UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

WASHINGTON, D.C. 20549

FORM 20-F

(Mark One)

☐ |

REGISTRATION STATEMENT PURSUANT TO SECTION 12(b) OR (g) OF THE SECURITIES EXCHANGE ACT OF 1934 |

OR

☒ |

ANNUAL REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

For the fiscal year endedDecember 31, 2023

OR

☐ |

TRANSITION REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

OR

☐ |

SHELL COMPANY REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF 1934 |

Date of event requiring this shell company report

For the transition period from to

Commission file number:000-41356

Electra Battery Materials Corporation

(Exact name of Registrant as specified in its charter)

N/A

(Translation of Registrant’s name into English)

Canada

(Jurisdiction of Incorporation or Organization)

133 Richmond Street W, Suite 602, Toronto, Ontario, M5H 2L3, Canada

(Address of Principal Executive Offices)

Trent Mell

Electra Battery Materials Corporation

133 Richmond Street W, Suite 602

Toronto, Ontario, M5H 2L3

Telephone: (416) 900-3891

(Name, Telephone, E-mail and/or Facsimile number and Address of Company Contact Person)

Securities registered or to be registered pursuant to Section 12(b) of the Act:

Title of each class |

Trading Symbol(s) |

Name of each exchange on which registered |

Common Shares |

ELBM |

The Nasdaq Stock Market LLC |

Securities registered or to be registered pursuant to Section 12(g) of the Act

None

(Title of Class)

Securities for which there is a reporting obligation pursuant to section 15(d) of the Act

None

(Title of Class)

Indicate the number of outstanding shares of each of the issuer’s classes of capital or common stock as of the close of the period covered by the annual report: 55,851,327.

Indicate by check mark if the registrant is a well-known seasoned issuer, as defined in Rule 405 of the Securities Act.

☐Yes ☒No

If this report is an annual or transition report, indicate by check mark if the registrant is not required to file reports pursuant to Section 13 or 15(d) of the Securities Exchange Act of 1934.

☐Yes ☒No

Indicate by check mark whether the registrant (1) has filed all reports required to be filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the preceding 12 months (or for such shorter period that the registrant was required to file such reports), and (2) has been subject to such filing requirements for the past 90 days.

☒Yes ☐No

Indicate by check mark whether the registrant has submitted electronically every Interactive Data File required to be submitted pursuant to Rule 405 of Regulation S-T (§232.405 of this chapter) during the preceding 12 months (or for such shorter period that the registrant was required to submit such files)

☒Yes ☐No

Indicate by check mark whether the registrant is a large accelerated filer, an accelerated filer, a non-accelerated filer, or an emerging growth company. See definition of “large accelerated filer,” “accelerated filer,” and “emerging growth company” in Rule 12b-2 of the Exchange Act.

Large accelerated filer ☐ |

Accelerated filer ☐ |

Non-accelerated filer ☒ |

|

|

Emerging growth company ☒ |

If an emerging growth company that prepares its financial statements in accordance with U.S. GAAP, indicate by check mark if the registrant has elected not to use the extended transition period for complying with any new or revised financial accounting standards† provided pursuant to Section 13(a) of the Exchange Act. ☐

†The term “new or revised financial accounting standard” refers to any updated issued by the Financial Accounting Standards Board to its Accounting Standards Codification after April 5, 2012.

Indicate by check mark whether the registrant has filed a report on and attestation to its management’s assessment of the effectiveness of its internal control over financial reporting under Section 404(b) of the Sarbanes-Oxley Act (15 U.S.C. 7262(b)) by the registered public accounting firm that prepared or issued its audit report. ☐

If securities are registered pursuant to Section 12(b) of the Act, indicate by check mark whether the financial statements of the registrant included in the filing reflect the correction of an error to previously issued financial statements. ☐

Indicate by check mark whether any of those error corrections are restatements that required a recovery analysis of incentive- based compensation received by any of the registrant’s executive officers during the relevant recovery period pursuant to §240.10D-1(b). ☐

Indicate by check mark which basis of accounting the registrant has used to prepare the financial statements included in this filing:

U.S. GAAP |

☐ |

International Financial Reporting Standards as issued by |

☒ |

Other |

☐ |

If “Other” has been checked in response to the previous question, indicate by check mark which financial statement item the registrant has elected to follow.

☐ Item 17 ☐ Item 18

If this is an annual report, indicate by check mark whether the registrant is a shell company (as defined in Rule 12b-2 of the Exchange Act).

☐Yes ☒No

(APPLICABLE ONLY TO ISSUERS INVOLVED IN BANKRUPTCY PROCEEDINGS DURING THE PAST FIVE YEARS)

Indicate by check mark whether the registrant has filed all documents and reports required to be filed by Section 12, 13 or 15(d) of the Securities Exchange Act of 1934 subsequent to the distribution of securities under a plan confirmed by a court

☐Yes ☐No

TABLE OF CONTENTS

|

i |

||

|

ii |

||

|

iii |

||

|

1 |

||

|

1 |

||

|

1 |

||

|

1 |

||

|

15 |

||

|

67 |

||

|

67 |

||

|

68 |

||

|

86 |

||

|

86 |

||

|

86 |

||

|

87 |

||

|

94 |

||

|

96 |

||

|

|

97 |

|

|

97 |

||

Material Modifications to the Rights of Security Holders and Use of Proceeds |

|

97 |

|

|

97 |

||

|

98 |

||

|

98 |

||

|

99 |

||

|

100 |

||

|

100 |

||

Purchases of Equity SEcurities by THE COMPANY and Affiliated Purchasers |

|

100 |

|

|

100 |

||

|

101 |

||

|

101 |

||

Disclosure Regarding Foreign Jurisdictions that Prevent Inspections |

|

101 |

|

|

101 |

||

|

102 |

||

|

|

103 |

|

|

103 |

||

|

103 |

||

|

103 |

||

i

GENERAL MATTERS

Unless otherwise noted or the context indicates otherwise “we”, “us”, “our”, the “Company” or “Electra” refers to Electra Battery Materials Corporation.

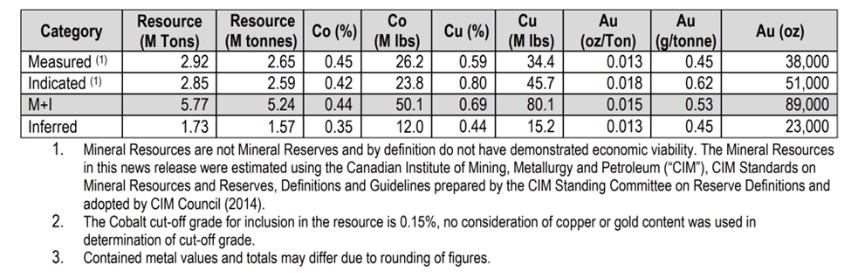

As used in this Annual Report on Form 20-F (this “Annual Report”), the terms “Mineral Resource,” “Measured Mineral Resource,” “Indicated Mineral Resource,” “Measured Mineral Resource,” and “Inferred Mineral Resource” and any grammatical variations thereof are based on the definitions of such terms set forth in Subpart 1300 of Regulation S-K (“S-K 1300”).

Unless otherwise indicated, financial information in this Annual Report has been prepared in accordance with International Financial Reporting Standards, or IFRS, as issued by the International Accounting Standards Board, or IASB. Unless otherwise noted herein, all references to “$,” “C$,” “Canadian dollars,” or “dollars” are to the currency of Canada and “US$,” “United States dollars,” or “U.S. dollars” are to the currency of the United States.

We are an “emerging growth company” as defined in the Jumpstart Our Business Startups Act of 2012, or the JOBS Act, and as such, we have elected to comply with certain reduced U.S. public company reporting requirements.

Unless otherwise indicated, the Company has obtained the market and industry data contained in this Annual Report from its internal research, management’s estimates and third-party public information and other industry publications. While the Company believes such internal research, management’s estimates and third-party public information is reliable, such internal research and management’s estimates have not been verified by any independent sources and the Company has not verified any third-party public information. While the Company is not aware of any misstatements regarding the market and industry data contained in this Annual Report, such data involves risks and uncertainties and are subject to change based on various factors, including those described under “Cautionary Statement Regarding Forward-Looking Information and Statements” and “Item 3.D. Risk Factors”. This Annual Report contains forward-looking statements that are subject to risks and uncertainties.

ii

CAUTIONARY NOTE REGARDING FORWARD-LOOKING STATEMENTS

These forward-looking statements include information about possible or assumed future results of our business, financial condition, results of operations, liquidity, plans and objectives. In some cases, you can identify forward-looking statements by terminology such as “believe,” “may,” “might,” “will,” “indicate,” “seek,” “likely,” “estimate,” “continue,” “anticipate,” “intend,” “should,” “plan,” “expect,” “predict,” “potential,” or the negative of these terms or other similar expressions. The statements we make regarding the following matters are forward-looking by their nature and are based on certain of the assumptions noted below: statements relating to the business and future activities of, and development related to, the Company after the date of this Annual Report, as applicable; the ability of the Company to continue as a going concern, our ability to generate revenue and our cash flows, statements regarding raising additional capital and financing activities, debt service, anticipated burn rate and operations; planned exploration and development programs and expenditures; plans to process black mass material and the ability to recover high value elements therefrom; expectations as to the timing of commissioning of equipment and the Refinery (as defined below); expectations as to the extension of the Company’s black mass processing and recovering activities; the memorandum of understanding with the Three Fires (as defined below); the Cobalt Supply Agreement (as defined below); commercial agreements with LGES (as defined below) and other parties; the Stratton Offtake Agreement (as defined below); the Glencore Offtake Agreement (as defined below); the results of the Refinery and black mass reviews; the results of the Strategic Review Process; timelines and milestones with respect to the Refinery; anticipated expenditures and programs at the Refinery and Iron Creek Project (as defined below); the results of any scoping study of an integrated nickel sulfide processing facility; the impact of any health pandemics on the Company; the estimation of mineral resources; magnitude or quality of mineral deposits; anticipated advancement of mineral properties and programs; future exploration prospects; proposed exploration plans and expected results of exploration; Electra’s ability to obtain licenses, permits and regulatory approvals required to implement expected future exploration plans; changes in commodity prices and exchange rates; future growth potential of Electra; future development plans; the 2023 Note Offering (as defined below) and the obligations of the Company and its subsidiaries in connection with the 2023 Note Offering; and currency and interest rate fluctuations. Any statements that express or involve discussions with respect to predictions, expectations, beliefs, plans, projections, objectives, assumptions or future events or performance (often, but not always, identified by words or phrases such as “expects”, “is expected”, “anticipates”, “believes”, “plans”, “projects”, “estimates”, “assumes”, “intends”, “strategy”, “goals”, “objectives”, “potential”, “possible” or variations thereof or stating that certain actions, events, conditions or results “may”, “could”, “would”, “should”, “might” or “will” be taken, occur or be achieved, or the negative of any of these terms and similar expressions) are not statements of fact and may be forward-looking statements. In particular, forward-looking information in this 20-F includes, but is not limited to, statements with respect to future events and is subject to certain risks, uncertainties and assumptions. Although we believe that the expectations reflected in the forward-looking information are reasonable, there can be no assurance that such expectations will prove to be correct. We cannot guarantee future results, performance, or achievements. Consequently, there is no representation that the actual results achieved will be the same, in whole or in part, as those set out in the forward-looking information.

iii

In addition, any statements that refer to expectations, intentions, projections or other characterizations of future events or circumstances contain forward-looking information. Forward-looking information is based on certain assumptions and analyses made by the Company in light of the experience and perception of historical trends, current conditions, and expected future developments and other factors it believes are appropriate and are subject to risks and uncertainties. The preceding list is not intended to be an exhaustive list of all of our forward-looking statements. The forward-looking statements are based on our beliefs, assumptions and expectations of future performance, taking into account the information currently available to us. These statements are only predictions based upon our current expectations and projections about future events. Although we believe that the assumptions underlying these statements are reasonable, they may prove to be incorrect, and we cannot assure that actual results will be consistent with this forward-looking information. Given these risks, uncertainties, and assumptions, you should not place undue reliance on this forward-looking information. Whether actual results, performance, or achievements will conform to the Company’s expectations and predictions is subject to a number of known and unknown risks, uncertainties, assumptions, and other factors, including those listed under “Risk Factors” in Item 3.D. of this Annual Report, and the following: economic and competitive uncertainties and contingencies that may cause the Company’s actual financial results, performance, or achievements to be materially different from those expressed or implied herein. Some of the material factors or assumptions used to develop forward-looking statements include, without limitation, the ability to extract valuable elements from black mass; general expectations with respect to the development of the Refinery (as defined below) including commodity prices with respect to its development; the state of the electric vehicle (“EV”) market; the future price of cobalt; anticipated costs of, and the Company’s ability to fund, its operations; the Company’s ability to carry on exploration and development activities; the timing and results of drilling programs; the discovery of additional mineral resources on the Company’s mineral properties; the timely receipt of required approvals and permits, including those approvals and permits required for successful project permitting, construction and operation of projects; the costs of operating and exploration expenditures; the Company’s ability to operate in a safe, efficient and effective manner; the potential impact of natural disasters, the impact of the Russo-Ukraine and Israel-Palestine wars; inflationary pressures; the Company’s ability to comply with its obligations in connection with the 2023 Note Offering; stock exchange and regulatory approvals required in connection with closing of the 2023 Note Offering; and the Company’s ability to obtain financing as and when required and on reasonable terms.

If any of these risks or uncertainties materialize, or if assumptions underlying the forward-looking information prove incorrect, actual results may vary materially from those anticipated in the forward-looking information. Furthermore, unless otherwise stated, the forward-looking statements contained in this Annual Report are made as of the date hereof, and we have no intention and undertake no obligation to update or revise any forward-looking statements, whether as a result of new information, future events, changes or otherwise, except as required by law.

iv

PART I

ITEM 1.IDENTITY OF DIRECTORS, SENIOR MANAGEMENT AND ADVISORS

Not required.

ITEM 2.OFFER STATISTICS AND EXPECTED TIMETABLE

Not required.

ITEM 3.KEY INFORMATION

3.A.

[Reserved]

3.B.Capitalization and Indebtedness

Not required.

3.C.Reasons for the Offer and Use of Proceeds

Not required.

3.D.Risk Factors

Following is a list of risks that the Company faces in its normal course of business. These are factors which, individually or in the aggregate, we think could cause our actual results to differ significantly from anticipated or historical results. The risks and uncertainties set out below are not exhaustive and are not the only ones the Company is facing. There are additional risks and uncertainties that the Company does not currently know about or that the Company currently considers immaterial which may also impair the Company’s business operations and cause the price of the of the Company (the “Common Shares”) to decline. If any of the following risks actually occur, the Company’s business may be harmed and the Company’s financial condition and results of operations may suffer significantly. Investors should carefully consider the risk factors set out below and consider all other information contained herein and in the Company’s other public filings before making an investment decision. The risks set out below are not an exhaustive list and should not be taken as a complete summary or description of all the risks associated with the Company’s business and the biotechnology business generally. Additionally, investors should not interpret the disclosure of a risk to imply that the risk has not already materialized.

Risks Related to the Company’s Financial Position and the Need for Additional Capital

The Company a history of operating losses, which may continue for the foreseeable future and our auditors have indicated that there is a substantial doubt about our ability to continue as a going concern.

The Company has suffered recurring losses from operations, has a net working capital deficiency and will require additional financing to continue operations, complete the construction of the Refinery, advance its battery recycling strategy, purchase required feedstock before the Refinery enters its operating phase and remain in compliance with minimum liquidity covenant under the subscription agreements with investors for the issuance of the aggregate of US$51,000,000 principal amount of 8.99% senior secured convertible notes due February 2028 (the “2028 Notes”). 2028 Notes. There can be no assurances that the Company will be able to obtain adequate financing in the future. This represents a material uncertainty that casts substantial doubt on the Company’s ability to continue as a going concern. The Company’s financial statements do not give effect to any adjustments relating to the carrying values and classification of assets and liabilities that would be necessary should we be unable to continue as a going concern.

1

The Company has not generated any revenue to date, have negative cash flow, and may never be profitable.

The Company is a pre-operations stage company with respect to the Refinery and an exploration stage company with respect to its mineral properties, and as a result has not to date generated cash flow from operations. The Company is devoting significant resources to the development of its assets, however there can be no assurance that it will generate positive cash flow from operations in the future. The Company expects to continue to incur negative consolidated operating cash flow and losses until such time as it achieves commercial production at a particular project.

The Company will require substantial additional funding, which may not be available to us on acceptable terms, or at all, and, if not available, may require us to delay, scale back, or cease our programs or operations.

Liquidity risk is the risk that the Company will not be able to meet its financial obligations as they fall due. The Company does not have sufficient financial resources necessary to complete the construction and final commissioning of the Refinery and the Company is going through a planning and budgeting process to update the capital estimates and completion schedule associated with the Refinery. The Company attempts to ensure there is sufficient access to funds to meet ongoing business requirements, considering its current cash position and potential funding sources.

Until we can generate a sufficient amount of revenue to finance our cash requirements, which we may never do, we expect to finance future cash needs primarily through a combination of public and private equity offerings. If sufficient funds on acceptable terms are not available when needed, or at all, we could be forced to significantly reduce operating expenses and delay, scale back or eliminate one or more of our programs or our business operation.

The Company is actively pursuing various alternatives including equity and debt financing to increase its liquidity and capital resources. The Company will require a working capital facility to cover the feedstock purchase cycle through to the sale of final cobalt sulfate and to meet minimum liquidity requirements under the 2028 Note Offering. The Company is in discussion with various parties on alternatives to finance the funding of feedstock purchases. The Company will also require additional financing to advance the Refinery, which is key to the Company’s long-term plans and financial success.

However, there can be no assurance that additional capital or other types of financing will be available when needed or that, if available, the terms of such financing will be acceptable to the Company. Failure to obtain sufficient financing when needed could result in the Company being unable to meet specified timelines for the advancement of the Refinery and may lead to the indefinite postponement of the advancement of the Refinery. The cost and terms of such financing may also significantly reduce the expected benefits from the Refinery or render the Refinery uneconomic.

The Company has future obligations to pay semi-annual interest payments and the principal upon maturity related to the convertible debt. Starting in 2026 repayment of the interest-free Government loan will begin in 19 equal installments. Upon the issuance of the 2028 Notes and retirement of the 2026 Notes (as defined below) in February 2023, the Company is subject to a minimum cash balance requirement of US$2,000,000.

Although the Company has historically been successful in obtaining financing, there can be no assurances that the Company will be able to obtain adequate financing in the future. This represents a material uncertainty that casts substantial doubt on the Company’s ability to continue as a going concern.

The Company’s ability to obtain financing and raise capital may be impacted by our operational results and general industry and macroeconomic trends beyond our control.

Historically, the Company’s capital requirements have been primarily funded through the sale of Common Shares and the issuance of notes. Factors that could affect the availability of financing include the progress and results of refurbishment of the Refinery, levels of debts and security over the Company’s assets, customer arrangements, ongoing exploration at the Company’s mineral properties, the state of international debt and equity markets, and investor perceptions and expectations of the transition to EVs and the global cobalt markets generally. There can be no assurance that such financing will be available in the amount required at any time or for any period or, if available, that it can be obtained on terms satisfactory to the Company. Based on the amount of funding raised, the Company’s planned exploration or other work programs may be postponed, or otherwise revised, as necessary.

2

The Company may be unable to meet its debt service obligations.

The Company now has debt service obligations arising from its convertible notes, which include ongoing coupon payments and payment of principal at maturity. In the event the refinery construction is not completed as planned or sufficient cash flow from refinery operations is note generated, there is a risk that the Company may not have sufficient available capital to meet its debt obligations. In this event, the assets pledged may be transferred to the lenders. There can be no assurance that refinery cash flows will be sufficient to meet future debt service obligations.

Raising additional capital may cause dilution to shareholders, restrict the Company’s operations or require it to relinquish substantial rights.

To the extent that the Company raises additional capital through the sale of equity or debt securities, including notes, its capital structure will be diluted, and the terms of these new securities may include liquidation or other preferences that adversely affect the rights of common shareholders. Debt financing, if available at all, may involve agreements that include covenants limiting or restricting our ability to take specific actions such as incurring additional debt, making capital expenditures, or declaring dividends. The Company cannot assure you that it will be able to obtain additional funding if and when necessary. If the Company is unable to obtain adequate financing on a timely basis, it could be required to delay, scale back or eliminate one or more of its programs or grant rights to develop and market product candidates that we would otherwise prefer to develop and market ourselves.

Commodity prices may not support corporate profit or operations.

The prices of commodities vary on a daily basis and is intensely competitive. Even if commercial quantities of minerals are discovered and developed, a profitable market will exist for the sale of same. Price volatility could have dramatic effects on the results of operations and the ability of the Company to execute its business plan. The price of cobalt materials may also be reduced by the discovery of new cobalt deposits, which could not only increase the overall supply of cobalt (causing downward pressure on its price), but could draw new firms into the cobalt industry which would compete with the Company. As the Company’s refinery business plan involves both buying cobalt products and selling cobalt products, its ultimate economics will be significantly impacted by market commodity prices.

Additionally, Factors beyond the control of the Company may affect the marketability of any minerals discovered. The prices of natural resources are volatile over short periods of time and is affected by numerous factors beyond the control of the Company, including international economic and political trends, expectations of inflation, currency exchange fluctuations, interest rates and global or regional consumption patterns, speculative activities and increased production. If the Company is unable to economically produce minerals from its projects, it would have a negative effect on the Company’s financial condition or require the Company to cease operations altogether.

Cost estimates and predictions may prove inaccurate.

The Company prepares estimates of operating costs and/or capital costs for each operation and project. The Company’s actual costs are dependent on a number of factors, including royalties, the price of cobalt and by-product metals and the cost of inputs used in exploration activities.

The Company’s actual costs may vary from estimates for a variety of reasons, including labour and other input costs, commodity prices, general inflationary pressures and currency exchange rates. Failure to achieve cost estimates or material increases in costs could have an adverse impact on the Company’s future cash flows, profitability, results of operations and financial condition.

3

Risks Relating to Our Operations

The Cobalt Supply Agreement is not a definitive agreement, and there is no guarantee the agreement will result in cobalt sales.

The Cobalt Supply Agreement is an agreement with respect to key commercial terms on which the parties intend to enter into a definitive supply agreement, not a definitive agreement with respect to the provision of cobalt to LG for cash. Until a definitive agreement exists, there is no enforceable or binding obligation on either party to purchase or deliver cobalt. Entering into a definitive agreement is subject to a number of conditions and factors, not all of which are in the Company’s control. If a definitive agreement is not entered into with respect to cobalt supply with LG on the terms described in the Cobalt Supply Agreement, or on terms different than those expressed therein, the Company will need to seek out additional customers for the purchase of cobalt sourced from the Refinery, and there may be other negative effects on the Company and on the value of Common Shares.

The Company’s ability to bring the Refinery online and the success of the Refinery is uncertain.

The Company’s strategic priority is the advancement of the Refinery, with significant metallurgical test work planned and a pilot plant work at third party facilities anticipated. There is no assurance that the outcomes of this test work and the results of the pilot plant work will be positive and that the Refinery will have the capabilities to produce specific end products. Furthermore, no assurance can be given that operating the Refinery will be economically viable. The Company will manage these risks through contracting technical experts on metallurgy and engineering to perform the required analysis and studies on the capability of the Refinery and its projected economics.

The success of the Company’s Refinery and long-term operations depends on the demand for Cobalt, which in turn is expected to be largely driven by consumer demand for electric vehicles and other applications in the transition from fossil-fuel based energy sources.

If the market for electric vehicles or other electronic consumer products that rely on cobalt does not develop as the Company expects, or develops more slowly than expected, or if current demand declines, the Company’s business prospects and economic outlook may be harmed. Additionally, demand for electric vehicles is driven by many factors outside of the company’s controls, including consumer sentiment and perceptions of the quality and value of electric vehicles compared to gasoline vehicles, competition among electric vehicle manufacturers and among other vehicle types, government regulations and economic incentives, and volatility in the cost of oil, gasoline, and industry.

The Company may not be able to insure itself against all operational risks.

The Company will be subject to a number of operational risks and may not be adequately insured for certain risks, including: environmental contamination, liabilities arising from historic operations, accidents or spills, industrial and transportation accidents, which may involve hazardous materials, labor disputes, catastrophic accidents, fires, blockades or other acts of social activism, changes in the regulatory environment, impact of non-compliance with laws and regulations, natural phenomena such as inclement weather conditions, floods, earthquakes, ground movements, cave-ins, and encountering unusual or unexpected geological conditions and technological failure of exploration methods.

There is no assurance that the foregoing risks and hazards will not result in damage to, or destruction of, the property of the Company, personal injury or death, environmental damage or, regarding the exploration or development activities of the Company, increased costs, monetary losses and potential legal liability and adverse governmental action. These factors could all have an adverse impact on the Company’s future cash flows, earnings, results of operations and financial condition.

No assurance can be given that insurance to cover the risks to which the Company’s activities are subject will be available at all or at commercially reasonable premiums. Additionally, the Company may be subject to liability or sustain loss for certain risks and hazards against which the Company cannot insure or which the Company may elect not to insure because of the cost. The Company is not currently covered by any form of environmental liability insurance, since insurance against environmental risks (including liability for pollution) or other hazards resulting from exploration and development activities is unavailable or prohibitively expensive. If the Company is unable to fully fund the cost of remedying an environmental problem, it might be required to suspend operations or enter into costly interim compliance measures pending completion of a permanent remedy. This lack of environmental liability insurance coverage could have an adverse impact on the Company’s future cash flows, earnings, results of operations and financial condition.

4

Additionally, the payment of any other liabilities for which the company is not insured, or underinsured, would reduce the funds available to the Company. This lack of insurance coverage could have an adverse impact on the Company’s future cash flows, earnings, results of operations and financial condition.

The Company may be subject to the risks associated with future acquisitions.

As part of its business strategy, the Company has sought and will continue to seek new operating, development and exploration opportunities in the mining industry. In pursuit of such opportunities, the Company may fail to select appropriate acquisition candidates or negotiate acceptable arrangements, including arrangements to finance acquisitions or integrate the acquired businesses and their personnel into the Company. The Company cannot assure you that it can complete any acquisition or business arrangement that it pursues, or is pursuing, on favourable terms, if at all, or that any acquisition or business arrangement completed will ultimately benefit its business. Such acquisitions may be significant in size, may change the scale of the Company’s business and may expose the Company to new geographic, political, operating, financial or geological risks. Further, any acquisition the Company makes will require a significant amount of time and attention of the Company’s management, as well as resources that otherwise could be spent on the operation and development of the Company’s existing business.

Any future acquisitions would be accompanied by risks, such as a significant decline in the relevant metal price after the Company commits to complete an acquisition on certain terms; the quality of the mineral deposit acquired proving to be lower than expected; the difficulty of assimilating the operations and personnel of any acquired companies; the potential disruption of the Company’s ongoing business; the inability of management to realize anticipated synergies and maximize the Company’s financial and strategic position; the failure to maintain uniform standards, controls, procedures and policies; the impairment of relationships with employees, customers and contractors as a result of any integration of new management personnel; and the potential for unknown or unanticipated liabilities associated with acquired assets and businesses, including tax, environmental or other liabilities. In addition, the Company may need additional capital to finance an acquisition. Debt financing related to any acquisition may expose the Company to risks related to increased leverage, while equity financing may cause existing shareholders to suffer dilution. There can be no assurance that any business or assets acquired in the future will prove to be profitable, that the Company will be able to integrate the acquired businesses or assets successfully or that it will identify all potential liabilities during the course of due diligence. Any of these factors could have a material adverse effect on the Company’s business, prospects, results of operations and financial condition.

The Company’s operations depend on its ability to access various consumables, and shortages or increases in such the prices of such could negatively impact the Company’s results of operations.

The Company’s planned exploration, development and operating activities, including the profitability thereof, will continue to be affected by the availability and costs of consumables used in connection with the Company’s activities. Of significance, this may include concrete, steel, copper, piping, diesel fuel and electricity and water. Other inputs such as labour, consultant fees and equipment components are also subject to availability and cost volatility. If inputs are unavailable at reasonable costs, this may delay or indefinitely postpone planned activities. Furthermore, many of the consumables and specialized equipment used in exploration, development and operating activities are subject to significant volatility. Market prices of input consumables and commodities can be subject to volatile price movements which can be material, occur over short periods of time and are affected by factors that are beyond the Company’s control, including global and regional supply and demand, political and economic conditions, and applicable regulatory regimes. There is no assurance that consumables will be available at all or at reasonable costs.

The Company’s titles to its properties may be contested or subject to the rights of various community stakeholders, including First Nations.

The Company has investigated its rights to explore and exploit its projects and, to the best of its knowledge, its rights in relation to lands covering the projects are in good standing. Nevertheless, no assurance can be given that such rights will not be revoked, or significantly altered, to the Company’s detriment. There can also be no assurance that the Company’s rights will not be challenged or impugned by third parties.

Although the Company is not aware of any existing title uncertainties with respect to lands covering material portions of its projects, there is no assurance that such uncertainties will not result in future losses or additional expenditures, which could have an adverse impact on the Company’s future cash flows, earnings, results of operations and financial condition.

5

Certain of the Company’s properties may be subject to the rights or the asserted rights of various community stakeholders, including First Nations and other indigenous peoples. The presence of community stakeholders may impact the Company’s ability to develop or operate its mining properties and its projects or to conduct exploration activities. Accordingly, the Company is subject to the risk that one or more groups may oppose the continued operation, further development or new development or exploration of the Company’s current or future mining properties and projects.

Such opposition may be directed through legal or administrative proceedings, or through protests or other campaigns against the Company’s activities.

Governments in many jurisdictions must consult with, or require the Company to consult with, indigenous peoples with respect to grants of mineral rights and the issuance or amendment of project authorizations. Consultation and other rights of indigenous peoples may require accommodation including undertakings regarding employment, royalty payments and other matters. This may affect the Company’s ability to acquire within a reasonable time frame effective mineral titles, permits or licenses in any jurisdictions in which title or other rights are claimed by First Nations and other indigenous peoples, and may affect the timetable and costs of development and operation of mineral properties in these jurisdictions. The risk of unforeseen title claims by indigenous peoples also could affect existing operations as well as development projects. These legal requirements may also affect the Company’s ability to expand or transfer existing operations or to develop new projects.

The Company faces reputational risks within the communities in which it operates.

The Company’s relationship with the host communities where it operates is critical to ensure the future success of its existing operations and the construction and development of its projects. There is an increasing level of public concern relating to the perceived effect of mining activities on the environment and on communities impacted by such activities. Certain non-governmental organizations (“NGOs”), some of which oppose globalization and resource development, are often vocal critics of the mining industry and its practices, including the use of cyanide and other hazardous substances in processing activities. Adverse publicity generated by such NGOs or others related to extractive industries generally, or the Company’s exploration or development activities specifically, could have an adverse effect on the Company’s reputation. Reputation loss may result in decreased investor confidence, increased challenges in developing and maintaining community relations and an impediment to the Company’s overall ability to advance its projects, which could have a material adverse impact on the Company’s results of operations, financial condition and prospects. While the Company is committed to operating in a socially responsible manner, there is no guarantee that the Company’s efforts in this respect will mitigate this potential risk.

Conflicts of interest may exist among the Company’s and its directors and officers.

The Company’s directors and officers are or may become directors or officers of other mineral resource companies or reporting issuers or may acquire or have significant shareholdings in other mineral resource companies and, to the extent that such other companies may participate in ventures in which the Company may, or may also wish to participate, the directors and officers of the Company may have a conflict of interest with respect to such opportunities or in negotiating and concluding terms respecting the extent of such participation.

The Company depends on key personnel, the loss of whom could negatively affect the Company’s results and operations.

The senior officers of the Company are critical to its success. In the event of the departure of a senior officer, the Company believes that it will be successful in attracting and retaining qualified successors, but there can be no assurance of such success. Recruiting qualified personnel as the Company grows is critical to its success. The number of persons skilled in the acquisition, exploration and development of mining properties is limited, and competition for such persons is intense. As the Company’s business activity grows, it will require additional key financial, administrative, engineering, geological and other personnel. If the Company is not successful in attracting and training qualified personnel, the efficiency of its operations could be affected, which could have an adverse impact on future cash flows, earnings, results of operations and the financial condition of the Company. The Company is particularly at risk at this state of its development as it relies on a small management team, the loss of any member of which could cause severe adverse consequences.

6

The Company’s properties may be subject to commitments that the Company may be unable to satisfy.

The Company’s mining properties may be subject to various land payments, royalties and/or work commitments. Failure by the Company to meet its payment obligations or otherwise fulfill its commitments under these agreements could result in the loss of related property interests.

The Company’s operations could be negatively affected by global instability, negative macroeconomic trends, and other events outside of our control including health epidemics, wars, or natural disasters.

The past few-years have been marked by political and economic instability brought about by a variety of factors, including the COVID-19 global pandemic, the Russian invasion of Ukraine, and the war in the Gaza Strip, banking failures, U.S. political instability, and natural disasters, among other factors. These factors have contributed to global supply chain volatility, unpredictable demands for consumer goods, rising inflation and interest rates, and general economic volatility, including volatility in stock markets. While the COVID-19 pandemic has subsided, the possibility that additional variants could revive containment measures or that future health pandemics or epidemics could arise remains. Such uncertainty and volatility has or could impact various other factors outside of the company’s control including, but not limited to currency exchange rates, trade tariff developments, transport availability and cost, including import-related taxes, transport security, sanctions, embargoes, expanded political conflict and violence, travel bans, stay-at-home orders, all of which have tickle-down impacts down effect on supply chains, commodity pricing and availability, the costs of capital and financing, and equipment and construction costs, all of which could impact the Company’s ability to both conduct its operations and access capital.

Inflationary pressures and rising interest rates could negatively affect the Company’s financial condition and results of operations.

Following the COVID-19 pandemic, the ongoing wars in the Ukraine and Gaza and other events, the global economy has faced significant instability marked by increased inflation, rising interest rates and supply chain volatility. Global economic conditions could further deteriorate, and the economy may contract and enter into a recession. Additionally, future economic shocks may be precipitated by a number of causes, including a rise in the price of oil, geopolitical instability, natural disasters and outbreaks of medical endemic or pandemic issues. Any sudden or rapid destabilization of global economic conditions could impact the Company’s ability to obtain equity or debt financing in the future on terms favourable to the Company. Additionally, any such occurrence could cause decreases in asset values that are deemed to be other than temporary, which may result in impairment charges. Further, in such an event, the Company’s operations and financial condition could be adversely impacted.

General inflationary pressures may affect labour and other costs, which could have a material adverse effect on the Company’s financial condition, results of operations and the capital expenditures required to advance the Company’s business plans. There can be no assurance that any governmental action taken to control inflationary or deflationary cycles will be effective or whether any governmental action may contribute to economic uncertainty. Governmental action to address inflation or deflation may also affect currency values. Accordingly, inflation and any governmental response thereto may have a material adverse effect on the Company’s business, results of operations, cash flow, financial condition and the price of the Company’s securities.

The Company faces risks related to its information technology systems and potential cyberattacks and security and privacy breaches.

The Company’s operations depend, in part, on how well it and its third-party service providers protect networks, equipment, information technology (“IT”) systems and software against damage from a number of threats, including, but not limited to, cable cuts, natural disasters, intentional damage and destruction, fire, power loss, hacking, computer viruses, vandalism and theft. The Company’s operations also depend on the timely maintenance, upgrade and replacement of networks, equipment, IT systems and software, as well as pre-emptive expenses to mitigate the risks of failures. Any of these and other events could result in information system failures, delays and/or increase in capital expenses. The failure of information systems or a component of information systems could, depending on the nature of any such failure, adversely impact the Company’s reputation and results of operations.

Recently, data security breaches suffered by well-known companies and institutions have attracted a substantial amount of media attention, prompting new foreign, federal, provincial and state laws and legislative proposals addressing data privacy and security. As a result, the Company may become subject to more extensive requirements to protect the customer information that it processes in connection with the purchase of its products, resulting in increased compliance costs.

7

The Company’s information technology systems and on-line activities, including its e-commerce websites, also may be subject to denial of service, malware or other forms of cyberattacks. While the Company has taken measures to protect against those types of attacks, those measures may not adequately protect its on-line activities from such attacks. If a denial-of-service attack or other cyber event were to affect the Company’s e-commerce sites or other information technology systems, its business could be disrupted, it may lose sales or valuable data, and its reputation may be adversely affected. The Company’s risk and exposure to these matters cannot be fully mitigated because of, among other things, the evolving nature of these threats. As a result, cyber security and the continued development and enhancement of controls, processes and practices designed to protect systems, computers, software, data and networks from attack, damage or unauthorized access is a priority. As cyber threats continue to evolve, the Company may be required to expend additional resources to continue to modify or enhance protective measures or to investigate and remediate any security vulnerabilities.

The Company is subject to risks relating to a changing climate.

Due to changes in local and global climatic conditions, many analysts and scientists predict an increase in the frequency of extreme weather events such as floods, droughts, forest and brush fires and extreme storms. Such events could materially disrupt the Company’s operations, particularly if they affect the Company’s sites, impact local infrastructure or threaten the health and safety of the Company’s employees, contractors and/or local communities.

The Company is focused on operating in a manner designed to minimize the environmental impacts of its activities; however, certain environmental impacts from mineral exploration and mining activities may be inevitable. Increased environmental regulation and/or the use of fiscal policy by regulators in response to concerns over climate change and other environmental impacts, such as additional taxes levied on activities deemed harmful to the environment, could have a material adverse effect on the Company’s financial condition or results of operations.

Risks Relating to Our Industry

The Company may be unable to exploit, expand, and replace its mineral reserves and mineral resources.

The Company’s mineral reserves and resources are by their nature, limited. Unless other mineral reserves or resources are discovered or acquired, The Company’s sources of future production for cobalt or other minerals will decrease over time if its current mineral reserves and mineral resources are exploited or otherwise depleted. There can be no assurance that the Company’s future exploration, development and acquisition efforts will be successful in replenishing its mineral reserves and resources. In addition, while the Company believes that many of its properties demonstrate development potential, there can be no assurance that they can or will be successfully developed and put into production in future years.

The Company’s ability to convert its mineral resources into mineral reserves is uncertain.

Mineral resources that are not mineral reserves do not have demonstrated economic viability. Due to the uncertainty which may attach to mineral resources, there can be no assurances that mineral resources will be upgraded to mineral reserves as a result of continued exploration or during operations.

There can be no assurances that any of the mineral resources stated in this AIF or published technical reports of the Company will be realized. Until a deposit is actually extracted and processed, the quantity of mineral resources or reserves, grades, recoveries and costs must be considered as estimates only. In addition, the quantity of mineral resources or reserves may vary depending on, among other things, product prices. Any material change in the quantity of mineral resources or reserves, grades, dilution occurring during mining operations, recoveries, costs or other factors may affect the economic viability of stated mineral resources or reserves. In addition, there is no assurance that mineral recoveries in limited, small scale laboratory tests or pilot plants will be duplicated by larger scale tests or during production. Fluctuations in cobalt prices, results of future drilling, metallurgical testing, actual mining and operating results, and other events subsequent to the date of stated mineral resources and reserves estimates may require revision of such estimates. Any material reductions in estimates of mineral resources or reserves could have a material adverse effect on the Company.

8

The exploration and development of mineral resources is speculative and there is no guarantee that the company will be successful in developing its resources.

Resource exploration and development is a speculative business and involves a high degree of risk. There is no known body of commercial ore on any of the Company’s mineral properties. There is no certainty that the expenditures to be made by the Company in the exploration of its mineral properties otherwise will result in discoveries of commercial quantities of minerals. The marketability of natural resources which may be acquired or discovered by the Company will be affected by numerous factors beyond the control of the Company. These factors include market fluctuations, the proximity and capacity of natural resource markets and processing equipment, government regulations, including regulations relating to prices, taxes, royalties, land tenure, land use, importing and exporting of minerals and environmental protection. The exact effect of these factors cannot be accurately predicted, but the combination of these factors may result in the Company not receiving an adequate return on invested capital.

The mining business is subject to cyclical volatility.

The mining business and the marketability of the products that are produced are affected by worldwide economic cycles. At the present time, the significant demand for cobalt and other commodities in many countries is driving increased prices, but it is difficult to assess how long such demand may continue. Fluctuations in supply and demand in various regions throughout the world are common.

As the Company’s mining and exploration business is in the exploration stage and as the Company does not carry on production activities, its ability to fund ongoing exploration is affected by the availability of financing which is, in turn, affected by the strength of the economy and other general economic factors.

The Company’s industry is highly regulated, and the regulatory framework, together with any future legislative or regulatory changes, may have a materially adverse effect on our operations.

Mining operations and exploration activities are subject to extensive laws and regulations. Such regulations relate to production, development, exploration, exports, imports, taxes and royalties, labor standards, occupational health, waste disposal, protection, and remediation of the environment, mine decommissioning and reclamation, mine safety, toxic and radioactive substances, transportation safety and emergency response, and other matters. Compliance with such laws and regulations increases the costs of exploring, drilling, developing, constructing, operating and closing mines and refining and other facilities. It is possible that, in the future, the costs, delays and other effects associated with such laws and regulations may impact decisions of the Company with respect to the exploration and development of properties such as the Iron Creek Project, the Refinery or the Cobalt Camp, or any other properties in which the Company has an interest. The Company will be required to expend significant financial and managerial resources to comply with such laws and regulations. Since legal requirements change frequently, are subject to interpretation and may be enforced in varying degrees in practice, the Company is unable to predict the ultimate cost of compliance with these requirements or their effect on operations. Furthermore, future changes in governments, regulations and policies and practices, such as those affecting exploration and development of the Company’s properties could materially and adversely affect the results of operations and financial condition of the Company in a particular year or in its long-term business prospects.

The development of mines and related facilities is contingent upon governmental approvals, licenses and permits which are complex and time consuming to obtain and which, depending upon the location of the project, involve multiple governmental agencies. The receipt, duration and renewal of such approvals, licenses and permits are subject to many variables outside the control of the Company, including potential legal challenges from various stakeholders such as environmental groups or non-government organizations. Any significant delays in obtaining or renewing such approvals, licenses or permits could have a material adverse effect on the Company, including delays and cost increases in the advancement of the Iron Creek Project, the Refinery and the Cobalt Camp.

The Company may be unable to obtain the necessary permits to develop its properties or conduct its operations.

The Company’s operations, Refinery and exploration activities are subject to receiving and maintaining licenses, permits and approvals, including regulatory relief or amendments, (collectively, “permits”) from appropriate governmental authorities. Before any development on any of its properties the Company must receive numerous permits, and continued operations at the Company’s mines is also dependent on maintaining, complying with, and renewing required permits or obtaining additional permits.

9

The Company may be unable to obtain on a timely basis or maintain in the future all necessary permits required to explore and develop its properties, commence construction or operation of mining facilities and properties or maintain continued operations. Delays may occur in connection with obtaining necessary renewals of permits for the Company’s existing operations and activities, additional permits for existing or future operations or activities, or additional permits associated with new legislation. It is possible that previously issued permits may become suspended or revoked for a variety of reasons, including through government or court action.

Without adequate infrastructure, the Company may be unable to pursue development opportunities or carry on its operations.

Mining, processing, development, and exploration activities depend on adequate infrastructure. Reliable roads, bridges, power sources and water supply are important determinants which affect capital and operating costs. Unusual or infrequent weather phenomena, sabotage, or community, government or other interference in the maintenance or provision of such infrastructure could adversely affect the Company’s operations, financial condition, and results of operations.

The Company operates in a competitive market.

The Company faces strong competition from other mining companies in connection with the identification and acquisition of properties producing, or capable of producing, precious and base metals. Many of these companies have greater financial resources, operational experience, and technical capabilities than the Company. As a result of this competition, the Company may be unable to identify, maintain or acquire attractive mining properties on acceptable terms or at all. In addition, the Company faces competition sourcing mine production for the Refinery. The Company’s plans for the Refinery, in part, include diverting African mine production from China to North America. Most cobalt is currently mined in the DRC and shipped to China for refining. The Company faces significant competition in diverting mine production, particularly ethically sourced mine production, to the Refinery and as a result, may be unable to identify, maintain or acquire mine production for the Refinery on acceptable terms or at all. Consequently, the Company’s prospects, revenues, operations, and financial condition could be materially adversely affected.

Given the highly competitive nature of the international resources industries, the value of any future reserves discovered and developed by the Company may be limited by competition from other world resource mining companies, or from excess inventories. Existing international trade agreements and policies and any similar future agreements, governmental policies or trade restrictions are beyond the control of the Company and may affect the supply of and demand for minerals, including cobalt, around the world.

Decommissioning and reclamation costs could be substantial.

Environmental regulators are increasingly requiring financial assurances to ensure that the cost of decommissioning and reclaiming sites is borne by the parties involved, and not by government. It is not possible to predict what level of decommissioning and reclamation (and financial assurances relating thereto) may be required in the future by regulators. The Company’s ability to advance its projects could be adversely affected by any inability on its part to obtain or maintain the required financial assurances.

The Company’s operations are subject to numerous environmental risks and related regulations.

All phases of mineral exploration and development businesses, including with respect to the Refinery, present environmental risks and hazards and are subject to environmental regulations. Environmental legislation provides for, among other things, restrictions and prohibitions on spills, releases or emissions of various substances used and or produced in association with natural resource exploration and production operations. The legislation also requires that facility sites be operated, maintained, abandoned, and reclaimed to the satisfaction of applicable regulatory authorities. Compliance with such legislation can require significant expenditures, and a breach may result in the imposition of fines and penalties, some of which may be material.

Environmental legislation is evolving in a manner expected to result in stricter standards and enforcement, larger fines and liability and potentially increased capital expenditures and operating costs. The discharge of pollutants into the air, soil or water may give rise to liabilities to foreign governments and third parties and may require the Company to incur costs to remedy such discharge. Based on risk assessments conducted by the Company, climate change is not an immediate material risk faced by the Company. However, no assurance can be given that the application of environmental laws to the business and operations of the Company will not result in a curtailment of production, or a material increase in the costs of production, development or exploration activities or otherwise adversely affect the Company’s financial condition, results of operations or prospects.

10

The Company is subject to regulations concerning its supply chain and mineral sources

Upon commencement of operations at the Refinery, the Company expects to source a material portion of feedstock for the Refinery from Glencore, IXM and CMOC. The Company reasonably expects Glencore, IXM and CMOC to source a majority, if not all, of the cobalt for such feedstock from their mineral projects located in the Democratic Republic of the Congo (“DRC”). On the Transparency International Corruption Perceptions Index, the DRC is ranked among the most highly corrupt countries in the world. Companies with operations or connections to the DRC have in the past and may in the future come under increased scrutiny from Canadian regulatory authorities with respect to the potential presence of forced labor in supply chains. While the Company does not currently, and do not expect to, have direct operations in the DRC, Canadian law nonetheless imposes due diligence obligations on an importer, which obligations include but are not limited to ensuring that imported goods are not produced in whole or in part through the use of forced labor. The consequences of the importation of goods that are produced with, or that contain any inputs that are produced with, forced labor include detention, seizure, forced destruction or re-exportation and/or forfeiture of the goods, administrative penalties, monetary penalties or criminal charges for the importer or its officers, directors or agents. The Company has taken reasonable steps to satisfy itself with respect to the origins of the Company’s feedstock in connection with the foregoing due diligence obligations, however any deemed failure by the Company to be deemed to have satisfied the onus of such due diligence obligations could have a material adverse effect on the Company and its operations. In addition, there have been recent unsuccessful attempts by legislators in Canada to pass legislation imposing greater obligations on companies to perform proactive supply chain due diligence in connection with forced labor. While the legislative efforts to this point have been unsuccessful, there can be no assurance that future efforts will continue to be unsuccessful. The passage of any such legislation could impose additional or enhanced due diligence obligations on the Company in connection with Electra’s supply chain, as well as enhanced penalties or enforcement measures, this may increase the time, effort and expense of conducting such due diligence investigations and in the event of any enforcement, result in a material adverse effect on the Company and its operations.

The Company’s construction projects are subject to time and cost overruns.

As a result of the substantial expenditures involved in development projects, developments are prone to material cost overruns versus budget, and actual time and costs may vary significantly from estimates for a variety of reasons, both within and beyond the control of the Company. The capital expenditures and time required to develop new mines are considerable and changes in cost or construction schedules can significantly increase both the time and capital required to build the project.

Construction costs and timelines can be impacted by a wide variety of factors, many of which are beyond the control of the Company. These include, but are not limited to, weather conditions, ground conditions, performance of the mining fleet and availability of appropriate rock and other material required for construction, availability and performance of contractors and suppliers, delivery and installation of equipment, design changes, accuracy of estimates and availability of accommodations for the workforce.

Project development schedules are also dependent on obtaining the governmental approvals necessary for the operation of a project. The timeline to obtain these government approvals is often beyond the control of the Company. A delay in start-up or commercial production would increase capital costs and delay receipt of revenues.

Failure to achieve time estimates and increases in costs may adversely affect the Company’s ability to continue exploration, develop the Iron Creek Project, the Refinery and the Cobalt Camp, and ultimately generate sufficient cash flows. There is no assurance that the Company’s estimates of time and costs will be achievable.

Risks Related to an Investment in the Common Shares

The market price of our common shares is volatile.

Capital and securities markets have a high level of price and volume volatility, and the market price of our securities have experienced wide fluctuations in price which have not necessarily been related to the operating performance, underlying asset values or prospects of such companies. Factors unrelated to the financial performance or prospects of the Company include macroeconomic developments in North America and globally, and market perceptions of the attractiveness of particular industries or asset classes. There can be no assurance that continued fluctuations in mineral or commodity prices will not occur. As a result of any of these factors, the market price of the Common Shares of the Company at any given time may not accurately reflect the long-term value of the Company.

11

In the past, following periods of volatility in the market price of a company’s securities, shareholders have instituted class action securities litigation against them. Such litigation, if instituted, could result in substantial cost and diversion of management attention and resources, which could significantly harm profitability and the reputation of the Company.

The Company has not and does not plan to pay dividends in the future. As a result, any return on investment may be limited to the value of our Common Shares.

The Company has never paid cash dividends on the Common Shares, and does not expect to pay any cash dividends in the future in favor of utilizing cash to support the development of the Company’s business. Any future determination relating to the Company’s dividend policy will be made at the discretion of the Company’s Board of Directors and will depend on a number of factors, including future operating results, capital requirements, financial condition and the terms of any credit facility or other financing arrangements the Company may obtain or enter into, future prospects and other factors the Company’s Board of Directors may deem relevant at the time such payment is considered.

As a result, shareholders will have to rely on capital appreciation, if any, to earn a return on their investment in the Common Shares for the foreseeable future. There can be no assurance regarding the amount of income to be generated by the Company and there can be no guarantee that an investment in the Common Shares will earn any positive return in the short term, long term, or at all. The market value of the Common Shares may deteriorate if we are unable to generate sufficient positive returns, and for macroeconomic and other factors that are outside the Company’s control. That deterioration may be significant. An investment in the common shares is appropriate only for investors who have the capacity to absorb a loss of some or all of their investment.

Failure to meet Nasdaq’s continued listing requirements could result in the delisting of the Common Shares, negatively impact the price of the Common Shares and negatively impact its ability to raise additional capital.

If the Company fails to satisfy the continued listing requirements of the Nasdaq Capital Market, such as corporate governance requirements or the minimum closing bid price requirement, the exchange may take steps to delist the Common Shares. Such a delisting would likely have a negative effect on the price of the Common Shares and would impair shareholders’ ability to sell or purchase its Common Shares when they wish to do so.

On September 21, 2023, we received a letter from the Nasdaq Stock Market, LLC indicating that, for the last 30 consecutive business days, the bid price for our Common Shares had closed below the minimum $1.00 per share required for continued inclusion on the Nasdaq Capital Market under the Nasdaq Listing Rules. The notice had no effect on the listing or trading of our Common Shares. On March 20, 2024, we received an additional 180-days notice from the Nasdaq to regain compliance with the Minimum Bid Price Requirement.

Under Nasdaq Listing Rule 5810(c)(3)(A), if during the 180 calendar day period following the date of the notice (being September 16, 2024), the closing bid price of our Common Shares is at or above $1.00 for a minimum of 10 consecutive business days, we would regain compliance with the Minimum Bid Price Requirement and our Common Shares would continue to be eligible for listing on the Nasdaq Capital Market, absent non-compliance with any other requirement for continued listing.

We intend to monitor the closing bid price of our Common Shares and consider our available options if the closing bid price of our Common Shares remains below $1.00 per share, including effecting a reverse stock split. There can be no assurance that we will be able to regain compliance with the Minimum Bid Price Requirement during the 180-day compliance period with respect to the Minimum Bid Price Requirement, maintain compliance with the other listing requirements, or maintain the listing of our Common Shares on Nasdaq.

12

Future sales or issuances of equity securities or the conversion of the Company’s securities into Common Shares could decrease the value of the Common Shares, dilute investors’ voting power, and reduce earnings per share.

Company’s articles permit the issuance of an unlimited number of Common Shares, and shareholders will have no pre-emptive rights in connection with such further issuances. Sales of a substantial number of Common Shares or other equity-related securities in the public markets by the Company or its significant shareholders could depress the market price of the Common Shares and impair the Company’s ability to raise capital through the sale of additional equity securities. The Company cannot predict the effect that future sales of Common Shares or other equity-related securities would have on the market price of the Common Shares. The price of the Common Shares could be affected by possible sales of the Common Shares by hedging or arbitrage trading activity. Moreover, additional Common Shares may be issued by the Company on the exercise of options under the Company’s stock option plan and other equity compensation plans, and upon the exercise of outstanding warrants. If the Company raises additional funding by issuing additional equity securities, such financing may substantially dilute the interests of shareholders of the Company and reduce the value of their investment.

There may be difficulty in enforcing judgments and effecting service of process on the Company and its directors and officers that are not citizens of the United States.

The enforcement by investors of civil liabilities under the United States federal or state securities laws may be affected adversely by the fact that the Company is governed by the CBCA, that some of the Company’s officers and directors are not residents of the United States, and that all, or a substantial portion, of their assets and certain of the Company’s assets are located outside the United States. It may not be possible for investors to effect service of process within the United States on certain of its directors and officers or enforce judgments obtained in the United States courts against the Company or certain of the Company’s directors and officers based upon the civil liability provisions of United States federal securities laws or the securities laws of any state of the United States. There is some doubt as to whether a judgment of a United States court based solely upon the civil liability provisions of United States federal or state securities laws would be enforceable in Canada against the Company or its directors and officers. There is also doubt as to whether an original action could be brought in Canada against the Company or its directors and officers to enforce liabilities based solely upon United States federal or state securities laws.

If the Company is characterized as a passive foreign investment company, U.S. holders may be subject to adverse U.S. federal income tax consequences.

U.S. investors should be aware that they could be subject to certain adverse U.S. federal income tax consequences in the event that the Company is classified as a “passive foreign investment company” (“PFIC”) for U.S. federal income tax purposes. The determination of whether the Company is a PFIC for a taxable year depends, in part, on the application of complex U.S. federal income tax rules, which are subject to differing interpretations, and the determination will depend on the composition of the Company’s income, expenses and assets from time to time and the nature of the activities performed by the Company’s officers and employees. Based on the composition of the Company’s income and the value of its assets, the Company believes that it was classified as a PFIC for its taxable year ending December 31, 2023 and may continue to be classified as a PFIC for the current taxable year. Prospective investors should carefully read the discussion under the heading “Material U.S. Federal Income Tax Considerations for U.S. Holders” for more information and consult their own tax advisors regarding the likelihood and consequences of the Company being treated as a PFIC for U.S. federal income tax purposes, including the advisability of making certain elections that may mitigate certain possible adverse U.S. federal income tax consequences that may result in an inclusion in gross income without receipt of such income.

13