the stockpiles was determined using a revenue-based approach with a gold price of US$1,700/oz and appropriate mining costs. Stockpiles that made a profit of at least $1.00 were then considered as Mineral Resources.

Underground Mineral Resources were reported using Deswik Stope Optimizer (Deswik SO) applying appropriate cut-off grades for the methods utilised, minimum mineable stope shape, reasonable mineability constraints (including a minimum mining width, a reasonable distance from current or planned development), and a positive profitability at a $1,700/oz gold price demonstrating a reasonable prospect for eventual economic extraction.

The estimate was reviewed internally as well as externally and approved by NGM prior to release.

A summary of the Mineral Resources for the Project is provided in Table 1-1.

| March 15, 2024 |

Page 20 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

Table 1-1 Turquoise Ridge Mineral Resources Summary, 100% Basis, as of December 31, 2023

| Location | Measured | Indicated | Measured + Indicated | Inferred | ||||||||||||||||||||

| Tonnes | Grade | Contained | Tonnes | Grade | Contained | Tonnes | Grade | Contained | Tonnes | Grade | Contained | |||||||||||||

| (Mt) | (g/t Au) | (Moz Au) | (Mt) | (g/t Au) | (Moz Au) | (Mt) | (g/t Au) | (Moz Au) | (Mt) | (g/t Au) | (Moz Au) | |||||||||||||

| Open Pits | - | - | - | 38 | 2.52 | 3.0 | 38 | 2.52 | 3.0 | 13 | 2.3 | 0.98 | ||||||||||||

| Twin Creeks Stockpile |

28 | 2.22 | 2.0 | - |

- | - | 28 | 2.22 | 2.0 | - | - | |||||||||||||

| Surface Total | 28 | 2.22 | 2.0 | 38 | 2.52 | 3.0 | 66 | 2.39 | 5.0 | 13 | 2.3 | 0.98 | ||||||||||||

| Underground Total |

17 | 10.72 | 5.8 | 31 | 8.96 | 9.0 | 48 | 9.57 | 15 | 2.4 | 7.7 | 0.61 | ||||||||||||

| Turquoise Ridge Total | 45 | 5.40 | 7.8 | 69 | 5.43 | 12 | 110 | 5.42 | 20 | 16 | 3.2 | 1.6 | ||||||||||||

Notes:

| • | Mineral Resources are reported on 100% basis. Barrick’s attributable share of the Mineral Resource is based on its 61.5% interest in NGM. |

| • | CIM (2014) Standards and CIM (2019) MRMR Best Practice Guidelines were followed for Mineral Resources |

| • | Underground Mineral Resources are estimated based on a positive net value stope economic analysis. |

| • | Surface Mineral Resources are estimated based on an economic pit shell using a pseudoflow algorithm. |

| • | Mineral Resources are estimated using a long-term gold price of US$1,700/oz. |

| • | Resource block model dimensions of 10 m x 10 m x 10 m were assumed to reflect mining selectivity. |

| • | Mineral Resources are inclusive of Mineral Reserves. |

| • | Numbers may not add due to rounding. |

| • | The QP responsible for this Mineral Resource Estimate is Craig Fiddes, SME Reg. |

| March 15, 2024 |

Page 21 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 1.5 | Mineral Reserve Estimate |

The Mineral Reserve estimates have been prepared according to the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) 2014 Definition Standards for Mineral Resources and Mineral Reserves dated 10 May 2014 (CIM (2014) Standards) as incorporated with National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101). Mineral Resource estimates were also prepared using the guidance outlined in CIM Estimation of Mineral Resource and Mineral Reserve Best Practice Guidelines 2019 (CIM (2019) MRMR Best Practice Guidelines).

The Mineral Reserves have been estimated from the Measured and Indicated Mineral Resources and do not include any Inferred Mineral Resources. Mineral Reserves include material that will be mined by open pit and underground mining methods, and stockpiles.

The estimate uses updated economic factors, the latest Mineral Resource and geological models, geotechnical and hydrological inputs, and metallurgical processing and recovery updates. The QPs responsible for estimating the Mineral Reserves have performed an independent verification of the block model tonnes and grade, and in their opinion the process has been carried out to industry standards.

For the open pit, economic pit shells were generated using the Pseudoflow algorithm within Deswik software and then used in the open pit mine design process and Mineral Reserve estimation. The final pit limit selection and design process is outlined in Section 16.

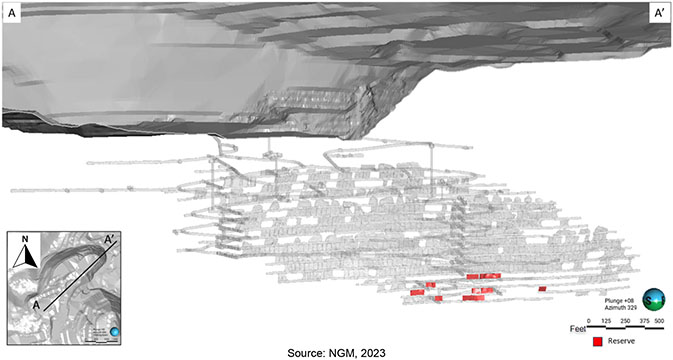

For the underground operations, the Deswik SO was used to evaluate the geological block model to create overall mining shapes. Preliminary stope wireframes were created and planned dilution was added to the mineable stope shape. Deswik Pseudo-flow software was used to estimate the cost, revenue, and resulting net value associated with each shape. Stopes with a positive net value were included in the Mineral Reserves estimate.

Mineral Reserves are summarised in Table 1-2 and stated:

| ● | As of December 31, 2023. |

| ● | Using a gold price of $1,300/oz. |

| ● | As ROM grades and tonnage delivered to the primary crushing facility. |

| ● | For Turquoise Ridge Underground, Vista Underground, Mega Pit, Vista Pit, and numerous historically mined surface ore stockpiles. |

A site specific financial model was populated and reviewed to demonstrate that the Mineral Reserves are economically viable.

| March 15, 2024 |

Page 22 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

Table 1-2 Turquoise Ridge Mineral Reserves Summary, December 31, 2023

| Location | Proven | Probable | Proven + Probable | |||||||||||||||||||||

| Tonnes | Grade | Contained | Attributable | Tonnes | Grade | Contained | Attributable | Tonnes | Grade | Contained | Attributable | |||||||||||||

| (Mt) | (g/t Au) | (Moz Au) | (Moz Au) | (Mt) | (g/t Au) | (Moz Au) | (Moz Au) | (Mt) | (g/t Au) | (Moz Au) | (Moz Au) | |||||||||||||

| Open Pits | - | - | - | - | 11 | 2.37 | 0.85 | 0.52 | 11 | 2.37 | 0.85 | 0.52 | ||||||||||||

| Twin Creeks Stockpile |

25 | 2.36 | 1.9 | 1.2 | - | - | - | - | 25 | 2.36 | 1.9 | 1.2 | ||||||||||||

| Surface Total | 25 | 2.36 | 1.9 | 1.2 | 11 | 2.37 | 0.85 | 0.52 | 36 | 2.36 | 2.8 | 1.7 | ||||||||||||

| Underground Total |

13 | 11.58 | 4.9 | 3.0 | 20 | 10.04 | 6.3 | 3.9 | 33 | 10.66 | 11 | 6.9 | ||||||||||||

| Turquoise Ridge Total |

38 | 5.53 | 6.8 | 4.2 | 31 | 7.24 | 7.2 | 4.4 | 69 | 6.29 | 14 | 8.6 | ||||||||||||

Notes

| • | Proven and Probable Mineral Reserves are reported on 100% basis. Barrick’s attributable share of the Mineral Reserve is 61.5% based on its interest in NGM. |

| • | The Mineral Reserve estimate has been prepared according to CIM (2014) Standards and using CIM (2019) MRMR Best Practice Guidelines. |

| • | Mineral Reserves are reported at a gold price of US$1,300/oz. |

| • | Underground Mineral Reserves are estimated based on a positive net value stope economic analysis applying appropriate cost and modifying factors. |

| • | Surface Mineral Reserves are estimated based on an economic pit design applying appropriate costs and modifying factors. |

| • | Mining recovery and dilution factors are applied based on calculated historic actual results. |

| • | All reported metal is contained before process recovery; metal recoveries are variable based on material type, gold grades, TCM grades, sulfide sulfur grades, and processing methodology. |

| • | Contained metal is reported in millions of troy ounces. |

| • | Numbers may not add due to rounding. |

| • | The QP responsible for the Surface Mineral Reserve Estimate is Timothy Webber, SME RM. |

| • | The QP responsible for the Underground Mineral Reserve Estimate is Paul Schmiesing, SME RM. |

| March 15, 2024 |

Page 23 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 1.6 | Mining Methods |

The Turquoise Ridge Complex consists of underground and open pit mining operations. The mining methods used are considered conventional and use conventional equipment.

Ore is mined from its source and transported to the ROM stockpiles where it is blended and fed to the various process facilities, or long-term stockpiles for future reclamation and processing.

Waste material is taken to several possible locations including; various dump locations underground, used as construction material, or placed onto long term waste rock storage facilities.

The mining rate is variable and dependent on the phase of the active operations, although when in full production it is expected to peak at approximately 3,200 tpd for the underground operations and more than 50 ktpd for the surface operations.

Life of Mine for the Reserves is expected to end in 2047 for Turquoise Ridge Underground (TRUG) operations, in 2034 for Turquoise Ridge Surface operations, and 2024 for Vista Underground (VUG).

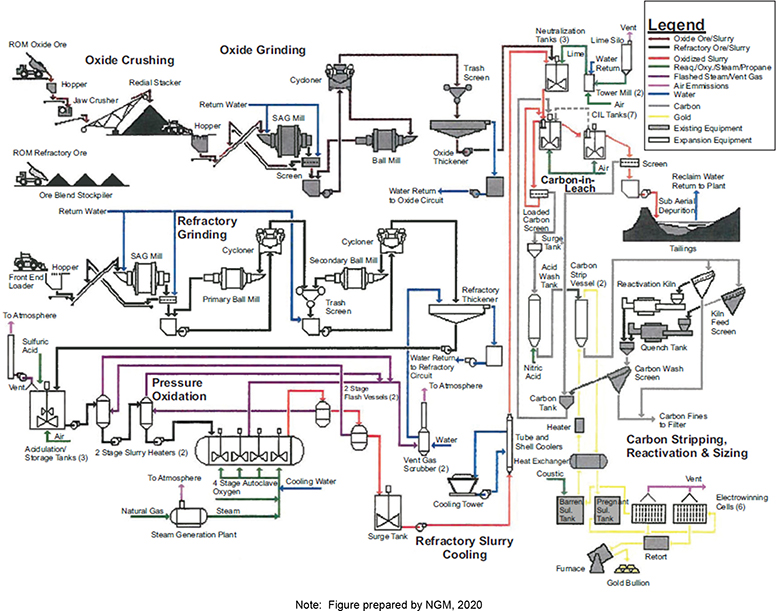

| 1.7 | Mineral Processing |

Processing of oxide and refractory ores at Turquoise Ridge is completed through the Juniper oxide mill, the Sage refractory facility, and a number of heap leach pads:

| ● | Oxide ore from the open pits is processed through the existing Juniper oxide mill or heap leach facilities, depending on ore grade and characteristics such as the clay and silica percentages. Oxide ores are those in which the gold is available for direct leaching by cyanide via conventional leach or milling methods. Oxide ores have been processed through the Juniper Mill (originally the Chimney Creek mill) since 1988. |

| ● | Low-grade oxide ores have been leached on multiple run-of-mine heap leach pads since at least 1996. |

| ● | Refractory ore from underground and open pit sources is processed through the Sage Mill pressure oxidation autoclaves, where the sulfide sulfur (SS) holding the gold is oxidized to liberate the gold so it can be recovered through conventional cyanidation (CIL). Refractory ores have been processed through the Sage Mill (originally the Twin Creeks mill) since 1996. |

| ● | On an ad-hoc basis the Turquoise Ridge process facilities have periodically toll treated ores from other sources of non-owned regional operations when excess process capacity is available and if there is a benefit to NGM in doing so. |

| March 15, 2024 |

Page 24 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

Laboratory testing is completed on new deposits and mine extensions to confirm the amenability of ores in the new areas/zones to the current process methods. The majority of testwork has been completed in the on-site testing facility with some specialty work completed off site.

Recent metallurgical testwork primarily focused on core samples from the proposed expansion of the Mega open pit.

The Turquoise Ridge processing facilities are suitable for processing the ores envisaged in the LOM plan. Various plant modifications for improved performance are periodically undertaken, such as the CIL inter-tank screen upgrades that are currently underway with both throughput and recovery enhancements expected.

| 1.8 | Project Infrastructure |

The Turquoise Ridge operation is a mature project that has been operating intermittently since 1934 with modern open pit operations beginning in 1987 and modern underground mining in 1994. It has well developed infrastructure supporting the current operations and plans for additional infrastructure to support the Project growth.

| 1.9 | Environmental, Permitting, and Social Considerations |

NGM maintains a number of permits for the operation. These compliance permits cover areas such as air quality, water rights, wastewater treatment, tailings storage, hazardous materials storage, land reclamation, and community relations. NGM maintains a legal obligation register to track permitting and ensure on-going compliance. The Turquoise Ridge Complex is operating in compliance in all material respects with all applicable regulations and permit requirements as required by the BLM and the NDEP.

Closure and reclamation strategies and methods remain in accordance with the existing, approved Reclamation Plans.

There are no major challenges with respect to government relations, non-governmental organizations, social or legal issues, and community development.

| 1.10 | Capital and Operating Costs |

Capital and operating costs for Turquoise Ridge are based on extensive experience gained from many years of operating these mines and an extensive number of years operating other gold mines

| March 15, 2024 |

Page 25 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

in Nevada and within NGM. Capital costs reflect current price trends and supporting studies. Operating costs are in-line with historical averages and considering recent inflationary pressures.

| 1.11 | Interpretations and Conclusions |

| 1.11.1 | Mineral Tenure, Rights, Royalties and Agreements |

Information from NGM’s in-house experts supports that the tenure held is valid and sufficient to support a declaration of Mineral Resources and Mineral Reserves.

NGM holds sufficient surface rights to allow mining activities. The surface rights are sufficient to support mining operations,

Three minor royalties are payable on a portion of the production from Turquoise Ridge Surface to Royal Gold described in 4.6.3.

The State of Nevada imposes a 5% net proceeds tax on the value of all minerals severed in the State.

Environmental liabilities are typical of those that would be expected to be associated with a long-life mining operations. NGM complies with all required permit and regulatory obligations to manage these liabilities.

To the extent known to the QP, there are no other significant factors and risks that may affect access, title, or the right or ability to perform work on the Project that are not discussed in this Report.

| 1.11.2 | Geology and Mineral Resources |

The Turquoise Ridge Complex suite of deposits are considered to be examples of Carlin-type or carbonate-hosted disseminated gold–silver deposits.

The understanding of the deposit settings, lithologies, mineralisation, and the geological, structural, and alteration controls on mineralisation is sufficient to support estimation of Mineral Resources and Mineral Reserves.

Exploration potential remains within the Project area. Targets include depth extensions under the current pits, and structural targets associated with faults and intersecting structures.

| March 15, 2024 |

Page 26 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

Exploration, Drilling and Analytical Data Collection in Support of Mineral Resource Estimation

The exploration programs completed to date are appropriate for the style of the deposits in the Project area.

The geometry of the mineralized bodies can be variable, largely controlled by structural and stratigraphic complexities. Uncertainty about the morphology and vertical or lateral extent is mitigated by drilling at various orientations to the mineralized body.

Sampling methods are acceptable for Mineral Resource estimation.

Sample preparation, analysis and security are generally performed in accordance with industry-accepted practices.

The quantity and quality of the logged geological data, collar, and downhole survey data collected in the exploration and infill drill programs are sufficient to support Mineral Resource and Mineral Reserve estimation.

No material factors were identified with the data collection from the drill programs that could significantly affect Mineral Resource estimation.

The sample preparation, analysis, and security practices and are acceptable, meet industry-standard practice, and are sufficient to support Mineral Resource estimation. The collected sample data adequately reflect deposit dimensions, true widths of mineralisation, and the style of the deposits.

The QA/QC programs adequately address issues of precision, accuracy and contamination. Drilling programs typically included blanks, duplicates and CRM samples. QA/QC submission rates meet industry-accepted standards at the time of the campaign. The QA/QC programs did not detect any material sample biases in the data reviewed that supports Mineral Resource estimation.

The data verification programs concluded that the data collected from the Project adequately support the geological interpretations and constitute a database of sufficient quality to support the use of the data in Mineral Resource estimation.

Mineral Resource Estimates

The Mineral Resource and Mineral Reserve estimates have been prepared according to the Canadian Institute of Mining, Metallurgy and Petroleum CIM (2014) Standards as incorporated by reference in NI 43-101. Mineral Resource and Mineral Reserve estimates were also prepared using the guidance outlined in CIM Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines 2019 (CIM (2019) MRMR Best Practice Guidelines).

| March 15, 2024 |

Page 27 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

In the QP’s opinion, the Mineral Resources top capping, domaining and estimation approach are appropriate, using industry accepted methods. Furthermore, the constraint of underground Mineral Resource reporting to use optimised mineable stope shapes and the process for Mineral Resource pit shell generation reflects best practice. The QP considers the Turquoise Ridge Mineral Resources as appropriately estimated and classified.

The QP is not aware of any environmental, permitting, legal, title, taxation socioeconomic, marketing, political, metallurgical, fiscal, or other relevant factors, that could materially affect the Mineral Resource estimate.

In the QP’s opinion there is upside potential for the estimates if mineralisation that is currently classified as Inferred can be upgraded to higher-confidence Mineral Resource categories.

The strategic focus of Turquoise Ridge exploration is to prioritise the delineation of additional near mine resource definition targets, thereby increasing years of production with complimentary underground and open pit sources.

| 1.11.3 | Mining and Mineral Reserves |

Mineral Reserve Estimate

The Mineral Reserve estimation for the Project incorporates industry-accepted practices and meets the requirements of the Canadian Institute of Mining, Metallurgy and Petroleum (CIM) 2014 Definition Standards for Mineral Resources and Mineral Reserves dated 10 May 2014 (CIM (2014) Standards) as incorporated with National Instrument 43-101 Standards of Disclosure for Mineral Projects (NI 43-101). Mineral Resource estimates were also prepared using the guidance outlined in CIM Estimation of Mineral Resources and Mineral Reserves (MRMR) Best Practice Guidelines 2019 (CIM (2019) MRMR Best Practice Guidelines).

Mineral Resources were converted to Mineral Reserves using a detailed mine plan, an engineering analysis, and consideration of appropriate modifying factors. Modifying factors include the consideration of dilution and ore losses, underground and surface mining methods, geotechnical and hydrogelogical considerations, metallurgical recoveries, permitting, and infrastructure requirements.

Mine Plan

Mining operations are conducted year-round.

The mine plans are based on the current knowledge of geotechnical, hydrogeological, mining and processing information.

Underground mine designs incorporate underground infrastructure and ventilation requirements.

| March 15, 2024 |

Page 28 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

Turquoise Ridge Surface uses conventional open pit methods, and a conventional mining fleet.

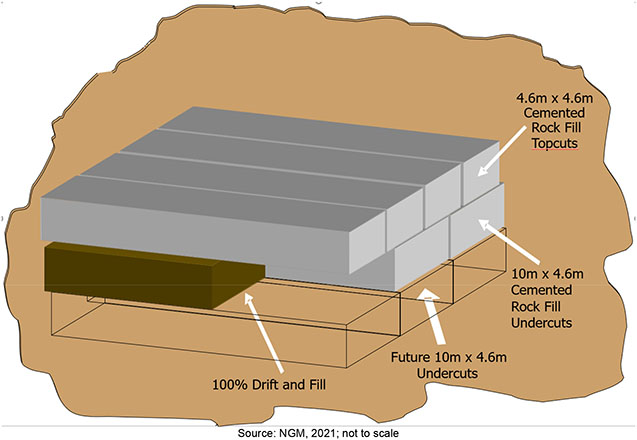

Underground operations use conventional drift-and-fill and longhole stoping mining methods and conventional equipment fleets.

Barrick, as the operator of the Project, has significant experience in other mining operations within the region and North America. The production rates, modifying factors, and costs are benchmarked against other operations to ensure they are suitable.

The current Mineral Reserves for Turquoise Ridge support a total mine life of 23 years, 11 years of open pit operations, and 23 years of underground mining. Gold production averages approximately 590 koz Au per year for the first 10 years based only on Mineral Reserves.

The QP is not aware of any environmental, legal, title, socioeconomic, marketing, mining, metallurgical, infrastructure, permitting, fiscal, or other relevant factors that could materially affect the Mineral Reserve estimate.

| 1.11.4 | Mineral Processing |

The process plant flowsheet designs were based on testwork results, previous study designs and industry-standard practices.

The process methods are generally conventional to the industry.

The process plants will produce variations in recovery due to the day-to-day changes in ore type or combinations of ore type being processed. These variations are expected to trend to the forecast recovery value for monthly or longer reporting periods through manipulation of blends and blending materials, varying reagent additions, adjusting throughput, and planned maintenance of key operational equipment.

The QP considers the modelled recoveries for all ore sources and the process and plant engineering unit costs applied to the Mineral Resource and Mineral Reserve process to be acceptable.

Metallurgical Testwork

Metallurgical testwork and associated analytical procedures were appropriate to the mineralisation type, appropriate to establish the optimal processing routes, and were performed using samples that are typical of the mineralisation styles.

Samples selected for testing were representative of the various types and styles of mineralisation. Samples were selected from a range of depths within the deposits. Sufficient samples were taken so that tests were performed on sufficient sample mass.

| March 15, 2024 |

Page 29 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

Recovery factors estimated are based on appropriate metallurgical testwork and are appropriate to the mineralisation types and the selected process routes. Recovery forecasts are periodically adjusted based on plant performance, which is tracked on at least a monthly basis.

Depending upon the specific processing facility, several processing factors or deleterious elements could have an economic impact on extraction efficiency of a certain ore source, based either on the presence, absence, or concentration of the following constituents in the processing stream: organic carbon; sulfide sulfur; carbonate carbon; arsenic; mercury; antimony; and copper. However, under normal ore routing and blending practices at NGM where material from several sites may be processed at one facility, the above list of constituents is typically not a concern.

| 1.11.5 | Infrastructure |

The majority of the infrastructure required for operations is constructed and operational. Some additional facilities, such as construction of a new TSF will be required to support the operations as envisaged in the LOM plan.

The existing infrastructure, staff availability, existing power, water, and communications facilities, and the methods whereby goods are transported to the mines are all in place and well-established and support the estimation of Mineral Resources and Mineral Reserves.

| 1.11.6 | Environmental, Permitting and Social Considerations |

NGM maintains a number of permits for the operation. These compliance permits cover areas such as air quality, water rights, wastewater treatment, tailings storage, hazardous materials storage, land reclamation, and community relations. NGM maintains a legal obligation register to track permitting and ensure on-going compliance. As of the date of this report, all material permits were in compliance or were in the process of renewal.

The Turquoise Ridge Complex is operating in compliance in all material respects with all applicable regulations and permit requirements as required by the BLM and the NDEP.

The addition of Cut 40 will require modification of the permits, a revised reclamation cost estimate, and approval from the BLM and NDEP. Cut 40 does not require surface disturbance outside of the existing PoO Boundary. The area anticipated to be directly impacted by the Cut 40 pit shape is currently disturbed or approved for disturbance by the regulatory agencies. The NDEP, Bureau of Mining Regulation and Reclamation would evaluate the project under the existing WPCP. The changes associated with the Cut 40 project will likely be assessed as a Major Modification to the Turquoise Ridge Surface WPCP.

Closure and reclamation strategies and methods remain in accordance with the existing, approved Reclamation Plans. The Turquoise Ridge Complex closure costs are updated each year, with

| March 15, 2024 |

Page 30 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

increases or decreases in disturbed areas noted and costed; the current cost for rehabilitation and closure of the mine according to the calculation model is approximately $94 million for the entire complex.

There are no major challenges with respect to government relations, non-governmental organizations, social or legal issues, and community development. A community and social relations policy is in place at the Turquoise Ridge Complex.

The Turquoise Ridge Complex is a significant employer to members of the local communities. Stakeholder engagement activities, community development projects and local economic development initiatives contribute to the maintenance and strengthening of the social licence to operate.

The QP considers the extent of all environmental liabilities, to which the property is subject, to have been appropriately met.

| 1.11.7 | Project Economics |

Using the assumptions detailed in this Report, the Turquoise Ridge Complex mines have strongly positive economics in the Mineral Reserves mine plan, which confirms the economic viability of the Mineral Reserves at $1300/oz gold sales price.

The basis for the combined LOM plan is the Proven and Probable Mineral Reserves estimate described in Section 15 of this Technical Report. Cost inputs have been priced in real Q4 2023 US dollars, without any allowance for inflation or consideration for changes in foreign exchange rates.

In the QP’s opinion, the open pit and underground LOM and cost estimates have been completed in sufficient detail to be satisfied that economic extraction of the Proven and Probable Mineral Reserves is justified.

Capital Cost Estimates

Capital cost estimates contained in this report are based on quantities generated from the open pit and underground development requirements are based on operating experience gained in the many years of current operations and where appropriate equipment capital costs are based upon quotes received from manufacturers. Sustaining (replacement) capital costs reflect current price trends. Any potential exploration expenditure has not been included in the economic forecasts due to being a variable cost that is justified on the basis of individual motivations.

Capital expenditure over the remaining LOM is estimated to be $1083 million (from 2024) based on Mineral Reserves, consisting of the following allocation of costs (as defined in Table 21-1).

| March 15, 2024 |

Page 31 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

Operating Cost Estimates

Operating cost estimates were developed based on a combination of actual costs to the end of 2023 and forecast figures over the LOM plan.

Open pit mining costs range from $1.37–$2.65/t over the expected open pit LOM, with an average LOM cost of $2.24/t. Underground mining costs range from $135.01–$170.27/t over the expected underground LOM, with an average LOM cost of $137.48/t. Sage Autoclave processing cost range from $30.92-52.30, with an average LOM cost of $41.20/t. Juniper Oxide Mill processing costs range from $6.93-$14.00/t, with an average LOM cost of $9.71/t. Leach processing LOM average costs are $3.81/t. The QPs consider the operating cost estimates in the LOM plan to be reasonable and consistent with historical performance.

| 1.12 | Recommendations |

| 1.12.1 | Geology and Mineral Resources |

| ● | Continue to improve geology and estimation models with learnings acquired through continued mining development. |

| ● | Continue to investigate and improve, geochemical signature modeling, as a geological reconciliation of visual alteration logging, to test the 1.0g/t grade shell currently used to removal bimodal distributions. |

| ● | Review grade capping strategy and metal at risk, as current approach is potentially conservative (removing too much metal). |

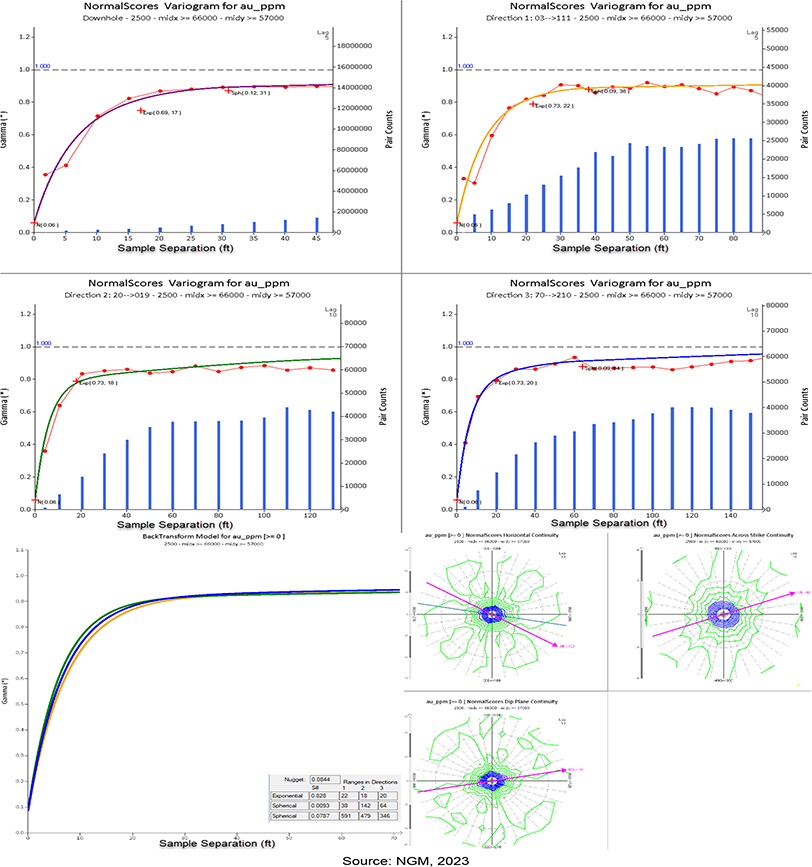

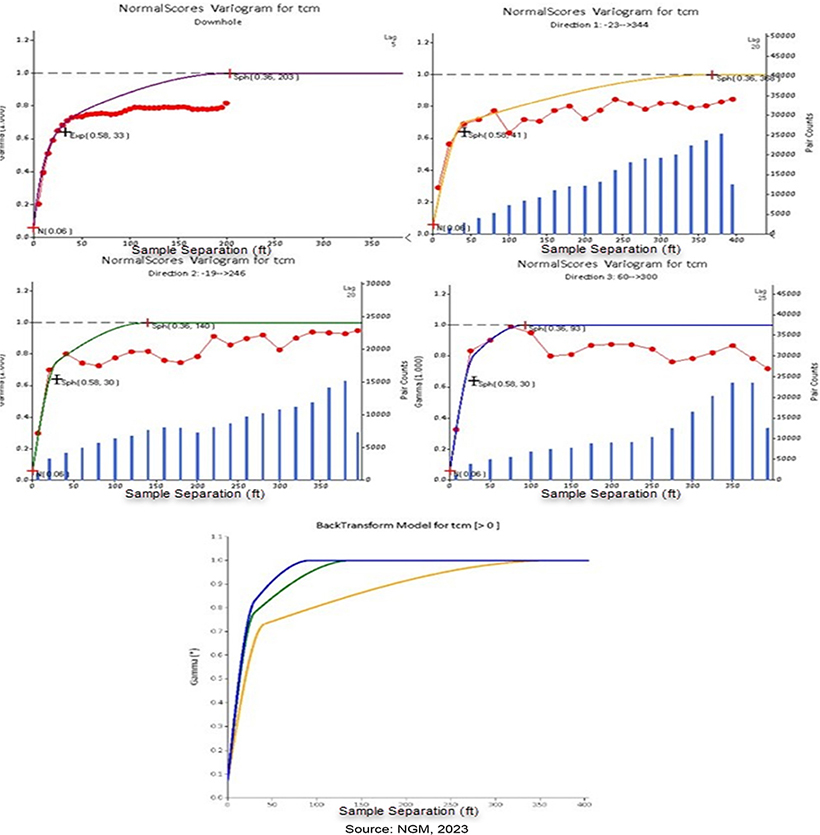

| ● | Incorporate additional data density variability samples into sample workflow and update current density estimation procedures. |

| ● | Continue to collect additional Sulfide Sulfur, Total and Organic Carbon assay data to drive continuous improvement in models. |

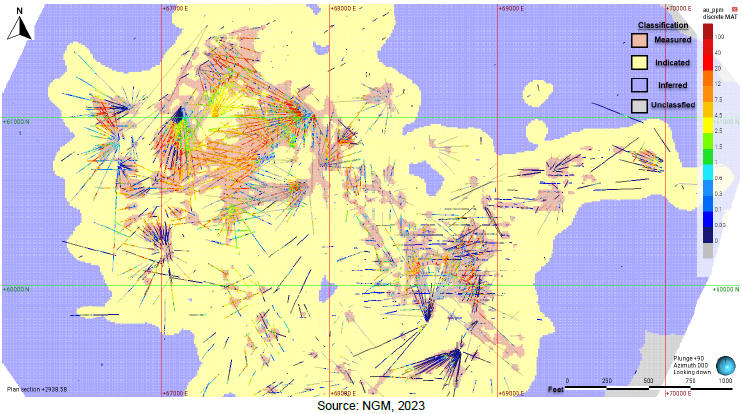

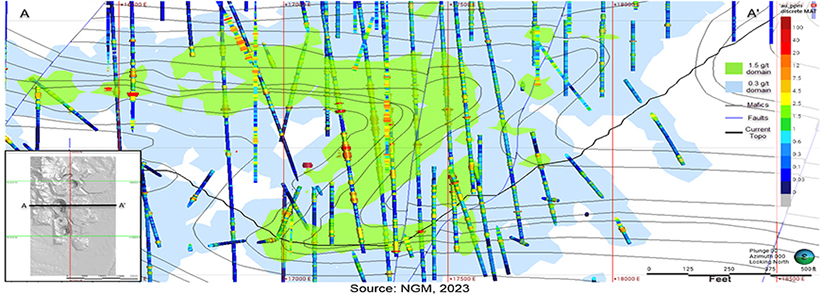

| ● | Update the Vista geologic model using current software, modeling practices, and geologic understanding in alignment with the more recent Mega model update. While this is not expected to result in any material changes to the Resource estimate, it is good practice to maintain consistency between models at the site. |

| ● | Continue to review the drill hole database for anomalies, unusual downhole surveys, grade discrepancies, etc. and resolve them based on findings. |

| March 15, 2024 |

Page 32 |

|

|

Turquoise Ridge Complex NI 43-101 Technical Report |

|

| 1.12.2 | Mining and Mineral Reserves |

| ● | Continue monitoring of pit slope movements – particularly the current highwall on the northwest side of the Mega Pit (Cut 24). Current monitoring indicates a slope failure is possible in this area. Should the failure occur, appropriate remediation steps can be implemented as Cut 40 mining commences. |

| ● | Evaluate hydraulic shovels currently in-use at other NGM open pit operations for potential transfer to Turquoise Ridge Open Pit (perhaps with a rebuild) rather than purchasing two new 5500-class hydraulic shovels to decrease operating costs and/or mining capital costs. |

| ● | Continue investigations into the possibility of processing transitional sulfide ores (sulfide sulfur < 1-2%) at the Juniper oxide mill. Particularly if the carbonate values are high (making them less ideal for the autoclave due to the acid cost to neutralize the ore) for the potential down stream neutralization benefit to the Sage Autoclave discharge. |

| ● | Improve the relationship between waste factors used on mining shapes used later in TRUG mining life and expensed waste development and, if possible, eliminate these waste factors. |

| 1.12.3 | Mineral Processing |

| ● | Continue with laboratory assessment of blend behaviors with differing regimes of reagents to ensure validity of the recovery and operating cost predictions, as well as pre-empt potential anomalies. |

| ● | Pursue remedies for future increasing carbonate concentrations, such as sulfide concentrate additions. |

| ● | Continue validation of bench testing methods for calibration to actual plant performance. |

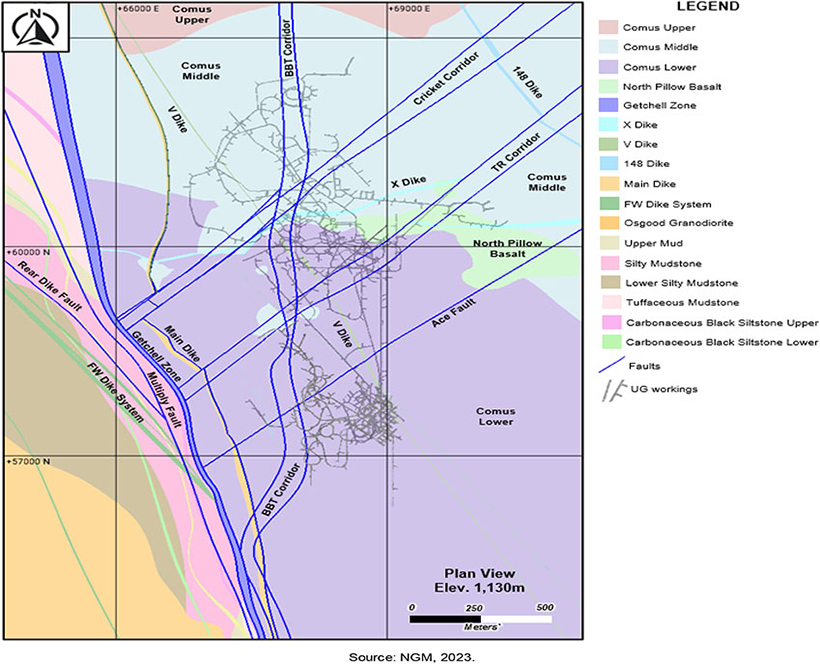

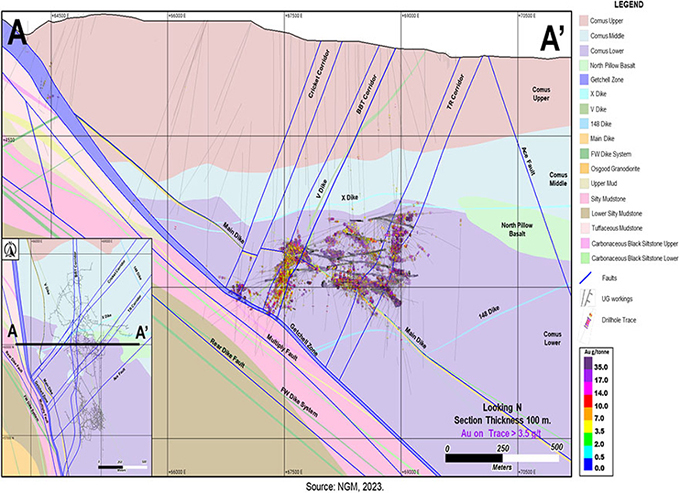

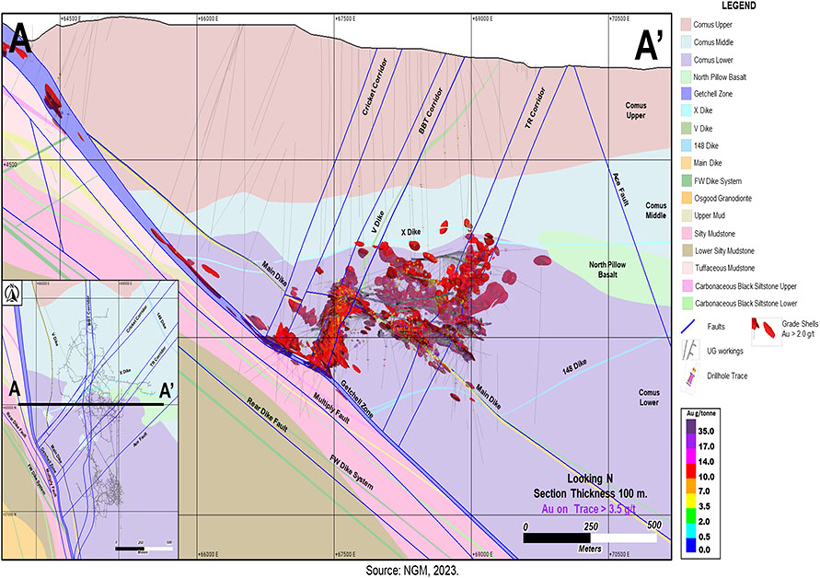

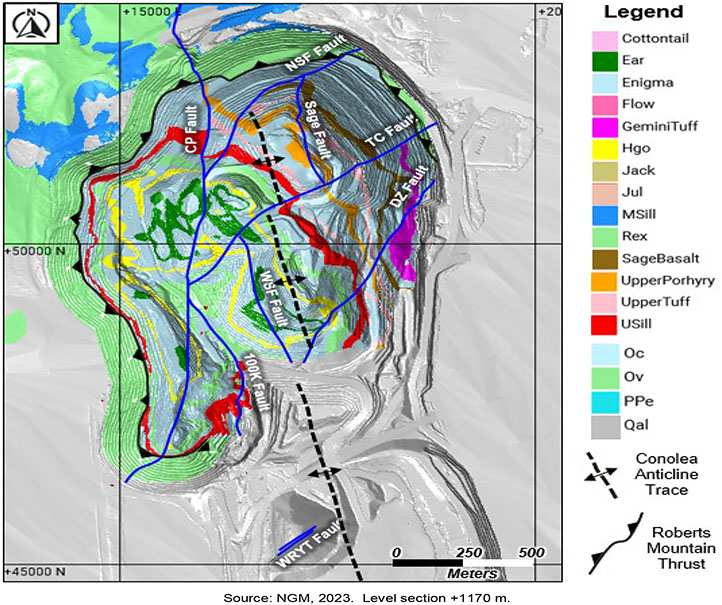

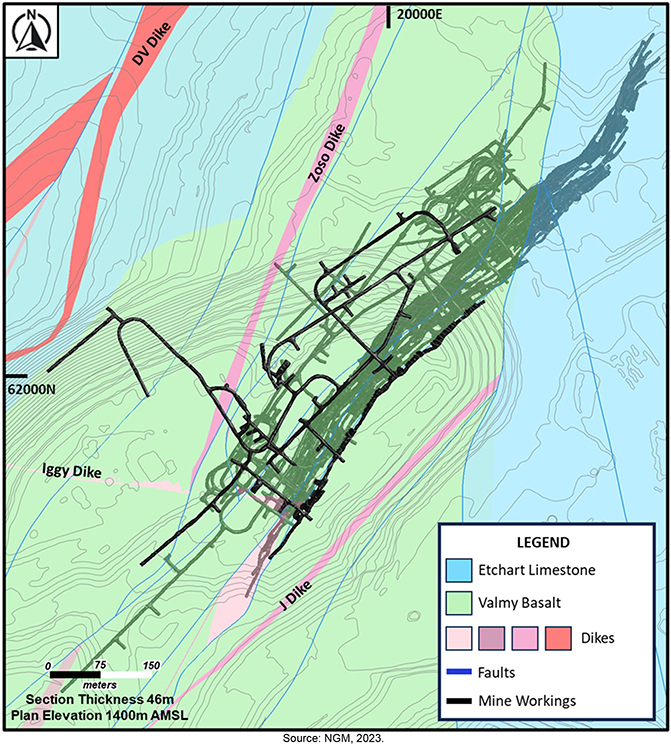

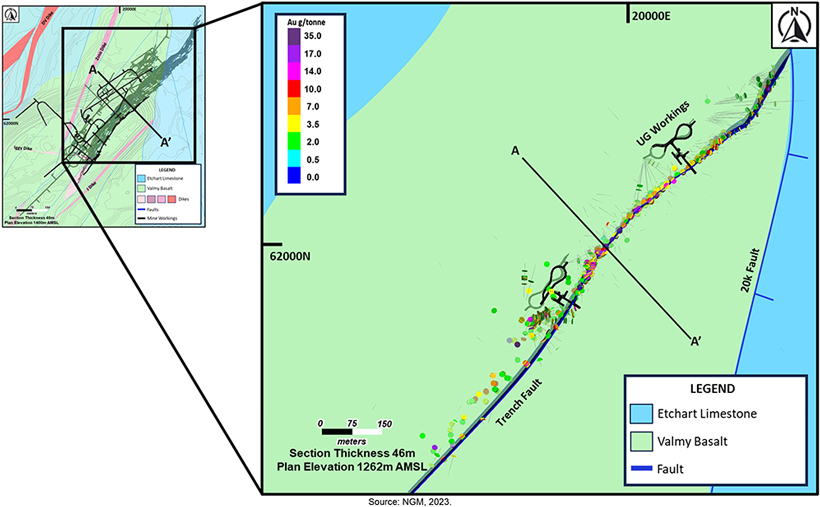

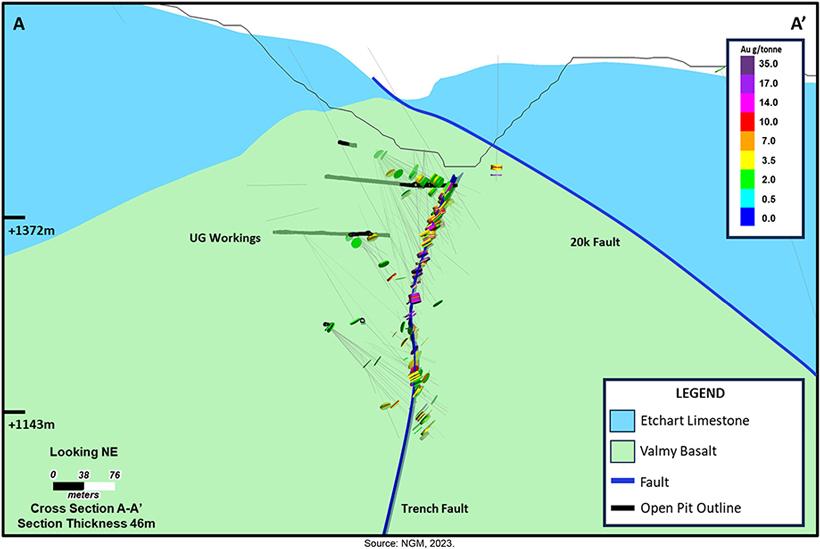

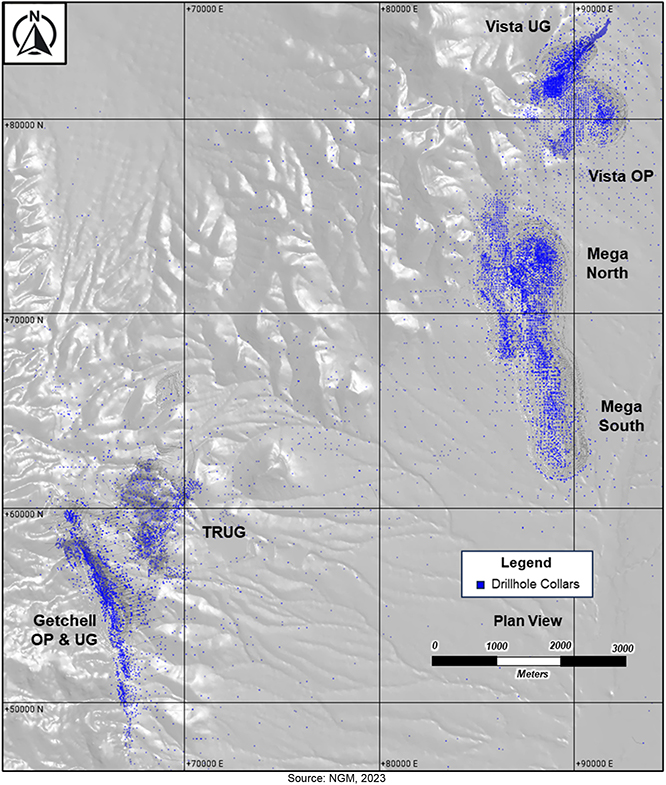

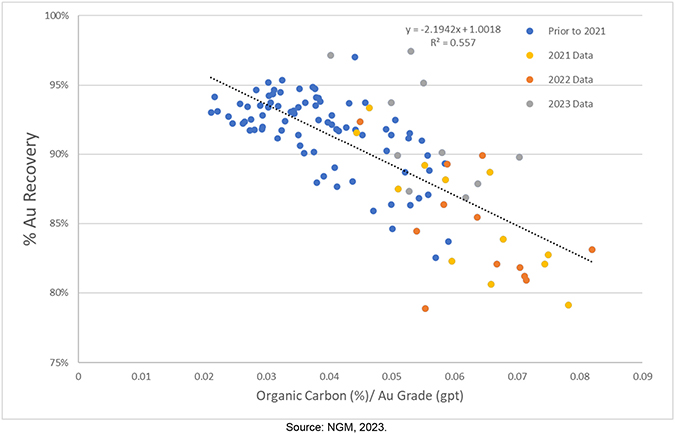

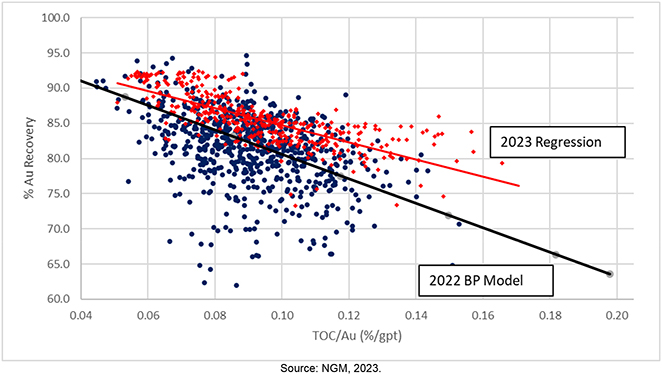

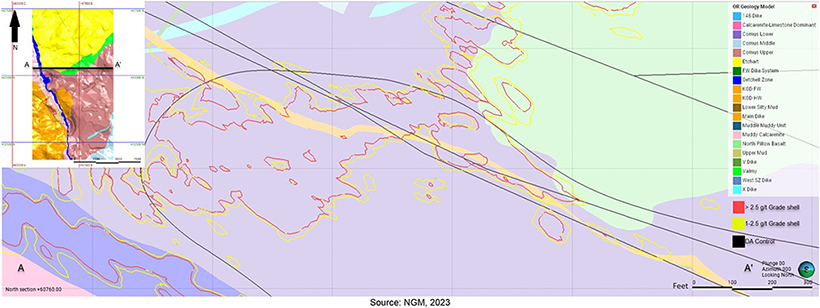

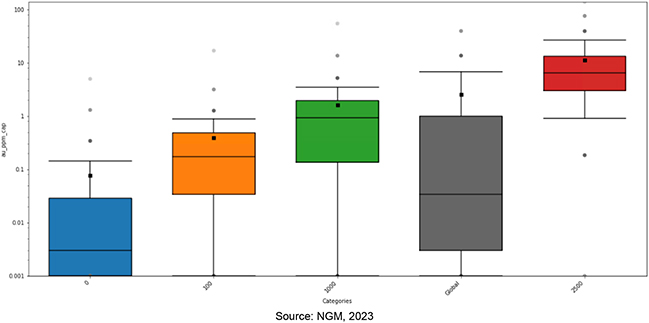

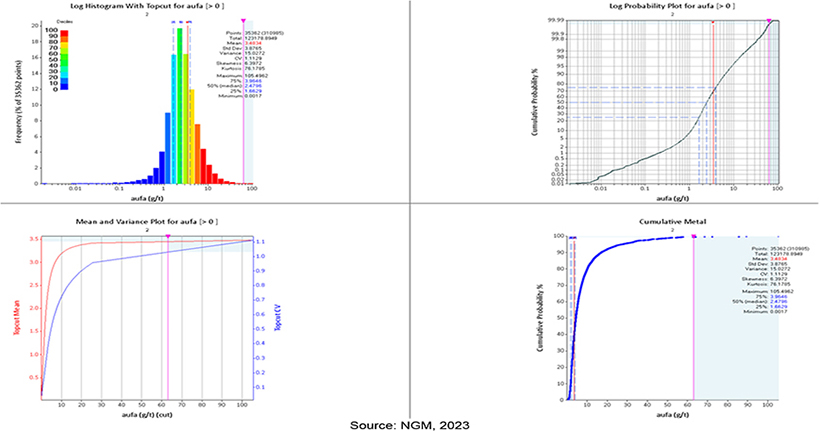

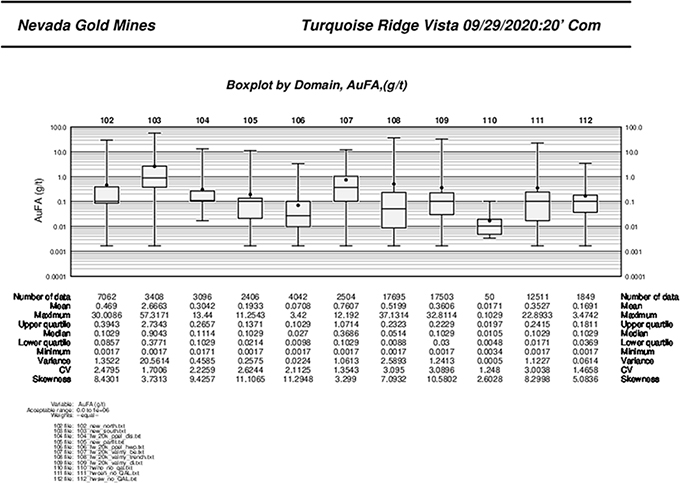

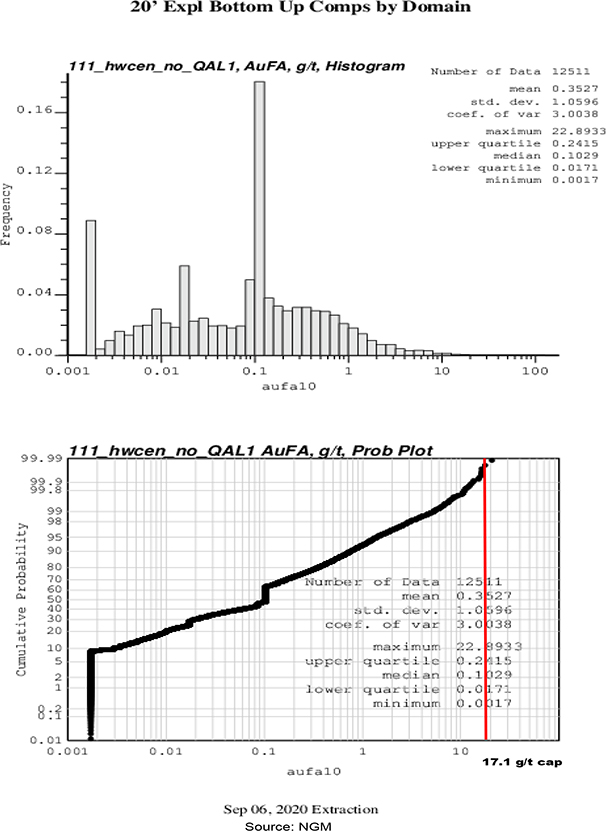

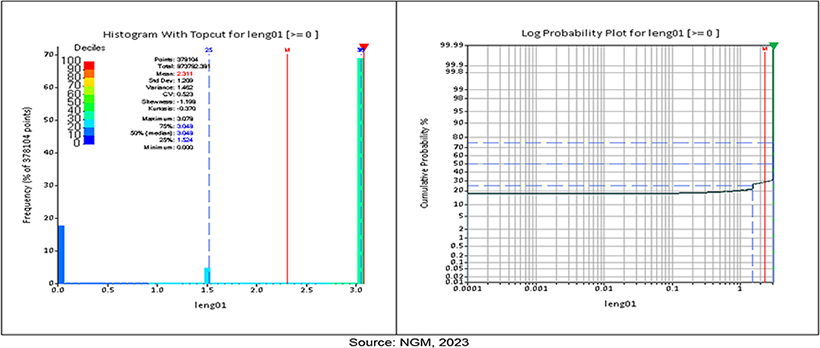

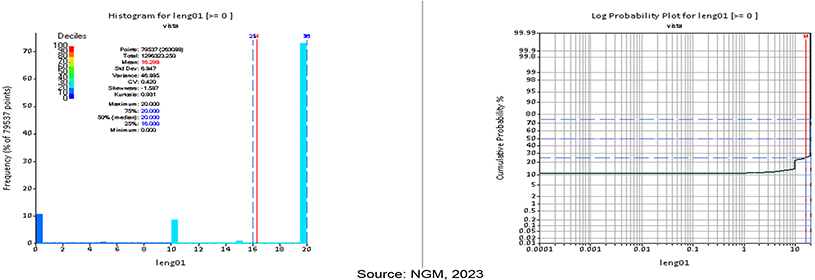

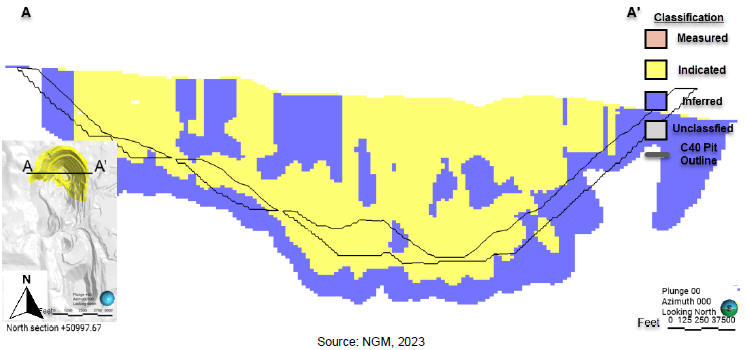

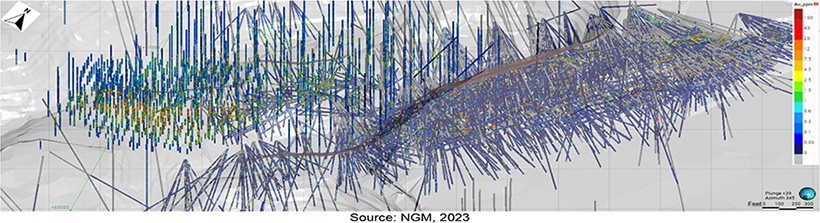

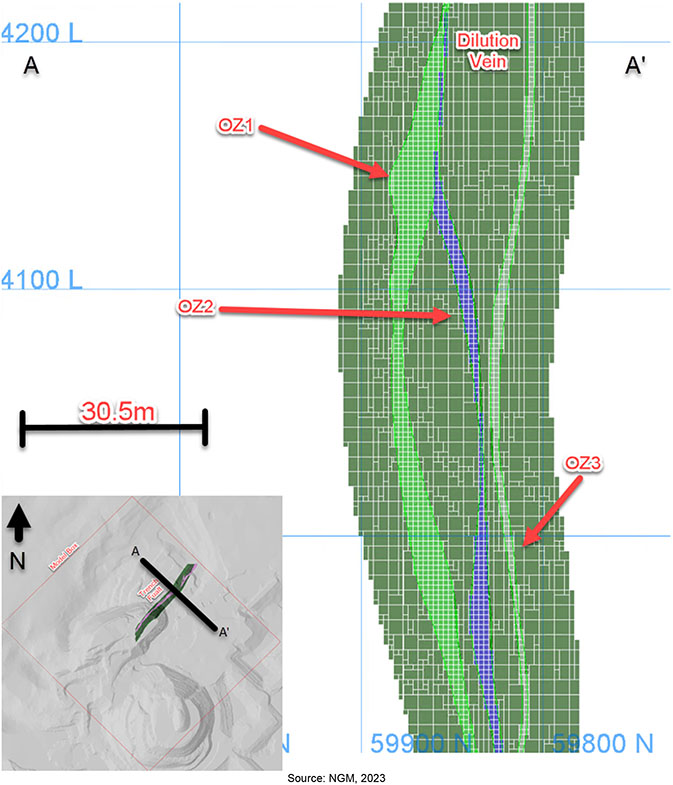

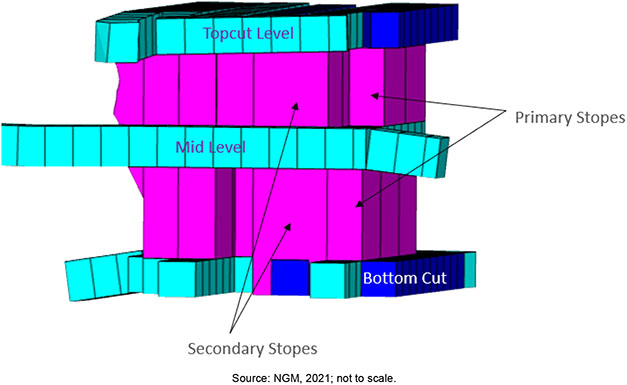

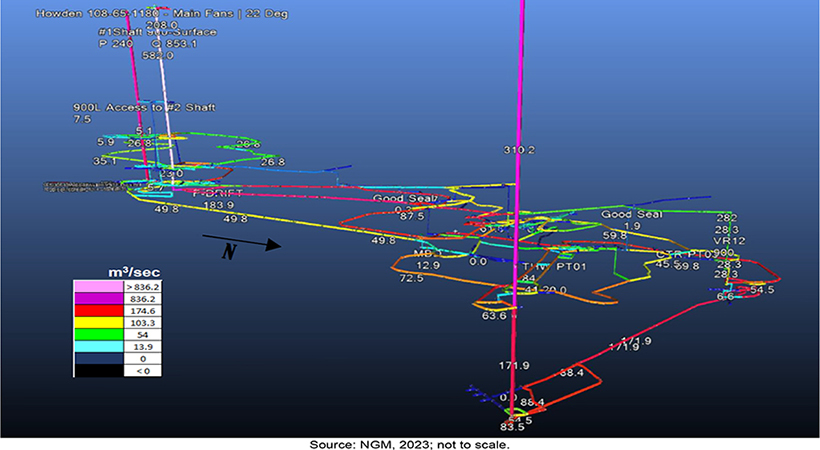

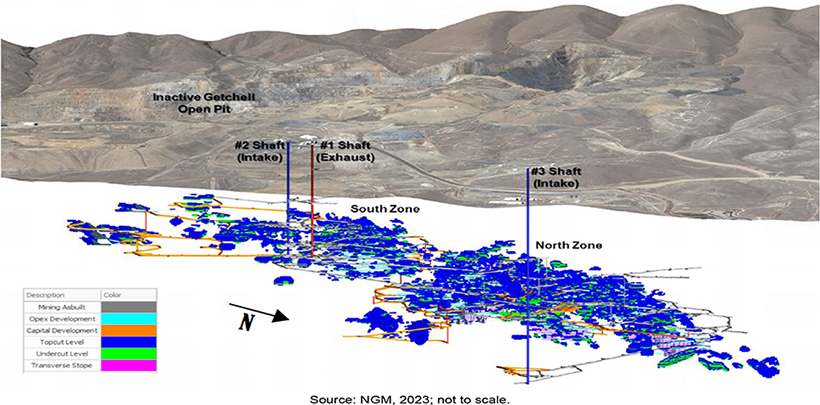

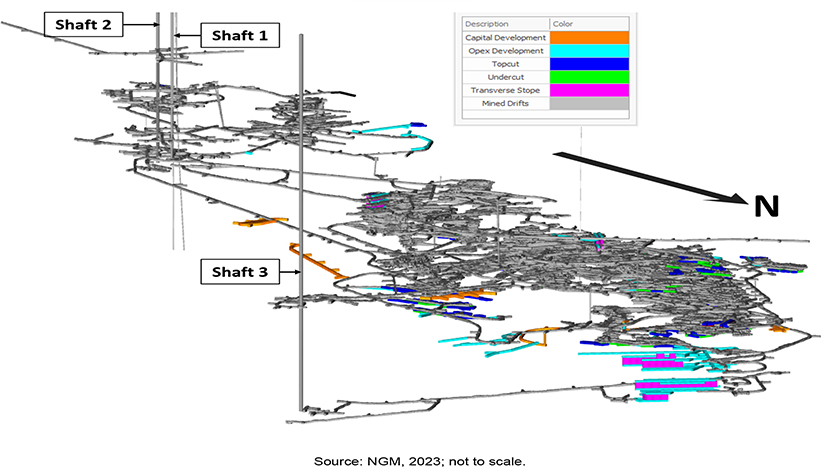

| ● | Continue reviewing sample density coverage of future TRUG ores and conduct bench-top testing to ensure recovery data is in line with predicted performance with representative sample selection. |