UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 6-K

REPORT OF FOREIGN PRIVATE ISSUER

PURSUANT TO RULE 13a-16 OR 15d-16

UNDER THE SECURITIES EXCHANGE ACT OF 1934

For the month of November, 2025

Commission File Number: 001-35936

B2Gold Corp.

(Translation of registrant’s name into English)

British Columbia, Canada

(Jurisdiction of incorporation or organization)

Suite 3400, Park Place

666 Burrard Street

Vancouver, British Columbia V6C 2X8

Canada

(Address of principal executive office)

Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40-F:

¨ Form 20-F x Form 40-F

DOCUMENTS INCLUDED AS PART OF THIS FORM 6-K

See the Exhibit Index hereto.

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| B2Gold Corp. | ||

| Date: November 7, 2025 | By: | /s/ Randall Chatwin |

| Name: | Randall Chatwin | |

| Title: | Senior Vice President, Legal and Corporate Communications | |

EXHIBIT INDEX

| Exhibit No. |

Description | |

| 99.1 | Technical Report for the Masbate Gold Project, Philippines |

November 7, 2025

British Columbia Securities Commission

Corporate Finance

P.O. Box 10142, Pacific Centre

701 West Georgia Street

Vancouver, BC V7Y 1L2

Dear Sirs and Mesdames:

| Re: | Filing by B2Gold Corp. (“B2Gold”) of a Technical Report not required by National Instrument 43-101 - Standards of Disclosure for Mineral Projects (“NI 43-101”) |

B2Gold is filing the attached technical report entitled “Masbate Gold Project, Philippines, NI 43-101 Technical Report” dated effective September 30, 2025 (the “Report”) in respect of its Masbate Gold Project located in the Philippines (the “Project”). The Report is being filed at this time to provide an incremental update for the Project on a voluntary basis as contemplated under section 4.2(12) of the Companion Policy to NI 43-101 and not as a result of a requirement under section 4.2 of NI 43-101.

Yours sincerely,

B2GOLD CORP.

| By: | /s/ Randall Chatwin | |

| Randall Chatwin | ||

| SVP, Legal and Corporate Communications |

cc: Alberta Securities Commission, Financial and Consumer Affairs Authority of Saskatchewan, Manitoba Securities Commission, Ontario Securities Commission, Autorite des marches financiers, Quebec, Nova Scotia Securities Commission, New Brunswick Securities Commission, Office of the Superintendent of Securities, Prince Edward Island, Office of the Superintendent of Securities, Newfoundland and Labrador I, Michael Johnson, P.Geo., am employed as the Manager, Technical Services, with B2Gold Corp.

Exhibit 99.1

CERTIFICATE OF QUALIFIED PERSON

(“B2Gold”), which has its head offices at 666 Burrard St #3400, Vancouver, BC V6C 2X8, Canada.

This certificate applies to the technical report titled “Masbate Gold Project, Philippines, NI 43-101 Technical Report”, that has an effective date of September 30, 2025 (the “Technical Report”).

I am a Professional Geoscientist in good standing with Engineers and Geoscientists British Columbia, Canada (#34923). I graduated from Queen's University with a B.Sc. in geology in 1996.

I have practiced my profession continuously for 29 years. In this time, I have been directly involved in mineral exploration, mine geology, mine reconciliation, and mineral resource estimates for a variety of commodities and mineral deposit types.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (“NI 43–101”).

I visited the Masbate Gold Project most recently from September 26–October 10, 2024, a duration of 15 days.

I am responsible for Sections 1.1, 1.2, 1.3, 1.4, 1.5, 1.6, 1.7, 1.8, 1.10, 1.11, 1.23, 1.25; Sections 2.1, 2.2, 2.3, 2.4.1; 2.5, 2.6, 2.7; Section 3; Section 4; Section 5; Section 6; Section 7; Section 8; Section 9; Section 10; Section 11; Sections 12.1, 12.2, 12.3.1; Section 14; Section 23; Sections 25.1, 25.2, 25.3, 25.4, 25.6, 25.17; Section 26, and Section 27 of the Technical Report.

I am not independent of B2Gold as independence is described by Section 1.5 of NI 43–101.

I have been continuously involved with the Masbate Gold Project since 2013.

I have read NI 43–101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

Dated: November 7, 2025

(Signed) “Michael Johnson”

Michael Johnson, P.Geo.

CERTIFICATE OF QUALIFIED PERSON

I, Peter Montano, P.E., am employed as the Vice President of Projects with B2Gold Corp. (“B2Gold”), which has its head offices at 666 Burrard St #3400, Vancouver, BC V6C 2X8, Canada.

This certificate applies to the technical report titled “Masbate Gold Project, Philippines, NI 43-101 Technical Report”, that has an effective date of September 30, 2025 (the “Technical Report”).

I am a registered Professional Engineer (#42745, Colorado, USA). I graduated from the Colorado School of Mines in 2004 with a B.Sc. in engineering and a B.Sc. in economics.

I have been directly involved in the design, construction, and operation of gold mines in Nicaragua, Namibia, Mali and have participated in and contributed to projects and studies of gold and coal projects in Canada, Venezuela, El Salvador, Colombia, Australia, and the Philippines. I have participated in long-term and strategic mine planning, Mineral Reserve estimation, and economic analyses of mining projects and mining operations, including from development to closure.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101).

I visited the Masbate Gold Project most recently from October 21–24, 2022, a duration of four days.

I am responsible for Sections 1.1, 1.2, 1.8, 1.12, 1.13, 1.14, 1.16, 1.18, 1.19 (excepting process), 1.20 (excepting process), 1.21, 1.22, 1.23, 1.24, 1.25; Sections 2.1, 2.2, 2.3, 2.4.2, 2.5, 2.6; Section 3; Section 5; Section 12.3.2; Section 15; Section 16; Section 18; Section 19; Sections 21.1, 21.2.1, 21.2.2, 21.2.4, 21.2.5, 21.2.6, 21.3.1, 21.3.2, 21.3.4, 21.3.5; Section 22; Section 24; Sections 25.1, 25.7, 25.8, 25.10, 25.12, 25.13 (excepting process), 25.14 (excepting process), 25.15, 25.16, 25.17, 25.18; Section 26; and Section 27 of the Technical Report.

I am not independent of B2Gold as independence is described by Section 1.5 of NI 43–101.

I have been involved with the Masbate Gold Project since 2013.

I have read NI 43–101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

Dated: November 7, 2025

(Signed) “Peter Montano”

Peter Montano, P.E.

CERTIFICATE OF QUALIFIED PERSON

I, John Rajala, P.E., am employed as the Vice President, Metallurgy with B2Gold Corp. (“B2Gold”), which has its head offices at 666 Burrard St #3400, Vancouver, BC V6C 2X8, Canada.

This certificate applies to the technical report titled “Masbate Gold Project, Philippines, NI 43-101 Technical Report”, that has an effective date of September 30, 2025 (the “Technical Report”).

I am a registered professional engineer in the state of Washington (No. 43299) and have a B.Sc. and M.Sc. in Metallurgical Engineering from Michigan Technological University (1976) and the University of Nevada – Mackay School of Mines (1981), respectively. I received a M.E. in Mining Engineering from the University of Arizona in 2022.

I have practiced my profession for 47 years, during which I have been directly involved in the operations and management of mineral processing plants for gold and base metals, and in process plant design and commissioning of projects located in Africa, Asia, North, Central and South America.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (“NI 43–101”).

I visited the Masbate Gold Project most recently from July 10–13, 2023, a duration of four days.

I am responsible for Sections 1.1, 1.2, 1.8, 1.9, 1.15, 1.19 (process costs only), 1.20 (process costs only), 1.25; Sections 2.1, 2.2, 2.3, 2.4.3; Section 12.3.3; Section 13; Section 17; Sections 21.2.3, 21.3.3; Sections 25.1, 25.5, 25.9, 25.13 (process costs only), 25.14 (process costs only); Section 26; and Section 27 of the Technical Report.

I am not independent of B2Gold as independence is described by Section 1.5 of NI 43–101.

I have been involved with the Masbate Gold Project since 2013. I previously co-authored a technical report on the Masbate Gold Project as follows:

| · | Garagan, T., Pemberton, K., Jones, K., Rajala, J., 2016: Masbate Gold Operation, Republic of Philippines: NI43-101 Technical Report on Operations: report prepared for B2Gold Corp., effective date December 31, 2016. |

I have read NI 43–101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument.

As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

Dated: November 7, 2025

(Signed) “John Rajala”

John Rajala, P.E.

CERTIFICATE OF QUALIFIED PERSON

I, Ken Jones, P.E., am employed as the Director, Sustainability, with B2Gold Corp. (“B2Gold”), which has its head offices at 666 Burrard St #3400, Vancouver, BC V6C 2X8, Canada.

This certificate applies to the technical report titled “Masbate Gold Project, Philippines, NI 43-101 Technical Report”, that has an effective date of September 30, 2025 (the “Technical Report”).

I am a registered Professional Engineer (#42718, Colorado, USA). I graduated from the University of Iowa in 2001 with a B. Sc. in Chemical Engineering.

I have practiced my profession for over 20 years. I have developed, conducted and/or directed environmental and social studies including baseline investigations; materials geochemical characterization; hydrologic, air and noise modeling; closure planning and costing; and environmental and social impact assessment for hard rock mining projects in over a dozen countries in North and South America, Africa and Asia. I have developed, implemented and maintained programs for engineering and administrative compliance regarding international environmental, health and safety regulations and best practices at gold projects in Canada, Nicaragua, Namibia, the Philippines, and Mali.

As a result of my experience and qualifications, I am a Qualified Person as defined in National Instrument 43–101 Standards of Disclosure for Mineral Projects (NI 43–101).

I visited the Masbate Gold Project most recently from August 21–28, 2025, a duration of eight days.

I am responsible for Sections 1.1, 1.2, 1.8, 1.17, 1.25; Sections 2.1, 2.2, 2.3, 2.4.4; Sections 4.8, 4.9, 4.10; Section 12.3.4; Section 20; Sections 25.1, 25.11, Section 26; and Section 27 of the Technical Report.

I am not independent of B2Gold as independence is described by Section 1.5 of NI 43–101.

I have been involved with the Masbate Gold Project since 2013. I previously co-authored a technical report on the Masbate Gold Project as follows:

| · | Garagan, T., Pemberton, K., Jones, K., and Rajala, J., 2016: Masbate Gold Operation, Republic of Philippines: NI43-101 Technical Report on Operations: report prepared for B2Gold Corp., effective date December 31, 2016. |

I have read NI 43–101 and the sections of the Technical Report for which I am responsible have been prepared in compliance with that Instrument.

| Page | 2 |

As of the effective date of the Technical Report, to the best of my knowledge, information and belief, the sections of the Technical Report for which I am responsible contain all scientific and technical information that is required to be disclosed to make the Technical Report not misleading.

Dated: November 7, 2025.

(Signed) “Ken Jones”

Ken Jones, P.E.

CAUTIONARY NOTE REGARDING FORWARD-LOOKING INFORMATION

This NI 43-101 Technical Report (the Report) contains “forward-looking information” and “forward-looking statements” (collectively “forward-looking statements”) within the meaning of applicable Canadian and United States securities legislation, including, but not limited to, B2Gold Corp.’s (B2Gold): objectives, strategies, intentions and expectations; projections; outlook; guidance; forecasts; estimates; schedules; plans; designs; and other statements regarding future or estimated financial and operational performance, gold production and sales, revenues and cash flows, capital (sustaining and non-sustaining) and operating costs, and budgets; assumptions as to closure costs and closure requirements; estimated ore grades, throughput and processing; statements regarding anticipated exploration, drilling, development, construction and permitting; statements regarding indications from, and potential impacts of, drilling results; and including, but not limited to: the objectives, strategies, intentions, expectations, production, cost, capital and exploration expenditure guidance, anticipated timelines, potential mineralization and recovery estimates, mine life and the estimated economics of the Masbate Gold Project (Project); events that may affect the Project’s operations, including systems, equipment and materials requirements; anticipated cash flows from the Project and related liquidity requirements; the Project’s ability and timeline to secure all relevant rights, licences, permits and authorizations; the anticipated effect of external factors on revenue, mining and/or development activities, such as commodity prices, exchange rates and metal price assumptions, estimation of Mineral Reserves and Mineral Resources, mine life projections, environmental liabilities, reclamation costs, economic outlook, tailings dam and storage facilities, the maintenance or provision of required infrastructure and information technology systems, government regulation of mining operations, potential effects of extreme weather events, including disruption of mining and transport operations, property damage, increased risk of food insecurity, water scarcity, civil unrest and the prevalence of disease; potential environmental, physical, social and economic impacts and plans, measures, and requirements to address such impacts, including the socio-economic impact of the Project, environmental considerations and closing and reclamation planning; stakeholder engagement; and other expectations regarding community relations and social licence to operate and artisanal and small miners working in the Project area; the lack of sole decision-making authority related to Filminera Resources Corporation; and outcomes of any government agency audits. All statements in this Report that address events or developments that are expected to occur in the future are forward-looking statements. Forward- looking statements are statements that are not historical facts and are generally, although not always, identified by words such as “expect”, “plan”, “anticipate”, “project”, “target”, “potential”, “schedule”, “forecast”, “budget”, “estimate”, “intend” or “believe” and similar expressions or their negative connotations, or that events or conditions “will”, “would”, “may”, “could”, “should”, “might” or will “likely” occur. All such forward-looking statements are based on the opinions and estimates of management as of the date such statements are made. All of the forward-looking statements in this Report are qualified by this cautionary note.

Forward-looking statements are not, and cannot be, a guarantee of future results or events. Forward- looking statements are based on, among other things, opinions, assumptions, estimates and analyses of qualified persons, as defined in NI 43-101, that, while considered reasonable at the date the forward- looking statements is provided, inherently are subject to significant risks, uncertainties, contingencies and other factors that may cause actual results and events to be materially different from those expressed or implied by the forward-looking statements. The material factors or assumptions that are identified and applied in drawing conclusions or making forecasts or projections set out in the forward-looking statements include, but are not limited to: the factors identified in Sections 1.9, 1.10, 1.11, 14 and 25 (and the tables identified thereunder) of this Report, which may affect the Mineral Resource estimate; the forward-looking statements and factors identified in Sections 1.12, 1.13, 1.19, 1.20, 15, 20 and 25 (and the tables identified thereunder) of this Report, which may affect the Mineral Reserve estimate; the metallurgical recovery estimates identified in Sections 1.9 and 13 of this Report; the assumptions identified in Table 14-6 and Sections 1.11, 1.12, and 14.11 of this Report as being used in evaluating prospects for eventual economic extraction; the factors and assumptions identified in Sections 15.4 to 15.8 of this Report as forming the basis for converting Mineral Resources to Mineral Reserves, as well as the assumptions identified in Section 16; the design parameters set forth in Table 16-1; the assumptions relating to waste rock storage facilities identified in Section 16.6, including Table 16-2; the assumptions relating to the production schedule in Section 16.8 (and the tables identified thereunder); the design and equipment assumptions identified in Sections 16, 17 and 18, including Table 17-1 and Figure 17-1 of this Report; the general assumptions identified in Sections 1.13, 1.14, 1.15, 1.16, 1.17, 1.18, 1.19, 1.20, 1.21, 16, 17, 18, 19, 20, 21, 22 and 25 of this Report, as well as the tables included therein; dilution, ore loss and mining recovery assumptions; assumptions regarding stockpiles; the success of mining, processing, exploration and development activities; the accuracy of geological, mining and metallurgical estimates; the financial models used; the supply and demand for, and the anticipated metals prices and the costs of production; no significant unanticipated operational or technical difficulties; the execution of B2Gold’s business and growth strategies, including the success of B2Gold’s strategic investments and initiatives; the availability of additional financing, if needed; the availability of personnel for exploration, development, and operational projects and ongoing employee relations; maintaining good relations with the communities surrounding the Project; no significant unanticipated events or changes relating to regulatory, environmental, health and safety matters; diminishing quantities or grades of reserves; increased costs, delays, suspensions, and technical challenges associated with the construction of capital projects; geotechnical and hydrogeological considerations during mining being different from what was assumed; market competition; no contests over title to B2Gold’s properties; no significant unanticipated litigation; certain tax matters; and no significant and continuing adverse changes in general economic conditions or conditions in the financial markets (including commodity prices and foreign exchange rates).

The risks, uncertainties, contingencies and other factors that may cause actual results to differ materially from those expressed or implied by the forward-looking statements may include, but are not limited to: risks generally associated with mining operations, including problems related to resource shortages and severe weather and climate in the Project area; economic factors, including fluctuations in commodity prices, currency, energy prices and general cost escalation; uncertainties related to the continued development and operation of the Project; the speculative nature of mineral exploration and development; changes to production, exploitation and exploration successes, cost and other estimates; changes to national and local government legislation, taxation laws, policies and practices in the jurisdictions in which we operate, and risks and uncertainties associated with political and economic instability in those jurisdictions; changes in the administration of laws, policies and practices, including political or economic developments in the United States; fluctuations in the price and availability of infrastructure, energy and other commodities; the impact of inflation; the market price of our common shares; compliance with government regulations, including anti-bribery and corruption laws, environmental, health and safety regulations and internal control over financial reporting; risks associated with infectious diseases; damage to B2Gold’s reputation due to actual or perceived occurrence of any number of events, including negative publicity with respect to the handling of environmental matters or dealings with community groups, whether true or not; risk of loss due to acts of war, terrorism, sabotage and civil disturbances; challenges to mineral or surface rights to our properties; the failure to obtain required licences, permits, approvals or clearances from governmental authorities, including environmental permits, on a timely basis or at all; contests over title to properties or over access to water, power and other required infrastructure; climate change; risks related to community relations and opposition, including claims by local communities; the ability to service our debt; uncertainties relating to Mineral Reserve and Mineral Resource estimates, including in relation to the geology, continuity, grade and estimates of Mineral Reserves and Mineral Resources and the potential for variations in grade and recovery rates; the potential for conflict with small scale miners; volatile financial markets and the ability to obtain additional financing; hedging transactions; the inability to insure against all risks; litigation risks; dependence on key personnel and employee relations; operational risks and hazards, industrial accidents, unusual or unexpected formations, unanticipated environmental, industrial and geological events and developments, ground conditions, pressures, slope instability, cave-ins, fire, flooding and gold ore losses (and the risk of inadequate insurance, or inability to obtain insurance, to cover these risks), failure of plant, equipment, processes, transportation and other infrastructure to operate as anticipated; depletion of Mineral Reserves; uncertain costs of reclamation activities, and the final outcome thereof; as well as other factors identified and as described in more detail under the heading “Risk Factors” in B2Gold’s most recent Annual Information Form and B2Gold’s other filings with Canadian securities regulators and the U.S. Securities and Exchange Commission, which may be viewed at www.sedar.ca and www.sec.gov, respectively.

The list is not exhaustive of the factors that may affect B2Gold’s forward-looking statements. There can be no assurance that such statements will prove to be accurate, and actual results, performance or achievements could differ materially from those expressed in, or implied by, these forward-looking statements. Accordingly, no assurance can be given that any events anticipated by the forward-looking statements will transpire or occur, or if any of them do, what benefits or liabilities B2Gold will derive therefrom. B2Gold’s forward-looking statements reflect current expectations regarding future events and operating performance and speak only as of the date hereof and B2Gold does not assume any obligation to update forward-looking statements if circumstances or management's beliefs, expectations or opinions should change other than as required by applicable law. For the reasons set forth above, undue reliance should not be placed on forward-looking statements.

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

Contents

| 1.0 | SUMMARY | 1-1 | |

| 1.1 | Introduction | 1-1 | |

| 1.2 | Terms of Reference | 1-1 | |

| 1.3 | Project Setting | 1-1 | |

| 1.4 | Mineral Tenure, Surface Rights, Water Rights, and Royalties | 1-2 | |

| 1.5 | Geology and Mineralization | 1-2 | |

| 1.6 | History | 1-3 | |

| 1.7 | Drilling and Sampling | 1-4 | |

| 1.8 | Data Verification | 1-5 | |

| 1.9 | Metallurgical Testwork | 1-6 | |

| 1.10 | Mineral Resource Estimation | 1-6 | |

| 1.11 | Mineral Resource Statement | 1-8 | |

| 1.12 | Mineral Reserve Estimation | 1-10 | |

| 1.13 | Mineral Reserve Statement | 1-10 | |

| 1.14 | Mining Methods | 1-10 | |

| 1.15 | Recovery Methods | 1-12 | |

| 1.16 | Project Infrastructure | 1-13 | |

| 1.17 | Environmental, Permitting and Social Considerations | 1-14 | |

| 1.17.1 | Environmental | 1-14 | |

| 1.17.2 | Closure | 1-15 | |

| 1.17.3 | Permitting | 1-15 | |

| 1.17.4 | Social | 1-16 |

| 1.18 | Markets and Contracts | 1-16 | |

| 1.19 | Capital Cost Estimates | 1-17 | |

| 1.20 | Operating Cost Estimates | 1-17 | |

| 1.21 | Economic Analysis | 1-17 | |

| 1.22 | Risks | 1-17 | |

| 1.23 | Opportunities | 1-18 | |

| 1.24 | Interpretation and Conclusions | 1-18 | |

| 1.25 | Recommendations | 1-18 | |

| 2.0 | INTRODUCTION | 2-1 | |

| 2.1 | Introduction | 2-1 | |

| 2.2 | Terms of Reference | 2-1 | |

| 2.3 | Qualified Persons | 2-1 | |

| 2.4 | Site Visits and Scope of Personal Inspection | 2-3 | |

| 2.4.1 | Mr. Michael Johnson | 2-3 |

| November 2025 | TOC |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| 2.4.2 | Mr. Peter Montano | 2-3 | |

| 2.4.3 | Mr. John Rajala | 2-3 | |

| 2.4.4 | Mr. Ken Jones | 2-3 |

| 2.5 | Effective Dates | 2-4 | |

| 2.6 | Information Sources and References | 2-4 | |

| 2.7 | Previous Technical Reports | 2-4 | |

| 3.0 | RELIANCE ON OTHER EXPERTS | 3-1 | |

| 4.0 | PROPERTY DESCRIPTION AND LOCATION | 4-1 | |

| 4.1 | Introduction | 4-1 | |

| 4.2 | Property and Title in the Philippines | 4-1 | |

| 4.2.1 | Mineral Title | 4-1 | |

| 4.2.2 | Surface Rights | 4-3 | |

| 4.2.3 | Mining Taxes (Royalties) | 4-3 | |

| 4.2.4 | Environmental | 4-3 |

| 4.3 | Project Ownership | 4-3 | |

| 4.4 | Mineral Tenure | 4-3 | |

| 4.5 | Surface Rights | 4-4 | |

| 4.6 | Water Rights | 4-10 | |

| 4.7 | Royalties and Encumbrances | 4-10 | |

| 4.8 | Permitting Considerations | 4-10 | |

| 4.9 | Environmental Considerations | 4-10 | |

| 4.10 | Social License Considerations | 4-10 | |

| 4.11 | Comments on Property Description and Location | 4-10 | |

| 5.0 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE, AND PHYSIOGRAPHY | 5-1 | |

| 5.1 | Accessibility | 5-1 | |

| 5.2 | Climate | 5-1 | |

| 5.3 | Local Resources and Infrastructure | 5-1 | |

| 5.4 | Physiography | 5-2 | |

| 5.5 | Seismicity | 5-2 | |

| 5.6 | Comments on Sufficiency of Surface Rights | 5-2 | |

| 6.0 | HISTORY | 6-1 | |

| 6.1 | Project History | 6-1 | |

| 6.2 | Production | 6-1 | |

| 7.0 | GEOLOGICAL SETTING AND MINERALIZATION | 7-1 | |

| 7.1 | Regional Geology | 7-1 | |

| 7.2 | Project Geology | 7-1 | |

| November 2025 | TOC |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| 7.3 | Deposit Descriptions | 7-7 |

| 7.3.1 | Main Vein | 7-7 | |

| 7.3.2 | Blue Quartz | 7-10 | |

| 7.3.3 | Old Lady | 7-13 | |

| 7.3.4 | Pajo | 7-16 | |

| 7.3.5 | Colorado | 7-19 | |

| 7.3.6 | Montana | 7-22 |

| 7.4 | Prospects and Exploration Potential | 7-25 | |

| 8.0 | DEPOSIT TYPES | 8-1 | |

| 8.1 | Deposit Model | 8-1 | |

| 8.2 | Comments on Deposit Types | 8-1 | |

| 9.0 | EXPLORATION | 9-1 | |

| 9.1 | Topographic Surveys | 9-1 | |

| 9.2 | Geological Mapping | 9-1 | |

| 9.3 | Geochemistry | 9-1 | |

| 9.4 | Pits and Trenches | 9-1 | |

| 9.5 | Geophysics | 9-1 | |

| 9.5.1 | Airborne Geophysics | 9-1 | |

| 9.5.2 | Ground Geophysics | 9-7 |

| 9.6 | Artisanal Small Miners | 9-7 | |

| 9.7 | Exploration Potential | 9-7 | |

| 10.0 | DRILLING | 10-1 | |

| 10.1 | Introduction | 10-1 | |

| 10.2 | Drill Methods | 10-1 | |

| 10.3 | Logging Procedures | 10-1 | |

| 10.4 | Recovery | 10-9 | |

| 10.5 | Collar Surveys | 10-9 | |

| 10.6 | Downhole Surveys | 10-9 | |

| 10.7 | Grade Control Drilling | 10-12 | |

| 10.8 | Metallurgical Drilling | 10-12 | |

| 10.9 | Condemnation and Geotechnical Drilling | 10-12 | |

| 10.10 | Sample Length/True Thickness | 10-12 | |

| 10.11 | Drilling Since Database Close-out Date | 10-15 | |

| 10.12 | Comments on Drilling | 10-15 | |

| 11.0 | SAMPLE PREPARATION, ANALYSES, AND SECURITY | 11-1 | |

| 11.1 | Geochemical Programs | 11-1 | |

| 11.2 | RC Sampling | 11-1 | |

| 11.3 | Core Sampling | 11-1 | |

| November 2025 | TOC |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| 11.4 | Density Determinations | 11-2 | |

| 11.5 | Analytical and Test Laboratories | 11-2 | |

| 11.6 | Sample Preparation | 11-2 | |

| 11.7 | Analysis | 11-5 | |

| 11.8 | Quality Assurance and Quality Control | 11-5 |

| 11.8.1 | Standards | 11-5 | |

| 11.8.2 | Blanks | 11-5 | |

| 11.8.3 | Duplicate Samples | 11-8 | |

| 11.8.4 | QA/QC Validation Criteria | 11-8 |

| 11.9 | Databases | 11-9 | |

| 11.10 | Sample Security | 11-9 | |

| 11.11 | Comments on Sample Preparation, Analyses and Security | 11-10 | |

| 12.0 | DATA VERIFICATION | 12-1 | |

| 12.1 | Data Verification by Third Parties | 12-1 | |

| 12.2 | B2Gold Data Checks | 12-1 | |

| 12.3 | Data Verification by Qualified Persons | 12-1 | |

| 12.3.1 | Mr. Michael Johnson | 12-1 | |

| 12.3.2 | Mr. Peter Montano | 12-2 | |

| 12.3.3 | Mr. John Rajala | 12-3 | |

| 12.3.4 | Mr. Ken Jones | 12-3 | |

| 13.0 | MINERAL PROCESSING AND METALLURGICAL TESTING | 13-1 | |

| 13.1 | Introduction | 13-1 | |

| 13.2 | Metallurgical Testwork | 13-1 | |

| 13.2.1 | 2013–2014 | 13-1 | |

| 13.2.2 | 2018 | 13-1 | |

| 13.2.3 | 2021 | 13-2 | |

| 13.2.4 | 2022 | 13-2 |

| 13.3 | Recovery Estimates | 13-3 | |

| 13.4 | Metallurgical Variability | 13-3 | |

| 13.5 | Deleterious Elements | 13-4 | |

| 14.0 | MINERAL RESOURCE ESTIMATES | 14-1 | |

| 14.1 | Introduction | 14-1 | |

| 14.2 | Exploratory Data Analysis | 14-1 | |

| 14.3 | Geological Models | 14-1 | |

| 14.3.1 | Mineralization Domains | 14-2 | |

| 14.3.2 | Lithology Model | 14-2 | |

| 14.3.3 | Weathering Domains and Regolith Models | 14-2 | |

| 14.3.4 | Historic Mined-Out Models | 14-2 |

| November 2025 | TOC |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| 14.3.5 | Metallurgical Recovery Model | 14-2 |

| 14.4 | Density Assignment | 14-3 | |

| 14.5 | Grade Capping/Outlier Restrictions | 14-3 | |

| 14.6 | Composites | 14-3 |

| 14.6.1 | Grade Composites | 14-3 | |

| 14.6.2 | Metallurgical Composites | 14-5 |

| 14.7 | Variography | 14-5 |

| 14.7.1 | Grade Variography | 14-5 | |

| 14.7.2 | Metallurgical Variography | 14-5 |

| 14.8 | Estimation/Interpolation Methods | 14-5 |

| 14.8.1 | Grade Estimation | 14-5 | |

| 14.8.2 | Metallurgical Estimation | 14-7 |

| 14.9 | Block Model Validation | 14-7 | |

| 14.10 | Classification of Mineral Resources | 14-8 | |

| 14.11 | Reasonable Prospects of Eventual Economic Extraction | 14-8 | |

| 14.12 | Mineral Resource Statement | 14-9 | |

| 14.13 | Factors That May Affect the Mineral Resource Estimate | 14-11 | |

| 14.14 | Comments on Mineral Resources | 14-11 | |

| 15.0 | MINERAL RESERVE ESTIMATES | 15-1 | |

| 15.1 | Introduction | 15-1 | |

| 15.2 | Mineral Reserves Statement | 15-1 | |

| 15.3 | Factors that May Affect the Mineral Reserves | 15-1 | |

| 15.4 | Basis of Estimates | 15-2 | |

| 15.5 | Process Costs and Recovery | 15-3 | |

| 15.6 | Gold Price, Excise Tax, and Discounting | 15-7 | |

| 15.7 | Cut-Off Grade | 15-7 | |

| 15.8 | Ore Loss and Dilution | 15-8 | |

| 15.9 | Comments on Open Pit Mineral Reserves | 15-8 | |

| 16.0 | MINING METHODS | 16-1 | |

| 16.1 | Overview | 16-1 | |

| 16.2 | Geotechnical Considerations | 16-1 | |

| 16.2.1 | Main Vein Pit | 16-4 | |

| 16.2.2 | Old Lady Pit | 16-4 | |

| 16.2.3 | Blue Quartz Pit | 16-5 | |

| 16.2.4 | Pajo Pit | 16-5 |

| 16.3 | Hydrogeological Considerations | 16-5 | |

| 16.4 | Open Pit Mining | 16-6 | |

| 16.5 | Stockpiles | 16-6 | |

| 16.6 | Waste Rock Storage Facility Design Criteria | 16-6 |

| November 2025 | TOC |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| 16.7 | Operational Cut-off Grades | 16-10 | |

| 16.8 | Production Schedule | 16-10 | |

| 16.9 | Open Pit Mobile Mining Equipment | 16-10 | |

| 17.0 | RECOVERY METHODS | 17-1 | |

| 17.1 | Process Flow Sheet | 17-1 | |

| 17.2 | Plant Design | 17-1 | |

| 17.3 | Product/Materials Handling | 17-1 | |

| 17.4 | Energy, Water, and Process Materials Requirements | 17-1 | |

| 17.4.1 | Reagents | 17-1 | |

| 17.4.2 | Power | 17-7 | |

| 17.4.3 | Water | 17-7 |

| 18.0 | PROJECT INFRASTRUCTURE | 18-1 | |

| 18.1 | Introduction | 18-1 | |

| 18.2 | Road and Logistics | 18-3 | |

| 18.2.1 | Roads | 18-3 | |

| 18.2.2 | Airstrip | 18-3 | |

| 18.2.3 | Port | 18-3 |

| 18.3 | Stockpiles | 18-3 | |

| 18.4 | Waste Rock Storage Facilities | 18-3 | |

| 18.5 | Tailings Storage Facilities | 18-4 |

| 18.5.1 | Development History and Overview | 18-4 | |

| 18.5.2 | Current Status and Future Expansion | 18-5 |

| 18.6 | Water Management | 18-5 | |

| 18.7 | Water Supply | 18-5 | |

| 18.8 | Camps and Accommodation | 18-6 | |

| 18.9 | Power and Electrical | 18-6 | |

| 19.0 | MARKET STUDIES AND CONTRACTS | 19-1 | |

| 19.1 | Market Studies | 19-1 | |

| 19.2 | Commodity Price Projections | 19-1 | |

| 19.3 | Contracts | 19-1 | |

| 19.4 | Comments on Market Studies and Contracts | 19-1 | |

| 20.0 | ENVIRONMENTAL STUDIES, PERMITTING, AND SOCIAL OR COMMUNITY IMPACT | 20-1 | |

| 20.1 | Introduction | 20-1 | |

| 20.2 | Environmental Studies and Consideration | 20-1 | |

| 20.3 | Reclamation and Closure Considerations | 20-3 | |

| 20.4 | Permitting | 20-5 | |

| 20.5 | Considerations of Social and Community Impacts | 20-5 | |

| November 2025 | TOC |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| 20.5.1 | Community Development | 20-6 | |

| 20.5.2 | Advancement of Mining Technology and Geosciences | 20-7 | |

| 20.5.3 | Information, Education, and Communication | 20-8 | |

| 21.0 | CAPITAL AND OPERATING COSTS | 21-1 | |

| 21.1 | Introduction | 21-1 | |

| 21.2 | Capital Cost Estimates | 21-1 | |

| 21.2.1 | Basis of Estimate | 21-1 | |

| 21.2.2 | Mine Capital Costs | 21-1 | |

| 21.2.3 | Process Capital Costs | 21-1 | |

| 21.2.4 | Site General Capital Costs | 21-1 | |

| 21.2.5 | Closure Costs | 21-2 | |

| 21.2.6 | Capital Cost Summary | 21-2 |

| 21.3 | Operating Cost Estimates | 21-2 |

| 21.3.1 | Basis of Estimate | 21-2 | |

| 21.3.2 | Mine Operating Costs | 21-2 | |

| 21.3.3 | Process Operating Costs | 21-2 | |

| 21.3.4 | Site General Operating Costs | 21-5 | |

| 21.3.5 | Operating Cost Summary | 21-5 | |

| 22.0 | ECONOMIC ANALYSIS | 22-1 | |

| 23.0 | ADJACENT PROPERTIES | 23-1 | |

| 24.0 | OTHER RELEVANT DATA AND INFORMATION | 24-1 | |

| 25.0 | INTERPRETATION AND CONCLUSIONS | 25-1 | |

| 25.1 | Introduction | 25-1 | |

| 25.1.1 | Ownership | 25-1 |

| 25.2 | Mineral Tenure, Surface Rights, Water Rights, and Royalties | 25-1 | |

| 25.3 | Geology and Mineralization | 25-2 | |

| 25.4 | Exploration, Drilling and Analytical Data Collection in Support of Mineral Resource Estimation | 25-2 | |

| 25.5 | Metallurgical Testwork | 25-3 | |

| 25.6 | Mineral Resource Estimates | 25-3 | |

| 25.7 | Mineral Reserve Estimates | 25-3 | |

| 25.8 | Mine Plan | 25-4 | |

| 25.9 | Recovery Plan | 25-4 | |

| 25.10 | Infrastructure | 25-4 | |

| 25.11 | Environmental, Permitting and Social Considerations | 25-5 | |

| 25.12 | Markets and Contracts | 25-5 | |

| 25.13 | Capital Cost Estimates | 25-6 |

| November 2025 | TOC |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| 25.14 | Operating Cost Estimates | 25-6 | |

| 25.15 | Economic Analysis in Support of Mineral Reserve Estimation | 25-6 | |

| 25.16 | Risks | 25-6 | |

| 25.17 | Opportunities | 25-7 | |

| 25.18 | Conclusions | 25-7 | |

| 26.0 | RECOMMENDATIONS | 26-1 | |

| 27.0 | REFERENCES | 27-1 | |

Tables

| Table 1-1: | Indicated Mineral Resource Statement | 1-9 |

| Table 1-2: | Inferred Mineral Resource Statement | 1-9 |

| Table 1-3: | Mineral Reserves Statement | 1-11 |

| Table 1-4: | Capital Cost Schedule By Area | 1-18 |

| Table 4-1: | Deposit Centroids | 4-2 |

| Table 4-2: | Patented Claims | 4-5 |

| Table 4-3: | Granted MPSA Mineral Concessions | 4-6 |

| Table 4-4: | Exploration Permits | 4-7 |

| Table 4-5: | Exploration Permit Applications Mineral Concessions | 4-7 |

| Table 6-1: | Exploration and Development History | 6-2 |

| Table 6-2: | Production History | 6-3 |

| Table 8-1: | Epithermal Deposit Type Features | 8-2 |

| Table 9-1: | Geochemical Sampling Programs | 9-2 |

| Table 9-2: | Airborne Geophysical Surveys | 9-10 |

| Table 9-3: | Ground Geophysics Campaigns | 9-12 |

| Table 9-4: | Advanced Prospects | 9-13 |

| Table 10-1: | Summary of Drilling and Continuous Surface Sampling by Year and Operator | 10-2 |

| Table 10-2: | Drilling Used in Mineral Resource Estimation | 10-4 |

| Table 11-1: | Sample Preparation and Analytical Laboratories | 11-3 |

| Table 11-2: | Analytical Methods | 11-6 |

| Table 11-3: | QA/QC Measures | 11-8 |

| Table 12-1: | Third Party Data Verification | 12-2 |

| Table 13-1: | Metallurgical Recovery Forecasts for LOM | 13-4 |

| Table 14-1: | Density Values Used for Tonnage Estimates | 14-4 |

| Table 14-2: | Gold Grade Capping Summary | 14-4 |

| Table 14-3: | Gold Grade Compositing Summary | 14-4 |

| Table 14-4: | Estimation Plan Composite Parameters | 14-6 |

| Table 14-5: | Metallurgical Recovery Estimation Parameters | 14-8 |

| Table 14-6: | Pit Shell Input Parameters | 14-9 |

| Table 14-7: | Indicated Mineral Resource Statement | 14-10 |

| Table 14-8: | Inferred Mineral Resource Statement | 14-10 |

| Table 15-1: | Mineral Reserves Statement | 15-2 |

| Table 15-2: | Main Vein Pit Optimization Parameters | 15-4 |

| November 2025 | TOC |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| Table 15-3: | Old Lady Pit Optimization Parameters | 15-5 |

| Table 15-4: | Blue Quartz Pit Optimization Parameters | 15-6 |

| Table 15-5: | Pajo Pit Optimization Parameters | 15-7 |

| Table 16-1: | Open Pit Design Parameters | 16-4 |

| Table 16-2: | WRSF Design Parameters | 16-7 |

| Table 16-3: | LOM Production Schedule Summary | 16-11 |

| Table 16-4: | LOM Mine Production Schedule | 16-12 |

| Table 16-5: | Stockpile Opening Balance | 16-13 |

| Table 16-6: | LOM Processing Summary | 16-14 |

| Table 16-7: | Open Pit Mining Equipment | 16-15 |

| Table 17-1: | Plant Design Assumptions | 17-3 |

| Table 17-2: | Plant Equipment List | 17-3 |

| Table 17-3: | Process Plant Key Equipment Numbers | 17-6 |

| Table 21-1: | Capital Cost Schedule By Area | 21-3 |

| Table 21-2: | Mine Operating Cost Summary | 21-3 |

| Table 21-3: | Process Operating Cost Summary | 21-4 |

| Table 21-4: | Site General Operating Cost Summary | 21-6 |

Figures

| Figure 2-1: | Location Plan | 2-2 |

| Figure 4-1: | Mineral Concessions Location Plan | 4-8 |

| Figure 4-2: | Mineral Concessions Location Plan Showing Major Deposits and Prospects | 4-9 |

| Figure 7-1: | Regional Geology Map | 7-2 |

| Figure 7-2: | Masbate Area Stratigraphy | 7-3 |

| Figure 7-3: | Project Geology Map | 7-4 |

| Figure 7-4: | Project Structural Geology Map | 7-6 |

| Figure 7-5: | Main Vein Geological Map | 7-8 |

| Figure 7-6: | Main Vein Geological Cross Section | 7-9 |

| Figure 7-7: | Blue Quartz Geological Map | 7-11 |

| Figure 7-8: | Blue Quartz Geological Cross Section | 7-12 |

| Figure 7-9: | Old Lady Geological Map | 7-14 |

| Figure 7-10: | Old Lady Geological Cross Section | 7-15 |

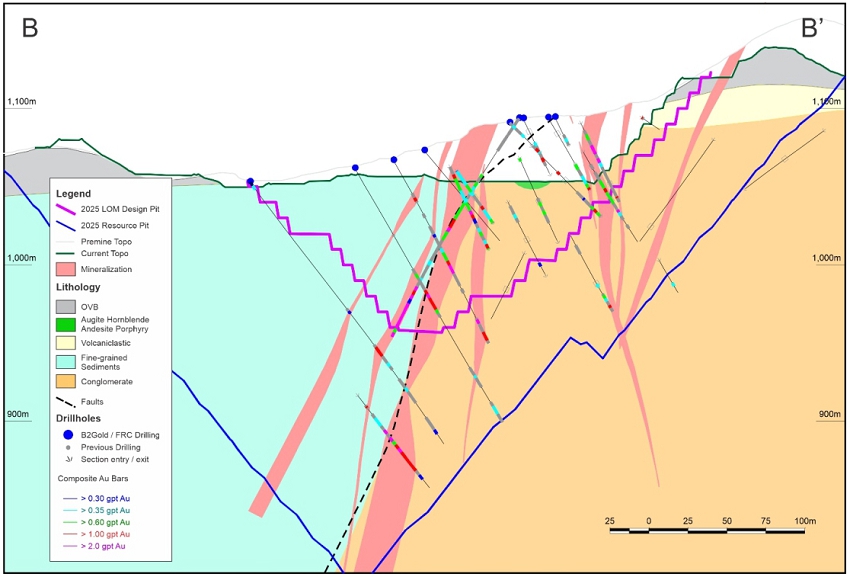

| Figure 7-11: | Pajo Geological Map | 7-17 |

| Figure 7-12: | Pajo Geological Cross Section | 7-18 |

| Figure 7-13: | Colorado Geological Map | 7-20 |

| Figure 7-14: | Colorado Geological Cross Section | 7-21 |

| Figure 7-15: | Montana Geological Map | 7-23 |

| Figure 7-16: | Montana Geological Cross Section | 7-24 |

| Figure 8-1: | Epithermal Model Schematic | 8-3 |

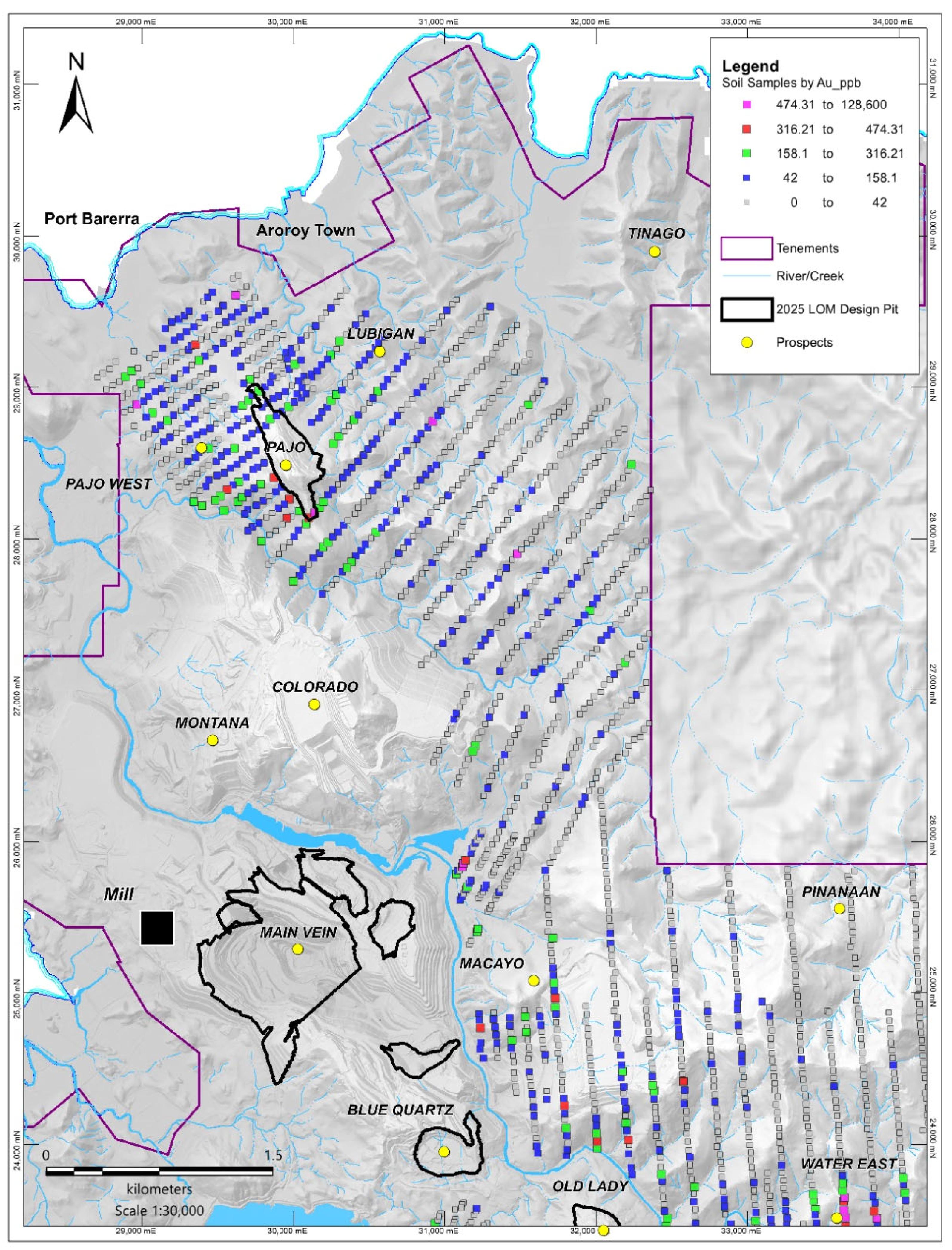

| Figure 9-1: | Rock and Stream Sediment Sample Location Map, North | 9-3 |

| Figure 9-2: | Rock Chip and Stream Sediment Sample Location Map, South | 9-4 |

| Figure 9-3: | Soil Sample Location Map, North | 9-5 |

| Figure 9-4: | Soil Sample Location Map, South | 9-6 |

| Figure 9-5: | Pit and Trench Location Map, North | 9-8 |

| November 2025 | TOC |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| Figure 9-6: | Pit and Trench Location Map, South | 9-9 |

| Figure 9-7: | Geophysical Survey – RTP Magnetic Tilt Derivative | 9-11 |

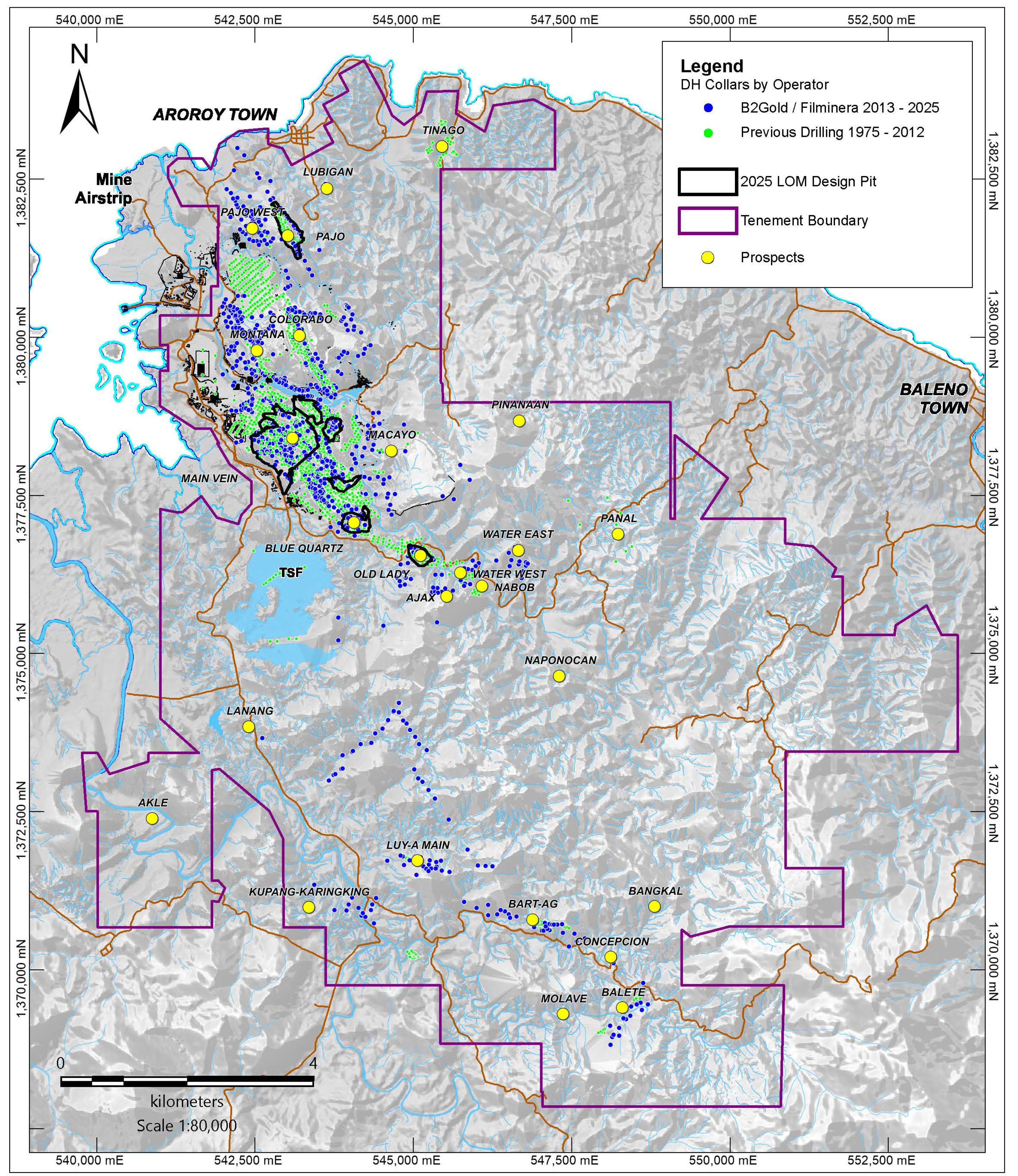

| Figure 10-1: | Project Drill Collar Location Plan | 10-6 |

| Figure 10-2: | Exploration Drill Hole Plan Map, North | 10-7 |

| Figure 10-3: | Exploration Drill Hole Plan Map, South | 10-8 |

| Figure 10-4: | RC Drilling Flowsheet | 10-10 |

| Figure 10-5: | Core Drilling Flowsheet | 10-11 |

| Figure 10-6: | Metallurgical Drill Hole Locations with Property Boundary | 10-13 |

| Figure 10-7: | Geotechnical and Sterilization Drill Hole Locations | 10-14 |

| Figure 16-1: | Main Vein Pit Geotechnical Design Sectors | 16-2 |

| Figure 16-2: | Old Lady Pit Geotechnical Design Sectors | 16-2 |

| Figure 16-3: | Blue Quartz Pit Geotechnical Design Sectors | 16-3 |

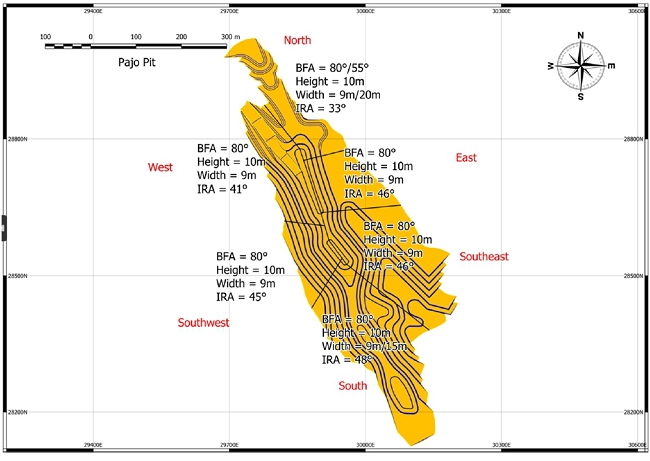

| Figure 16-4: | Pajo Pit Geotechnical Design Sectors | 16-3 |

| Figure 16-5: | Main Vein South Pit 1 WRSF | 16-7 |

| Figure 16-6: | Main Vein Stage 6 WRSF | 16-8 |

| Figure 16-7: | Colorado S4/S5 WRSF | 16-8 |

| Figure 16-8: | Blue Quartz WRSF | 16-9 |

| Figure 16-9: | Pajo WRSF | 16-9 |

| Figure 16-10: | Open Pit LOM Schedule | 16-11 |

| Figure 16-11: | Ore Grade and Tonnes Processed by Stockpile Bin | 16-13 |

| Figure 16-12: | Forecast LOM Gold Production | 16-14 |

| Figure 17-1: | Process Flowsheet | 17-2 |

| Figure 18-1: | Infrastructure Location Plan | 18-2 |

| November 2025 | TOC |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| 1.0 | SUMMARY |

| 1.1 | Introduction |

Mr. Michael Johnson, P.Geo., Mr. Peter Montano, P.E., Mr. John Rajala, P.E., and Mr. Ken Jones, P.E., prepared an NI 43-101 Technical Report (the Report) on the Masbate Gold Project (the Project) for B2Gold Corp. (B2Gold). The Masbate Gold Project is in the municipality of Aroroy, Masbate Island, Region V, Republic of the Philippines.

B2Gold holds the Project interest through its indirect 40% interest in Filminera Resources Corporation (Filminera) and its indirect 100% interest in the Phil. Gold Processing & Refining Corp. (PGPRC). The remaining 60% interest in Filminera is held by a Philippines-registered company, Zoom Mineral Holdings Inc. (Zoom).

Filminera owns almost all of the mineral tenements and is responsible for the mining, environmental, social and community relations on the Project site. PGPRC developed and owns the process plant on the island of Masbate and is responsible for the sale of all gold. PGPRC and Filminera are parties to an ore purchase agreement pursuant to which PGPRC purchases all of the ore production from Filminera at a price equal to the cost for the ore plus a predetermined percentage, while maintaining joint financial and legal liability for the social and environmental obligations under Filipino laws.

| 1.2 | Terms of Reference |

This Report provides updated information on the operation of the Masbate Gold Project, including an updated Mineral Resource and Mineral Reserve estimate.

Units used in the Report are metric units unless otherwise noted. Monetary units are in United States dollars (US$) unless otherwise stated. Mineral Resources and Mineral Reserves are classified using the 2014 edition of the Canadian Institute of Mining and Metallurgy (CIM) Definition Standards for Mineral Resources and Mineral Reserves (the 2014 CIM Definition Standards).

| 1.3 | Project Setting |

The Masbate Gold Project is located within the Republic of the Philippines near the northern extremity of the island of Masbate. The mine is situated about 360 km southeast of Manila, the capital of the Philippines, within the municipality of Aroroy, Masbate Province, Region V.

The operations are accessed by commercial airline service from Clark City or Cebu City on alternate days to Masbate City. From there, it is a 70 km drive on a partially sealed road to the mine site. Alternate access to the site is via a one-hour boat ride from Masbate City. A registered Civil Aviation Authority of the Philippines light air strip and helipad are located close to the Masbate Gold Project. Charter flights to Manila take approximately one hour. The mine site is equipped with a barge loading jetty where heavy equipment and consumables are delivered.

| November 2025 | Page 1- |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

The Philippines has a tropical climate, including a monsoon season. Mining operations are conducted year-round. Rainfall may curtail access to exploration areas for short periods.

The mining operation is within the Aroroy municipality, and about 5 km from the main municipality township of Aroroy. The Project area falls within approximately 22 barangays (villages), eight of which are host to, or directly impacted by, mining operations. Coconut farming and artisanal gold mining are the primary livelihood of the residents in the mine area. Coastal residents primarily engage in fishing and small-scale vegetable farming.

| 1.4 | Mineral Tenure, Surface Rights, Water Rights, and Royalties |

Mining permits in the Project area are held in the name of Filminera, and consist of 29 patented mineral claims, three mineral production sharing agreements, and five exploration permits. Collectively the patented claims, mineral production sharing agreements, and exploration permits cover an area of 9,940.63 ha. Renewal applications have been lodged where required. At the Report effective date there were three exploration permit applications, covering about 4,392.60 ha. The property boundaries are marked by legal description and surface markers where practicable. Filminera has carried out numerous surveys on the property to properly ascertain the lease boundaries and the Philippines Mines and Geosciences Bureau have reviewed these boundaries.

Filminera holds the surface rights to all current open pits, waste rock storage facilities (WRSFs) and stockpiles, the process plant, tailings storage facility (TSF) and associated infrastructure facilities, such as the causeway, port, airstrip, and housing areas. Additional surface rights will need to be acquired to support mining operations for some of the planned satellite pits.

Filminera holds the appropriate permits that allow for extraction of water from various sources, including groundwater, rivers, and seawater.

Filminera holds an interest in the Pajo property, which is situated to the north of mineral production sharing agreement (MPSA) 95-97-V and the area of patented claims. The property is covered by MPSA 219-2005-V which was later consolidated into MPSA 255. Although the Pajo area was assigned to Filminera, Vicar Mining Corporation holds a royalty share equivalent to 2% of the gross receipts (less certain expenses) of the mineral products realized from the Pajo portion of the mineral production sharing agreement.

An excise tax of 1–5% on the gross output of minerals or mineral products extracted or produced is payable annually to the Philippine government. Under Filipino laws, mining companies are required to spend an amount equal to 1.5% of their annual operating cost from the previous year on expenditures for social development of host communities.

| 1.5 | Geology and Mineralization |

The Masbate deposits are considered to be examples of low-sulphidation epithermal systems.

| November 2025 | Page 1- |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

Mineralization is developed in an Early Pliocene volcano–plutonic arc and is controlled by the central segment of the Philippine Fault Zone.

Mineralization is primarily hosted within monomictic to polymictic andesitic volcaniclastic units, interbedded with coherent andesites interpreted as lava flows, domes, and plugs. Additionally, diorite and quartz diorite bodies serve as mineralization hosts, particularly where epithermal structures intersect the mid- to late-Eocene Aroroy Diorite. The width and structural style of mineralization, whether vein, breccia, or veinlet, are influenced by the host lithology. All formations have demonstrated mineralization potential, however augite-hornblende porphyritic plugs and dikes are typically barren and interpreted as post- to syn-mineralization intrusions.

Gold bearing veins are located along regional and local scale faults. Reactivation of secondary northeast-trending cross-faults/fracture systems structurally offset the host stratigraphic sequence and mineralization in an apparent sinistral movement.

Hydrothermal alteration shows distinct zonation, progressing from a core of intense silicification to an outward argillic (sericite-illite-smectite) zone, and finally to a surrounding propylitic (chlorite–calcite ± epidote) zone. The alteration envelope is more widespread where tectonic fracturing has affected the host rocks.

Approximately 31 gold vein deposits and prospects have been identified to date in the wider district, over an area of about 24 x 4 km. Gold is typically hosted in grey to white crystalline to chalcedonic quartz, and is frequently associated with pyrite, marcasite, and minor amounts of chalcopyrite and sphalerite. Veins typically show epithermal textures, mostly massive and comb, but also colloform–crustiform banding and hydrothermal vein–breccia textures. The carbonate species are mainly calcite and manganite.

High-grade veins are generally narrow, but some may reach 20 m in width, while sheeted veinlets and stockworks can reach as much as 75 m in width. Individual veins may be traced for long distances, as much as 2 km. Veins are commonly faulted, and high gold grades can be associated with cataclastic or gouge-rich, quartz bearing structures. Carbonate-dominated veins are generally lower in gold grades.

The vein systems typically remain open at depth, and Main Vein, Colorado and Montana veins retain some potential along strike. Filminera has identified several advanced prospects that may warrant additional exploration.

| 1.6 | History |

A number of companies have completed exploration activities in the general Project area, including Atlas Consolidated Mining & Development Corporation (Atlas), London Fiduciary Trust PLC/Philippine Gold PLC (Philippine Gold), Thistle Mining Inc. (Thistle Mining), and CGA Mining Limited (CGA). Filminera became the in-country operating entity for the Masbate Gold Project in 1997. B2Gold obtained its Project interest in 2013.

| November 2025 | Page 1- |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

Work programs completed have included geological mapping, mapping of artisanal workings, geochemical sampling (stream sediment, rock chip, grab, channel and trench, and soil auger), helicopter geophysical surveys (magnetics and radiometrics), an orientation induced polarization (IP) survey, core, and reverse circulation (RC) drilling, metallurgical testwork, environmental studies, and mining and technical studies.

Artisanal miners are currently active in the Project area.

| 1.7 | Drilling and Sampling |

The Project exploration drill hole database as of September 30, 2025 contains a total of 4,282 drill holes (546,510 m), of which there are 1,996 core holes (299,261 m), 2,057 RC holes (205,022 m), 229 holes pre-collared with RC and completed with core tails (42,227 m) and three core holes from grade control (293 m). Additionally, there are 1,129 units of surface sampling including 1,087 trench/channel (27,817 m) and 42 pits (157 m).

The Mineral Resource estimate for the Masbate Gold Project was updated in late 2023. The exploration drill hole cut-off date was August 15, 2023, and the grade control database cut-off was May 31, 2023. Data used for the 2023 update include a total of 1,782 core (293,059 m), 1,928 RC drill holes (195,891 m) and 1,015 trenches (24,684 m) from the exploration database and 124,001 drill holes (2,516,709 m) from the grade control RC drilling database.

Drilling used for Mineral Resource estimation had a cut-off date of August 15, 2023 for exploration drill holes. Drilling that has been completed since the Mineral Resource estimate database close-out date include 46 core holes totalling 9,503 m. Additional core drilling is generally outside of Mineral Resource areas. Where new drilling affects existing resources, the drill holes generally support modeled interpretations and grades with only minor variations.

RC drill holes were typically 11.4 cm (4½ inch), 13.3 cm (5 ¼ inch), or 14 cm (5.5 inch) in diameter. Core diameters completed included PQ core (83.1 mm core diameter), HQ (61.1 mm), and NQ (47.6 mm). BQ (36.5 mm) and AQ (27 mm) core were primarily drilled underground.

For RC drill holes, samples are split at the rig using a riffle splitter. The RC cuttings were logged following mineralogical examination of a small, washed sample. Chip trays were retained for each drill hole. Core is photographed, logged, and sampled. Meter intervals are marked up and the core cut in half using a diamond saw. Hand sampling could be used when the core is soft or very broken. Geological information collected during logging includes lithologies, alteration types, vein percentages, sulphide type and quantity, and structures. Geotechnical information collected includes weathering condition, type of structures, joint spacing, joint condition, and type of joint filling (e.g. gouge, mylonite, breccia, vein). Magnetic susceptibility is also measured by Filminera.

Core recovery can vary depending on the degree of mineralization and the era drilled. Filminera programs during the B2Gold era have averaged 92.2% core recovery.

Methods used to survey drill hole collar locations have included theodolite, total station, and global positioning system (GPS) instruments. Down-hole surveys have been performed at regular downhole intervals using a number of different instrument types, including Tropari, Ausmine, Eastman, Proshot and Reflex instrumentation.

| November 2025 | Page 1- |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

Depending on the drill program and drill type, sample lengths have varied from 1–3 m. Current sampling is typically conducted on 1 m intervals for RC, core, and grade control drilling.

The database currently contains approximately 15,276 bulk density measurements. Measurements were taken on oxide, transitional and fresh rocks.

Sample preparation and analytical laboratories varied over time. Where known, the following independent laboratories were used: McPhar Laboratories, SGS Philippines, SGS Tianjin, SGS Masbate, Intertek, Manila, and ACME/Bureau Veritas Vancouver. Laboratory accreditations included ISO 9001 and ISO/IEC 17025. Non-independent laboratories included the Atlas laboratory in Cebu, and the onsite mine laboratory, neither of which were/are accredited.

Sample preparation has used crush and pulverization criteria that were in line with industry norms at the time. Crush sizes include <6 mm, <2 mm, 75% passing -2 mm, and pulverization sizes included <200 mesh (75 µm), 90% passing -200 mesh, and 85% passing 75 µm mesh. Analytical methods for core and RC samples included fire assay for gold, a multi-element suite from inductively coupled plasma with either an optical emission spectroscopy or mass spectrometry finish, and carbon and sulphur assays using a carbon and sulphur analyser or carbon assays using infrared combustion.

Modern quality assurance and quality control (QA/QC) programs have been in place since at least 2000, and include submission of blank, standard reference materials (standards) and duplicates. QA/QC results are reviewed on a regular basis upon receipt of analytical results from the laboratory. Any discrepancies or outliers identified during these reviews are reported to the laboratory for investigation, and are documented in a monthly QA/QC report. When a warning or failure is identified, additional investigation is conducted.

Data are verified by the project geologists and database manager prior to upload into the database.

Sample security practices were in line with industry norms prevailing at the time the sample was collected. Samples are currently stored in a secure facility prior to being shipped to the preparation and analytical laboratories.

| 1.8 | Data Verification |

Site visits were completed. The QPs individually reviewed the information in their areas of expertise, and concluded that the information supported Mineral Resource and Mineral Reserve estimation, and could be used in mine planning and in the economic analysis that supports the Mineral Reserve estimates.

| November 2025 | Page 1- |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| 1.9 | Metallurgical Testwork |

Metallurgical testwork was performed by Atlas prior to commencing operations, and by Filminera in support of feasibility studies that were undertaken in 1998 and 2006. These supported that the Masbate ores were amenable to conventional whole ore cyanidation processes. Experimental testwork investigated recovery variation due to grind size, leach time, and cyanide concentration, as well as documenting leach kinetics, cyanide and lime consumption, silver recovery, slurry rheology, carbon adsorption, and cyanide detoxification. Ores ranged in hardness, depending on oxidation state, but were typically classified as “medium hard”. From the recovery response obtained for the cyanidation testwork, the material can be categorized as either free-milling or mildly refractory. Gold recoveries were also established by oxidation type and gold head grade, ranging from 74% in fresh ore (<1 g/t Au) to 93% in oxide ore (>1 g/t Au). Gold recovery was found to increase with finer grind size. As a result, the plant design grind was established at P80 grind size of 106 µm, and design leach residence time was 24 hours for a 4 Mt/a plant.

The process plant was expanded to 6.5 Mt/a in 2016 primarily with additional leach capacity and again in 2019 with crushing circuit upgrades and the addition of a third ball mill. Current plant throughput is 8 Mt/a, grind size P80 is 130–150 µm and leach residence time is 26 hours.

PGPRC completed a major testwork campaign at SGS Minerals from 2013–2014 to optimize the existing mill process and to examine the response of samples from a number of mineralized zones to cyanide leaching using an optimized carbon-in-leach (CIL) process. CIL modelling results indicated that the current circuit was operating well and the performance was very good for a CIL plant that has significant leaching occurring in the adsorption tanks.

Samples from the Old Lady and Blue Quartz deposits were tested in 2018 and 2021, and included detailed chemical analysis, Bond work index, and standard bottle roll tests, to determine the effect on the process plant if the material from these deposits was blended into the mill feed. The mineralization was considered amenable to the current process circuit.

Current metallurgical recoveries vary by deposit and zone. The life-of-mine (LOM) average recovery is estimated at approximately 75.6% from all sources to be treated in the LOM plan.

There are no known deleterious elements that incur penalties in the doré or cause metallurgical processing issues.

| 1.10 | Mineral Resource Estimation |

Mineral Resources were estimated for Pajo, Colorado, Montana, Blue Quartz, Old Lady, and several sub-deposits collectively referred to as Main Vein including Libra, Main Vein, and Panique. The Mineral Resources for all deposits were captured in a single block model. Software used in the estimation included Leapfrog Geo (modelling), Surpac (estimation), Supervisor (geostatistics), and Whittle (open pit optimization).

| November 2025 | Page 1- |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

Both exploration and grade control drill data were used in the Mineral Resource estimate. Geological logging, structural logging and assay results from exploration core and RC drill holes were used as the basis of the three-dimensional (3D) models of overburden, lithology, structure, mineralization zones, and gold grade estimates. The model was created in late 2023. Drill hole data cut-offs for this model are August 15, 2023 for exploration drilling data and May 31, 2023 for all grade control drilling data. The resource model accounts for depletion to September 30, 2025.

Geological models were created for higher-grade quartz vein and breccia structures and lower-grade stockwork halo zones. In many areas, fault and lithology models were created and are used to guide mineralization models where needed. Models of historic and current mined-out areas were also created. Metallurgical sample data were used to estimate metallurgical recovery into the block model mineralization domains using ordinary kriging (OK) over a variety of scales. This resulted in local estimates of metallurgical recovery and the ability to calculate a recoverable gold grade for each block.

Gold assay values were capped before compositing and estimation. Regularized composites for grade estimation were created using 3 m “best fit” lengths with hard boundaries on each mineralization domain boundary (i.e. vein and halo), except when similar domains were grouped. Estimations of metallurgical recovery used 6 m composites, approximately the most common length of the sample data.

Variograms were created for domains with sufficient composites to determine the directions and distances of gold grade continuity. The modeled variograms were used as input for ordinary kriging interpolation and other estimation parameters. In domains where insufficient composites were available for variography, a typical variogram was used. A global variogram was modeled for all metallurgical recovery data and used as input for recovery estimation parameters.

Mineralization and oxidation domains were coded to 10 x 10 x 6.67 m blocks using sub-cells of 2.5 x 2.5 x 1.67 m. Gold grades were interpolated into five types of domains: vein/breccia, halo, surficial (eluvial/alluvial), dump, and mined-out/void/backfilled stopes.

For each domain type, grades were estimated using ordinary kriging (OK), inverse distance squared (ID2), and nearest-neighbour (NN) interpolation methods. In the halo domains, estimation is also completed using indicator kriging (IK). ID2 and NN models are used for comparison and validation of estimates. The final grade model for halo domains uses the IK estimate while OK is used for all other domain types. Estimation search ellipses were aligned along domain structure trends. In all cases, estimations were completed in three passes. Grade control composites were used (unrestricted) in conjunction with exploration data for Pass 1. In Pass 2, grade control composites were treated as a single drill hole and constrained by the maximum number of composites permitted per drill hole for each domain. Grade control composites were not used in Pass 3 at all. Metallurgical recovery was estimated into all vein and halo mineralization domains as a single grouped domain. Estimation was completed by OK with NN and ID2 used for validation and comparison. Estimation was completed in one pass, aligned along the individual mineralization domains using dynamic anisotropy.

| November 2025 | Page 1- |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

Resource models were classified using an assessment of geological and mineralization complexity, data quality, and data density. Classification was implemented using drill hole spacing as the primary criterion.

| · | Indicated: blocks in regions of 50 m spacing; supported by two or more drill holes and estimated in Pass 1 or Pass 2; |

| · | Inferred: blocks in regions of 100 m spacing and estimated in Pass 2 or Pass 3. |

No Measured Mineral Resources were classified.

Mineral Resources considered potentially amenable to open pit mining methods were constrained within Whittle optimized pit shells.

Because the mineralization has variable metallurgical recoveries, the Mineral Resource estimates are stated at variable cut-off grades that average 0.29 g/t Au.

| 1.11 | Mineral Resource Statement |

Mineral Resources are reported in situ or in stockpiles using the CIM Definition Standards and have an effective date of September 30, 2025.

The Qualified Person for the estimate is Michael Johnson, P.Geo., Manager of Technical Services for B2Gold.

The Mineral Resource estimates account for depletion to September 30, 2025.

Indicated Mineral Resources are reported in Table 1-1 inclusive of those Indicated Mineral Resources that were converted to Probable Mineral Reserves. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. Inferred Mineral Resources are reported in Table 1-2.

Factors that may affect the Mineral Resource estimates include: metal price and exchange rate assumptions; changes to the assumptions used to generate the gold grade cut-off grade; changes to geological and mineralization shapes, and geological and grade continuity assumptions; accuracy of historical drilling and mining records; density and domain assignments; geometallurgical and oxidation assumptions; changes to geotechnical, mining, and metallurgical recovery assumptions; accuracy of historical drilling and mining records changes to the input and design parameter assumptions that pertain to the conceptual pit constraining the estimates; and assumptions as to the continued ability to access the site, retain mineral and surface rights titles, maintain environment and other regulatory permits, and maintain the social license to operate.

| November 2025 | Page 1- |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| Table 1-1: | Indicated Mineral Resource Statement |

| Region | Tonnes

(x 1000 t) |

Gold

Grade (g/t Au) |

Contained

Gold (x 1000 oz) |

| North | 30,818 | 0.66 | 656 |

| South | 80,339 | 0.74 | 1,918 |

| Stockpiles | 38,610 | 0.59 | 735 |

| Total Indicated | 149,767 | 0.69 | 3,308 |

| Table 1-2: | Inferred Mineral Resource Statement |

| Region | Tonnes

(x 1000 t) |

Gold

Grade (g/t Au) |

Contained

Gold (x 1000 oz) |

| North | 17,587 | 0.67 | 381 |

| South | 34,117 | 0.70 | 767 |

| Total Inferred | 51,704 | 0.69 | 1,148 |

Notes:

| 1. | Mineral Resources have been classified using the 2014 CIM Definition Standards. Mineral Resources are reported in situ or in stockpiles inclusive of those Mineral Resources that have been modified to Mineral Reserves. Mineral Resources that are not Mineral Reserves do not have demonstrated economic viability. |

| 2. | Mineral Resources are reported on a 100% project basis. Pursuant to the ore sales and purchase agreement between Filminera and PGPRC, a wholly-owned subsidiary of B2Gold, PGPRC has the right to purchase all ore from Filminera. B2Gold has a 40% interest in Filminera, which owns the mineral tenements, and the remaining 60% is owned by a Philippines-registered company, Zoom Mineral Holdings Inc. |

| 3. | The Qualified Person for the in situ Mineral Resource estimate is Michael Johnson, P.Geo., Manager Technical Services, Exploration, B2Gold. |

| 4. | The Qualified Person for the stockpile estimate is Peter Montano, P.E., Vice President, Projects, B2Gold. |

| 5. | The Mineral Resource estimate for the Masbate Gold Project accounts for mining depletion as of September 30, 2025. The Mineral Resource estimate has an effective date of September 30, 2025. |

| 6. | Mineral Resource estimates assume an open pit mining method. |

| 7. | Mineral Resources are reported within conceptual open pit shells based on a gold price of US$2,550/oz, modeled metallurgical recovery (resulting in average metallurgical recoveries by resource area that range from 61–89%), and operating cost estimates of US$1.50–US$2.00/t mined (mining), US$14.26/t processed (processing) , US$2.48–US$3.78/t processed (general and administrative) and a selling cost of US$108.00/oz. |

| 8. | Mineral Resources are reported at an average cut-off grade of 0.29 g/t Au. |

| 9. | North and South designations refer to locations north and south of the Guinobatan River, respectively. |

| 10. | All tonnage, grade and contained metal content estimates have been rounded; rounding may result in apparent summation differences between tonnes, grade and contained metal content. |

| November 2025 | Page 1- |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| 1.12 | Mineral Reserve Estimation |

Mineral Reserves were estimated from four deposits based on open pit mining methods: Main Vein, Old Lady, Blue Quartz, and Pajo.

Mineral Reserves were converted from Indicated Mineral Resources. Inferred Mineral Resources are treated as waste in all pit optimization and production scheduling. The mine plan is based on open-cut mining using conventional mining methods and equipment. The economic parameters used for open pit optimization were used to create cut-off grades for reporting of Mineral Reserves. Final pit designs were completed by personnel at the mine site. Mineral Reserves include stockpiled ore which is reported from operational survey data for volume calculation of individual stockpiles, with grade estimated from grade control. Mined Mineral Reserves in the LOM plan presented in this Report are contained within four main open pits, with the Main Vein pit being the largest and the only pit that is mined in phases.

Mineral Reserves are reported at an assay cut-off grade of 0.42 g/t Au. Mining dilution and mining losses are applied to the Mineral Resource block model to create a Mineral Reserve model for pit optimization analysis.

| 1.13 | Mineral Reserve Statement |

The Mineral Reserve estimates, reported within the ultimate open pits and stockpiles, are presented in Table 1-3. The Qualified Person for the estimate of Mineral Reserves in the open pits and stockpiles is Mr. Peter Montano, P.E., Vice President, Projects, an employee of B2Gold. The estimate has an effective date of September 30, 2025.

Factors that may affect the Mineral Reserve estimates apply to both open pit and underground reserves, and include: changes to the gold price assumptions; changes to the input assumptions used to optimize the pit shell and the mine plan that is based on the resulting open pit designs; changes to geotechnical, hydrogeological, and dewatering assumptions; changes to inputs to capital and operating cost estimates; changes in mining or milling productivity assumptions; changes to modifying factor assumptions, including environmental, permitting, and social licence to operate; accuracy of historical drilling and mining records; ability to obtain mining permits and/or surface rights for the satellite pit areas; ability to maintain social and environmental licence to operate.

| 1.14 | Mining Methods |

Mining operations use conventional open pit mining method and equipment. Under the current mine plan, mining operations will end in 2028 and stockpile processing will be completed in 2034. The mine plan assumes that all necessary permits will be granted in support of the mining operations and that the necessary surface rights can be obtained.

| November 2025 | Page 1- |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |

| Table 1-3: | Mineral Reserves Statement |

| Deposit | Mining Method | Tonnes

(x 1,000 t) |

Gold

Grade (g/t Au) |

Contained

Gold (x 1,000 oz) |

| Main Vein Pit, Phase 1 | Open pit | 14,290 | 1.06 | 490 |

| Main Vein Pit, Phase 3 | Open pit | 290 | 1.53 | 10 |

| Main Vein Pit, Phase 5 | Open pit | 2,190 | 0.72 | 50 |

| Old Lady Pit | Open pit | 3,020 | 0.77 | 80 |

| Blue Quartz Pit | Open pit | 2,010 | 0.86 | 60 |

| Pajo Pit | Open pit | 6,190 | 0.75 | 150 |

| Subtotal - Open Pits | 27,980 | 0.92 | 830 | |

| Stockpiles | 38,610 | 0.59 | 740 | |

| Total Probable Reserves | 66,590 | 0.73 | 1,560 | |

Notes:

| 1. | Mineral Reserves have been classified using the 2014 CIM Definition Standards, and are reported at the point of delivery to the process plant. |

| 2. | Mineral Reserves are reported on a 100% project basis. Pursuant to the ore sales and purchase agreement between Filminera and PGPRC, PGPRC has the right to purchase all ore from Filminera. B2Gold has a 40% interest in Filminera, which owns the mineral tenements, and the remaining 60% is owned by a Philippines-registered company, Zoom Mineral Holdings Inc. |

| 3. | The Qualified Person for the Mineral Reserve estimate is Peter Montano, P.E., B2Gold’s Vice President, Projects. |

| 4. | Mineral Reserves are based on a conventional open pit mining method, gold price of US$1,750/oz, modeled metallurgical recovery (resulting in average LOM metallurgical recoveries by pit that range from 63–87%), and average base operating cost estimates of US$1.46–US$2.23/t mined (mining), US$14.26/t processed (processing), US$2.48–3.78/t processed (site general), and US$75.34/oz selling cost including freight and excise tax. |

| 5. | Reserve model dilution and ore loss were applied through whole block averaging such that at a 0.45 g/t Au cut-off there is a 5.1% increase in tonnes, a 5.9% reduction in grade, and a 1.2% reduction in ounces when compared to the Mineral Resource model. |

| 6. | Mineral Reserves are reported at an assay cut-off grade of 0.42 g/t Au. |

| 7. | All tonnage, grade and contained metal content estimates have been rounded; rounding may result in apparent summation differences between tonnes, grade, and contained metal content. |

Pit wall designs were developed based on guidelines provided by a third-party geotechnical consultant. Design considerations included considerations of voids and backfill from historical mining activities, and the presence of fault zones, and rock and clay types within the pit walls. Pit wall depressurisation programs are typically carried out using 30 m long sub horizontal depressurisation holes. No hydrological information is currently available for the Old Lady, Blue Quartz, and Pajo pits. The mine plan allows for wall depressurisation drilling.

The open pit mining sequence involves grade control drilling; drill and blast operations; and excavation and hauling of materials to run-of-mine (ROM) pad of the process plant, or to temporary low-grade ore stockpiles or to the waste rock storage facility. Mining operations are conducted under an owner operator model and activities scheduled on 24 hours, seven days per week basis.

| November 2025 | Page 1- |

|

| Masbate Gold Project | |

| Philippines | |

| NI 43-101 Technical Report |