UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 6-K

REPORT OF FOREIGN PRIVATE ISSUER PURSUANT TO RULE 13a-16 OR 15d-16 UNDER

THE

SECURITIES EXCHANGE ACT OF 1934

For the month of April 2024.

Commission File Number 33-65728

CHEMICAL AND MINING COMPANY OF CHILE INC.

(Translation of registrant’s name into English)

El Trovador 4285, Santiago, Chile (562) 2425-2000

(Address of principal executive office)

Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40-F.

SQM FILES TECHNICAL REPORT SUMMARIES

Form 20-F: x Form 40-F Santiago, Chile, April 5, 2024 – Sociedad Química y Minera de Chile S.A. ( SQM or the “Company”) issued technical report summary for the Salar de Atacama property (the “Technical Report Summary”). The Technical Report Summary is filed as Exhibit 96.1 to this Report on Form 6-K and incorporated herein by reference.

Exhibits

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

| CHEMICAL AND MINING COMPANY OF CHILE INC. | |

| (Registrant) | |

| Date: April 5, 2024 | /s/ Gerardo Illanes |

| By: Gerardo Illanes | |

| CFO |

Exhibit 23.1

CONSENT OF QUALIFIED PERSON

I, Juan Becerra , state that I am responsible for preparing or supervising the preparation of part(s) of the technical report summary titled "Technical Report Summary, Operation Report, Salar de Atacama" with an effective date of April 5, 2024, as signed, and certified by me (the “Technical Report Summary”).

Furthermore, I state that:

| a. | I consent to the public filing of the Technical Report Summary by Sociedad Química y Minera de Chile S.A. (the “Company”) as an exhibit to Form 6-K of the Company (the “Form 6-K”); |

| b. | the document that the Technical Report Summary supports is the Company’s Annual Report on Form 20-F for the year ended December 31, 2023, and any existing amendments or supplements and/or exhibits thereto (the "Form 20-F") (the Form 6-K and Form 20-F, collectively the “Document”); |

| c. | I consent to the use of my name in the Document, to any quotation from or summarization in the Document of the parts of the Technical Report Summary for which I am responsible, and to the incorporation by reference of the Technical Report Summary into Form 20-F; and |

| d. | I confirm that I have read the Document, and that the Document fairly and accurately reflects, in the form and context in which it appears, the information in the parts of the Technical Report Summary for which I am responsible. |

| By | /s/ Juan Becerra | |

| Juan Becerra | ||

| Superintendent of Geology | ||

| SQM |

Dated at Santiago, Chile on April 5, 2024

Exhibit 23.2

CONSENT OF QUALIFIED PERSON

I, Rodrigo Riquelme Tapia , state that I am responsible for preparing or supervising the preparation of part(s) of the technical report summary titled "Technical Report Summary, Operation Report, Salar de Atacama" with an effective date of April 5, 2024, as signed, and certified by me (the “Technical Report Summary”).

Furthermore, I state that:

| a. | I consent to the public filing of the Technical Report Summary by Sociedad Química y Minera de Chile S.A. (the “Company”) as an exhibit to Form 6-K of the Company (“Form 6-K”); |

| b. | the document that the Technical Report Summary supports is the Company’s Annual Report on Form 20-F for the year ended December 31, 2023, and any existing amendments or supplements and/or exhibits thereto (the "Form 20-F") (the Form 6-K and Form 20-F, collectively the “Document”); |

| c. | I consent to the use of my name in the Document, to any quotation from or summarization in the Document of the parts of the Technical Report Summary for which I am responsible, and to the incorporation by reference of the Technical Report Summary into Form 20-F; and |

| d. | I confirm that I have read the Document, and that the Document fairly and accurately reflects, in the form and context in which it appears, the information in the parts of the Technical Report Summary for which I am responsible. |

| By | /s/ Rodrigo Riquelme Tapia | |

| Rodrigo Riquelme Tapia | ||

| CEO | ||

| GeoInnova |

Dated at Santiago, Chile on April 5, 2024

Exhibit 96.1

Technical Report Summary

OPERATION REPORT

SALAR DE ATACAMA

Sociedad Química y Minera de Chile

April 5, 2024

TECHNICAL REPORT SUMMARY

OPERATION REPORT

SALAR DE ATACAMA

Sociedad Química y Minera de Chile

April 5, 2024

TABLE OF CONTENTS

| 1.1 Property and Mineral Rights | 1 | |

| 1.2 Geology and Mineralization | 1 | |

| 1.3 Mineral Resource Estimate | 2 | |

| 1.4 Mineral Reserve Estimate | 3 | |

| 1.5 Mining Method | 4 | |

| 1.6 Metallurgy and Mineral Processing | 4 | |

| 1.7 Capital Costs, Operating Costs, and Financial Analysis | 5 | |

| 1.8 Conclusions | 8 | |

| 2.1 Terms of Reference and Purpose of the Report | 9 | |

| 2.2 Source of Data and Information | 13 | |

| 2.3 Details of Inspection | 13 | |

| 2.4 Previous Reports on Project | 13 | |

| 3.1 Property Location | 14 | |

| 3.2 Lease Agreement and Mineral Rights | 16 | |

| 3.3 Environmental Impacts and Permitting | 16 | |

| 3.4 Other Significant Factors and Risks | 16 | |

| 3.5 Royalties and Agreements | 17 | |

| 4.1 Topography, Elevation, and Vegetation | 18 | |

| 4.2 Accessibility and Transportation to the Property | 18 | |

| 4.3 Climate | 18 | |

| 4.4 Infrastructure Availability and Sources | 18 | |

| 6.1 Regional Geology | 22 | |

| 6.2 Local Geology | 22 | |

| 6.3 Property Geology | 24 | |

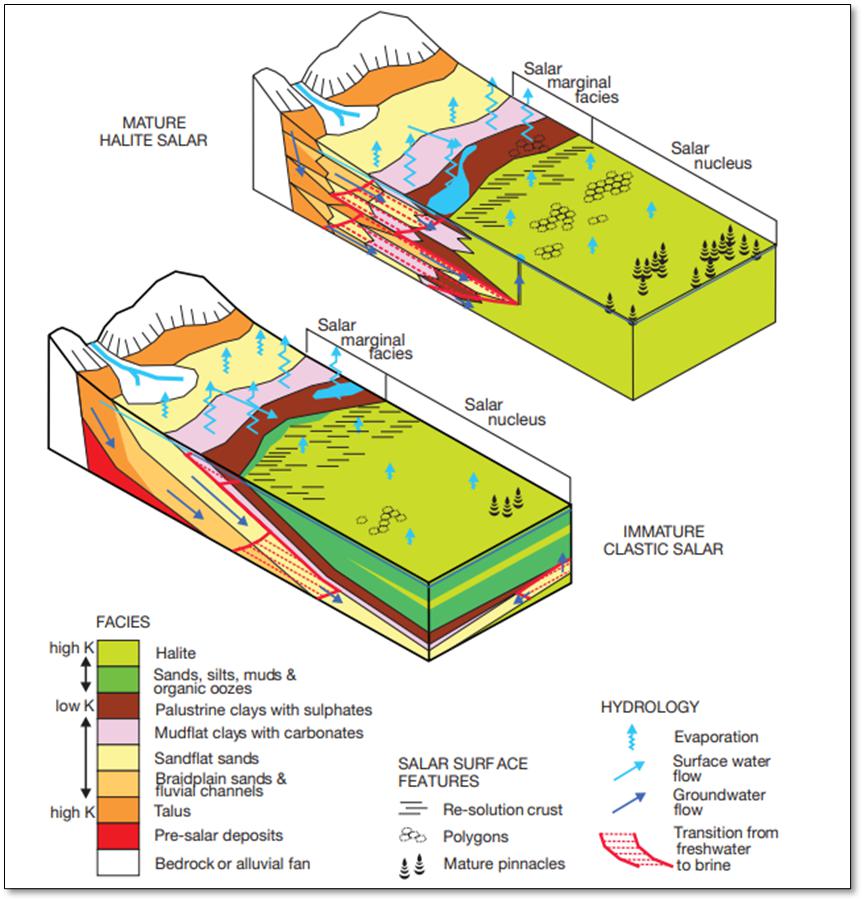

| 6.4 Deposit Types | 28 | |

| 7.1 Geophysical Surveys | 30 | |

| 7.2 Exploration Drilling | 32 | |

| 7.3 Conceptual Hydrogeology | 37 | |

| 7.4 Qualified Person’s Opinion | 43 | |

| 7.5 Geotechnical Considerations | 44 | |

| 8.1 Methods, Splitting and Reduction, and Security Measures | 45 | |

| 8.2 Sample Preparation, Assaying and Analytical Procedures | 46 | |

| 8.3 Opinion of Adequacy | 55 | |

| 9.1 Data Verification Procedures | 56 | |

| 9.2 Data Management | 56 | |

| 9.3 Technical Procedures | 56 | |

| 9.4 Quality Control Procedures | 56 | |

| 9.5 Precision Evaluation | 56 | |

| 9.6 Accuracy Evaluation | 57 | |

| 9.7 Pollution Evaluation | 57 | |

| 9.8 Qualified Person’s Opinion of Data Adequacy | 57 | |

| 10.1 Test Procedures | 58 | |

| 10.2 Analytical and Testing Laboratories | 71 | |

| 10.3 Sample Representativeness | 72 | |

| 10.4 Testing and Relevant Results | 73 | |

| 10.5 Significant Risk Factors | 77 | |

| 10.6 Qualified Person´s Opinion | 78 | |

| 11.1 Estimation Methods, Parameters, and Assumptions | 80 | |

| 11.2 Cut-off Grades | 97 | |

| 11.3 Mineral Resource Classification | 98 | |

| 11.4 Mineral Resource Statement | 102 | |

| 11.5 Uncertainty | 103 | |

| 11.6 Opinion and Recommendations | 103 | |

| 12.1 Numerical Model Design | 104 | |

| 12.2 Numerical Model Calibration | 112 | |

| 12.3 Projected Model Simulation | 117 | |

| 12.4 Mineral Reserves | 120 | |

| 12.5 Uncertainty | 126 | |

| 12.6 Opinion and Recommendations | 127 | |

| 13.1 Brine Extraction: Geotechnical and Hydrological Models, and Other Relevant Parameters | 128 | |

| 13.2 Production Rates, Expected Mine Life, Mining Unit Dimensions, And Mining Dilution and Recovery Factors | 129 | |

| 13.3 Requirements for Stripping, Underground Development, and Backfilling | 129 | |

| 13.4 Required Mining Equipment Fleet, Machinery, and Personnel | 129 | |

| 13.5 Final Mine Outline | 131 | |

| 14.1 Process Description | 134 | |

| 14.2 Process Specifications and Efficiencies | 146 | |

| 14.3 Process Requirements | 151 | |

| 14.4 Qualified Person´s Opinion | 157 | |

| 15.1 Access to Production Areas, Storage, and Port Shipping | 161 | |

| 15.2 Productive Areas and Infrastructure | 162 | |

| 15.3 Communications | 169 | |

| 15.4 Power Supply | 169 | |

| 15.5 Supply of Fuels | 170 | |

| 15.6 Water Supply | 171 | |

| 16.1 Material Contracts for Salar de Atacama | 172 | |

| 16.2 Lithium and its Derivatives, Market, Competition, Products, Customers | 173 | |

| 16.3 Supply | 175 | |

| 16.4 Demand | 175 | |

| 16.5 Balance | 176 | |

| 16.6 Lithium Price | 177 | |

| 16.7 Potassium | 178 | |

| 17.1 Environmental Studies | 181 | |

| 17.2 Environmental Management Plan | 194 | |

| 17.3 Environmental Monitoring | 195 | |

| 17.4 Permitting | 209 | |

| 17.5 Social and Community Aspect | 224 | |

| 17.6 Mine closure | 229 | |

| 17.7 Qualified Person´s Opinion | 232 | |

| 18.1 Capital Costs | 233 | |

| 18.2 Operating Costs | 243 | |

| 19.1 Production and Revenues | 247 | |

| 19.2 Production Costs | 247 | |

| 19.3 Capital Investments | 249 | |

| 19.4 Discounted Cashflow Analysis | 249 | |

| 19.5 Sensitivity Analysis | 250 | |

| 22.1 Conclusions | 255 | |

| 22.2 Risks | 259 | |

TABLES

| Table 1-1. SQM’s Salar de Atacama Lithium and Potassium Mineral Resources, Exclusive of Mineral Reserves (Effective December 31, 2022) | 2 |

| Table 1-2. SQM’s Salar de Atacama Lithium and Potassium Mineral Reserves, Factoring Process Recoveries (Effective December 31, 2023) | 3 |

| Table 1-3. Capital Costs for Lithium and Potassium Operations | 6 |

| Table 1-4. Assumptions for the Base Case Economic Analysis | 7 |

| Table 1-5. Projected Sales of Lithium and Potassium Products | 7 |

| Table 1-6. Estimated Cashflow Analysis | 8 |

| Table 2-1. Acronyms and Abbreviations | 10 |

| Table 2-2. Site visits | 13 |

| Table 3-1. Payment Agreements with CORFO | 17 |

| Table 7-1. Summary of the Conducted Geophysical Datasets | 31 |

| Table 7-2. Summary of the Conducted Borehole Geophysics | 31 |

| Table 7-3. Summary of Boreholes with Porosity Measurements | 33 |

| Table 7-4. Hydrogeological Unit Descriptions | 38 |

| Table 7-5. Hydraulic Conductivity Ranges for each Hydrogeological Unit | 40 |

| Table 8-1. Evaluation of Analytical and Field Duplicates in Lab SA | 47 |

| Table 8-2. Summary of Possible Pollution Ratios of Blank Samples during Analysis. | 50 |

| Table 8-3. Summary of Possible Pollution Ratios of Blank Samples during Analysis. | 51 |

| Table 8-4. Duplicate Sample Evaluation in the Porosity Lab | 53 |

| Table 10-1. List of Laboratory Facilities Available for Analysis in Salar de Atacama | 60 |

| Table 10-2. List of Installations Available for Analysis at PQC | 61 |

| Table 10-3. Categorization of Brine Samples from Wells | 62 |

| Table 10-4. List of Analyses for the Chemical Characterization | 65 |

| Table 10-5. Mean Annual Evaporation Rates for each Subsystem in the 2020-2023 Period | 67 |

| Table 10-6. List of Requested Analyses for Plant Control | 69 |

| Table 10-7. Analysis of Products (Li2CO3/LiOH) | 70 |

| Table 10-8. List of Laboratory Facilities Available for Analysis in Salar de Atacama | 71 |

| Table 11-1. Total Number of Wells used for Construction of the Geological Model | 80 |

| Table 11-2. Total Number of Drillholes used to Estimate the Brine Volume | 80 |

| Table 11-3. Total Number of Wells used for the Chemistry Interpolation | 81 |

| Table 11-4. Block Model Discretization | 81 |

| Table 11-5. Conditions and Assumptions for Filtering Cells in the Block Model | 82 |

| Table 11-6. Summary of Assigned Pe Values | 83 |

| Table 11-7. Effective Porosity Estimation Domains, Brine Volume Estimate | 84 |

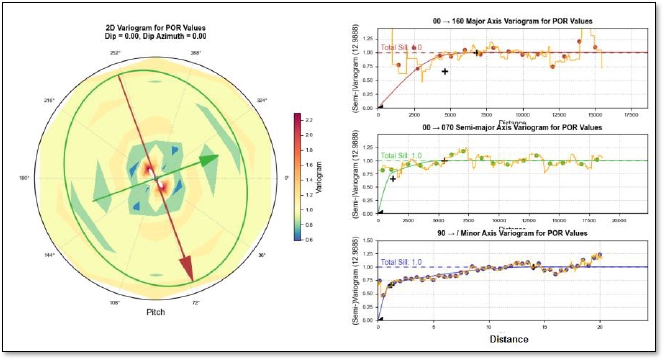

| Table 11-8. Search Radius Parameters, Effective Porosity Estimate (SQM, 2021a) | 86 |

| Table 11-9. Variogram Model Parameters, Effective Porosity Estimate (SQM, 2021a) | 86 |

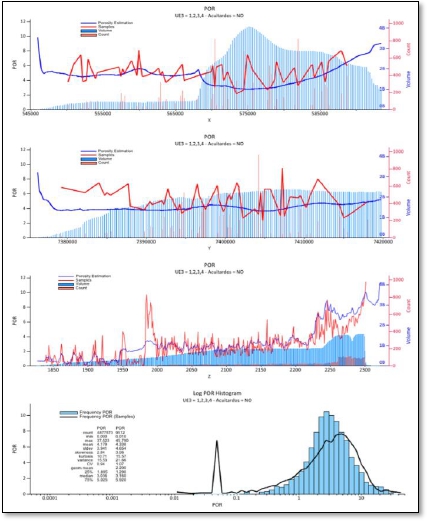

| Table 11-10. Effective Porosity (%) Interpolation Summary | 87 |

| Table 11-11. Equivalence between Hydrogeological Units and Brine Chemistry Domains | 90 |

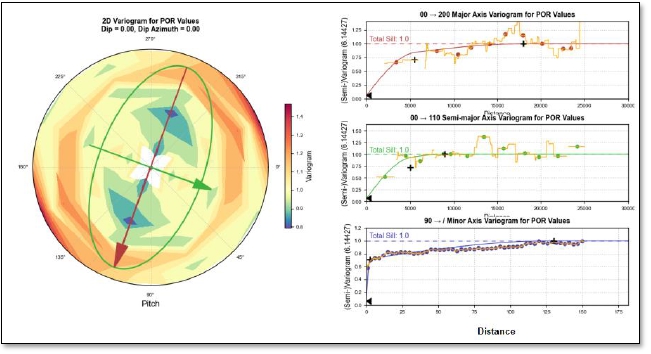

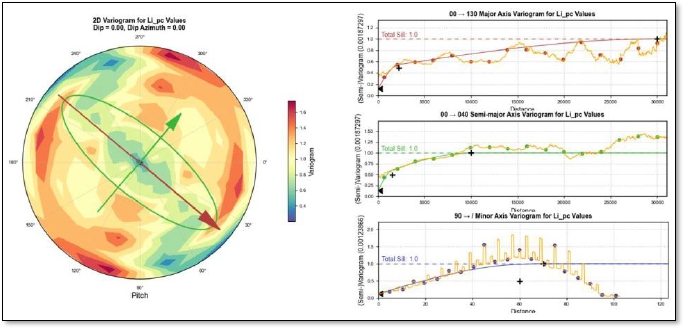

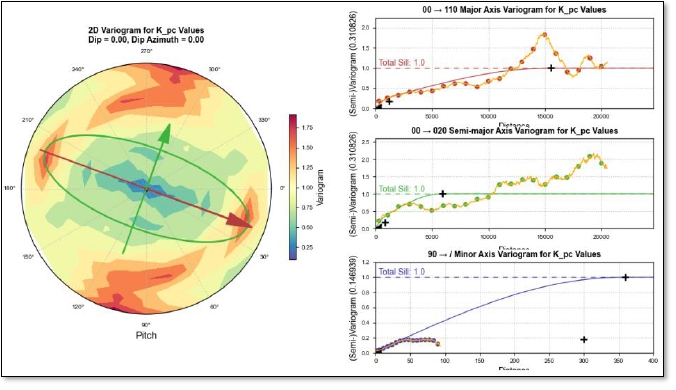

| Table 11-12. Search Radius Parameters, Li and K Interpolation (SQM, 2021a) | 92 |

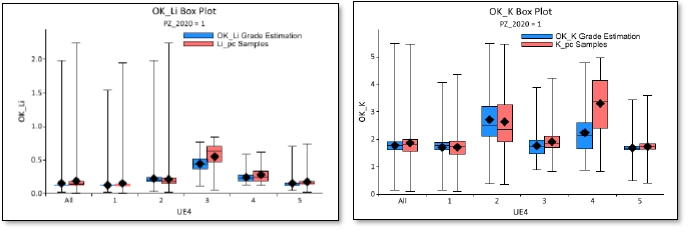

| Table 11-13. Variogram Model Parameters, Li and K Interpolation (SQM, 2021a) | 93 |

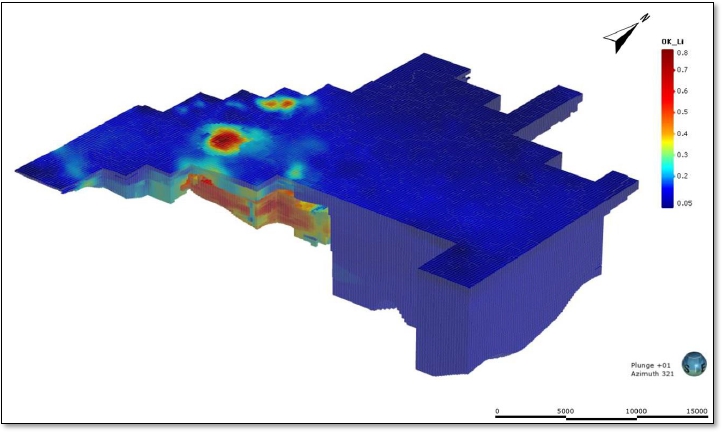

| Table 11-14. Average Li and K Concentrations after Interpolation, OMA Extraction Area | 94 |

| Table 11-15. Univariate Statistics of Density Weighted by Sample Length | 95 |

| Table 11-16. Variogram Model Parameters for the Brine Density Interpolation (SQM, 2021a) | 96 |

| Table 11-17. Brine Chemistry Domains and Level of Hydrogeological Characterization | 99 |

| Table 11-18. Categorization of Measured, Indicated, and Inferred Mineral Resources | 100 |

| Table 11-19. SQM’s Salar de Atacama Lithium and Potassium Resource Statement, Exclusive of Mineral Reserves (Effective December 31, 2022) | 102 |

| Table 12-1. Grid Specifics and Layers | 104 |

| Table 12-2. Average Simulated Water Balance Components, 2015-2020 Calibration Period | 107 |

| Table 12-3. Summary of Assigned Model Parameters | 111 |

| Table 12-4. Numerical model verification | 116 |

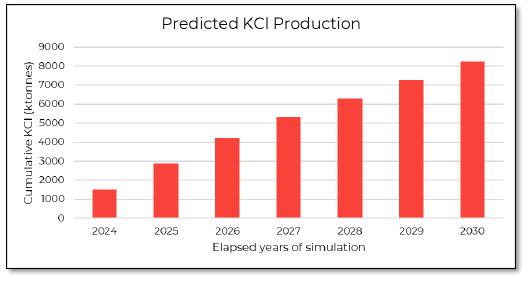

| Table 12-5. Simulated Li and LCE Extraction by Year | 121 |

| Table 12-6. Simulated K and KCl Extraction by Year | 122 |

| Table 12-7. SQM’s Salar de Atacama Lithium Mineral Reserve Estimate, Considering Process Recoveries (Effective December 31, 2023) | 123 |

| Table 12-8. SQM’s Salar de Atacama Potassium Reserve Estimate Considering Process Recoveries (Effective December 31, 2023) | 124 |

| Table 14-1. Facilities Available for Production | 133 |

| Table 14-2. Products of the Salar de Atacama | 136 |

| Table 14-3. Nominal Production Capacity per Process Plant | 146 |

| Table 14-4. Production Data for 2019 to 2022 | 147 |

| Table 14-5. Average Volume of Brine Extracted and Re-injected per Year | 147 |

| Table 14-6. Global Yield and IGS Yield for 2019 and 2021 | 148 |

| Table 14-7. Projected Yield Increase in the Lithium Production System Based on the Yield Increase Plan | 149 |

| Table 14-8. Industrial Plan for 2023 to 2030 for the Salar de Atacama and PQC Operations | 150 |

| Table 14-9. Summary of Energy Consumption per Year | 151 |

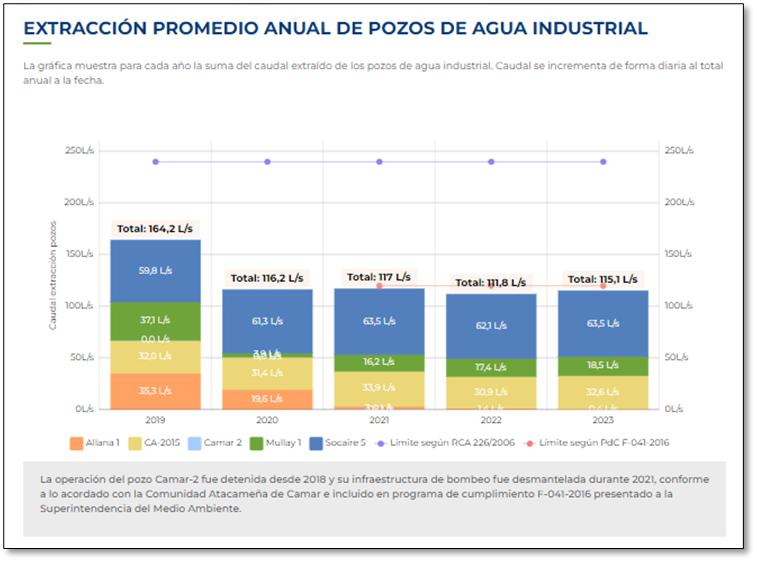

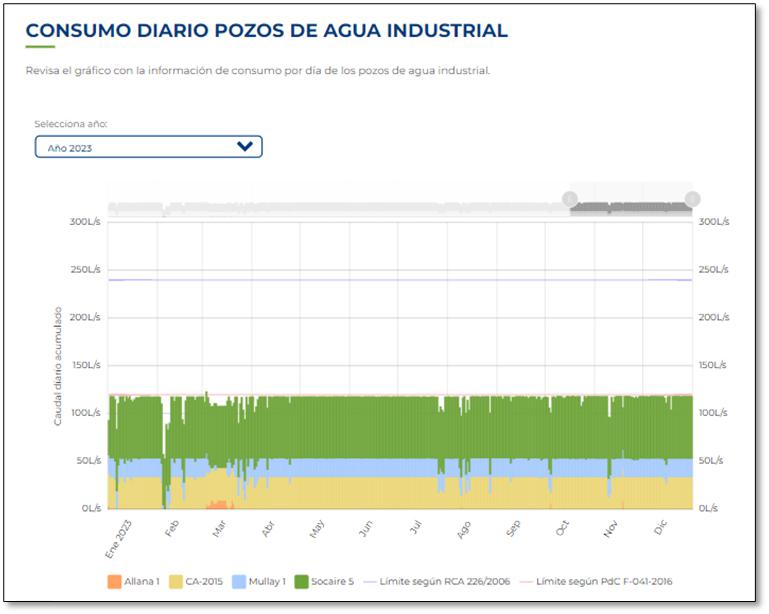

| Table 14-10. Annual Industrial Water Extraction from Wells | 152 |

| Table 14-11. Drinking water consumption per year at the Salar de Atacama | 152 |

| Table 14-12. Personnel required by area/activity | 154 |

| Table 14-13. Personnel by area | 154 |

| Table 14-14. Process Reagents and Consumption rates per year | 155 |

| Table 14-15. Consumption of Material and Generation of RIL/RIS on Carmen Lithium Chemical Plant (PQC)from 2022 to 2030 | 156 |

| Table 16-1. Potassium Chloride and Potassium Sulfate Volume and Revenues | 179 |

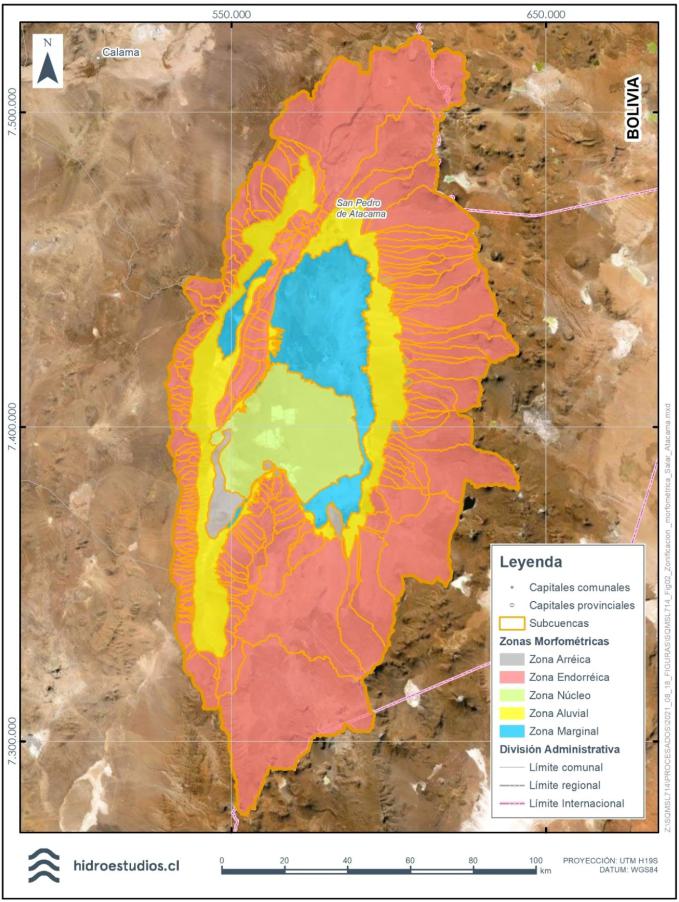

| Table 17-1. Hydrological Zones Defined in Salar Basin | 183 |

| Table 17-2 Land use units observed in the project area (USDA, 2001) | 187 |

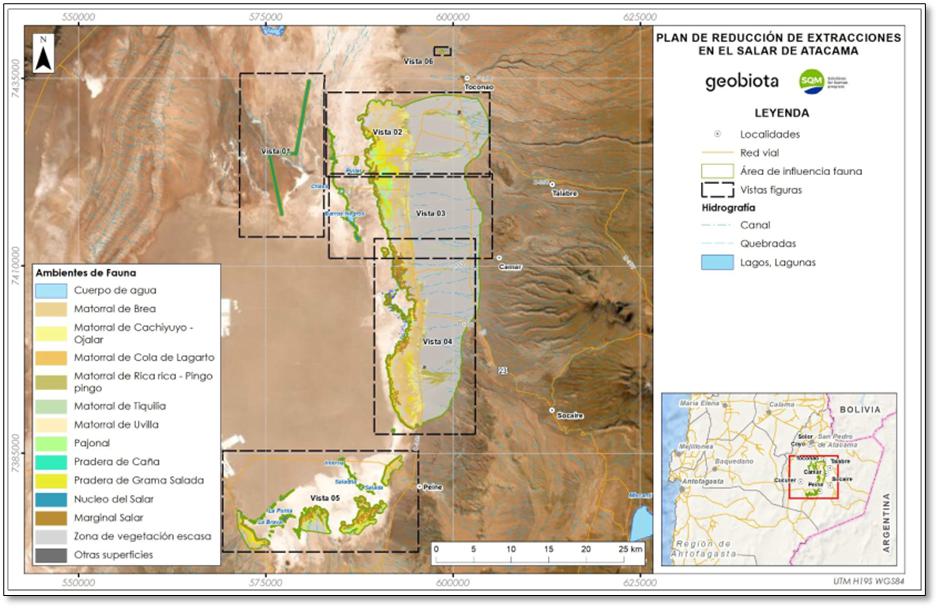

| Table 17-3. Species Richness by Faunal Environment | 189 |

| Table 17-4. Systems to be Protected | 201 |

| Table 17-5. Summary of Incidents Associated with the Hydrogeological Component, Year 2023 | 202 |

| Table 17-6. Industrial Water Extraction | 205 |

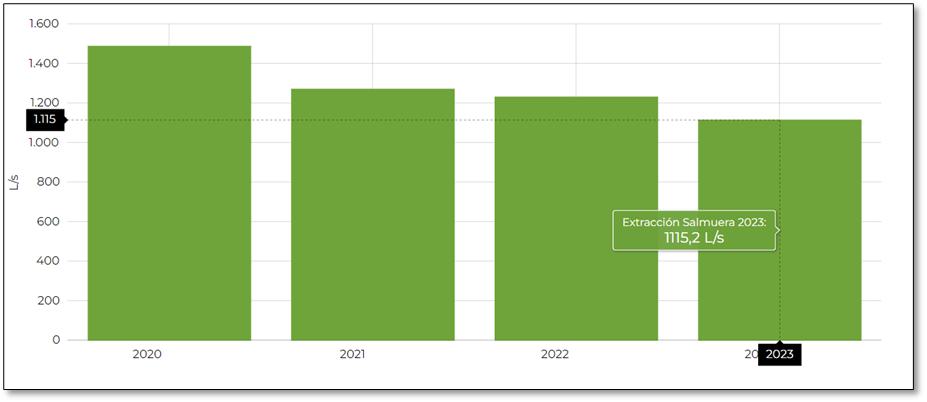

| Table 17-7: Brine Extraction period August 2022 to August 2023 and Approved in RCA N°226/2006 | 207 |

| Table 17-8. Historical EIAs/DIAs, carried out in the Salar de Atacama and the Salar del Carmen Plant, Sent to the Competent Authority (SEIA) | 210 |

| Table 17-9. Facts Considered (Charges) | 214 |

| Table 17-10. Status of execution of PdC Actions | 216 |

| Table 17-11. Closure measures and actions of the Closure Plan for the Salar de Atacama Mine | 230 |

| Table 17-12. Post-closure measures of the Closure Plan of the Salar de Atacama Mine | 230 |

| Table 17-13. Salar De Atacama Mine Site Closure Costs | 230 |

| Table 17-14. Salar De Atacama Mining Site Post-Closure Costs | 231 |

| Table 17-15. Guarantee Update of the Salar de Atacama Plant Closure Plan (referential table) | 231 |

| Table 18-1. Capital Costs | 233 |

| Table 18-2. Lithium Plant Investments | 235 |

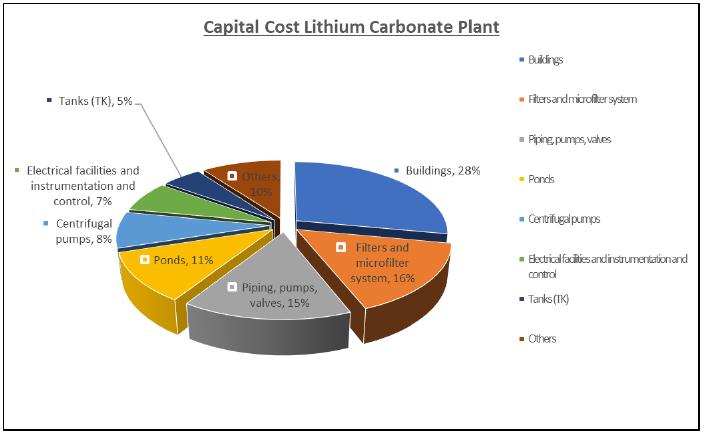

| Table 18-3. Investment in the Lithium Carbonate Plant | 236 |

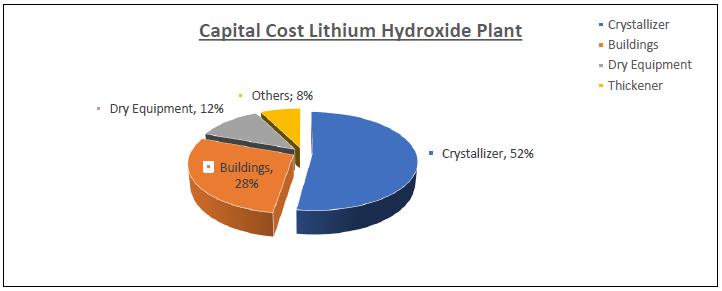

| Table 18-4. Investments in the Lithium Hydroxide Plant | 237 |

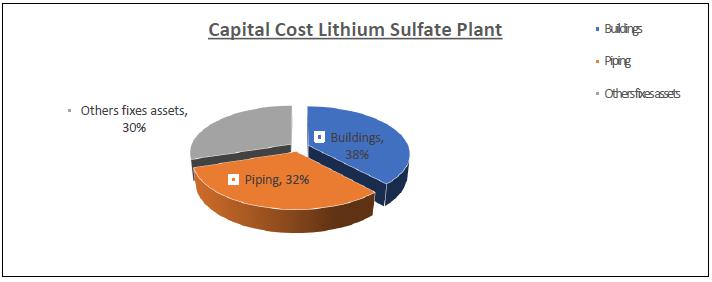

| Table 18-5. Investments in the Lithium Sulfate Plant | 238 |

| Table 18-6. Main Investments in Evaporation and Harvest Ponds | 239 |

| Table 18-7. Main Investments in MOP I and MOP II Ponds | 240 |

| Table 18-8. Main Investments in SOP Ponds | 240 |

| Table 18-9. Main Investments in Lithium Ponds | 240 |

| Table 18-10. Main Investments in Wet Plants | 240 |

| Table 18-11. Detailed Investments in Wet Plants | 241 |

| Table 18-12. Main Investments in Brine Extraction Wells | 241 |

| Table 18-13. Detailed Investments in Brine Extraction Wells | 241 |

| Table 18-14. Projects in Execution (2022 to 2024 Period) | 242 |

| Table 18-15. Distribution of Operating Costs | 243 |

| Table 18-16. Payment Agreements with CORFO | 244 |

| Table 19-1. Projected Sales of Lithium and KCl | 247 |

| Table 19-2. Revenues of Lithium and KCl | 247 |

| Table 19-3. Main Costs of Lithium and KCl production | 247 |

| Table 19-4. Operating Costs | 248 |

| Table 19-5. Estimated Capital Investments | 249 |

| Table 19-6. Estimated Cashflow Analysis | 249 |

| Table 19-7. Estimated Sum Of Payments to CORFO And Other Agreements and Taxes (2024-2030) | 250 |

| Table 19-8. Assumptions for the Base Case | 250 |

| Table 19-9. Lithium Carbonate Price Sensitivity at 250 ktpy | 251 |

| Table 19-10. Cost Sensitivities | 251 |

| Table 19-11. KCl Price Sensitivities | 251 |

| Table 19-12. CORFO Rights and other Agreements Sensitivities | 252 |

| Table 19-13. Tax Sensitivities | 252 |

| Table 19-14. Contribution to the State of Chile (Taxes, CORFO Rights and Others) | 252 |

| Table 25-1. Information Provided by the Registrant (SQM) | 266 |

FIGURES

| Figure 3-1. Location of SQM’s Salar de Atacama Project | 15 |

| Figure 6-1. Local Geology Map of Salar de Atacama | 23 |

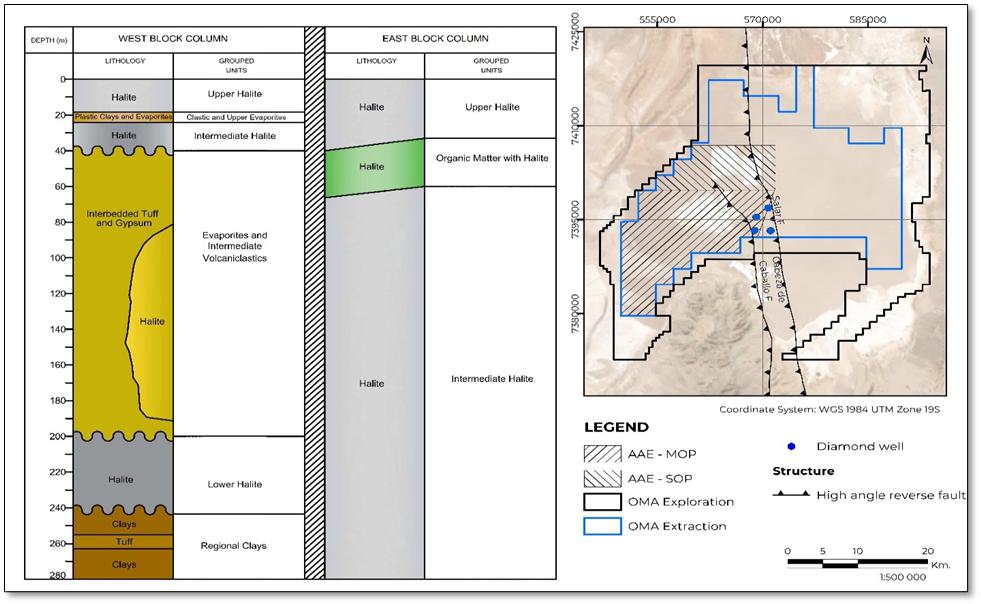

| Figure 6-2. Geological Cross Sections | 27 |

| Figure 6-3. Stratigraphic Columns of the Western and Eastern Blocks | 28 |

| Figure 6-4. Mature and Immature Salt Flats (Houston et al., 2011) | 29 |

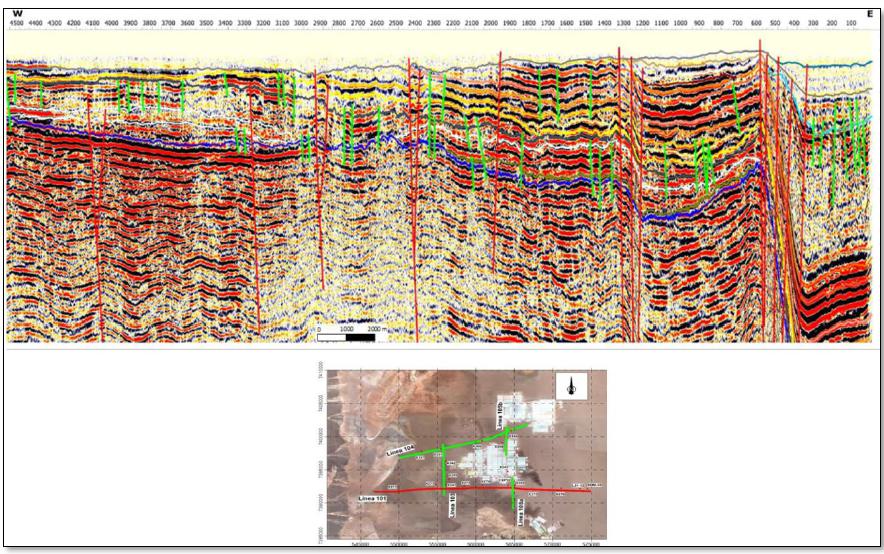

| Figure 7-1. Seismic Reflection Survey (AguaEx, 2020) | 31 |

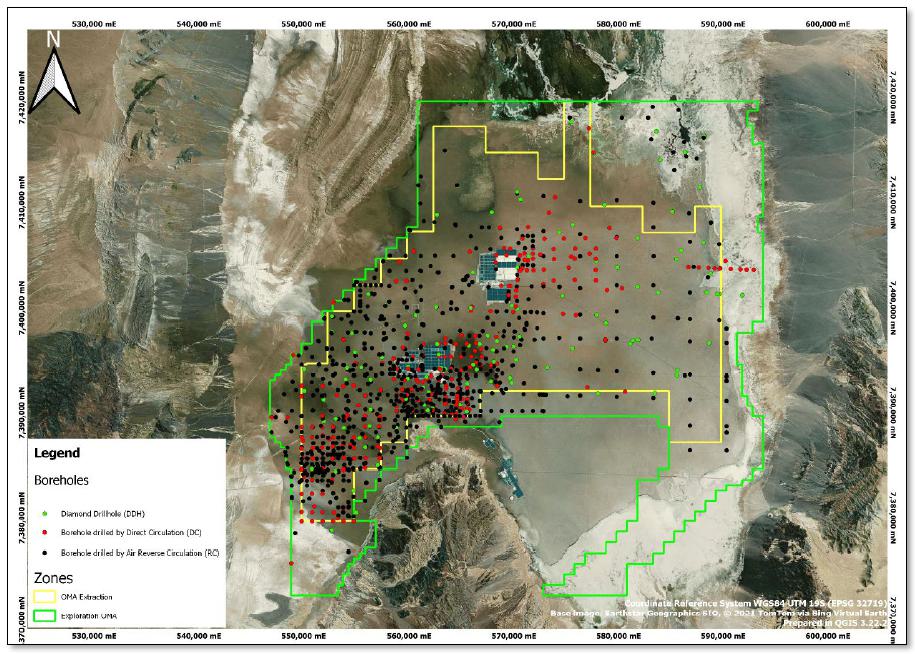

| Figure 7-2. Distribution of Wells that provide Geological and Hydrogeological Information for the Project (SQM, 2020) | 32 |

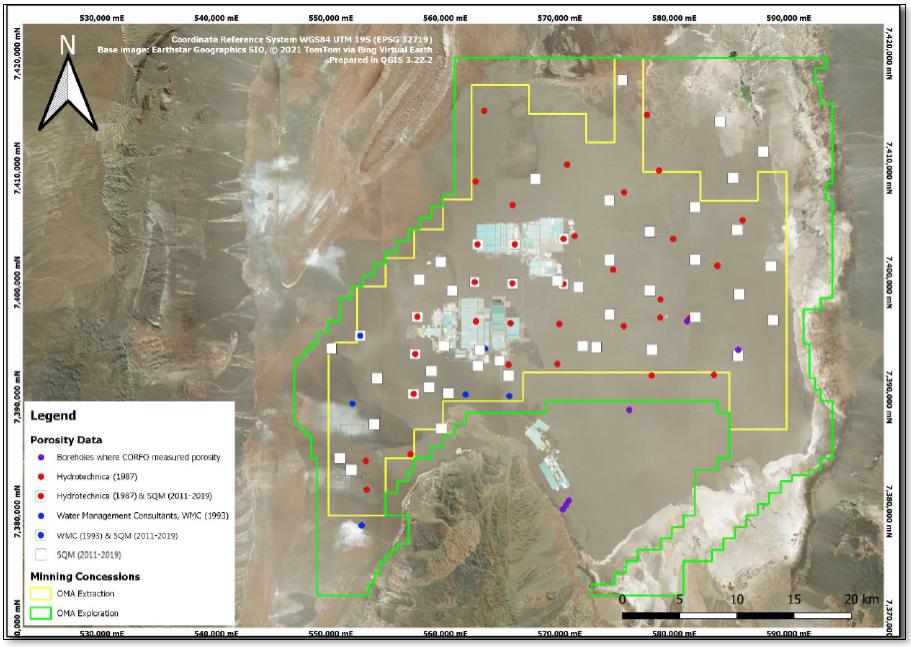

| Figure 7-3. Distribution of Boreholes with Porosity Measurements | 34 |

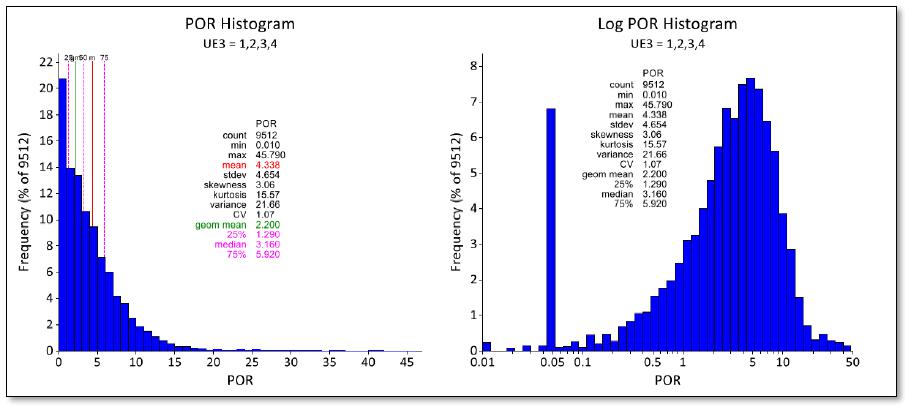

| Figure 7-4. Effective Porosity (%) Histogram of the Upper Halite, Intermediate Halite, and Halite with Organic Matter | 34 |

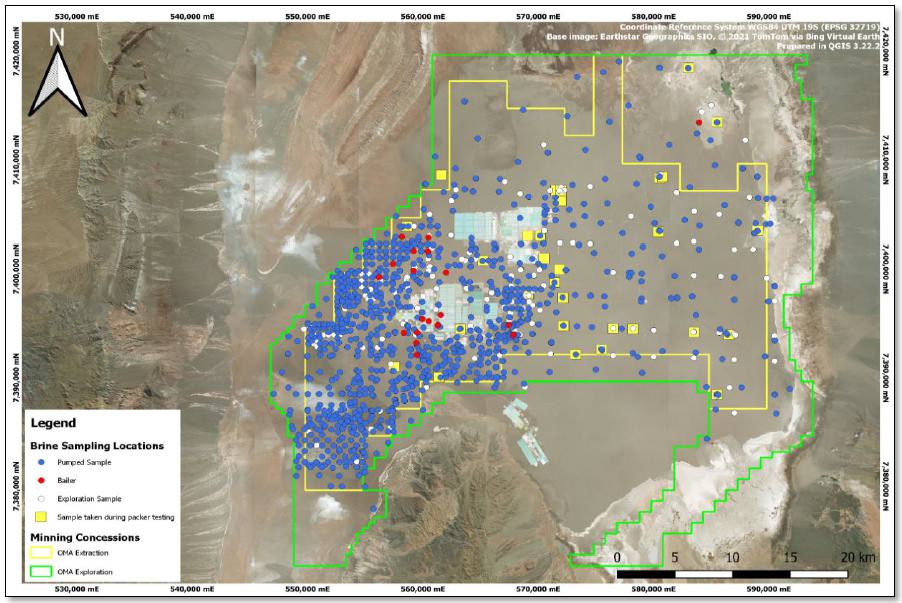

| Figure 7-5. Distribution of Boreholes with Brine Chemistry Measurements | 36 |

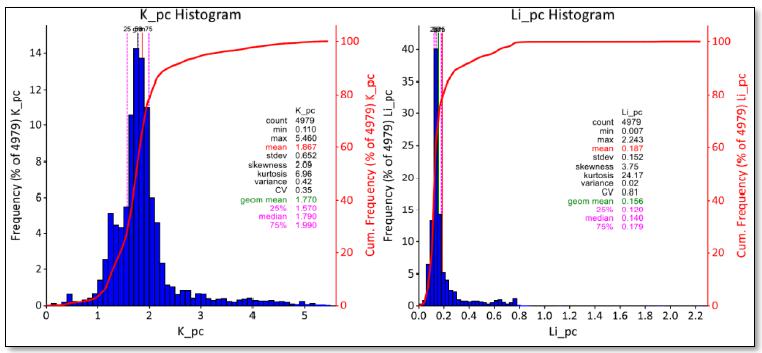

| Figure 7-6. Histogram of Li and K Concentrations (%) | 36 |

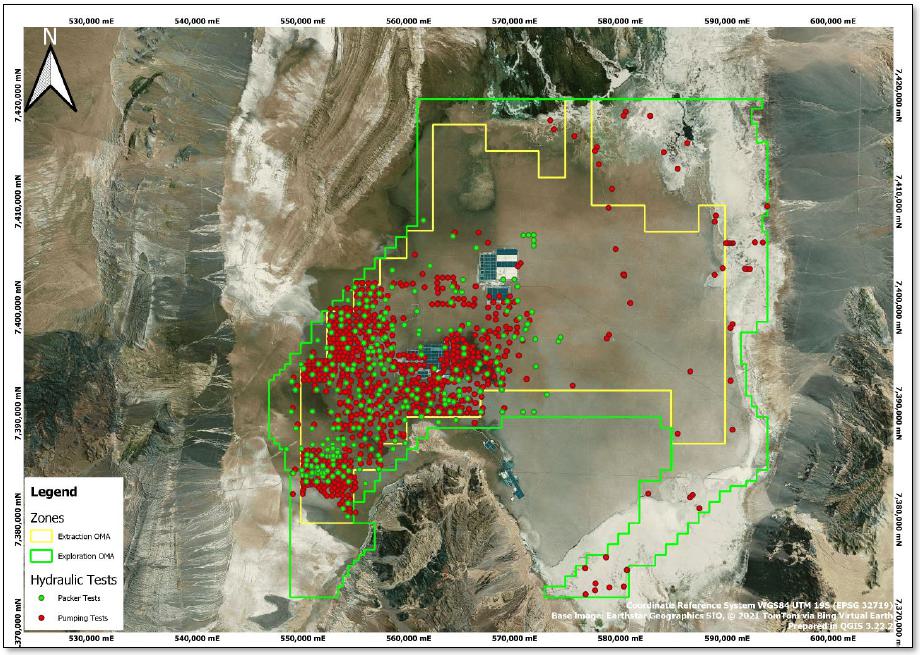

| Figure 7-7. Hydraulic Testing Locations, OMA Exploration | 39 |

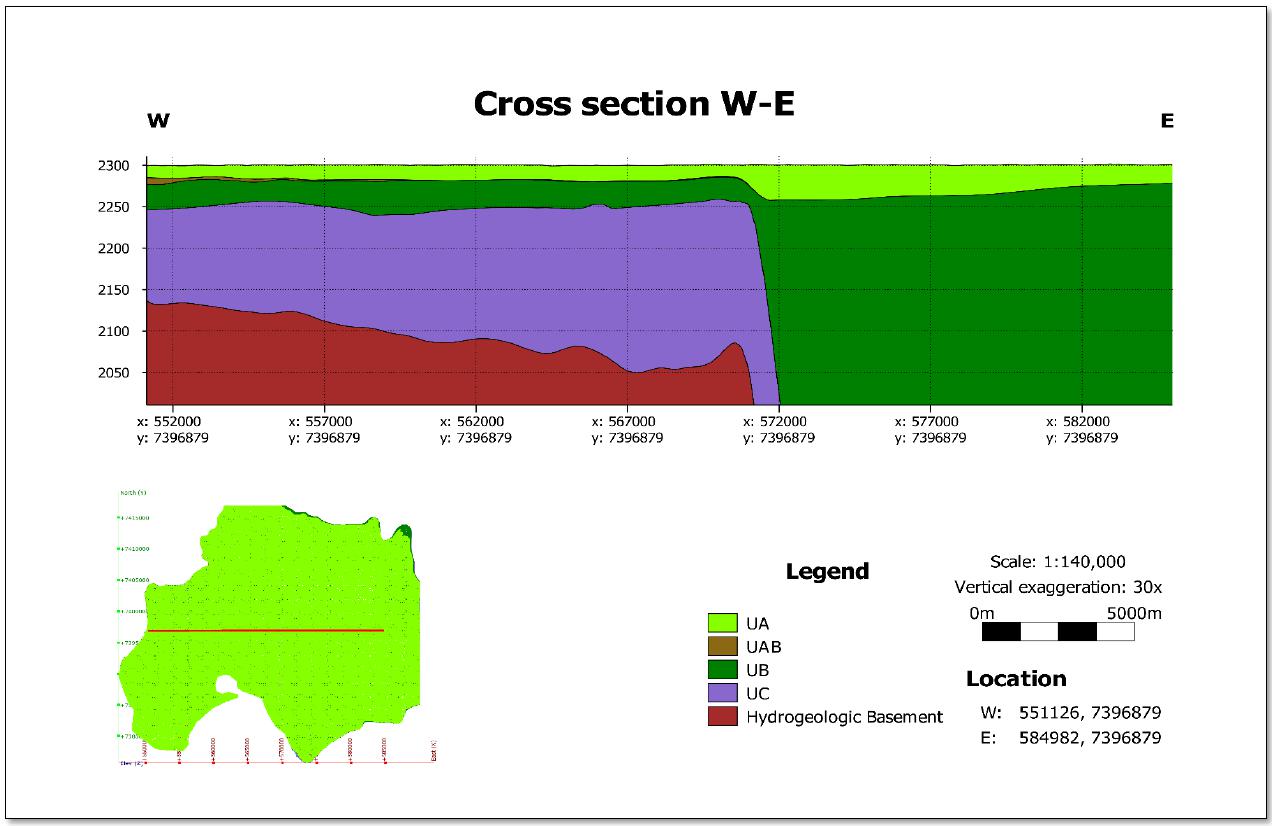

| Figure 7-8. W – E Hydrogeological Cross Section from the Hydrogeological Model | 41 |

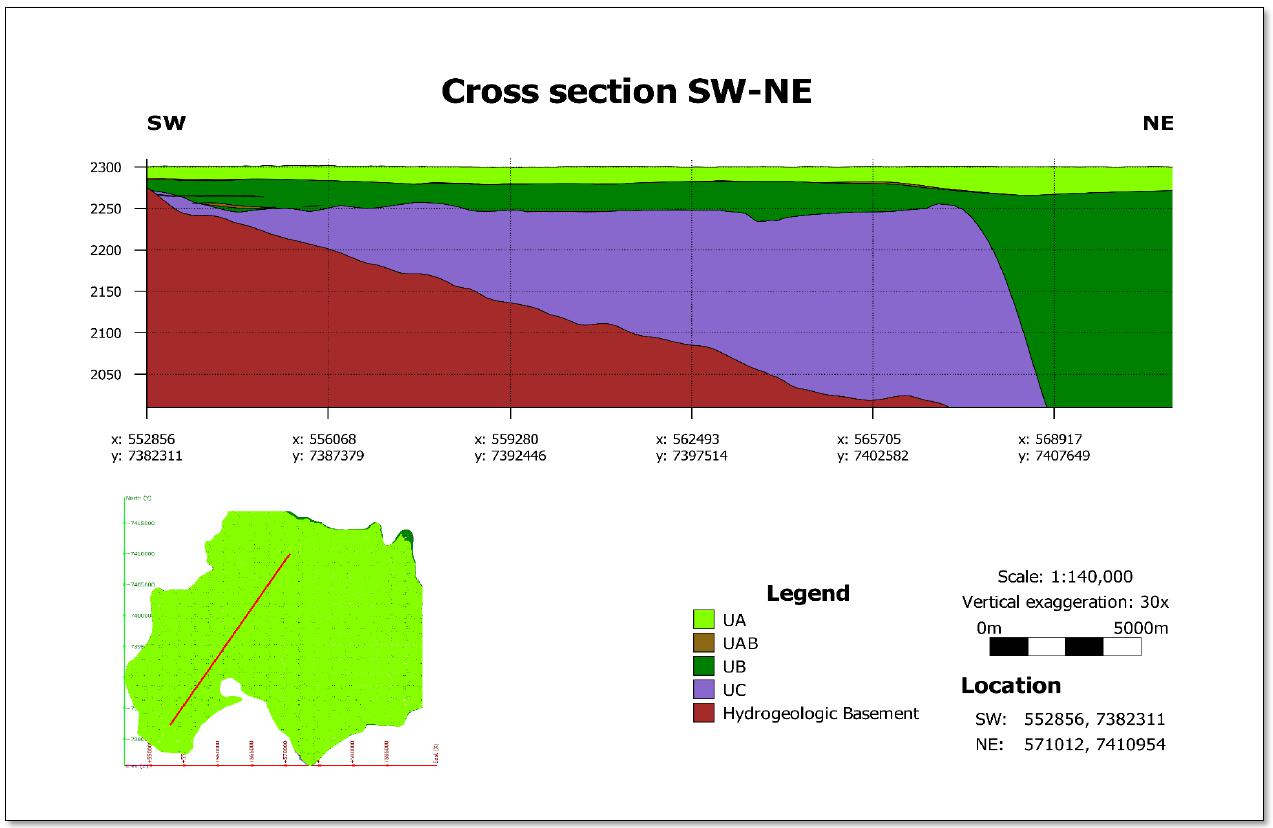

| Figure 7-9. SW - NE Hydrogeological Cross Section from the Hydrogeological Model | 42 |

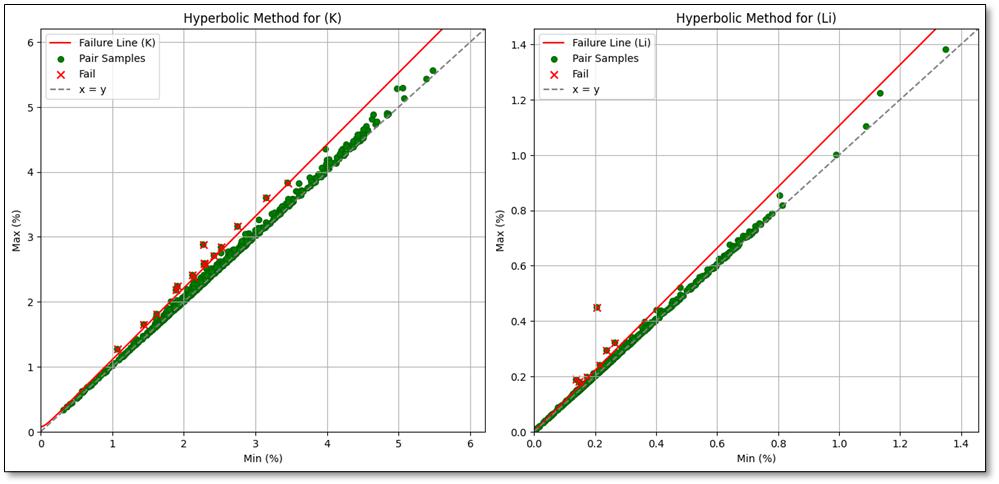

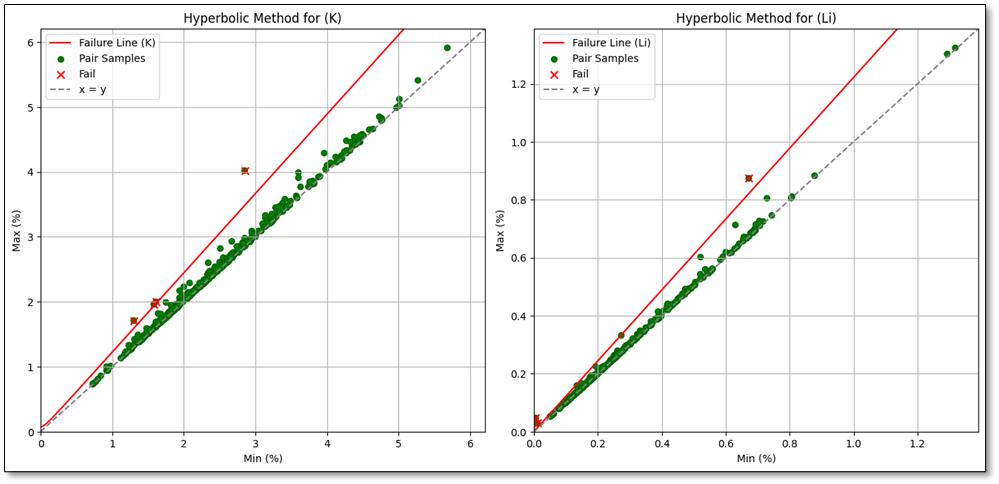

| Figure 8-1. Error Ratio Plots, Analytical Duplicates | 48 |

| Figure 8-2. Error Ratio Plots, Field Duplicates | 48 |

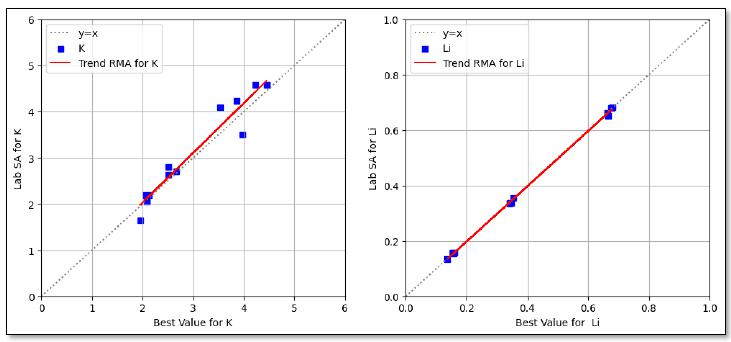

| Figure 8-3. Accuracy Plots, Reference Materials | 51 |

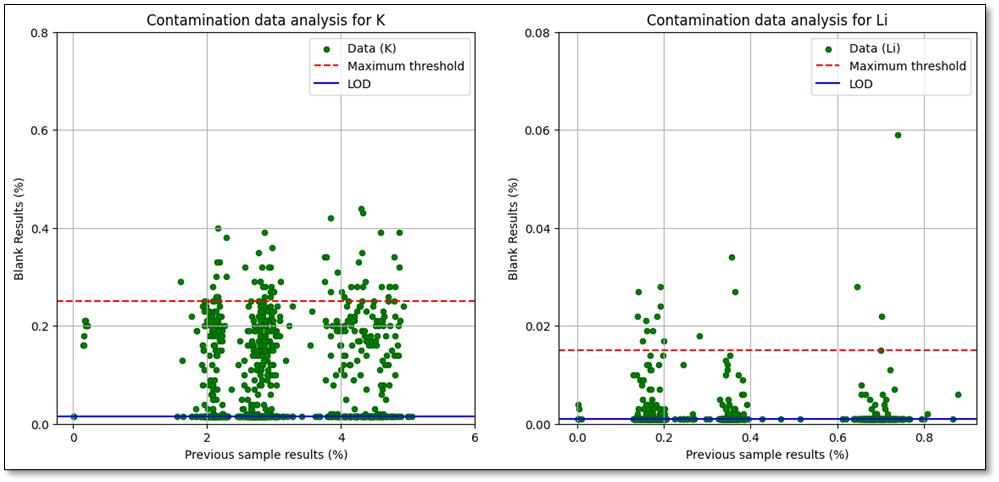

| Figure 8-4. Contamination Plots, Blank Samples | 52 |

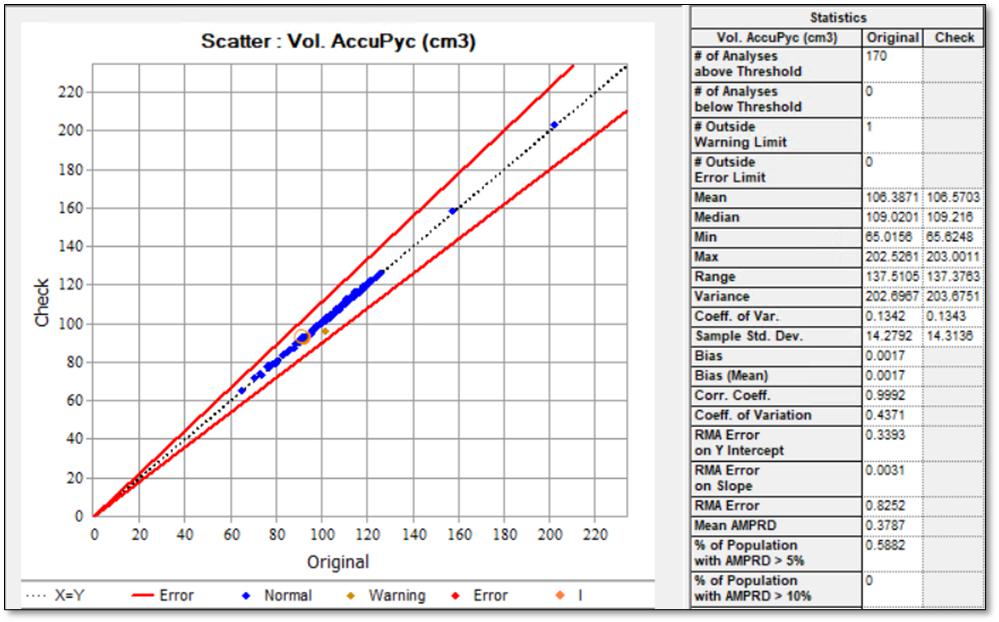

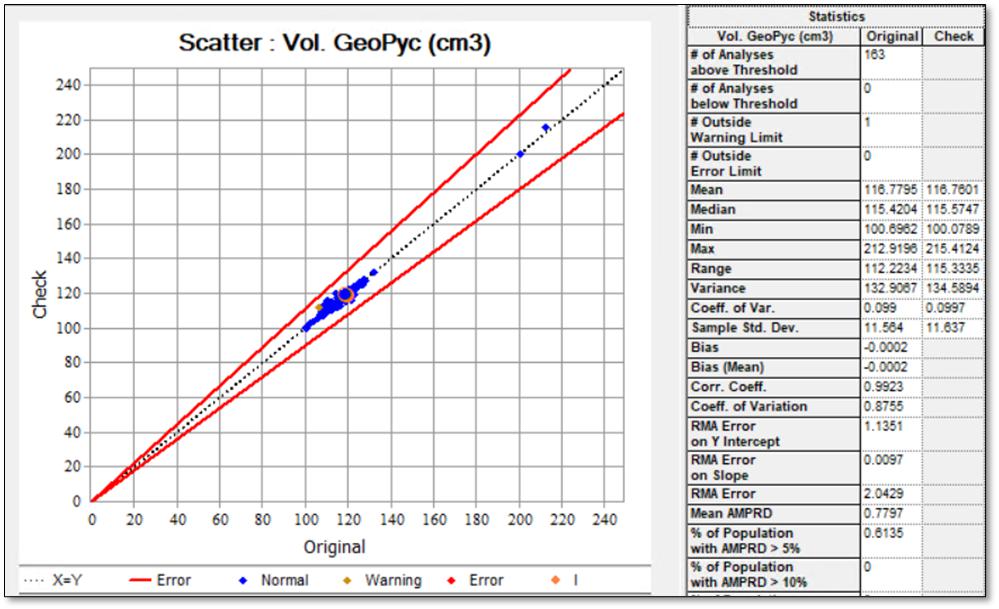

| Figure 8-5. Scatter Plot for Pairs Analyzed with Accupyc | 54 |

| Figure 8-6. Scatter Plot for pairs analyzed with Geopyc | 54 |

| Figure 10-1. Determination of In-situ Brine Parameters at Pumping Wells | 63 |

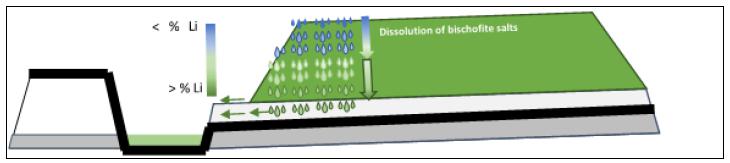

| Figure 10-2. Improved Treatment Scheme for Bischofite Platforms | 75 |

| Figure 10-3. Improved Treatment Scheme for Harvested Salts | 75 |

| Figure 11-1. Mineral Resource Estimate General Flowchart | 79 |

| Figure 11-2. Variograms of Effective Porosity Domain 1 (Upper Halite) | 84 |

| Figure 11-3. Variograms of Effective Porosity Domain 3 (Intermediate Halite) | 85 |

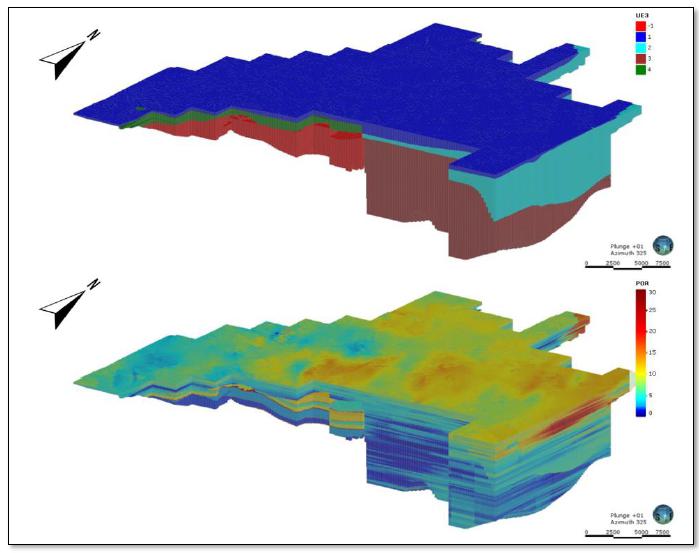

| Figure 11-4. Block Model with Pe Domains and Interpolated Values, OMA Extraction Zone | 7 |

| Figure 11-5. Swath Plots of Effective Porosity within the 4 Estimation Domains | 88 |

| Figure 11-6. Lithium Variograms of Brine Chemistry Domain 1 | 91 |

| Figure 11-7. Potassium Variograms of Brine Chemistry Domain 1 | 91 |

| Figure 11-8. Interpolated Li (wt %) in the Block Model, Saturated Area of the OMA Zone (Modified from (SQM, 2021a)) | 94 |

| Figure 11-9. Box Plots of Measured Sample Values versus estimated Block Model Values, Li and K | 95 |

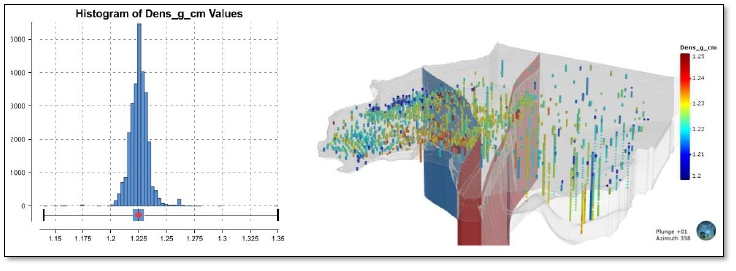

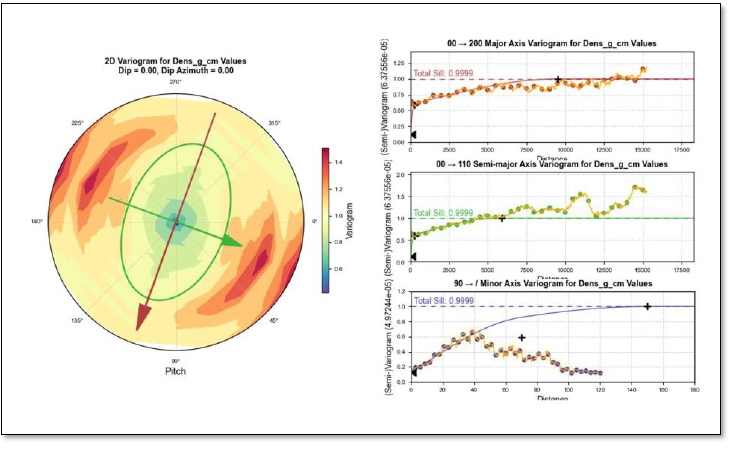

| Figure 11-10. Density Histogram and Spatial Distribution | 96 |

| Figure 11-11. Density Estimate Variogram | 97 |

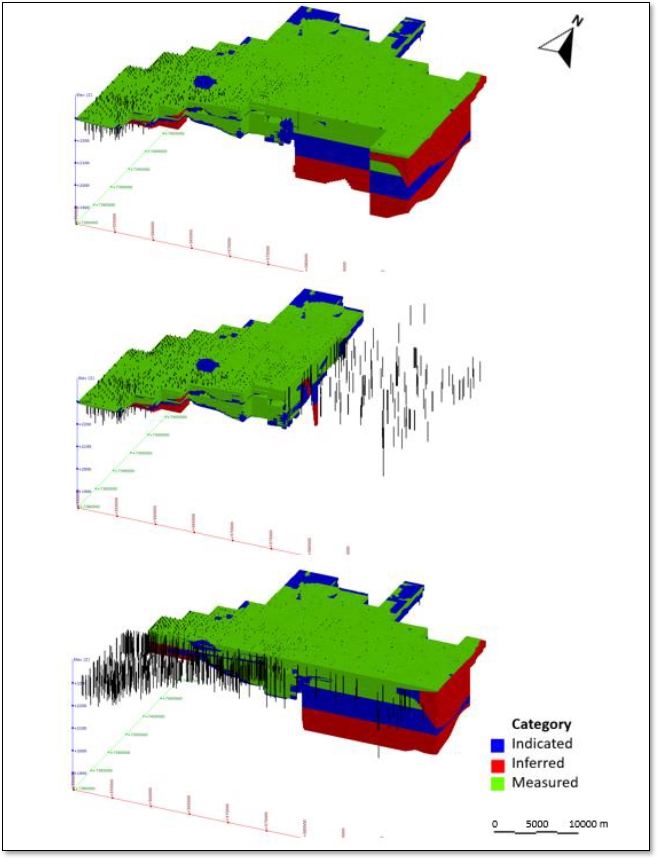

| Figure 11-12. Resource Categorization in 3 Dimensions | 101 |

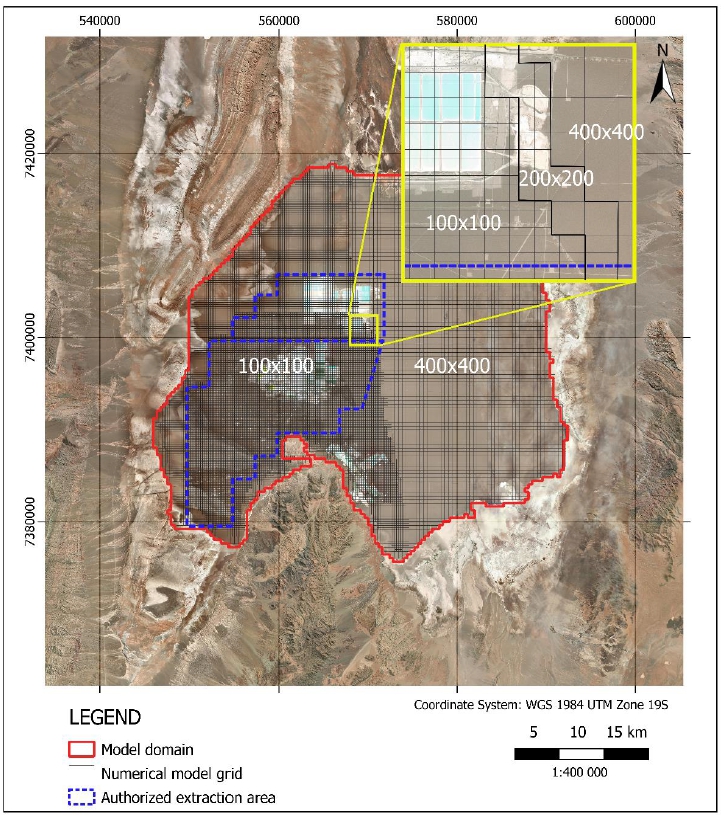

| Figure 12-1. Numerical Model Domain and Grid | 105 |

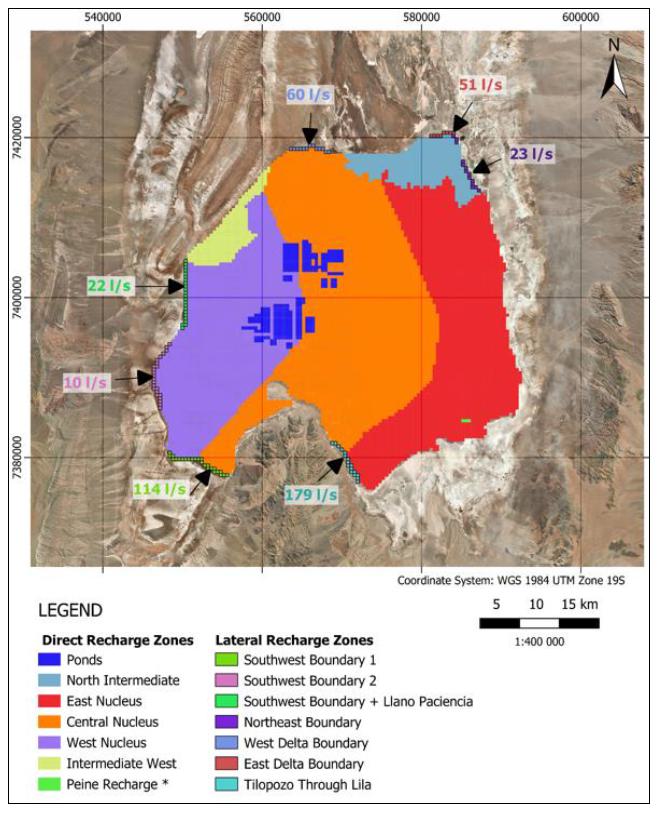

| Figure 12-2. Direct Recharge and Lateral Recharge Zones | 108 |

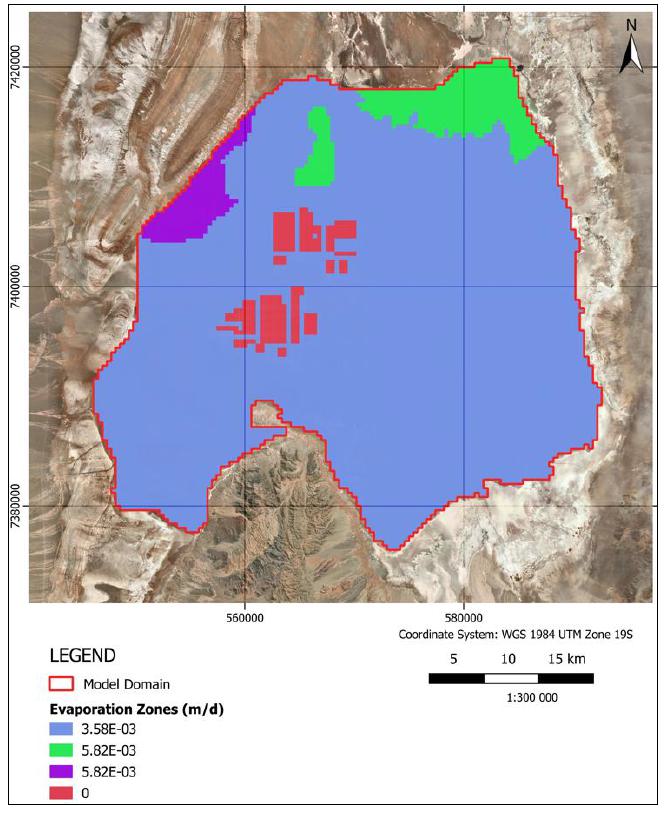

| Figure 12-3. Evaporation Zones in the Numerical Model | 109 |

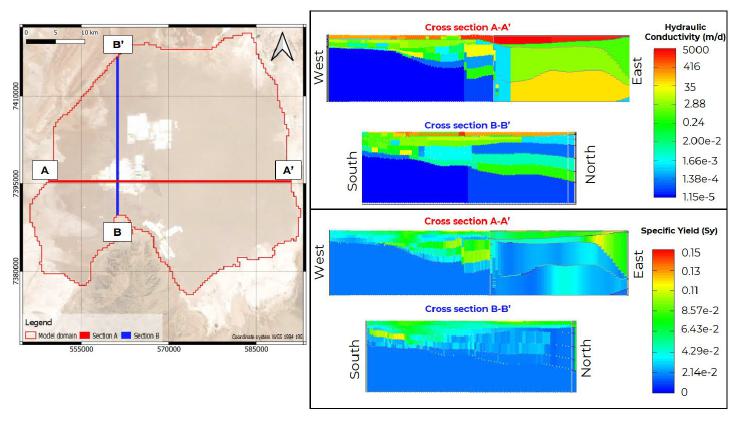

| Figure 12-4. Representative Hydraulic Conductivity (Kh) and Specific Yield - Effective Porosity (Sy -Pe) Distribution in Numerical Model | 111 |

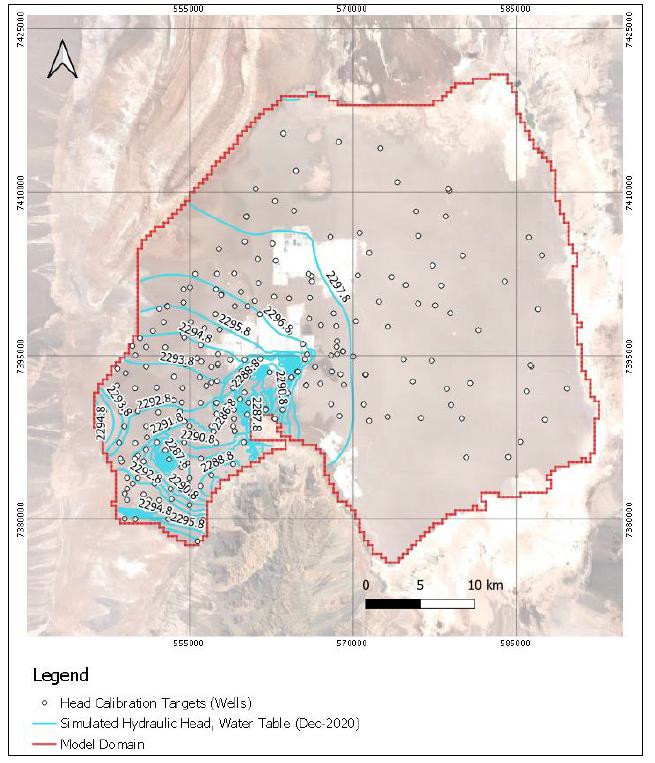

| Figure 12-5. Head Observation Targets and Simulated Water Table for the End of the Calibration Period | 113 |

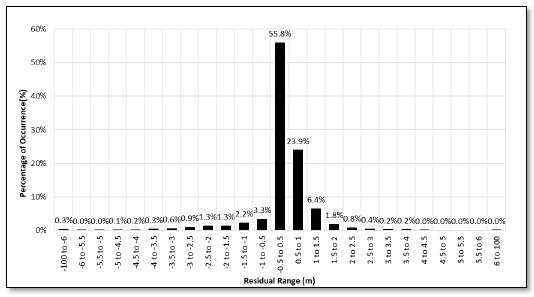

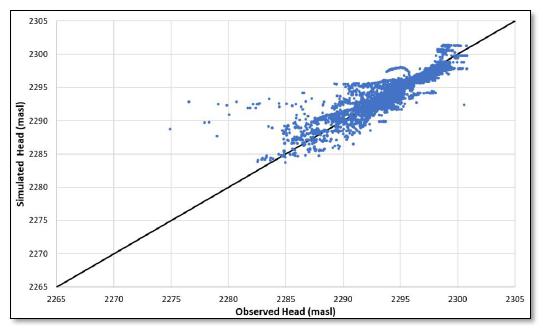

| Figure 12-6. Head Calibration Results | 114 |

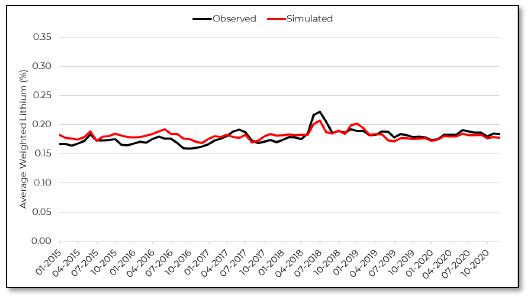

| Figure 12-7. Extracted Concentration Fit during the Calibration Period (2015 – 2020) | 115 |

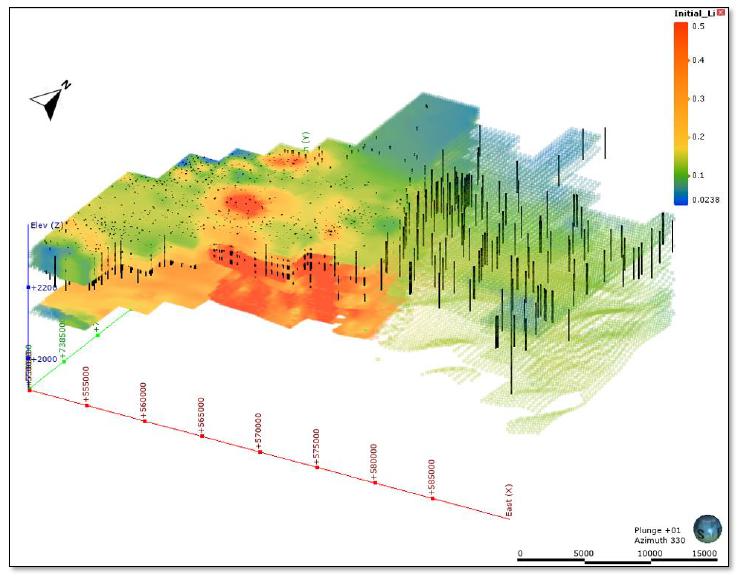

| Figure 12-8. Lithium Concentration (%) Distribution following the Calibration Period | 117 |

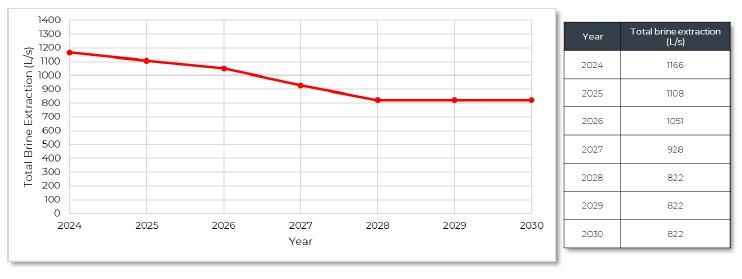

| Figure 12-9. SQM’s Future Brine Pumping and Voluntary Reduction | 118 |

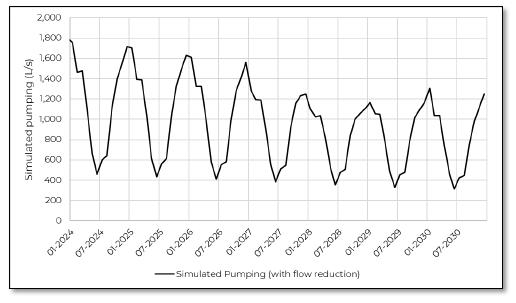

| Figure 12-10. Simulated SQM Pumping Rates, Reserve Simulation | 119 |

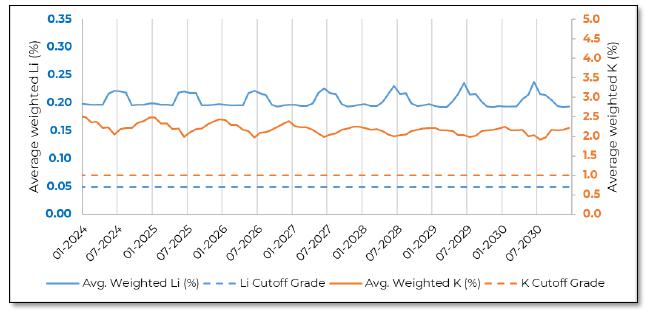

| Figure 12-11. Average Weighted Concentrations Extracted from SQM’s Production Wells, Reserve Simulation | 119 |

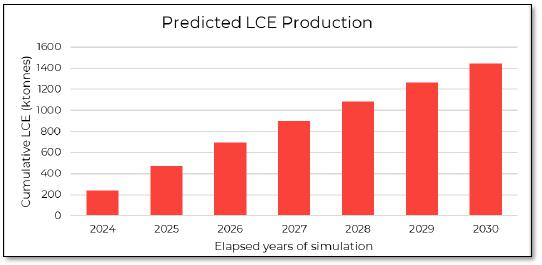

| Figure 12-12. Predicted Cumulative Annual LCE Production (Considering Process Recoveries) | 121 |

| Figure 12-13. Predicted Annual KCl Production (Considering Process Recoveries) | 122 |

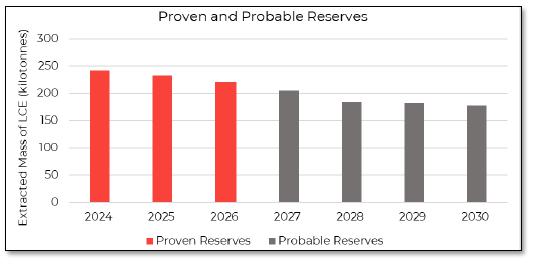

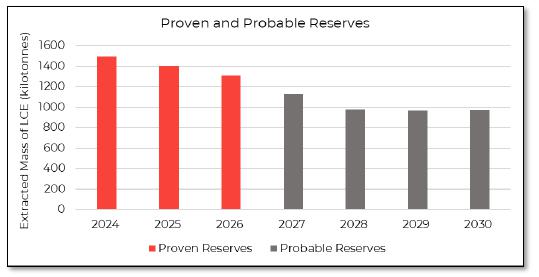

| Figure 12-14. SQM’s Salar de Atacama Lithium Mineral Reserve Estimate Considering Process Recoveries (Effective December 31, 2023) | 124 |

| Figure 12-15. SQM’s Salar de Atacama Potassium Reserve Estimate Considering Process Recoveries (Effective December 31, 2023 | 125 |

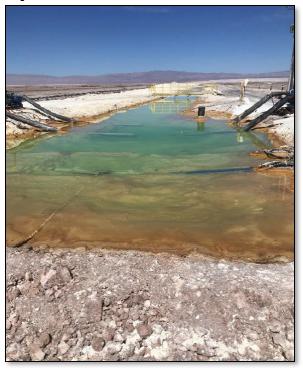

| Figure 13-1. Field Pictures of a Typical Salar de Atacama Brine Production Well, Pipe, and Gathering Pond | 130 |

| Figure 13-2. Final Mine Outline | 131 |

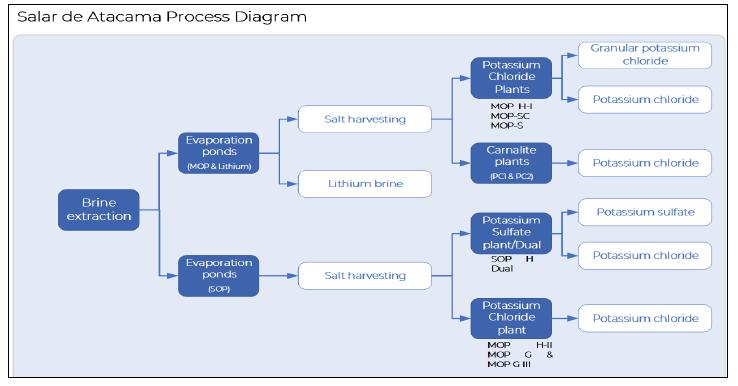

| Figure 14-1. Simplified Process Flowsheet for the Salar de Atacama | 133 |

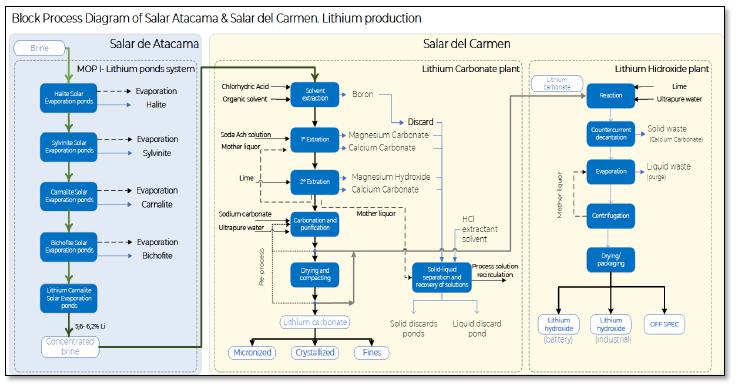

| Figure 14-2. General Block Process Diagram for Lithium Salts Products | 134 |

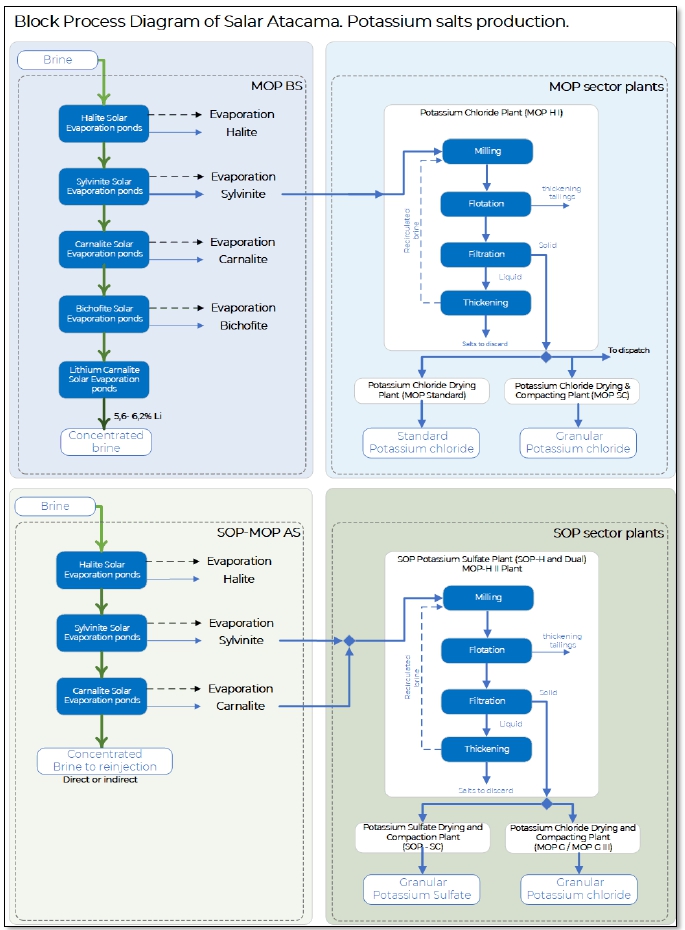

| Figure 14-3. General Block Process Diagram for Potassium Salts Products | 137 |

| Figure 14-4. Map of the location of the Brine extraction area. SQM Salar de Atacama | 138 |

| Figure 14-5. Location of solar evaporation ponds (light blue zone) and salt deposits (green zone). Salar de Atacama | 140 |

| Figure 14-6. Block process diagram of PQC’s Operations | 143 |

| Figure 14-7. Properties Adjacent to SQM’s Concessions, Salar de Atacama | 158 |

| Figure 15-1. General Location Salar de Atacama Site | 160 |

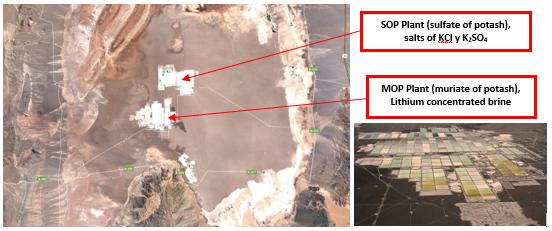

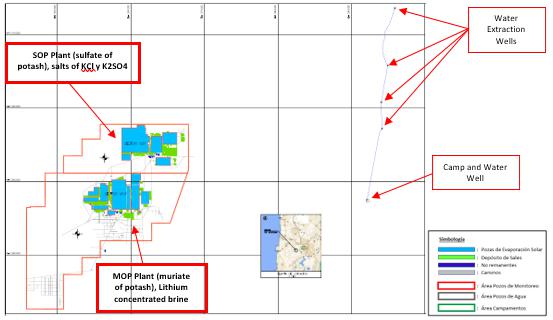

| Figure 15-2. SOP and MOP Plants | 164 |

| Figure 15-3. Location SOP and MOP Plants | 164 |

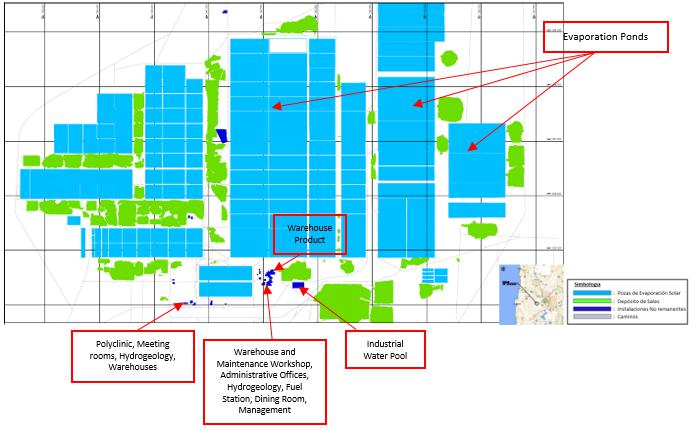

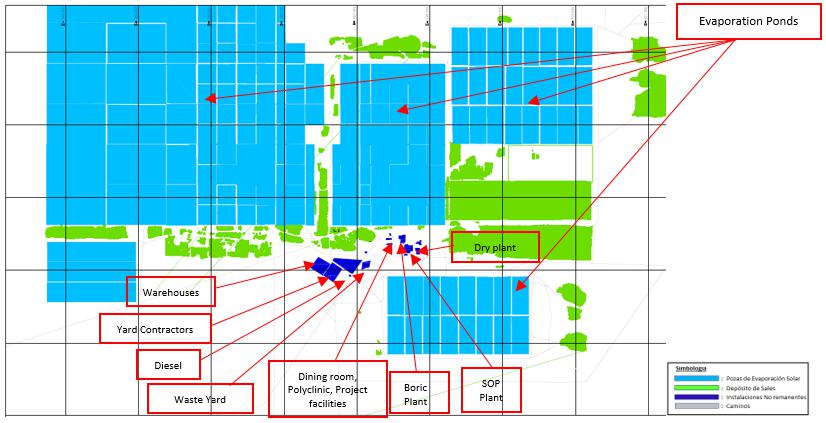

| Figure 15-4. Facilities MOP | 165 |

| Figure 15-5. Facilities SOP | 165 |

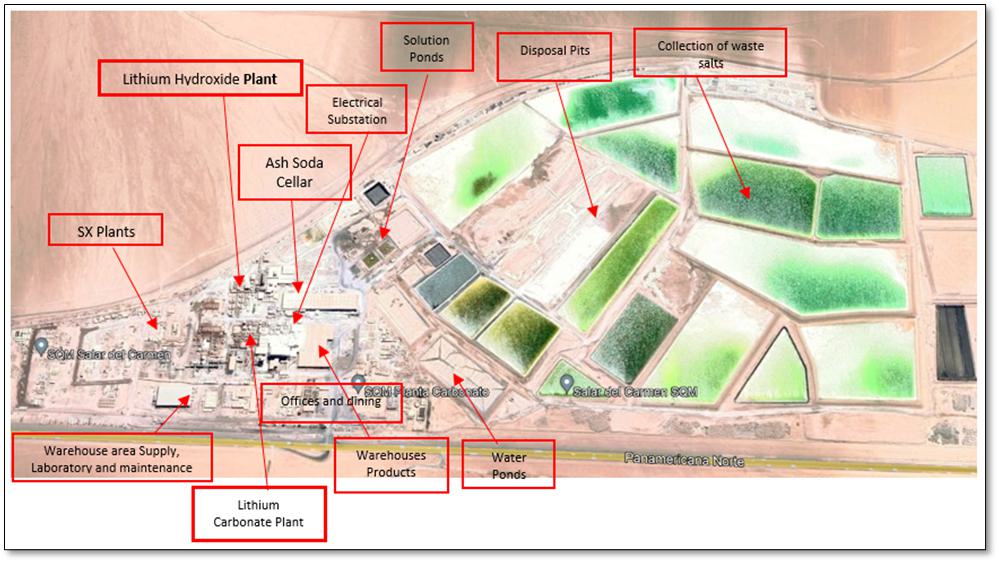

| Figure 15-6. Main Facilities of the Salar del Carmen | 168 |

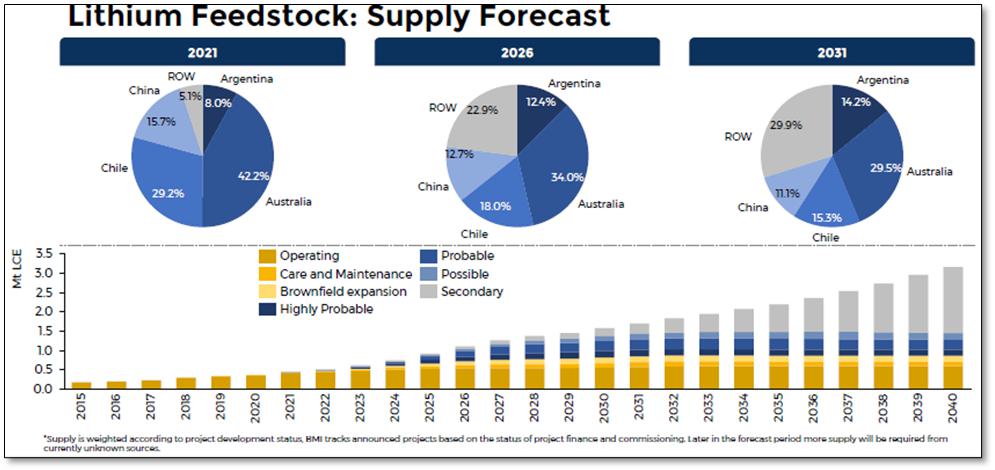

| Figure 16-1. Lithium Feedstock, supply forecast | 175 |

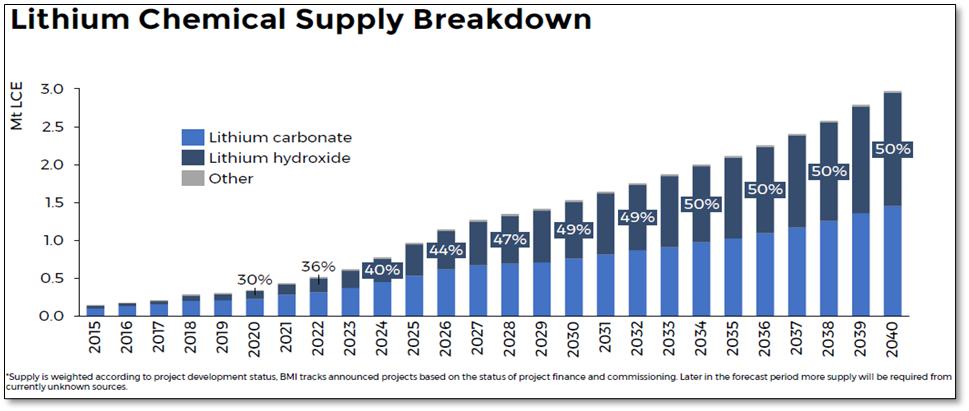

| Figure 16-2. Lithium Chemical Supply Breakdown | 176 |

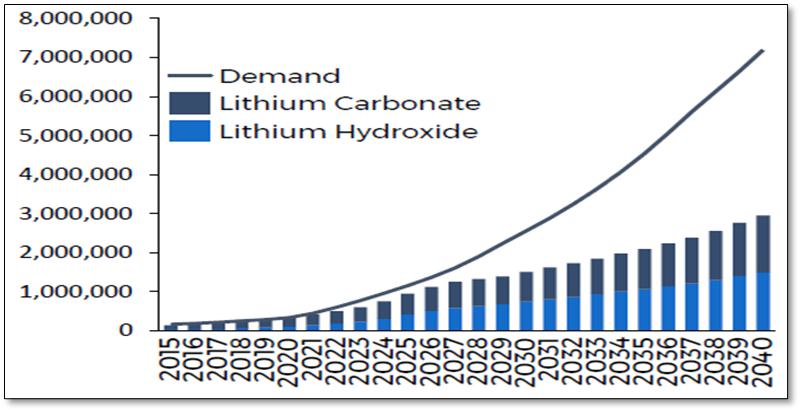

| Figure 16-3. Lithium Carbonate and Hydroxide demand | 177 |

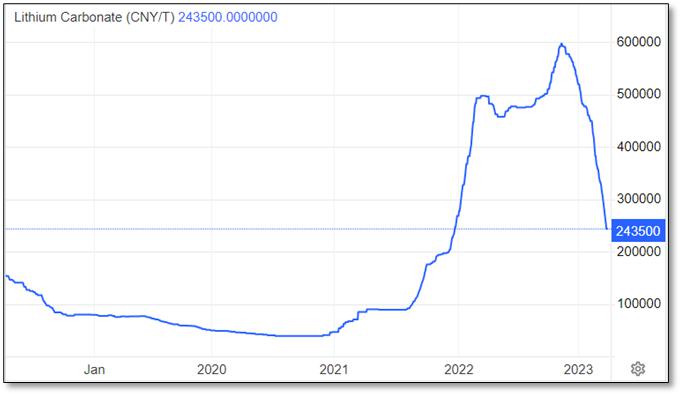

| Figure 16-4. Lithium historic Price Evolution | 177 |

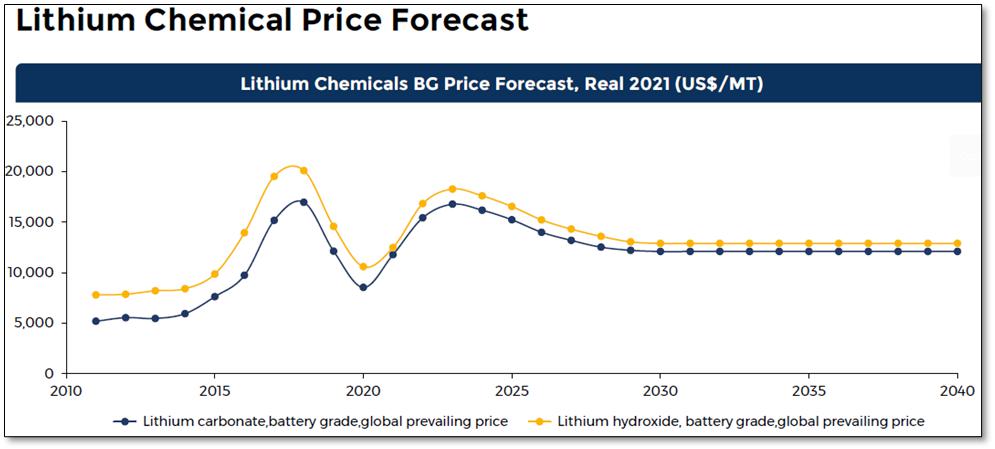

| Figure 16-5. Lithium Chemical Price Forecast | 178 |

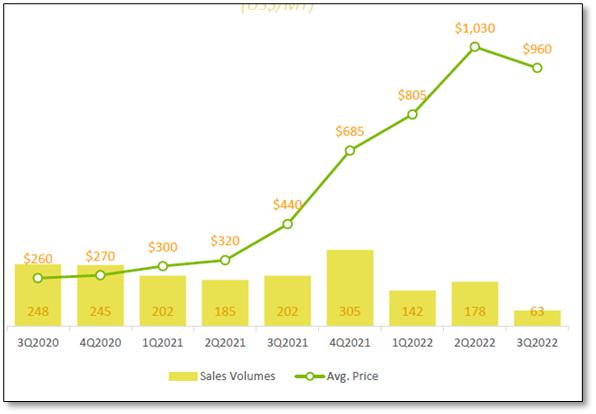

| Figure 16-6. Potassium Quarterly Sales Volumes and Average Prices | 180 |

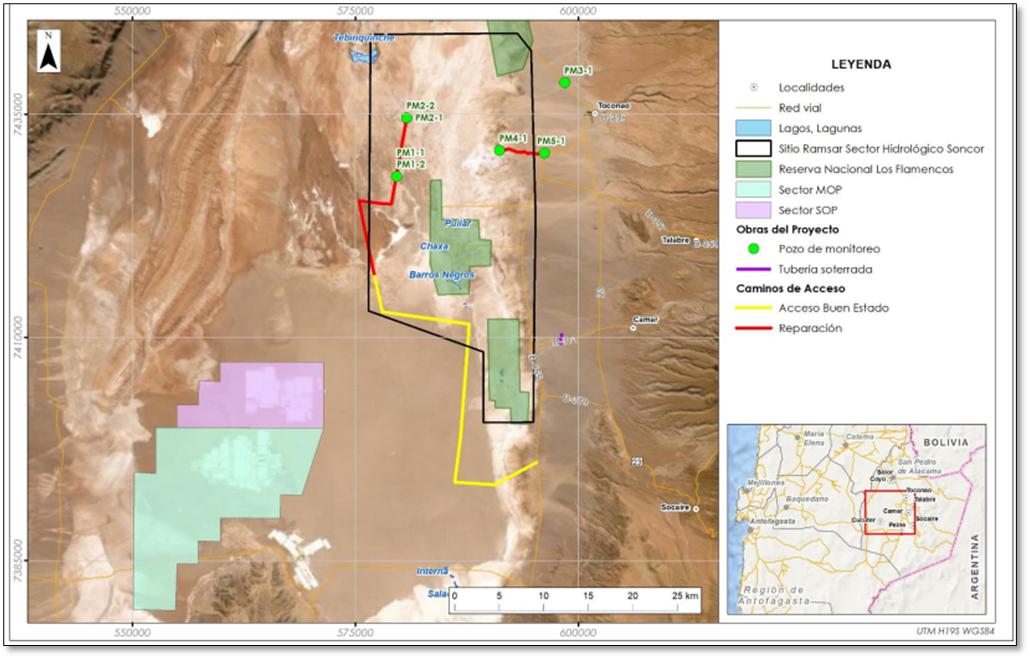

| Figure 17-1. Ramsar Site, Soncor Hydrogeological System and Reserva Nacional Los Flamencos Protected Area boundaries. | 182 |

| Figure 17-2: Salar de Atacama Morphometrics Zones | 184 |

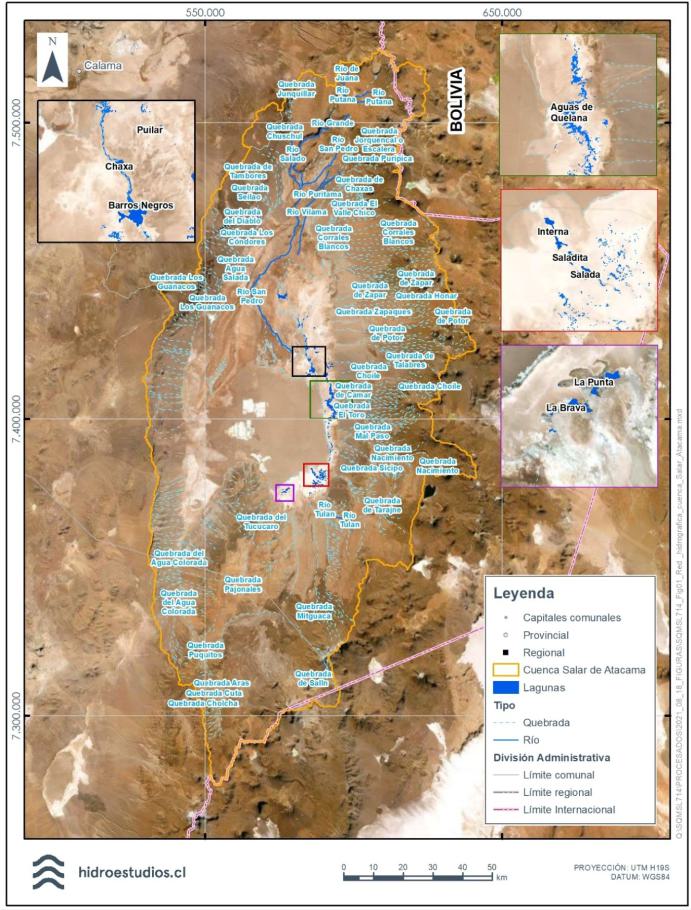

| Figure 17-3. Hydrographic Network of the Salar de Atacama Basin | 185 |

| Figure 17-4: Environmental Monitoring Zones RCA226/2006 | 186 |

| Figure 17-5. Faunal Environments | 188 |

| Figure 17-6. Sectors in the Area of Influence (AI) of Inland Aquatic Ecosystems | 191 |

| Figure 17-7. Salar de Atacama’s Human Environment | 192 |

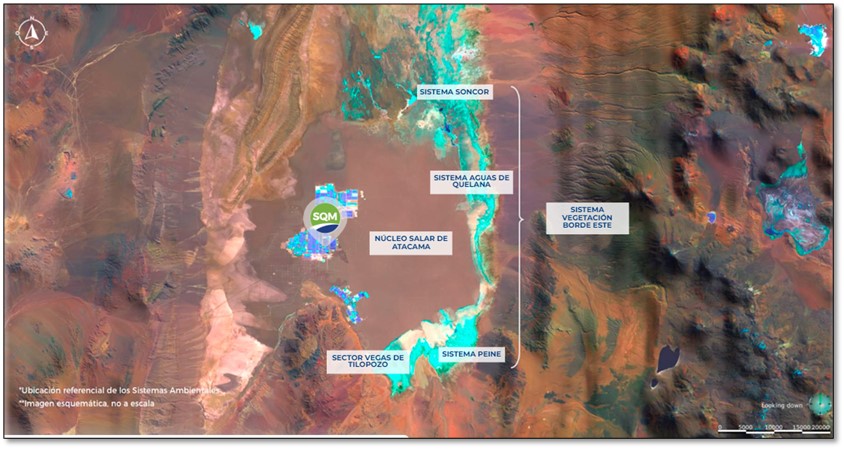

| Figure 17-8. Schematic location of the Environmental Systems and Sectors of the Hydrogeological PES. | 198 |

| Figure 17-9. PES Schematic Location | 199 |

| Figure 17-10. Annual and Daily Extractions of Water Industrial Wells | 205 |

| Figure 17-11 Annual Net Extraction in Units of L/S Each Calendar Year (January 1 to December 31) | 208 |

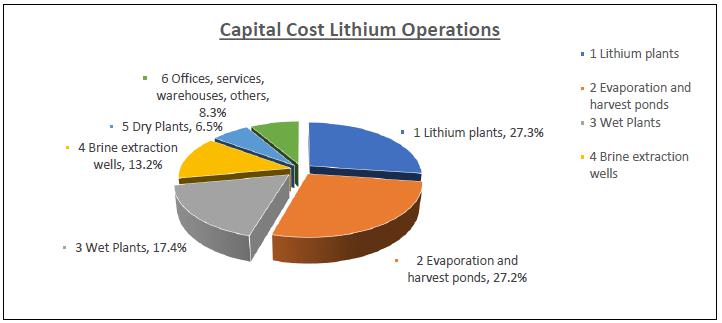

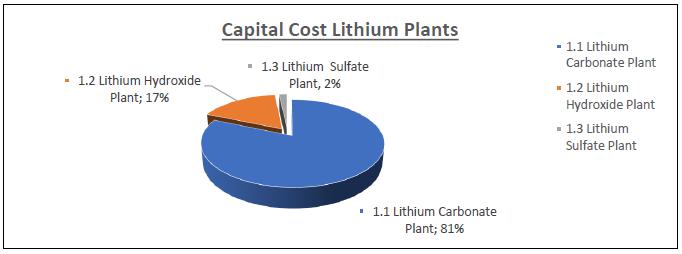

| Figure 18-1. Capital Cost of Lithium Operations | 234 |

| Figure 18-2. Capital Costs for Lithium Plants | 235 |

| Figure 18-3. Capital Cost for the Lithium Carbonate Plant | 236 |

| Figure 18-4. Capital Costs for the Lithium Hydroxide Plant | 237 |

| Figure 18-5. Capital Cost Lithium Sulfate Plant | 238 |

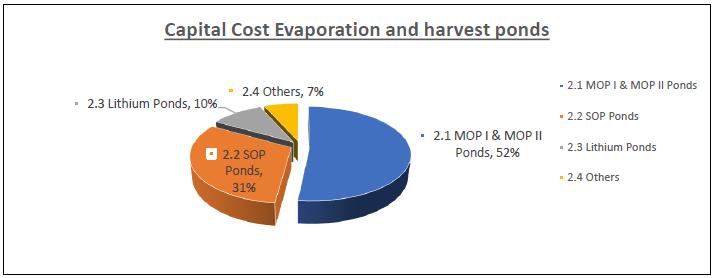

| Figure 18-6. Capital Cost Evaporation and Harvest Ponds | 239 |

| Figure 20-1. Properties Adjacent to SQM’s Concessions, Salar de Atacama | 254 |

| 1 | EXECUTIVE SUMMARY |

This Technical Report Summary (TRS) was prepared on behalf of the Sociedad Química y Minera de Chile (SQM) for their operations in the Salar de Atacama (the “Project”). Since the previously filed TRS (2022), it is the QPs’ opinion that there have been no material changes related to exploration, the Mineral Resource, or the Mineral Reserve.

| 1.1 | Property and Mineral Rights |

The Project is located in the Antofagasta Region of Chile which covers the Loa Province and San Pedro de Atacama commune. The Salar de Atacama mine tenements are owned by the Corporación de Fomento de la Producción (CORFO) of Chile which grants special operating contracts, or administrative leases, to private companies for the extraction of brine over a certain period. SQM has a lease agreement with CORFO, signed in 1993, to extract and generate lithium (Li) and potassium (K) products from brines in the Salar de Atacama deposit.

In 2018, SQM and CORFO performed a reconciliation process that modified the pre-existing lease and Project contracts. The expiration date of the current SQM-CORFO lease agreement is December 31, 2030, and SQM holds leases for a total area of approximately 1,400 square kilometers (km2) with permission to extract brines from an area of approximately 820 km2.

| 1.2 | Geology and Mineralization |

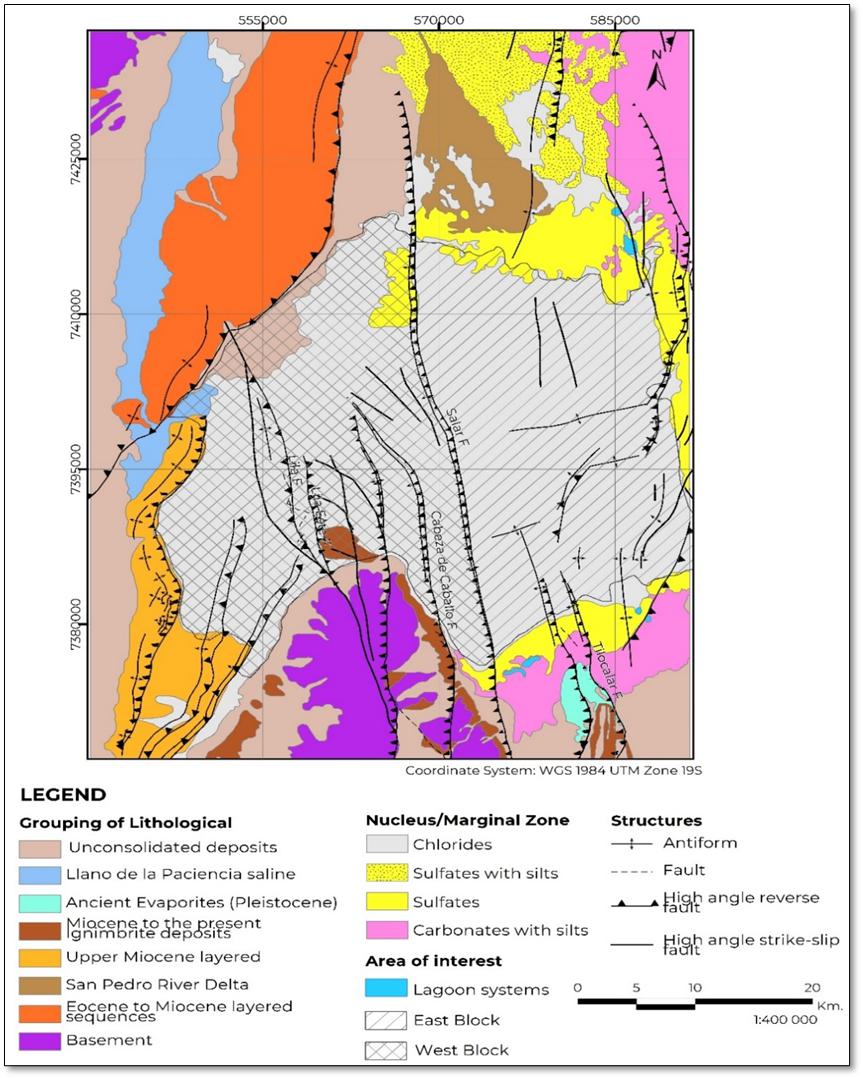

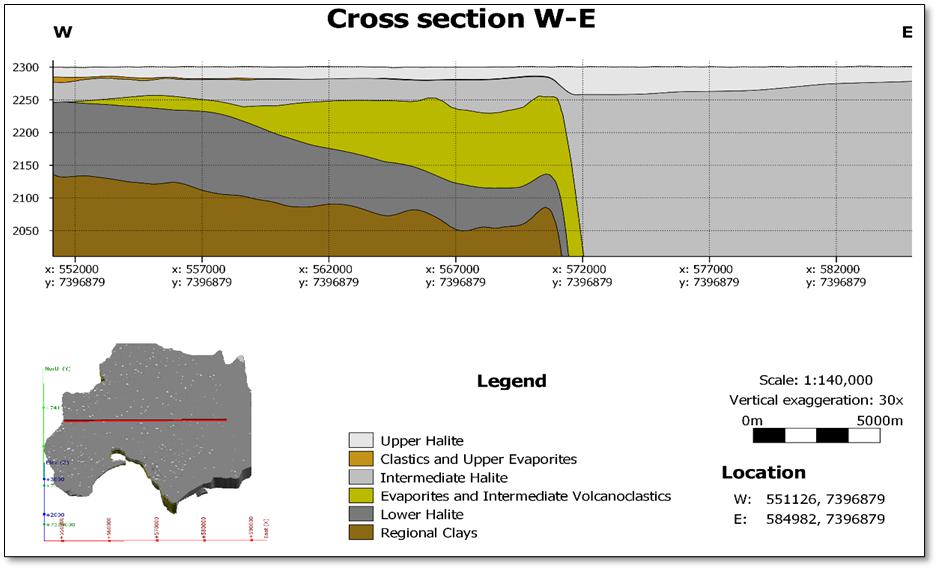

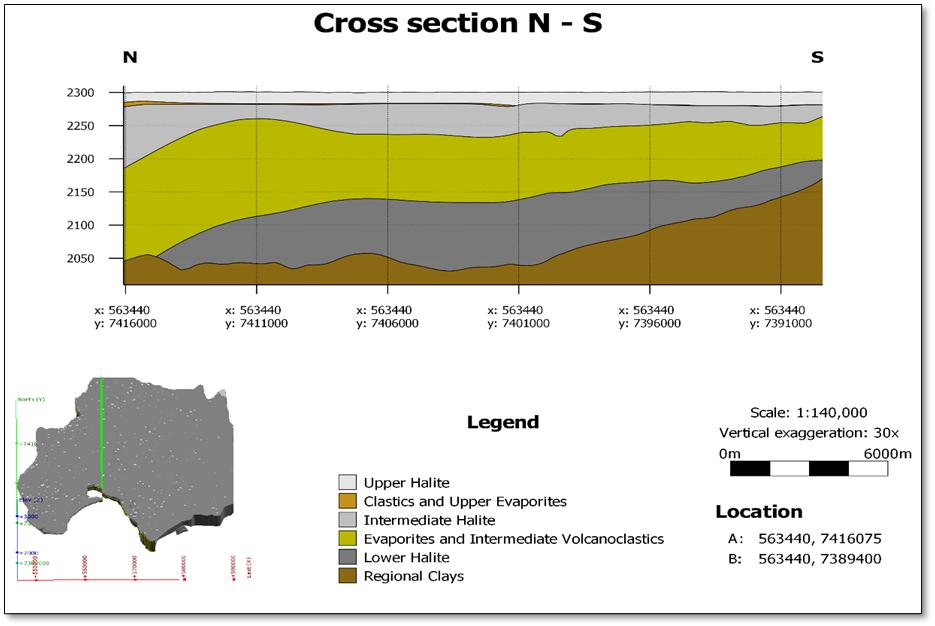

The general geology of the Salar de Atacama Basin is characterized by Paleozoic to Holocene igneous and sedimentary rocks as well as recent, unconsolidated clastic deposits and evaporitic sequences. The salt flat resides in a tectonic basin, where important subsidence and sediment deposition have historically occurred. Over time, the process of evaporation has precipitated salts, and at depth, evaporitic, clastic, and volcanic ash deposits host brine. Several structural blocks and fault systems have been identified, where displacement and deformation of the geological units have occurred.

According to Houston et. al. (2011), the Salar de Atacama is a mature salt flat with mineralization characterized by Li- and K-rich brine, residing in the porous media of the subsurface reservoir along with elevated concentrations of other dissolved constituents (e.g., boron and sulfate). The explored reservoir covers an area of 1,100 km2 and depth of up to 900 meters (m), where a thick section of halite (> 90%) and sulfate can be found in addition to a minor percentage of clastic sediments, volcanic ash, and interbedded evaporites (Bevacqua, 1992; Xterrae, 2011). The arithmetic mean concentrations of Li and K from all brine samples (and all units) correspond to 0.187 weight percent (wt.%) and 1.867 wt.%, respectively.

| 1.3 | Mineral Resource Estimate |

This sub-section contains forward-looking information related to Mineral Resource estimates for the Project. The material factors that could cause actual results to differ materially from the conclusions, estimates, designs, forecasts, or projections in the forward-looking information include any significant differences from one or more of the material factors or assumptions that were set forth in this sub-section including geological and grade interpretations, as well as controls, assumptions, and forecasts associated with establishing the prospects for economic extraction.

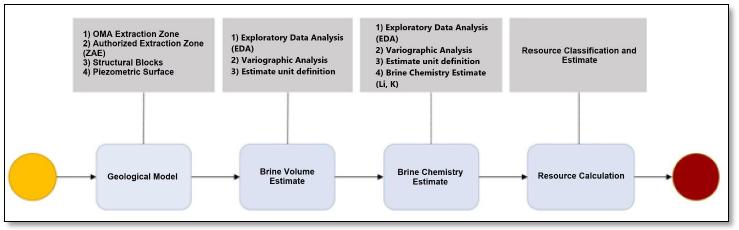

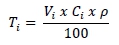

SQM’s Mineral Resource estimate for the Salar de Atacama comprises in-situ Li- and K- enriched brine situated below the surface of the salt flat. The Mineral Resource estimates include consideration of brine concentration, reservoir geometry, and drainable, interconnected pore volume. Within SQM’s leased mining concessions, the Mineral Resource is supported by extensive exploration and a large dataset of depth-specific brine and porosity samples from each unit. A geological model was developed, using Leapfrog Geo software, from which the block model was constructed, and the Mineral Resource was estimated using Leapfrog Edge.

The Mineral Resource was classified into Measured, Indicated, and Inferred categories, according to the amount of information from the hydrogeological units as well as geostatistical criteria. Hydrogeological knowledge was prioritized based on exploration, monitoring, and historical production data, while geostatistical variables were used as secondary criteria.

The in-situ Li and K Mineral Resource estimate, exclusive of Mineral Reserves (without processing losses), is summarized in Table 1-1. Mean Li and K grades are reported above the designated cut-off grades of 0.05 wt.% for Li and 1.0 wt.% for K. This indicates that the prospective extraction of the Mineral Resource is economically feasible (see Section 11.2 of this Technical Report Summary [TRS] for additional discussion on the cut-off grades).

Table 1-1. SQM’s Salar de Atacama Lithium and Potassium Mineral Resources, Exclusive of Mineral Reserves (Effective December 31, 2023)

| Brine Volume | Mean Grade (wt. %) | Mass (Million tonnes) | ||||||||||||||||||

| Resource Classification | (Mm3) | K | Li | K | Li | |||||||||||||||

| Measured | 2,254 | 1.80 | 0.20 | 49.8 | 5.4 | |||||||||||||||

| Indicated | 1,435 | 1.70 | 0.16 | 30.0 | 2.8 | |||||||||||||||

| Measured + Indicated | 3,689 | 1.77 | 0.18 | 79.8 | 8.2 | |||||||||||||||

| Inferred | 1,614 | 1.77 | 0.13 | 34.9 | 2.6 | |||||||||||||||

| Total | 5,303 | 1.77 | 0.17 | 114.7 | 10.8 | |||||||||||||||

Notes:

(1) Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability. There is no certainty that all or any part of the Mineral Resource will be converted into Mineral Reserves upon the application of modifying factors.

(2) Mineral Resources are reported as in-situ and exclusive of Mineral Reserves, where the estimated Mineral Reserve without processing losses during the reported LOM (Chapter 12) and real declared extraction from 2021 were subtracted from the Mineral Resource inclusive of Mineral Reserves. A direct correlation between Proven Reserves and Measured Resources, as well as Probable Reserves and Indicated Resources was assumed.

(3) Compared to the previously filed TRS (2022), mining occurred in 2023 and the end of the LOM (year 2030) has not changed. Given the acceptable reserve model fit to real 2023 production (see Chapter 12), there is no change in the Mineral Resource exclusive of Mineral Reserves since December 31, 2022 (SQM, 2023).

(4) Effective porosity was utilized to estimate the drainable brine volume based on the measurement techniques of the SQM porosity laboratory (Gas Displacement Pycnometer). Although specific yield is not used for the estimate, the QP considers that the high frequency sampling of effective porosity, its large dataset, and general lack of material where specific retention can be dominant permits effective porosity to be a reasonable parameter for the Mineral Resource estimate.

(5) The conversion of brine volume to Li and K tonnes considered the estimated brine density in each block model cell.

(6) Comparisons of values may not add due to the rounding of numbers and differences caused by use of averaging methods.

(7) The Mineral Resource estimate considers a 0.05 wt.% cut-off grade for Li based on the cost of generating Li product, lithium carbonate sales, and the respective cost margin. Based on historical lithium prices from 2010 and the forecast to 2040, a projected lithium carbonate price of $ 11,000 USD/tonnes with the corresponding cost and profit margin are considered with a small increase to accommodate the evaporation area and use of additives. A similar pricing basis and analysis was undertaken for K, where the cut-off grade of 1 wt.% was set by SQM based on respective costs, sales, and margin (Section 16 and Section 19).

| 1.4 | Mineral Reserve Estimate |

This sub-section contains forward-looking information related to Mineral Reserve estimates for the Project. The material factors that could cause actual results to differ materially from the conclusions, estimates, designs, forecasts or projections in the forward-looking information include any significant differences from one or more of the material factors or assumptions that were set forth in this sub-section including Mineral Resource model tonnes and grade, modifying factors including pumping and recovery factors, production rate and schedule, equipment and plant performance, commodity market and prices, and projected operating and capital costs.

A groundwater flow and solute transport model was developed using the Groundwater Vistas interface and Modflow-USG code to evaluate the extraction of Li and K-rich brine from pumping wells during the 7-year life-of-mine (LOM). The numerical model was constructed based on the geometry of the geological and resource block model parameters. The transfer of relevant resource estimate parameters (concentrations and effective porosity) was performed to ensure consistency between the Resource and Reserve model properties. To confirm sufficient calibration of the aquifer parameters (e.g., hydraulic conductivity) and representation of the water balance components in the salt flat nucleus, the numerical model was calibrated to observed brine levels and extracted brine concentrations during the 2015 to 2020 period. Extracted mass was subsequently verified for the 2021 to 2023 period.

The Mineral Reserve estimate considers the modifying factors of converting Mineral Resources to Mineral Reserves, including the production wellfield design and efficiency (e.g., location and screen of the production wells), environmental considerations (e.g., pumping schedule), and recovery factors for Li and K. The simulated mass of extracted Li and K after 7 years of pumping is summarized in Table 1-2. The table considers process recovery factors, where the model extracted mass at the production wellheads, was multiplied by a pond recovery factor associated with the type of extracted brine. Thus, the reserve was estimated from the point of reference of processed brine after passing through the evaporation ponds (rather than at the production wellheads).

The Mineral Reserve was classified into Proven and Probable Reserves based on industry standards for brine projects, the Qualified Person’s (QP’s) experience, and the confidence generated by SQM’s historical production in the Salar de Atacama. A majority of the extracted mass is sourced from Measured Resources; nonetheless, Proven Reserves were specified by the QP for the first 3 years given the adequate model calibration during the 2015-2020 period and overall verification of simulated production in 2021, 2022 and 2023. Probable Reserves were conservatively assigned for the last 4 years of the LOM considering that the numerical model will be continually improved and recalibrated in the future due to potential changes to neighboring pumping, hydraulic parameters, and the water balance, among other factors.

Table 1-2. SQM’s Salar de Atacama Lithium and Potassium Mineral Reserves, Factoring Process Recoveries (Effective December 31, 2023)

| Extracted Mass | Extracted Mass | |||||||||||||||||||||||||||

| Classification | Brine Volume (Mm3) Pumped | Average Extracted Lithium Grade (wt.%) |

Li (Million tonnes) |

LCE (Million tonnes) |

Average Extracted Potassium Grade (wt.%) |

K (Million tonnes) |

KCl (Million tonnes) |

|||||||||||||||||||||

| Proven Reserves | 104 | 0.200 | 0.13 | 0.70 | 2.31 | 2.20 | 4.20 | |||||||||||||||||||||

| Probable Reserves | 107 | 0.200 | 0.14 | 0.75 | 2.16 | 2.12 | 4.04 | |||||||||||||||||||||

| Total | 211 | 0.200 | 0.27 | 1.44 | 2.24 | 4.32 | 8.24 | |||||||||||||||||||||

(1) The process efficiency of SQM is summarized in Section 12.4.1; based on the type of extracted brine at each well over the course of the simulation, the average process efficiency is approximately 52% for Li and approximately 75% for K.

(2) Lithium carbonate equivalent (“LCE”) is calculated using mass of LCE = 5.323 multiplied by the mass of lithium metal and potassium chloride equivalent (“KCl”) is calculated using mass of KCl = 1.907 multiplied by the mass of potassium metal.

(3) The values in the columns for “Li” and “LCE”, as well as “K” and “KCl”, above are expressed as total contained metals.

(4) The average lithium and potassium concentration is weighted by the simulated extraction rates in each well, and it is subsequently weighted by pumping over the indicated period.

(5) Comparisons of values may not add due to the rounding of numbers and differences caused by averaging.

(6) The Mineral Reserve estimate considers a 0.05 wt.% cut-off grade for Li based on the cost of generating Li product, lithium carbonate sales, and the respective cost margin. Based on historical lithium prices, a projected lithium carbonate price of $ 11,000 USD/tonnes with the corresponding cost and profit margin is considered with a small increase to accommodate the evaporation area and use of additives. A similar pricing basis and analysis was undertaken for K where the cut-off grade of 1 wt.% has been set by SQM based on respective costs, sales, and margin (Section 16 and Section 19).

(7) This Reserve estimate differs from the in-situ base Reserve previously reported (SQM, 2020) and considers the modifying factors of converting mineral resources to Mineral Reserves, including the production wellfield design and efficiency, as well as environmental and process recovery factors.

It is the QP’s opinion that the declared Reserve estimate and corresponding methods conform with the SEC regulations. Furthermore, the reserve classification is believed to be conservative, given that SQM’s brine production has been ongoing for decades. The presented analysis includes a detailed calibration process and time-based reserve classification to account for potential future changes in hydraulic parameters (with more field data and testing), the water balance, and neighboring pumping, among other factors.

| 1.5 | Mining Method |

In the Salar de Atacama, SQM’s mining method corresponds to brine extraction. Production is characterized by the construction of pumping wells capable of extracting brine from different reservoirs of interest. Subsequently, the brine extracted from each of the production wells is accumulated in gathering ponds for distribution to evaporation ponds and metallurgical plants.

Due to limitations of the SQM-CORFO lease agreement, the current mine life ends on December 31, 2030. Until this date, the expected brine production had been evaluated with a decreasing total brine extraction rate from 1,159 L/s (2024) to 822 L/s (2030).

| 1.6 | Metallurgy and Mineral Processing |

| 1.6.1 | Metallurgical Testing |

The developed test work is aimed at estimating the response of different brines by concentration, via solar evaporation, and overall metallurgical recoveries of the process plants, in addition to assessing raw material treatability for finished lithium and potassium products.

SQM employees regularly collect brine samples and complement this by considering temporal, geological, spatial, and operational criteria of the wells, with an emphasis on maintaining an updated and accurate dataset of brine chemistry characteristics. The Salar de Atacama laboratory, through its facilities, generates metallurgical assay databases which include the chemical composition, density, and porosity test results, among other assays which allow for process control and planning.

Historically, SQM has analyzed the different plant and/or pilot scale tests through its Research and Development Area, allowing them to improve the recovery process and product quality. Currently, there is a plan to increase yield at the Salar de Atacama which consists of a series of operational improvement initiatives, development and expansion projects, as well as new process evaluations to recover a greater amount of lithium in the LiCl production system.

| 1.6.2 | Brine and Salt Processing |

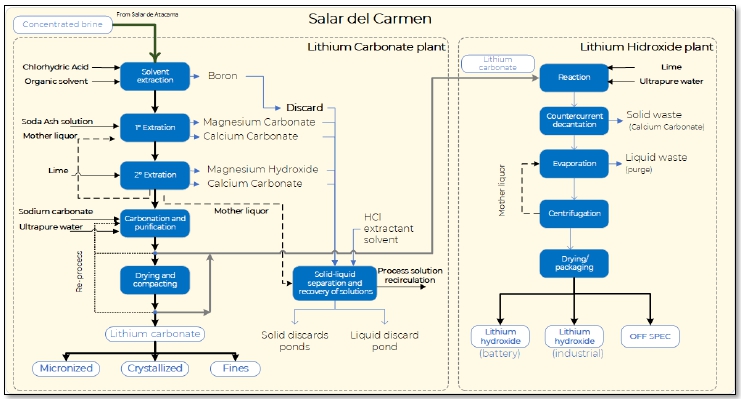

SQM has developed a process model to convert the brine extracted from available salt properties containing potassium, lithium, sulfates, boron, and magnesium into commercial potassium and lithium salts products. The process follows industry standards, considering the stages of brine pumping from the reservoirs to concentrate it by sequential evaporation, treating the harvested potassium salts to obtain refined salts, and treating the brine concentrate in a plant to produce high quality lithium carbonate and lithium derivatives.

Thus, the objective of the Project is to produce potassium salts, such as potassium chloride (KCl) and potassium sulfate (K2SO4), as well as lithium salts such as lithium carbonate (Li2CO3) and lithium hydroxide (LiOH). There are two production lines, one focused on obtaining potassium products (SQM Salar de Atacama process plants), and another concentrated on the production of lithium carbonate and hydroxide (SQM Carmen Lithium Chemical Plant), both of which are two facilities that make up SQM’s Salar de Atacama operations.

SQM's production process is characterized by being integrated (i.e., exchanging raw materials and products with each other). The Carmen Lithium Chemical Plant (PQC), located near Antofagasta, has production facilities that comprise a Lithium Carbonate Plant and a Lithium Hydroxide Plant. The production capacity of the lithium carbonate plant at PQC until the year 2021 was 120,000 tonnes per year (Mtpy), and at that time, it was projected to increase production to 180,000 tonnes per year (Mtpy). Additionally, the lithium hydroxide plant had a production capacity of 21,500 tonnes per year (Mtpy), with plans to increase production capacity to 30,000 (Mtpy). However, the current production is now 150,000 (Mtpy), with plans to increase production to 210,000 Mtpy. Furthermore, the lithium hydroxide plant has a production capacity of 24,500 Mtpy, with plans to increase production capacity to 32,500 Mtpy.

| 1.7 | Capital Costs, Operating Costs, and Financial Analysis |

| 1.7.1 | Capital and Operating Costs |

This section contains forward-looking information related to capital and operating cost estimates for the Project. The material factors that could cause actual results to differ materially from the conclusions, estimates, designs, forecasts or projections in the forward-looking information include any significant differences from one or more of the material factors or assumptions that were set forth in this section. These include prevailing economic conditions which continue in a manner that the unit costs are as estimated, projected labor and equipment productivity levels are maintained, and that contingency is sufficient to account for changes in material factors or assumptions.

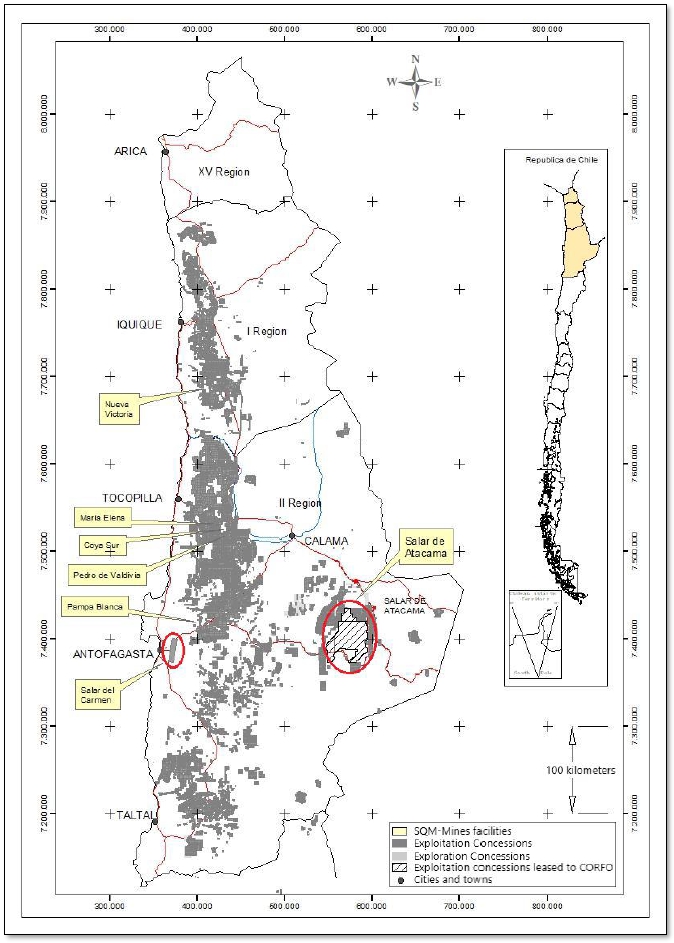

SQM is the world’s largest producer of potassium nitrate and iodine, and one of the world’s largest lithium producers. It also generates specialty plant nutrients, iodine derivatives, lithium derivatives, potassium chloride, potassium sulfate, and certain industrial chemicals (including industrial nitrates and solar salts). The products are sold in approximately 110 countries through SQM’s worldwide distribution network, with more than 90% of the sales derived from countries outside of Chile.

The facilities for lithium and potassium production operations include brine extraction wells, evaporation and harvest ponds, lithium carbonate and lithium hydroxide production plants, dry plants and wet plants for potassium chloride and sulfate, as well as other minor facilities. Offices and services include common areas, hydrogeological assets, water resources, supply areas, powerhouse, laboratories, and research areas.

At the end of 2020, the capital cost that had been invested (reposition cost) in these facilities was close to 2,300 million dollars. The cost of capital distributed in the areas related to lithium and chloride and sulfate potassium production is shown in Table 1-3. As indicated, the main investments in lithium and potassium production are the “Lithium Carbonate and Lithium Hydroxide Plants”, as well as the “Evaporation and Harvest Ponds”, accounting for about 55% of the total investment.

Table 1-3. Capital Costs for Lithium and Potassium Operations

| Capital Cost | |||||

| Lithium and Potassium Operations | % | ||||

| 1 | Lithium Carbonate and Lithium Hydroxide plants | 28 | % | ||

| 2 | Evaporation and harvest ponds | 27 | % | ||

| 3 | Wet Plants | 17 | % | ||

| 4 | Brine extraction wells | 13 | % | ||

| 5 | Dry Plants | 7 | % | ||

| 6 | Offices, services, warehouses, others | 8 | % | ||

The main investment in the lithium carbonate plant, which represents about 81% of the lithium plants, are in buildings, mechanical equipment, such as filters, pumps, valves, pipes, ponds, and drying equipment. For the Evaporation and Harvest Ponds, the main investments are in the MOP (Muriate of Potash) I and II, and SOP (Sulfate of Potash) ponds, accounting for 83% of the total investment in the ponds.

SQM has plans to continue the capacity expansion of its plants, complying with the CORFO quota agreements. As mentioned in Chapter 1.6.2, the production capacity and projected production increase until the year 2021 of the lithium carbonate plant in PQC were 120,000 tons per year and 180,000 tons per year, respectively. Also, for the same year, the lithium hydroxide plant had a production capacity and a projected production capacity increase of 21,500 tons per year and 30,000 tons per year, respectively.

The highest operating cost is in the CORFO rights and other agreements, representing about 79% during 2022. The other major item in raw material and consumables, employee benefit expenses, depreciation expense, and contractor works, representing 18% of the operating cost.

During the first 9 months of 2022, the operating cost that has been spent to produce lithium and potassium chloride and sulphate at the Salar de Atacama and Salar del Carmen plants was close to 2,900 million dollars.

| 1.7.2 | Economic Analysis |

This section contains forward-looking information related to economic analysis for the Project. The material factors that could cause actual results to differ materially from the conclusions, estimates, designs, forecasts, or projections in the forward-looking information include any significant differences from one or more of the material factors or assumptions that were set forth in this sub-section including estimated capital and operating costs, project schedule and approvals timing, availability of funding, projected commodities markets, and prices.

The Economic Analysis considers the actual concession agreement with CORFO, as it is at the end of 2023, where the Project Agreement expires on December 31, 2030. SQM declares that, on December 27, 2023, SQM and Codelco, Chilean state-owned company which had been mandated by the Chilean Government to negotiate its participation in the lithium operations in the Salar de Atacama, signed a memorandum of understanding (MoU), which, among other matters, established the ground terms and conditions for the definitive agreements which will allows SQM Salar to exploit mineral resources in the Salar de Atacama until 2060. The full text of the MoU is referenced in the Exhibit 94.4 of the Report on Form 20-F. See also “— Risks Relating to Chile — The new National Lithium Strategy announced by the Chilean government in April 2023 has created and may continue to create uncertainty in the Chilean lithium industry, which could have a material adverse effect on our business performance or the value of our shares and ADSs.” The definitive agreements are subject to negotiation and we cannot guarantee that said agreements will be implemented.”

To obtain an income flow in relation to the production of Li2CO3, LiOH, and KCl for the period of 2024 to 2030 with the investments projected for a 210 ktpy carbonate plant and 100 ktpy hydroxide plant expansion have been considered. In the case of the long-term price of Li2CO3, a base value of 12,110 USD/tonne has been considered with a long-term KCl price of 300 USD/ton. The price of LiOH was assumed to be 5% higher than the price of Li2CO3. As it is shown in Figure 16 4, it is important to note that lithium prices have had an unexpected behavior: at the end of 2022 and 2023, the lithium price was close to 78,000 and 13,500 USD/tonne respectively. For this analysis, a conservative scenario is assumed, based in the market study described in chapter 16, where the long term lithium carbonate price at 12,110 USD/tonne will be required to sustain new project development. Table 1-4 shows the main assumptions taken for the base case.

Table 1-4. Assumptions for the Base Case Economic Analysis

| Base Case | ||||

| Assumptions | Units | Quantity | ||

| Production Plant | ktpy | 210 | ||

| Lithium Carbonate Price | US$/tonne |

12,110 (2024-2030) |

||

| Lithium Hydroxide Price | US$/tonne | 5% over Lithium Carbonate Price | ||

| Potassium Chloride Price* | US$/tonne | 300 | ||

| Estimated Cost + CORFO Rights and other agreements | US$/tonne | 5,700 + calculate (18.1% of Revenues for 12,110) | ||

| Taxes | % | 27 | ||

| Discount rate | % | 10 | ||

(*) Price of K defined according to the application of its products and derivatives.

The projected sales of lithium carbonate, lithium hydroxide and potassium chloride for the LOM until 2030 is presented in Table 1-5.

Table 1-5. Projected Sales of Lithium and Potassium Products

| 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | |||||||||||||||||

| Lithium Carbonate | ktpy | 170 | 140 | 110 | 110 | 110 | 110 | 110 | |||||||||||||||

| Lithium Hydroxide | ktpy | 40 | 70 | 100 | 100 | 100 | 100 | 70 | |||||||||||||||

| Potassium Chloride | ktpy | 1,200 | 1,200 | 1,200 | 1,200 | 1,200 | 1,200 | 1,200 | |||||||||||||||

Note: Reserves of Chapter 12 are declared based on brine recovery factors associated with the evaporation ponds (i.e. the point of reference being after passing through the evaporation ponds), while the final sales product is presented here; note that values are rounded if comparing totals.

The Net Present Value (NPV) estimates for Salar de Atacama and PQC production are provided in Table 1-6.

Table 1-6. Estimated Cashflow Analysis

| 2024 | 2025 | 2026 | 2027 | 2028 | 2029 | 2030 | ||||||||||||||||

| Lithium Carbonate Sales | ktpy | 170 | 140 | 110 | 110 | 110 | 110 | 110 | ||||||||||||||

| Lithium Hydroxide Sales | ktpy | 40 | 70 | 100 | 100 | 100 | 100 | 70 | ||||||||||||||

| Potassium Chloride Sales | ktpy | 1,200 | 1,200 | 1,200 | 1,200 | 1,200 | 1,200 | 1,200 | ||||||||||||||

| Lithium Carbonate Price | USD/tonne | 12,110 | 12,110 | 12,110 | 12,110 | 12,110 | 12,110 | 12,110 | ||||||||||||||

| Lithium Hydroxide Price | USD/tonne | 12,716 | 12,716 | 12,716 | 12,716 | 12,716 | 12,716 | 12,716 | ||||||||||||||

| Potassium Chloride Price | USD/tonne | 300 | 300 | 300 | 300 | 300 | 300 | 300 | ||||||||||||||

| Lithium Revenues | M US$ | 2,567 | 2,585 | 2,604 | 2,604 | 2,604 | 2,604 | 2,604 | ||||||||||||||

| KCI Revenues | M US$ | 360 | 360 | 360 | 360 | 360 | 360 | 360 | ||||||||||||||

| 1.8 | Conclusions |

This study concludes that the Salar de Atacama Project in operation for the treatment of brines to obtain Li and K salts is economically feasible, according to financial and reserve parameters. Furthermore, SQM has vast experience in the treatment of brines and salts. Their track record includes knowledge of the Mineral Resources and raw materials during the different processing stages, including operational data on reagent consumption and costs.

All reported categories were prepared in accordance with the resource classification pursuant to the SEC's new mining rules under subpart 1300 and Item 601(96)(B)(iii) of Regulation S-K (the "New Mining Rules").

| 2 | INTRODUCTION AND TERMS OF REFERENCE |

This Technical Report Summary (TRS) was prepared for the Sociedad Química y Minera de Chile (SQM) and its aim is to provide investors with a comprehensive understanding of the mining property based on the requirements of Regulation S-K, Subpart 1300 of the United States Securities Exchange Commission (SEC), which hereafter is referred to as the SK-1300.

| 2.1 | Terms of Reference and Purpose of the Report |

SQM produces a wide variety of commercial chemicals from the naturally occurring brines in the Salar de Atacama salt crust found in northern Chile. Products derived from the brines include potassium nitrate, lithium derivatives, iodine derivatives, potash, and other industrial chemicals.

This TRS provides technical information to support Mineral Resource and Mineral Reserve estimates for the operations of SQM in the Salar de Atacama (the Project). It also details related brine processing information in the Carmen Lithium Chemical Plant (PQC).

The effective date of this TRS Report is April 8, 2023, while the effective date of the Mineral Resource and Mineral Reserve estimates is December 31, 2023. It is the QP’s opinion that there are no known material changes impacting the Mineral Resource and Mineral Reserve estimates between December 31, 2023, and April 8, 2024.

This TRS uses English spelling and Metric units of measure. Grades are presented in weight percent (wt.%). Costs are presented in constant US Dollars (USD), as of December 31, 2022.

Except where noted, coordinates in this TRS are presented in Metric units, using the World Geodetic System (WGS) 1984 Universal Transverse Mercator (UTM) ZONE 19 South (19S).

The purpose of this TRS is to report Mineral Resources and Mineral Reserves for SQM’s Salar de Atacama operation.

Table 2-1 details the acronyms and abbreviations used in this TRS.

Table 2-1. Acronyms and Abbreviations

| Abbreviation/Acronym | Definition |

| °C | degrees Celsius |

| AA | atomic absorption |

| AAE | Authorized Areas of Extraction |

| AAS | Atomic Absorption Spectrometry |

| acQuire | acQuire |

| ADI | Indigenous Location Area |

| ADUP | Analytical duplicates |

| AR | average |

| B | boron |

| BLK | blanks |

| CCHEN | Chilean Nuclear Energy Commission |

| CCTV | closed-circuit TV |

| CM | counter sample |

| CONAMA | Comisión Nacional del Medio Ambiente |

| COREMA | Comisión Regional del Medio Ambiente |

| CORFO | Corporación de Fomento de la Producción |

| DDH | diamond drill hole |

| DICTUC | Dirección de Investigaciones Científicas y Tecnológicas de la UC |

| DPS | salt deposit |

| EDA | exploratory data analysis |

| ER | error ratio |

| ERT | Electrical Resistivity Tomography |

| ETS | Evapotranspiration Segments |

| ETFA | Enforcement Technical Entity |

| FDUP | Field Duplicates |

| GHS | SQM’s Hydrogeology Department |

| GHS | Gerencia Hidrogeología Salar |

| GPS | Salar de Atacama Production Management |

| GU | geological units |

| Ha (with capital H) | Recent Alluvial and Fluvial Deposits |

| Ha | hectare |

| ICP | inductively coupled plasma analysis |

| IGS | specific yield (processing and recovery methods) |

| IIG | Instituto de Investigaciones Geológicas |

| K | potassium |

| K2SO4 | potassium sulfate |

| KCL | potassium chloride or potassium chloride equivalent |

| Kh | hydraulic conductivity |

| km2 | square kilometer |

| Kt | kilotonnes |

| Ktpy | kilotonnes per year |

| Abbreviation/Acronym | Definition |

| kV | kilovolt |

| Kv/Kh | vertical-horizontal anisotropy |

| KvA | kilovolt amperes |

| L/s | liter per second |

| Lab POR | Laboratorio de Porosidad del Salar de Atacama |

| Lab SA | Laboratorio Salar de Atacama |

| Lab UA | laboratory of the University of Antofagasta |

| LCE | Lithium carbonate equivalent |

| LFP | Lithium Ferro Phosphate |

| Li | lithium |

| Li2CO3 | lithium carbonate |

| LIMS | laboratory information management system |

| LiOH | lithium hydroxide |

| LNG | Natural gas |

| LOM | life-of-mine |

| LPG | Liquefied gas |

| LSC | Salar del Carmen Laboratory |

| M | meter |

| mE | meters East (coordinates) |

| mS | meters South (coordinates) |

| M | million |

| m/d | meters per day |

| m2 | square meter |

| m3 | cubic meter |

| Mm3 | million cubic meters |

| Masl | meters above sea level |

| MINSAL | Sociedad Minera Salar de Atacama Limitada |

| mL | milliliter |

| Mm | millimeters |

| mm3 | cubic millimeters |

| MMBTU | million British thermal unit |

| MOP | muriato de potasio (potassium chloride product) |

| MT | Magnetotelluric |

| Mt | Metric ton |

| Mtpy | Metric ton per year |

| MW | megawatt |

| MWh | megawatt hour |

| Na2CO3 | Sodium Carbonate |

| NCM | Nickel, Cadmium and Manganese |

| NMR/BMR | Natural Gamma, and Borehole Nuclear Magnetic Resonance |

| NNW-SSE | north-northwest-south-southeast |

| Nobody's Land | Tierra de Nadie |

| Abbreviation/Acronym | Definition |

| NPV | Net Present Value |

| NW | northwest |

| OK | Ordinary Kriging |

| OMA Exploration | SQM’s distinct areas of exploration |

| OMA Extraction | SQM’s distinct areas of extraction |

| PCA | Environmental control points |

| PdC | compliance program |

| Pe | Effective Porosity |

| PlHa | Alluvial Deposits |

| PlHs | Salar de Atacama Saline Deposits |

| PPR | Possible Pollution Ratios |

| PQC | Carmen Lithium Chemical Plant |

| PSA | Environmental monitoring plan |

| QA/QC | quality assurance and quality control |

| QC | duplicate samples |

| QP | Qualified Person |

| RC | reverse circulation |

| RCA | Resolución de Calificación Ambiental |

| RIL | liquid waste |

| RIS | solid waste |

| RM | reference materials |

| RMS | Root Mean Square |

| RS | Reference Samples |

| Salar | Salar |

| SCL | Sociedad Chilena de Litio |

| SEC | Securities Exchange Commission |

| SERNAGEOMIN | Servicio Nacional de Geología y Minería |

| SING | Sistema Interconectado Norte Grande |

| S-K 1300 | Subpart 1300 of the United States Securities Exchange Commission |

| SMA | Enforcement Authority |

| SOC | Samples Out of Control |

| SOP | sulfato de potasio (potassium sulfate product) |

| SQM | Sociedad Química y Minera de Chile |

| SQM Salar | SQM subsidiary SQM Salar S.A |

| SRK | SRK Consulting (U.S.), Inc. |

| Ss | specific storage |

| SW | southwest |

| Sy | specific yield |

| t/h | tonnes per hour |

| t/y | tonnes per year |

| TEM | transient electromagnetic method |

| Thousand United States Dollars | KUSD |

| TRS | Technical Report Summary |

| UA | Unit A |

| UB | Unit B |

| USD | United States Dollars |

| USD/t | United States Dollars per tonne |

| UTM | Universal Transverse Mercator |

| V | volt |

| WGS | World Geodetic System |

| wt.% | weight percent or % |

| ZAE | Zona Autorizada de Extracción, or Authorized Extraction Zone |

| 2.2 | Source of Data and Information |

This TRS is based on information provided by SQM. All the utilized information is cited throughout this TRS and is referenced in Chapter 24 (References) at the end of this Report.

| 2.3 | Details of Inspection |

The details of the site inspections by the QPs are summarized in Table 2-2.

Table 2-2. Site visits

| Qualified Person (QP) | Relation to Registrant and their Role | Company | Date of Site Visit | Detail of Visit | Years of Relevant Experience | Responsible for disclosure of |

| Juan Becerra | Superintendent of Geology. Resource QP |

SQM S.A. | Several visits between 2017 - 2023 | Operations, extraction wells, evaporation ponds, processing plants | 14 | Sections 1.1, 1.6, 1.2, 1.3, 1.8, 2, 3, 4, 5, 6, 7, 8, 9, 10 11, 14, 15, 17, 20, 21, 22, 23, 24 & 25 |

| Rodrigo Riquelme | M.A. Economics Georgetown University. Reserve QP |

Geoinnova Consultores Ltda. | February 28, 2023 | Operations, extraction wells, evaporation ponds, processing plants | +20 | Sections 1.4, 1.5, 1.7, 1.8 12, 13, 16, 18, 19, 21, 22, 23, 24 & 25 |

During the various site visits, the QPs toured the general areas of mineralization, the historical and current mine, as well as the drill sites. The group also reviewed existing infrastructure, evaporation ponds, processing plants, wells, drill cores, and project data files with SQM technical staff.

| 2.4 | Previous Reports on Project |

This is the second TRS prepared for SQM's Salar de Atacama brine deposit. This TRS is an update of a previously filed TRS (2022).

| 3 | PROPERTY DESCRIPTION |

| 3.1 | Property Location |

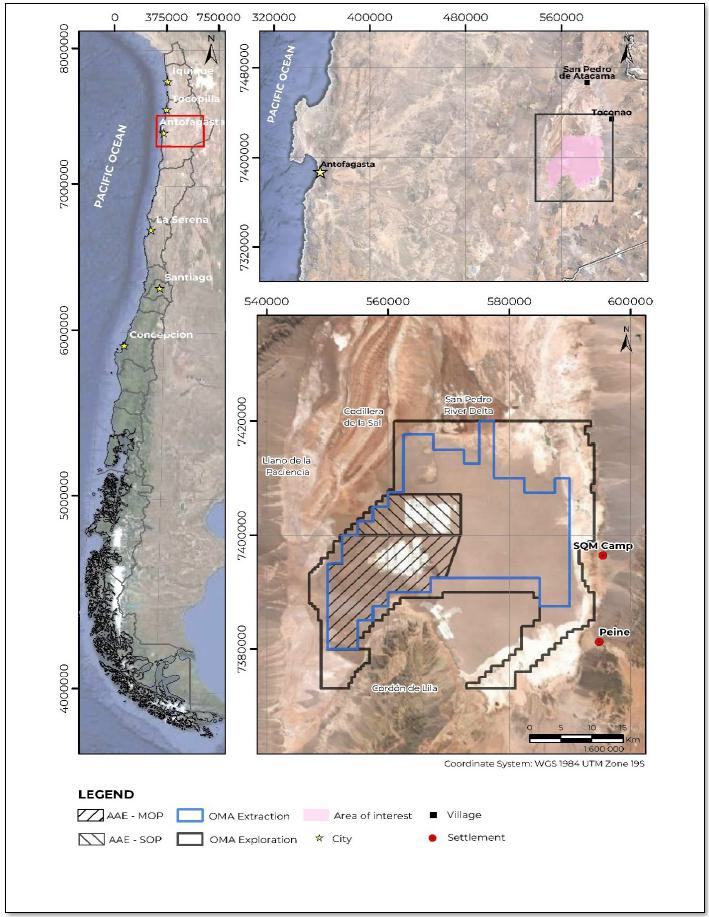

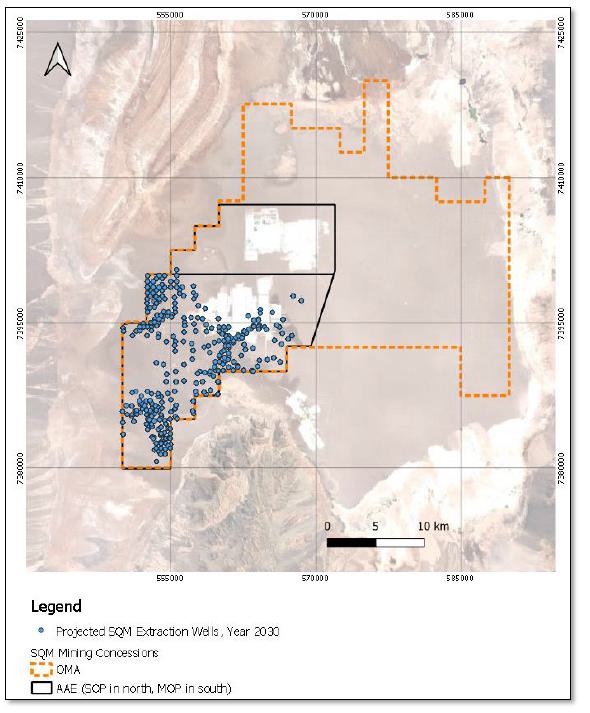

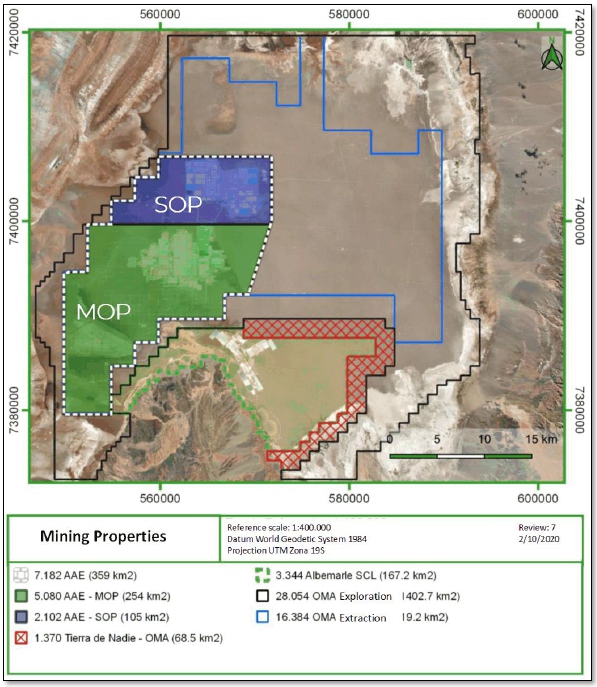

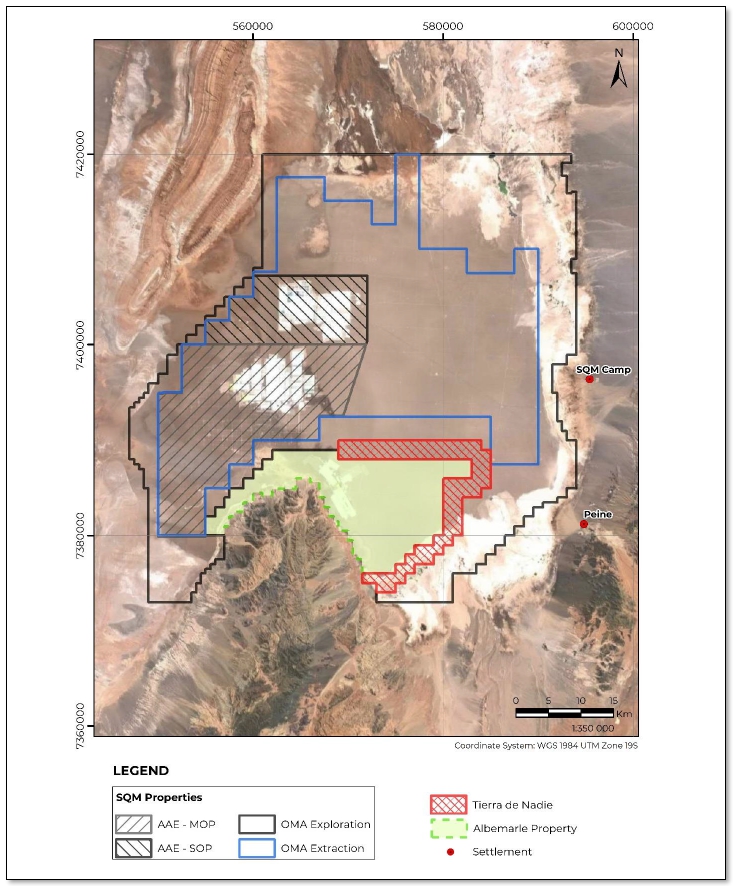

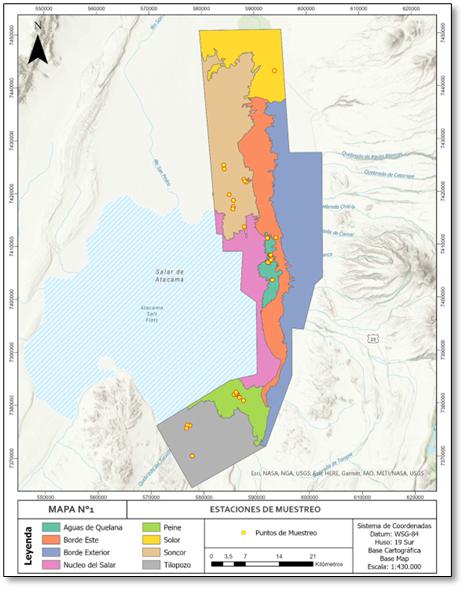

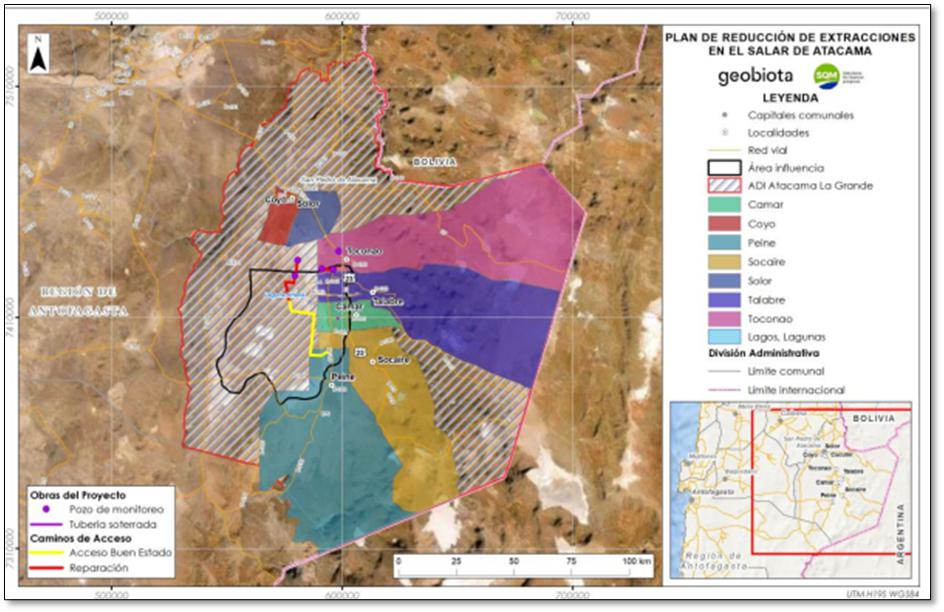

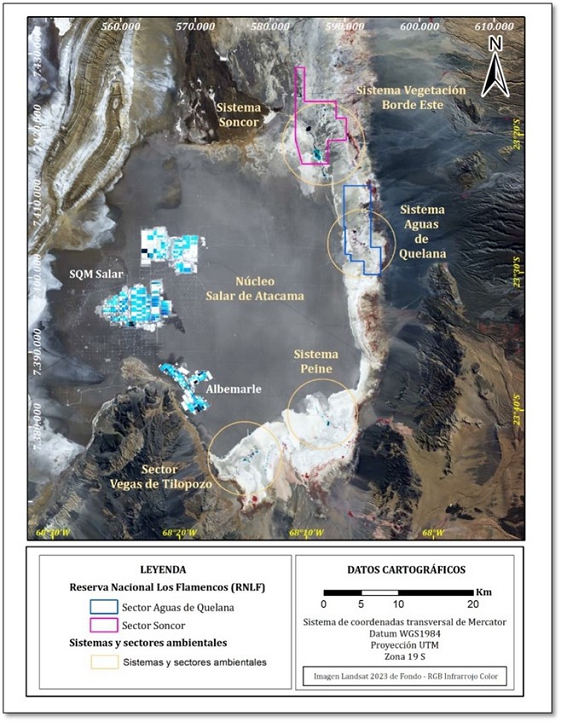

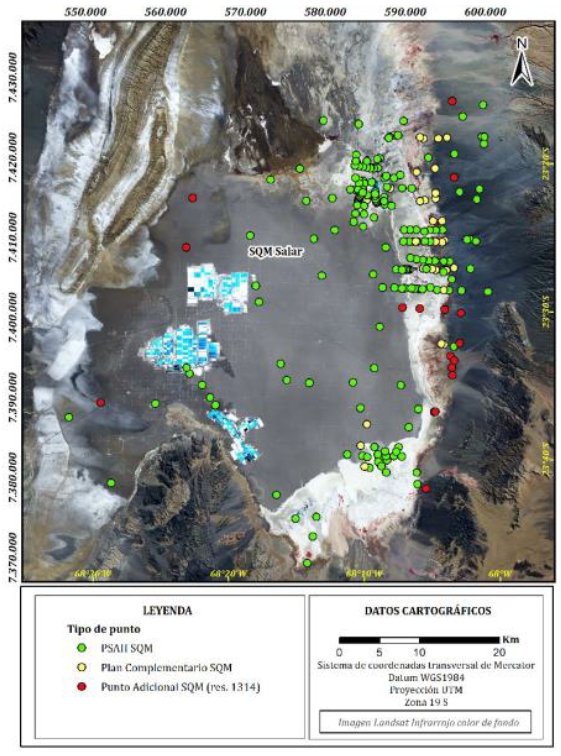

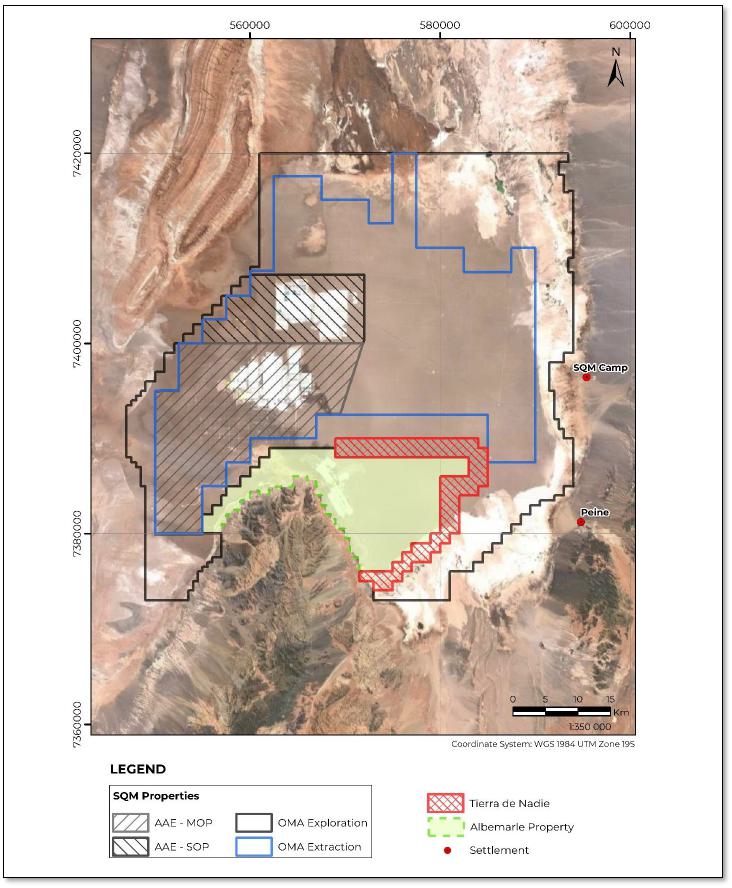

The Salar de Atacama Basin is located in the El Loa Province, within the Antofagasta Region of northern Chile, between 548,420 mE and 589,789 mE and 7,394,040 mS and 7,393,788 mS (Coordinate Reference System WGS84, UTM 19S). As shown on Figure 3-1, the mining property operated by SQM extends between approximately 550,000 mE and 593,000 mE, and 7,371,000 mS and 7,420,000 mS (Coordinate Reference System WGS84, UTM 19S). SQM’s distinct areas of exploration (OMA Exploration) and extraction (OMA Extraction) are detailed in the following subsection.

Figure 3-1. Location of SQM’s Salar de Atacama Project

| 3.2 | Lease Agreement and Mineral Rights |

In 1993, SQM entered a lease agreement with the Corporación de Fomento de la Producción or Production Development Corporation of Chile (CORFO), the governmental agency that owns the mineral rights in the Salar de Atacama. The lease between CORFO and SQM will last until December 31, 2030, granting SQM exclusive rights to Mineral Resources beneath 140,000 hectares (ha) (28,054 mineral concessions) of the Salar de Atacama. SQM is permitted to extract minerals from a subset of 81,920 ha (16,384 mineral concessions), corresponding to 59.5% of the total area of the leased land. The 140,000 ha of land leased by CORFO to SQM are referred to as the “OMA” concessions, a name devised by CORFO in 1977. SQM refers to the 81,920-ha subset, where extraction can occur as the “OMA Extracción” (OMA Extraction) Area. The remaining 58,350 ha are termed the “OMA Exploración” (OMA Exploration) Area, where only mineral exploration can occur. The terms of the agreement established that CORFO will not allow any other entity aside from SQM to explore or exploit any Mineral Resource in the indicated 140,000 ha area of the Salar de Atacama.

In 2018, SQM and CORFO undertook a reconciliation process that modified the pre-existing lease and project contracts. As part of this Arbitration Agreement, SQM generated additional resources for the state and local communities of Antofagasta as well as for research and development. The expiration date of the lease (December 31, 2030) was not modified. Regarding brine production, in the lease agreement, Comisión Chilena de Energía Nuclear, or Chilean Nuclear Energy Commission (CCHEN) established a total accumulated sales limit of up to 349,553 tonnes of metallic lithium (1,860,670 tonnes of lithium carbonate equivalent) in addition to approximately 64,816 tonnes of metallic lithium (345,015 tonnes of lithium carbonate equivalent) remaining from the originally authorized quantity of the CORFO Arbitration Agreement of 2018.

| 3.3 | Environmental Impacts and Permitting |

The environmental permit, “Resolución de Calificación Ambiental, RCA N° 226/2006,” issued on October 19, 2006, by the Comisión Regional del Medio Ambiente, or Regional Environmental Commission (COREMA), authorizes SQM to extract brines via pumping wells from a specific portion of the OMA Exploration Area. SQM refers to these brine extraction areas as Áreas Autorizadas para la Extracción, or Authorized Areas of Extraction (AAE) zones, and they are further divided based on the products historically generated in each sector (Figure 3-1). The northern portion is denominated the AAE-SOP, where “SOP” signifies sulfato de potasio (potassium sulfate product) and covers a surface area of 10,512 ha equivalent to 29.27% of the total AAE area. The southern portion is referred to as AAE-MOP, where “MOP” indicates muriato de potasio (potassium chloride product), covering a surface area of 25,399 ha equivalent to 70.73% of the total AAE area.

The water that SQM uses for its mineral production in the Salar de Atacama is obtained from wells located in the alluvial aquifer on the eastern edge of the salt flat, for which the company has rights and the corresponding environmental authorization (RCA 226/2006) to use groundwater. As part of the voluntary sustainability commitment assumed by SQM in 2020, the company will reduce its water consumption by up to 50% in 2030 (SQM I, 2021).

| 3.4 | Other Significant Factors and Risks |

SQM’s operations are subject to certain risk factors that may affect the business, financial conditions, cashflow, or SQM’s operational results. Potential risk factors are summarized below:

| · | The potential inability to extend, or renew, mineral exploitation rights in the Salar de Atacama beyond the defined expiration date (December 31, 2030) in the CORFO-SQM lease agreement. |

| · | Risks related to being a company based in Chile; potential political risks and changes in legislation may affect development plans, production levels, and costs. |

| · | Risks related to financial markets. |

| 3.5 | Royalties and Agreements |

SQM made payments to the Chilean government for the exploration and exploitation concessions, including those which are leased from CORFO of approximately US $ 7.9 million in 2019 and US $ 6.5 million in 2020. These payments do not include those made directly to CORFO by virtue of the lease agreement, according to the established percentages related to the sale value of the resulting products of brine exploitation (Table 3-1)

SQM does not have contracts that require other payments for: licenses, franchises, or royalties (not contemplated in the Royalty Law of Chile). SQM carries out its own operations through mining rights, production facilities, as well as transportation and storage facilities.

Table 3-1. Payment Agreements with CORFO

Payments 1

| Li2CO3 | LiOH | ||

| US$/MT | % | US$/MT | % |

| <4,000 | 6.80 | <5,000 | 6.80 |

| 4,000-5,000 | 8.00 | 5,000-6,000 | 8.00 |

| 5,000-6,000 | 10.00 | 6,000-7,000 | 10.00 |

| 6,000-7,000 | 17.00 | 7,000-10,000 | 17.00 |

| 7,000-10,000 | 25.00 | 10,000-12,000 | 25.00 |

| >10,000 | 40.00 | >12,000 | 40.00 |

Source Company

(1) Effective as of April 10, 2018

(2) % of final sale price

(3) % of FOB price

| 4 | ACCESSIBILITY, CLIMATE, LOCAL RESOURCES, INFRASTRUCTURE AND PHYSIOGRAPHY |

| 4.1 | Topography, Elevation, and Vegetation |

The Salar de Atacama salt crust covers an area of approximately 2,200 km2 with a greater north-south distance of 85 km and maximum west-east width of 50 km. The average elevation of the salt flat nucleus is approximately 2,300 meters above sea level (masl).

Vegetation is mainly found along the marginal zone of the basin and is associated with a desert ecosystem and low-precipitation environment (SRK, 2020). There are four main vegetation types in the basin which correspond to crops, vegas, tamarugos, and bofedales.

| 4.2 | Accessibility and Transportation to the Property |

The SQM facilities of Salar de Atacama Project are located 35.6 km from Peine and at 57.4 km from Toconao. The closest cities are Calama, located 160 km to the west of the basin, and Antofagasta, which is located 230 km to the west.

It is possible to travel to site by plane, via the Loa Airport, or Andrés Sabella Airport, located in Calama and Antofagasta, respectively. From Calama, the road to the site is through Route R-23 over 220 km, and from Antofagasta, it is via Route B-385 for 272 km. It is also possible to access the area through two public roads, Route B-355 that runs from Toconao to Peine, as well as Route B-385 which connects Baquedano to the Salar de Atacama.

| 4.3 | Climate |

Recorded temperatures at the SQM station Campamento Andino vary between -6 degrees Celsius (°C) and 33°C, with an annual average lower than 18°C, which is characteristic of a cold desert environment.

Precipitation is registered both in the winter and summer, with a majority of the precipitation occurring in summer (December, January, and February). Maximum values range between 29.3 mm (KCL Station, March 2002) and 88 mm (Toconao Station, February 2012). Operations occur year-round (continuously), with higher evaporation rates in the summer and lower rates in winter.

| 4.4 | Infrastructure Availability and Sources |

Since 2017, the operations at Salar de Atacama are connected to the national electrical system that provides energy to most of the cities and industries in Chile. Most energy needs are covered by the Electric Power Supply Agreement which was enacted with AES Gener S.A. on December 31, 2012. For natural gas, SQM has a five-year contract with Engie since 2019, and liquid gas is supplied by Lipigas. The freshwater supply for the Salar de Atacama is obtained from nearby freshwater wells in the basin for which the company has the corresponding rights and environmental authorization.

| 5 | HISTORY |

Between 1994 and 1999, SQM invested in the development of the Salar de Atacama Project to produce potassium chloride, and lithium carbonate among other products (SQM, 2020). Prior to SQM’s involvement in the Project, numerous historical studies were completed in the Salar de Atacama Basin to investigate the geology, surface and groundwater hydrology, hydrogeochemistry, and water and brine resources. The most relevant technical studies, previous operations, and relevant exploration and development work are summarized below:

| · | Brüggen (1942): General description of the geology setting of the Atacama salt flats and their surroundings. |

| · | Dingman (1965): Surface geological mapping of the Salar de Atacama Basin. |

| · | Dingman (1967): In collaboration with the IIG and CORFO, the first published analysis of brines in the nucleus of the Salar de Atacama which reported the high concentrations of potassium and lithium. |

| · | Díaz del Río et al. (1972): Evaluation of the brine resource and the groundwaters to the east and north of the salt flat nucleus for the IIG and CORFO. |

| · | Moraga et al. (1974): Built on the work of Díaz del Río et al. (1972), including: (a) the preparation of an economic evaluation of the brine resource; and (b) the development of topographic cartography of the Salar de Atacama Basin at a 1:250,000 scale. |

| · | Ide (1978): University of Chile Thesis for the degree of Mining Engineer (sponsored by CORFO), which provided an estimate of the mass of the various crystalline salts within the nucleus of the Salar de Atacama and presented a brine resource characterization based on the analysis of over 400 samples. |

| · | Harza Engineering Company Ltd (1978): Water Resources Evaluation, including the completion of hydrogeological investigation wells in the marginal zone to the east and north of the nucleus of the Salar de Atacama. Study associated with the United Nations Project CHI-69/535 titled, “Desarrollo de los Recursos Hídricos en el Norte Grande de Chile” (Development of the Water Resources of the Norte Grande of Chile). |

| · | Dalannais (1979): Católica del Norte University, Antofagasta, Chile. Thesis for the degree of Geologist titled, “Hidrogeología del Borde Oriental del Salar de Atacama” (Hydrogeology of the Eastern Border of the Salar de Atacama). |

| · | During the 1980s, the Chilean National Petroleum Company, or Empresa Nacional del Petróleo (ENAP), conducted seismic reflection surveys in the Salar de Atacama Basin. This data was subsequently analyzed and interpreted by several groups that concluded that the data demonstrated good lateral continuity of the deposited sediment and evaporite units in the Salar de Atacama Basin over the last 23 million years, between the Miocene Epoch and present day. |

| · | Ramírez & Gardeweg (1982): SERNAGEOMIN geological map of the Salar de Atacama Basin at 1:250,000 scale with an accompanying 117-page Memorandum (Carta Geológica de Chile, Serie Geología Básica, N° 54, Hoja Toconao). |

| · | Hydrotechnica (1987). Evaluation of Brine Reserves in the Salar de Atacama. Report that summarizes a drilling campaign, hydraulic test, and drainable porosity studies to characterize hydraulic parameters in the nucleus of Salar de Atacama as well as the reserves. |

| · | Bevacqua (1992): Universidad Católica del Norte, Antofagasta, Chile. Geology thesis titled, “Geomorfología del Salar de Atacama y Estratigrafía de su Núcleo y Delta” (Geomorphology of the Salar de Atacama and Stratigraphy of its Nucleus and Delta). |

| · | Includes the evaluation of hydraulic parameters of the salt flat nucleus based on data from field campaigns, conducted by Sociedad Minera Salar de Atacama Ltda. (MINSAL S.A.) and CORFO. Information analyzed includes diamond core data, pumping test results, and drainable porosity estimates. |

| · | SQM (1993): In 1993, based on an agreement with MINSAL S.A., SQM implemented a project to produce potassium chloride from the Salar de Atacama for use in fertilizer production. A pilot production wellfield began brine extraction in 1994, and was expanded in 1996, with technical support provided by the consulting firm, Water Management Consultants (WMC). |

| · | Water Management Consultants. (1993). Salar de Atacama. Southwest Corner Investigation. 1150/2, Prepared for Minsal S.A. Geological and hydrogeological characterization of the southeast corner of Salar de Atacama. Includes drainable porosity characterization. |

| · | Alonso & Risacher (1996): Evaluation of the water balance and geochemistry of the Salar de Atacama Basin. |

| · | Carmona (2002): Doctoral thesis that further develops the evaluation of the water balance and geochemistry of the Salar de Atacama Basin. |

| · | EIA (2005): EIA submitted by SQM in January 2005 in support of the project titled, “Cambios y Mejoras de la Operación Minera en el Salar de Atacama” (Changes and Improvements of the Mining Operation in the Salar de Atacama). SQM received the corresponding environmental approval (RCA 226/2006) for the project in October 2006. A numerical model was developed to evaluate how the hydrological system of the Salar de Atacama would react over time due to the extraction of (a) brine from the salt flat nucleus for mineral extraction; and (b), fresh groundwater from the marginal zone to supply SQM’s mining operation. |

| · | Jordan et al. (2002; 2007), and Arriagada et al. (2006): Evaluation of seismic reflection data obtained out by ENAP during the 1980s. The analysis identified compressive deformation and a correlation between sediment deposition and tectonic events. |

| · | Geohidrología Consultores (2007): Supervision of the construction of monitoring wells in accordance with the conditions of the environmental permit awarded with respect to the 2005 EIA. |

| · | AMPHOS 21 Consulting (2008): Hydrogeological analysis of data collected during the 2007 monitoring well construction campaign, and development of a hydrogeological model to support the hydrogeological evaluation of the Soncor wetland system in the marginal zone to the northeast of the nucleus of the Salar de Atacama. |

| · | Xterrae Geología (2011): Preparation of a digital model of the 3D distribution of hydrogeological units of the Salar de Atacama Basin based on field and laboratory data compiled by SQM. Model prepared by Xterrae Geología, a consulting firm based in Santiago, Chile. |

| · | Niemeyer (2013): Geological mapping of the high ground of the Cordón de Lila, to the south of the nucleus of the Salar de Atacama, at a scale of 1: 100,000. |

| · | Becerra et al. (2014): “Geología del área Salar de Atacama, región de Antofagasta. Servicio Nacional de Geología y Minería” (Geology of the Salar de Atacama Area, Antofagasta Region, SERNAGEOMIN). Conducted a geological survey of the Salar de Atacama areas (scale 1: 100,000). |

| · | Xterrae Geología (2015): Update of the model of the 3D distribution of hydrogeological units of the Salar de Atacama Basin, incorporating field and laboratory data compiled by SQM since completion of the 2011 model. |