UNITED

STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

FORM 6-K

REPORT OF FOREIGN PRIVATE ISSUER

Pursuant to Rule 13a-16 or 15d-16 of

the Securities Exchange Act of 1934

For the month of September 2023

SKEENA RESOURCES LIMITED

(Translation of Registrant's Name into English)

| 001-40961 | ||

| (Commission File Number) | ||

| 1021 West Hastings Street, Suite 650, Vancouver, British Columbia, V6E 0C3, Canada | ||

| (Address of Principal Executive Offices) | ||

Indicate by check mark whether the registrant files or will file annual reports under cover of Form 20-F or Form 40-F:

Form 20-F ¨ Form 40-F 🗹

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(1): ¨

Indicate by check mark if the registrant is submitting the Form 6-K in paper as permitted by Regulation S-T Rule 101(b)(7): ¨

Exhibits 99.1, 99.2, 99.3, 99.4, 99.5, and 99.6 to this report, furnished on Form 6-K, are furnished, not filed, and will not be incorporated by reference into any registration statement filed by the registrant under the Securities Act of 1933, as amended.

EXHIBIT INDEX

SIGNATURES

Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on its behalf by the undersigned, thereunto duly authorized.

Date: September 26, 2023

| SKEENA RESOURCES LIMITED | ||

| By: | /s/ Andrew MacRitchie | |

| Andrew MacRitchie | ||

| Chief Financial Officer | ||

Exhibit 99.1

|

|

Skeena Files Technical Report for Snip MRE

Vancouver, BC (September 26, 2023) Skeena Resources Limited (TSX: SKE, NYSE: SKE) (“Skeena” or the “Company”) is pleased to announce that it has filed a detailed Technical Report (the “Report”) for the Mineral Resource Estimate (“MRE”) at its 100% owned Snip Gold Project (“Snip” or the “Project”). The Report is titled “Independent Technical Report for the Snip Project, Canada” and is compliant with National Instrument 43-101 Standards of Disclosure for Mineral Projects. The key results from the Report were summarized in the Company’s news release dated September 5, 2023. A copy of the full report is available on Skeena’s website and has been filed on SEDAR+ at www.sedarplus.ca and EDGAR at www.sec.gov.

About Skeena

Skeena Resources Limited is a Canadian mining exploration and development company focused on revitalizing the Eskay Creek and Snip Projects, two past-producing mines located in Tahltan Territory in the Golden Triangle of northwest British Columbia, Canada. The Company released a Feasibility Study for Eskay Creek in September 2022 which highlights an after-tax NPV5% of C$1.4B, 50% IRR, and a 1-year payback at US$1,700/oz Au and US$19/oz Ag. Skeena is currently continuing exploration drilling and plans on releasing a Definitive Feasibility Study for Eskay Creek in Q4 2023.

On behalf of the Board of Directors of Skeena Resources Limited,

| Walter Coles | Randy Reichert | |

| Executive Chairman | President & CEO |

Contact Information

Investor Inquiries: info@skeenaresources.com

Office Phone: +1 604 684 8725

Company Website: www.skeenaresources.com

Qualified Persons

In accordance with National Instrument 43-101 Standards of Disclosure for Mineral Projects, Paul Geddes, P.Geo., Senior Vice President, Exploration & Resource Development, is the Qualified Person for the Company and has reviewed and approved the technical and scientific content of this news release.

Sheila Ulansky, P.Geo., Senior Resource Geologist for SRK Consulting (Canada) Inc., is an independent Qualified Person as defined by National Instrument 43-101 and has reviewed and approved the contents of this news release. Ms. Ulansky is responsible for the 2023 Mineral Resources Estimate for the Snip Project.

Jeff Austin, P.Eng., President of International Metallurgical and Environmental Inc., is an independent Qualified Person as defined by National Instrument 43-101 and has reviewed and approved the contents of this news release. Mr. Austin is responsible for mineral processing and metallurgical testing for the Snip Project.

|

|

|

The Company strictly adheres to CIM Best Practices Guidelines in conducting, documenting, and reporting the exploration activities on its projects.

Cautionary note regarding forward-looking statements

Certain statements and information contained or incorporated by reference in this press release constitute “forward-looking information” and “forward-looking statements” within the meaning of applicable Canadian and United States securities legislation (collectively, “forward-looking statements”). These statements relate to future events or our future performance. The use of words such as “anticipates”, “believes”, “proposes”, “contemplates”, “generates”, “progressing towards”, “in search of”, “targets”, “is projected”, “plans to”, “is planned”, “considers”, “estimates”, “expects”, “is expected”, “often”, “likely”, “potential” and similar expressions, or statements that certain actions, events or results “may”, “might”, “will”, “could”, or “would” be taken, achieved, or occur, may identify forward-looking statements. All statements other than statements of historical fact are forward-looking statements. Specific forward-looking statements contained herein include, but are not limited to, statements regarding the results of the Feasibility Study, processing capacity of the mine, anticipated mine life, probable reserves, the potential impact of the Definitive Feasibility Study for Eskay Creek, and the Maiden Engineering Study for Snip on the anticipated mine life and/or the conversion of resource ounces from the Inferred to Indicated categories or from Measured or Indicated categories to the Reserve category, estimated project capital and operating costs, potential reductions in process plant capital and operating costs, sustaining costs, results of test work and studies, planned environmental assessments, the future price of metals, metal concentrate, and future exploration and development generally and specifically in relation to the potential for additional mineralization in the recently increased land package. Such forward-looking statements are based on material factors and/or assumptions which include, but are not limited to, the estimation of mineral resources and reserves, the realization of resource and reserve estimates, metal prices, taxation, the estimation, timing and amount of future exploration and development, capital and operating costs, the availability of financing, the receipt of regulatory approvals, environmental risks, title disputes and the assumptions set forth herein and in the Company’s MD&A for the year ended December 31, 2022, its most recently filed interim MD&A, and the Company’s Annual Information Form (“AIF”) dated March 22, 2023. Such forward-looking statements represent the Company’s management expectations, estimates and projections regarding future events or circumstances on the date the statements are made, and are necessarily based on several estimates and assumptions that, while considered reasonable by the Company as of the date hereof, are not guarantees of future performance. Actual events and results may differ materially from those described herein, and are subject to significant operational, business, economic, and regulatory risks and uncertainties. The risks and uncertainties that may affect the forward-looking statements in this news release include, among others: the inherent risks involved in exploration and development of mineral properties, including permitting and other government approvals; changes in economic conditions, including changes in the price of gold and other key variables; changes in mine plans and other factors, including accidents, equipment breakdown, bad weather and other project execution delays, many of which are beyond the control of the Company; environmental risks and unanticipated reclamation expenses; and other risk factors identified in the Company’s MD&A for the year ended December 31, 2022, its most recently filed interim MD&A, the AIF dated March 22, 2023, the Company’s short form base shelf prospectus dated January 31, 2023, and in the Company’s other periodic filings with securities and regulatory authorities in Canada and the United States that are available on SEDAR+ at www.sedarplus.ca or on EDGAR at www.sec.gov.

Readers should not place undue reliance on such forward-looking statements. Any forward-looking statement speaks only as of the date on which it is made and the Company does not undertake any obligations to update and/or revise any forward-looking statements except as required by applicable securities laws.

|

|

|

Cautionary note to U.S. Investors concerning estimates of mineral Reserves and mineral Resources

Skeena’s mineral Reserves and mineral Resources included or incorporated by reference herein have been estimated in accordance with National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”) as required by Canadian securities regulatory authorities, which differ from the requirements of U.S. securities laws. The terms “mineral reserve”, “proven mineral reserve”, “probable mineral reserve”, “mineral resource”, “measured mineral resource”, “indicated mineral resource” and “inferred mineral resource” are Canadian mining terms as defined in accordance with NI 43-101 and the Canadian Institute of Mining, Metallurgy and Petroleum (“CIM”) “CIM Definition Standards – For Mineral Resources and Mineral Reserves” adopted by the CIM Council (as amended, the “CIM Definition Standards”). These standards differ significantly from the mineral property disclosure requirements of the U.S. Securities and Exchange Commission in Regulation S-K Subpart 1300 (the “SEC Modernization Rules”). Skeena is not currently subject to the SEC Modernization Rules. Accordingly, Skeena’s disclosure of mineralization and other technical information may differ significantly from the information that would be disclosed had Skeena prepared the information under the standards adopted under the SEC Modernization Rules.

In addition, investors are cautioned not to assume that any part or all of Skeena’s mineral Resources constitute or will be converted into Reserves. These terms have a great amount of uncertainty as to their economic and legal feasibility. Accordingly, investors are cautioned not to assume that any “measured”, “indicated”, or “inferred” mineral Resources that Skeena reports are or will be economically or legally mineable. Further, “inferred mineral Resources” have a great amount of uncertainty as to their existence, and great uncertainty as to their economic and legal feasibility. It cannot be assumed that all or any part of an “inferred mineral resource” will ever be upgraded to a higher category. Under Canadian securities laws, estimates of “inferred mineral Resources” may not form the basis of feasibility or prefeasibility studies, except in rare cases where permitted under NI 43-101.

For these reasons, the mineral reserve and mineral resource estimates and related information presented herein may not be comparable to similar information made public by U.S. companies subject to the reporting and disclosure requirements under the U.S. federal securities laws and the rules and regulations thereunder.

|

|

|

Exhibit 99.2

Independent Technical Report for the Snip Project, Canada

Prepared for

Skeena Resources Ltd

Prepared by

SRK Consulting (Canada) Inc.

| Effective Date: | September 05, 2023 |

| Issue Date: | September 26, 2023 |

| Project: | CAPR002721 |

Independent Technical Report for the Snip Project, Canada

Effective Date: September 05, 2023

Release Date: September 26, 2023

| Prepared for | Prepared by |

|

Skeena Resources Ltd 650 – 1021 West Hastings Street Vancouver, BC, V6E 0C3

|

SRK Consulting (Canada) Inc. 2700 - 320 Granville Street Vancouver, BC, V6C 1S9 Canada |

|

Tel: +1 604-684-8725 Web: www.skeenaresources.com |

Tel: +1 604 681 4196 Web: www.srk.com |

Authored By

| Sheila Ulansky, PGeo | Jeff Austin, P.Eng |

| SRK Consulting (Canada) Inc. | International Metallurgical and Environmental Inc. |

| Project No: | CAPR002721 | |

| File Name: | Skeena Resources_Snip_NI43-101_Report_CAPR002721_20230926.docx |

Cover image: Snip camp. Courtesy of R. Markel 2021.

Copyright © SRK Consulting (Canada) Inc., 2023

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

Important Notice

This report was prepared as a National Instrument 43-101 Technical Report for Skeena Resources Limited (Skeena) by SRK Consulting (Canada) Inc. (SRK). The quality of information, conclusions, and estimates contained herein is consistent with the level of effort involved in SRK’s services, based on: i) information available at the time of preparation, ii) data supplied by outside sources, and iii) the assumptions, conditions, and qualifications set forth in this report. This report is intended for use by Skeena subject to the terms and conditions of its contract with SRK and relevant securities legislation. The contract permits Skeena to file this report as a Technical Report with Canadian securities regulatory authorities pursuant to National Instrument 43-101, Standards of Disclosure for Mineral Projects. Except for the purposes legislated under provincial securities law, any other uses of this report by any third party is at that party’s sole risk. The responsibility for this disclosure remains with Skeena. The user of this document should ensure that this is the most recent Technical Report for the property as it is not valid if a new Technical Report has been issued.

Copyright

© 2023 SRK Consulting (Canada) Inc.

This document is protected by copyright vested in SRK Consulting (Canada) Inc. It may not be reproduced or transmitted in any form or by any means whatsoever to any person without the written permission of the copyright holder, other than in accordance with stock exchange and other regulatory authority requirements.

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| 1 | Executive Summary |

| 1.1 | Introduction |

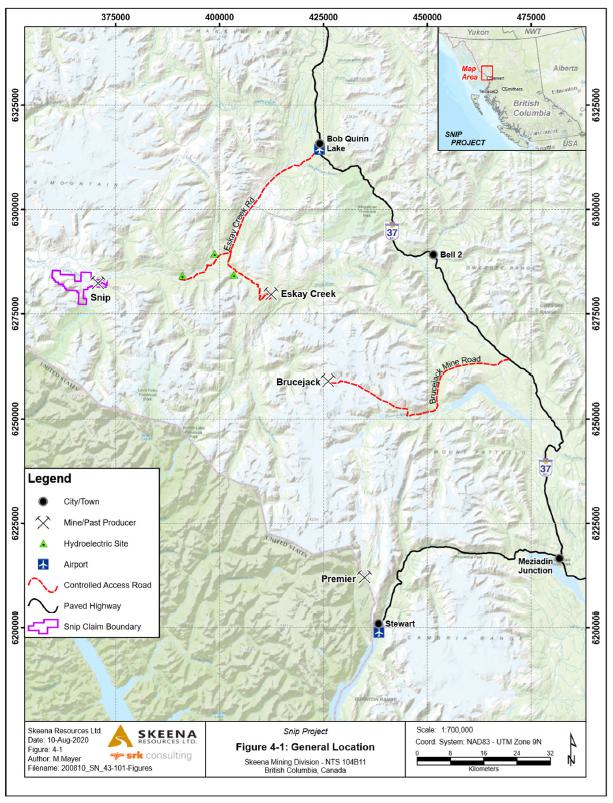

The Snip Project, located in northwest British Columbia (BC), is a past producing underground mine that hosts high-grade structurally controlled mineralized veins in a brittle-ductile shear zone system. Skeena is a Canadian junior mining exploration company focused on developing prospective precious and base metal properties in the Golden Triangle of northwest British Columbia, Canada.

In June 2023, Skeena commissioned SRK to provide resource estimation technical support and validation for an updated Mineral Resource Estimate on the Snip deposit, as well as provide a NI-43101 compliant Technical Report. The effective date of the 2023 Mineral Resource is September 05, 2023.

The services were rendered between June and September 2023 leading to the preparation of the Mineral Resource Statement that was disclosed publicly by Skeena in a news release on September 05, 2023. The effective date of the 2020 NI 43-101 Technical Report is September 26, 2023.

The Technical Report was prepared following the guidelines of the Canadian Securities Administrators’ National Instrument 43-101 and Form 43-101F1. The Mineral Resource Statement reported herein was prepared in conformity with generally accepted CIM “Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines”.

| 1.2 | Property Location and Ownership |

The Snip Project occurs within the Iskut River region of the Golden Triangle in British Columbia. Stewart, BC, is the nearest district municipality, 105 km to the south southeast. The property is located wholly within NTS map sheet 104B/11 as well as on the Tahltan National Traditional Territory.

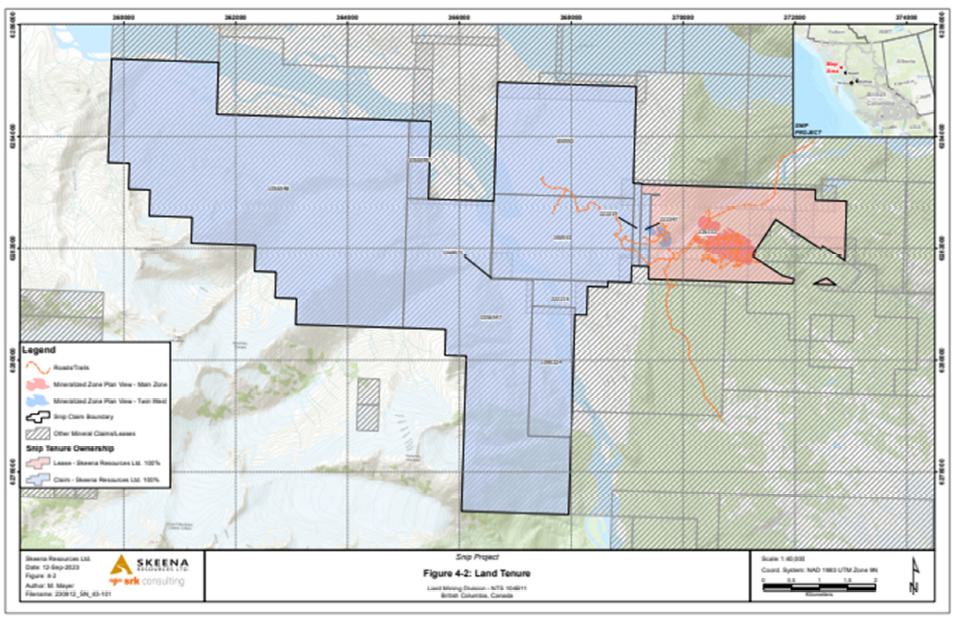

The Project covers a total of 4,724.07 hectares (11,673.43 acres) and consists of nine (9) mineral claims and one (1) mineral lease.

In July 2017, Skeena exercised their right to acquire all of Barrick Gold Inc.’s (“Barrick”) 100% “right, title and interest in and to the Property and the Permits” (the “Original Snip Property”), subject to the retention by Barrick of a 51% Back-In Right. In September 2018, Skeena and Hochschild entered into an option agreement for Hochschild to earn in a 60% undivided interest in the Original Snip Property by spending twice the amount Skeena had spent since it originally optioned the Original Snip Property from Barrick. In October of 2021 Hochschild gave notice of its intention to start its earn in. On April 5th, 2023, Hochschild terminated its option to earn 60% of the Snip Gold Project resulting in Skeena reassuming management of the Project and retaining 100% ownership.

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| 1.3 | Accessibility, Climate, Local Resources, Infrastructure and Physiography |

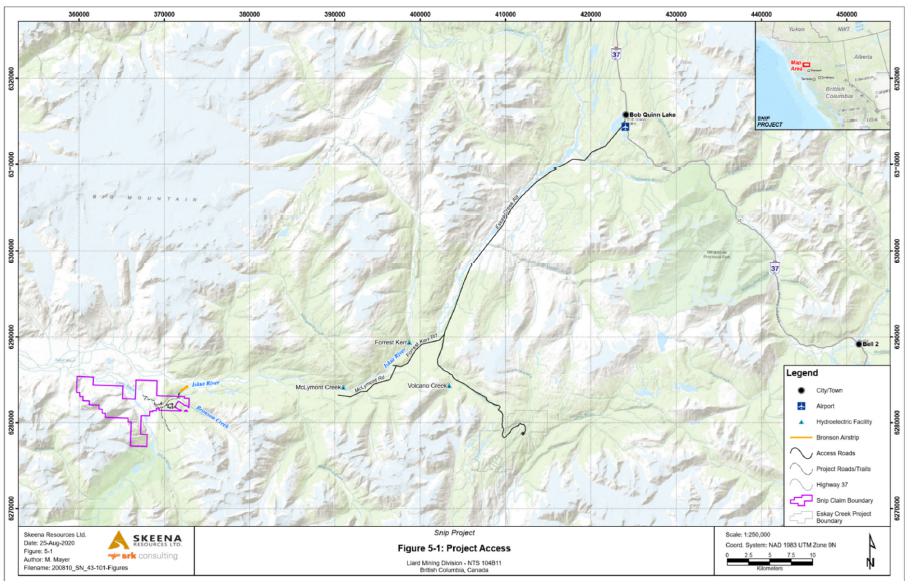

Access to the Snip Property can be gained either by direct air or boat transportation to the 1.5 km long Bronson Airstrip on the Iskut River. Direct charter flights by fixed wing aircraft can land at the Bronson airstrip maintained by SnipGold Corp., a subsidiary of Seabridge Gold. Vehicle access from Smithers can be achieved by route of Hwy 16 to Kitwanga, then north along highway 37 to the Eskay Mine Road, 3 km south of Bob Quinn. Road access to the McLymont staging area is 45 km west of Bob Quinn and requires a road usage permit from AltaGas. From McLymont, it is a 10-minute helicopter flight to the Snip camp.

Support services for mining and other resource sector industries in the region are provided primarily from the communities of Smithers (pop. 5,400) and Terrace (pop. 11,500). Both communities are accessible by commercial airlines with daily flights to and from Vancouver.

The Snip property lies within the Coast Mountains. The dominant feature of the region is the Stikine Icecap which is centered 80 km to the NW of the property along the Alaska border. The Snip Property lies between the Iskut River, Craig River and Bronson Creek within the Stikine Watershed.

The property lies within the Coastal Western Hemlock zone. The Snip property has almost no alpine vegetation, with sub-alpine flora dominated by scattered Sitka Spruce, with transition to Engelmann Spruce, farther East. At the Bronson Creek level, natural vegetation is Western Hemlock and Sitka Spruce, with riparian populations of cottonwood and spruce. Natural regrowth is rapid, with hemlock and spruce growing to 5 m within 20 years.

| 1.4 | History, Exploration and Drilling |

The history of the camp goes back to the early 1900’s when the Iskut Mining Company staked the first claims on the west side of Bronson Creek in 1907. Following this, the Red Bluff claims were staked in 1909. The first mining was completed between 1908 and 1911 when several short adits were driven into the Red Bluff Porphyry to obtain a bulk sample. The area saw limited work until 1929 when Cominco Ltd. staked 42 claims, however little of interest was found and the claims were abandoned.

Thirty-five years would pass before the Tuksi Mining Company acquired crown grants in 1964. In the same year Jodee Exploration company, Cominco Ltd. and Copper Soo Mining company all staked claims around Tuksi’s grants. In 1965 the Snip discovery outcrop was made by geologists who were surveying a creek gully; the outcrop contained visible gold in a vein. The following year, in 1966, channel sampling on the vein returned assays up to 244 ppm Au over 1.2 m.

The area once again lay dormant for nearly a decade and a half until 1980 when Cominco Ltd. restaked the discovery outcrop on the Snip claims. Between 1980 to 1986, grass roots exploration, soil sampling and trenching were conducted by Cominco. In 1986, Cominco signed a JV agreement with Delaware Resources Corp., who provided funding for the project, and over two years, drilled over 15,000 m. The work outlined the Main Twin Zone on 50 m centers.

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

In 1988, a decision was made to go underground via a portal at the 300 m elevation. An additional 6,800 m of surface drilling, coupled with underground development and related drilling on 12.5 m centers, was completed and by 1989 the first reserve estimate for the Main Twin Zone was calculated at 940,000 tonnes grading 28.5 g/t Au.

The Snip Mine operated between January 1991 and June 1999, first by Cominco Ltd. and then, beginning in 1996, by Homestake Canada Inc. The mine was successfully closed in October 1999. In 2001, the property was acquired by Barrick Gold Inc. (Barrick) as part of its acquisition of Homestake Canada Inc.

The property lay dormant until 2016 when Skeena entered into an agreement with Barrick granting an option to acquire 100% interest in the past producing gold mine and mineral claims.

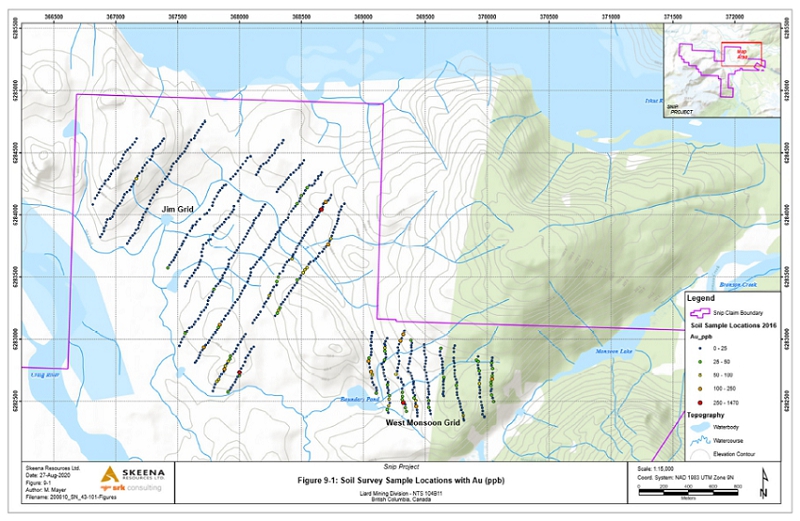

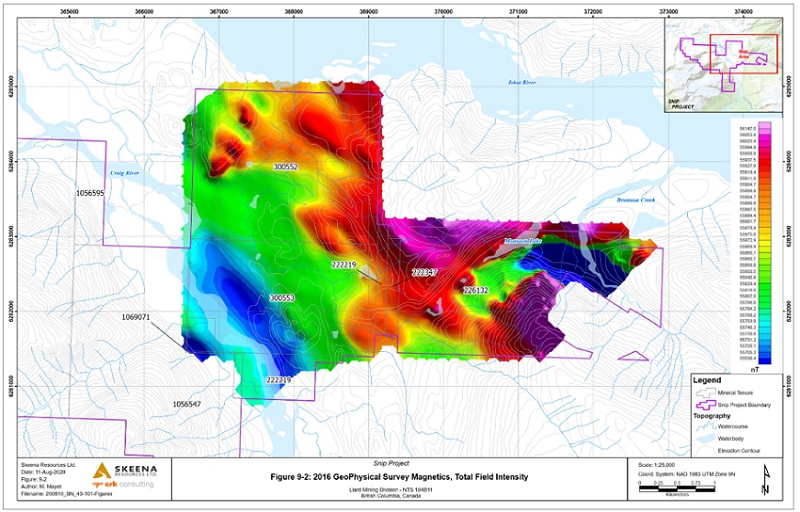

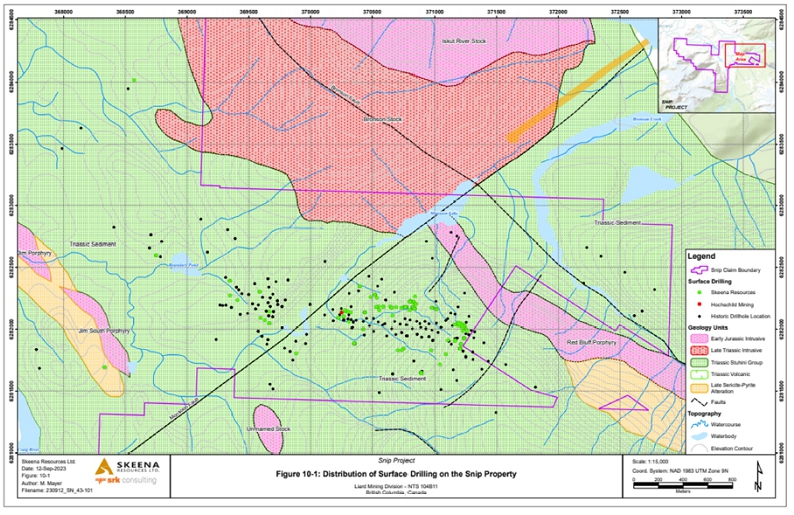

In 2016, Skeena completed 7,422 m of diamond drilling in 28 holes, collected 668 soil samples and completed 171-line kilometers of airborne magnetic surveying. The majority of drilling was completed on the portion covering the mining lease and was designed to test the targets in the Main Twin and Twin West zones as well as regional targets located on the mineral claims portion of the property. Infill soil sampling was conducted to test the continuity of historical gold anomalies and to add multi-element data in areas which previously only had gold.

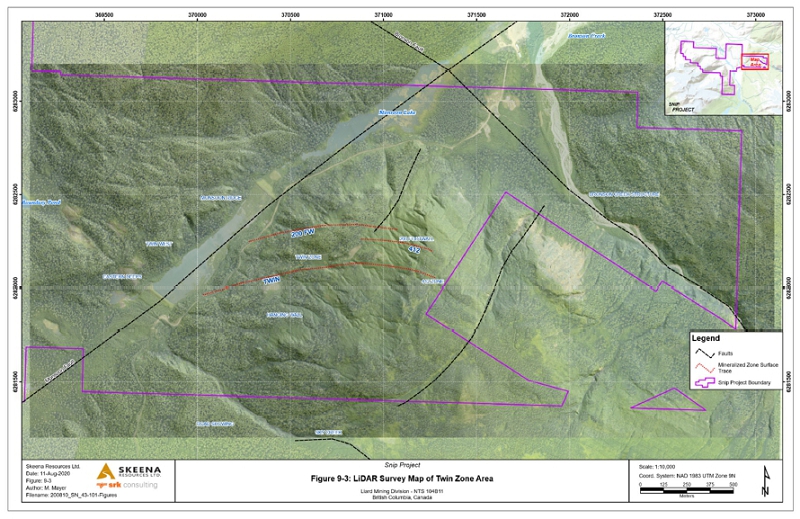

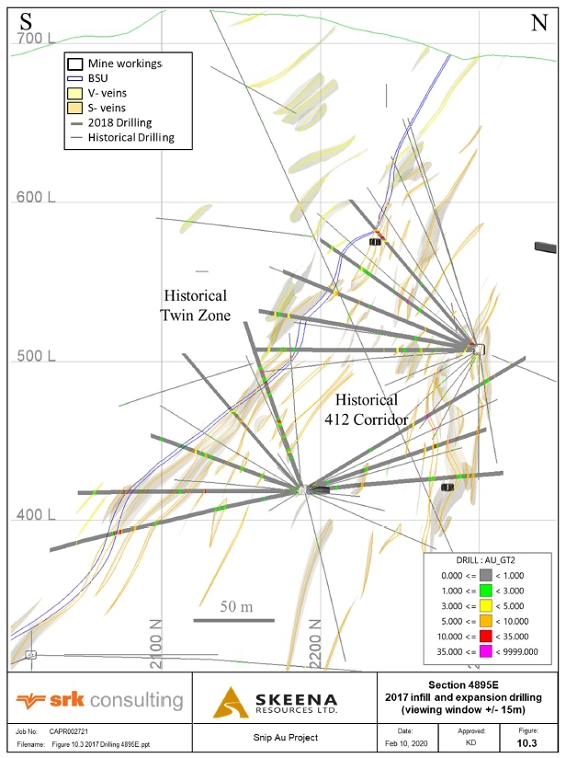

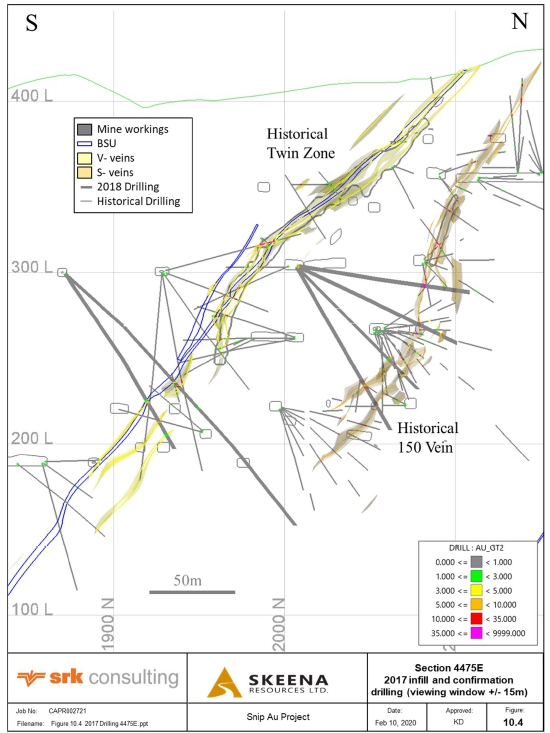

In 2017, Skeena acquired 100% right, title and interest in and to the Property and Permits and worked entirely on the mining lease. Work focused on camp expansion along with reopening the 300-portal access road and rehabilitation of the underground. A total of 8,703 m from 62 holes were drilled from underground testing targets including the Main Twin Zone, 150 Veins, 412 Corridor and other footwall structures. In addition, Skeena commissioned a surface mapping LiDAR survey of the property having 25 cm pixel resolution.

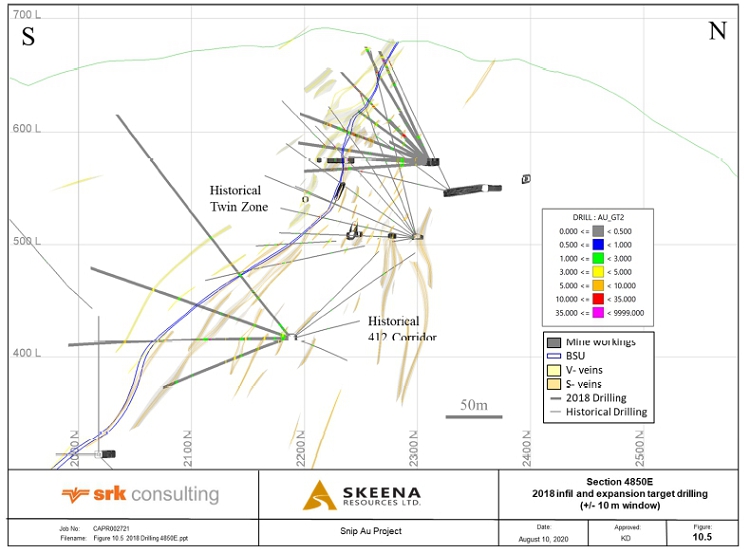

In 2018, Skeena completed 6 surface holes totalling 2,121 m targeting the Jim Porphyry and Sky Creek Shear zone, as well as below the western vein extension of the Main Twin Zone. In addition, 46 holes totalling 9,088 m targeting the Main Twin Zone, 412 Corridor and the 200 Footwall Zone was completed to further delineate areas of known mineralization with increased drill density, to expand new zones and confirm historical drilling.

In 2019 Skeena drilled 8 surface holes totalling 1,816 m targeting the 200 Footwall Zone and footwall veins. They were successful in intersecting the footwall, as well as identifying mineralization 75 m deeper. A petrography study to compare biotitic phyllite and Biotite Spotted Unit (BSU) was conducted to test composition relations.

In 2020, Skeena drilled 9 surface holes totaling 5,327 m some of which were designed as infill holes and others to test vein extensions. The main targets were the 130 and 150 veins, and the Main Twin zone.

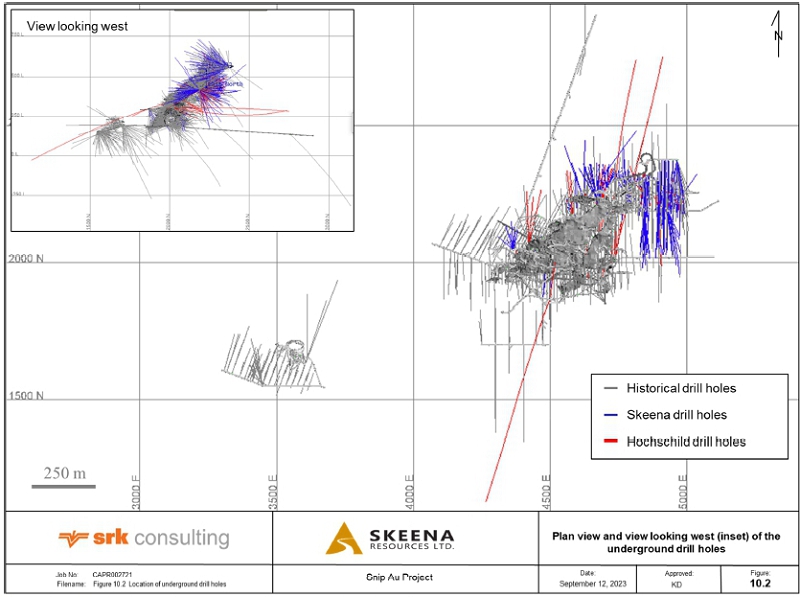

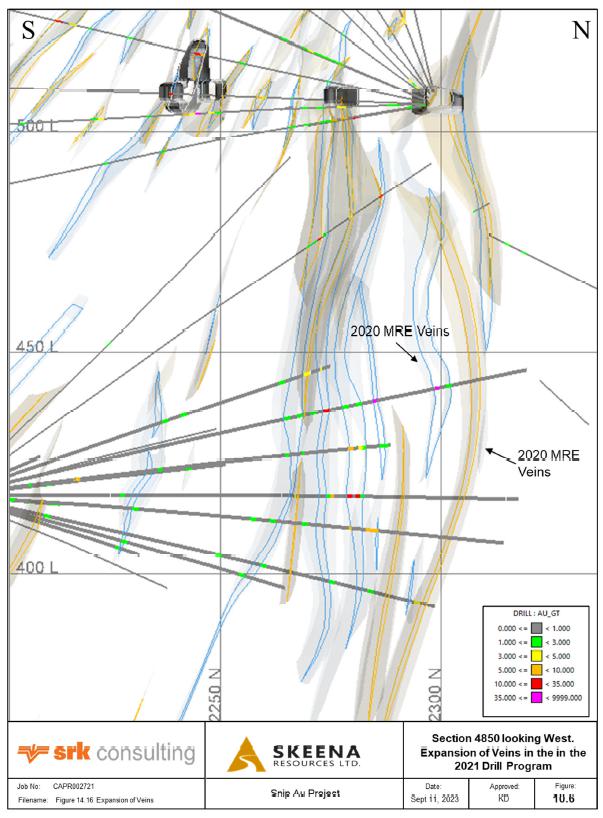

In 2021, Skeena drilled 95 surface holes totaling 14,608 m and 134 underground holes totaling 15,955 m. The objective was two-fold: to infill drill areas and to test vein extensions predominantly in the S-Veins. This campaign included 8 drill holes that that corresponded spatially in 3-D orientation to 8 historical holes being no more than several meters in 3-D separation. These holes (known as “Twin Holes”) were designed to validate historical drilling at the Snip Mine. The remaining holes targeted the 130 and 150 veins, the 200 Footwall corridor, the 412-corridor, the Main Twin zone, and other footwall structures.

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

In September 2018, Skeena granted Hochschild an option to earn in 60% of the Original Snip Property and Hochschild gave notice in October of 2021 of its intention to start earning-in 60% of Skeena’s interest in the Original Snip Property.

In 2022, Hochschild completed 68 underground holes totaling 9,876 meters. This campaign included 20 drill holes that corresponded spatially in 3-D orientation to 20 historical holes being no more than several meters in 3-D separation. These Twin Holes were designed to validate historical drilling at the Snip Mine. An additional 48 holes were drilled to infill untested areas and to evaluate for vein extensions in the S-Veins and deeper footwall structures. One surface hole totalling 501 m was drilled to target the deep, western down hole extents of the V-Vein sets.

On April 5th, 2023, Hochschild terminated its option to earn 60% of the Snip Gold Project resulting in Skeena reassuming management of the Project and retaining 100% ownership.

| 1.5 | Geology and Mineralization |

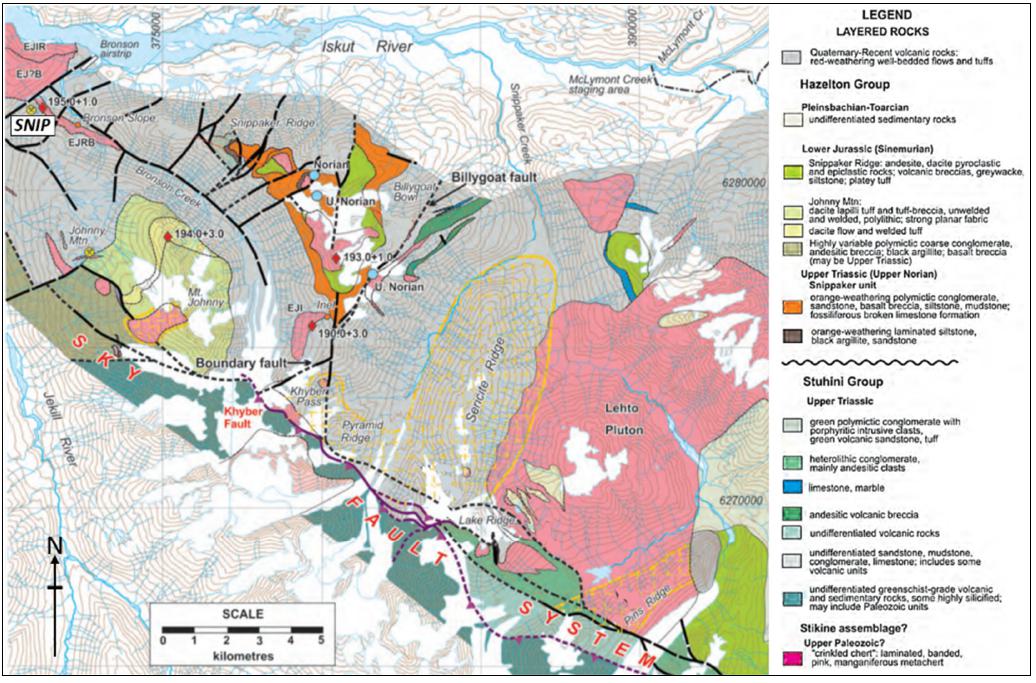

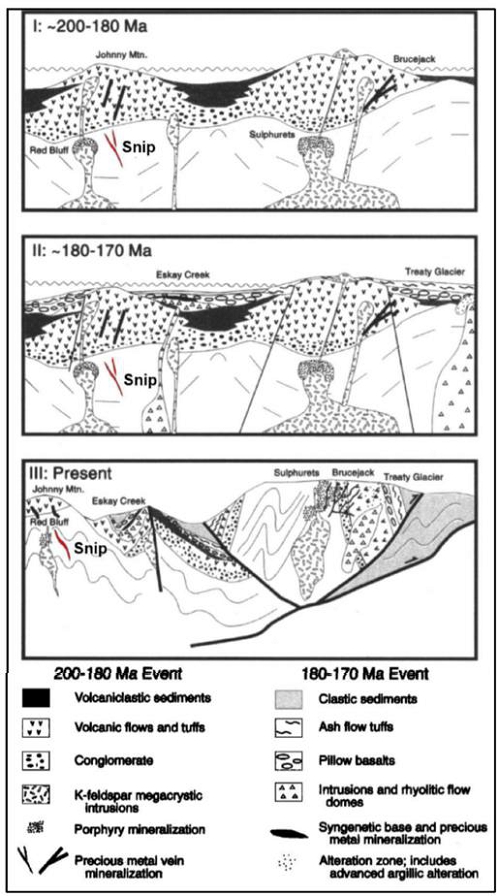

The Snip Au (Cu-Mo-Zn) deposit, located within the economically important “Golden Triangle” region, is a structurally controlled mineralized vein and brittle-ductile shear zone system, hosted within a sequence of laminated turbidites of the Upper Triassic Stuhini Group. Mineralization has both Orogenic style gold characteristics as well as mineralogical and paragenetic similarities to porphyry related vein systems, being contemporaneous with the adjacent Early Jurassic Red Bluff porphyry, a calc-alkaline, I-type, magnetite-series intrusion of quartz monzodioritic composition.

Regional investigations have indicated the importance of the Stuhini Group unconformity with the overlying Lower Jurassic Hazelton Group and a major northwest-southeast trending zone, the Bronson corridor. Throughout the “Golden Triangle” major deposits, including the Snip deposit, occur within 2.5 km of this unconformity and numerous mineral occurrences are associated with the Bronson corridor, characterized by the Sky fault system. This wide fault zone likely formed close to the boundary of a rift-type basin, controlled plutonism, fluid circulation and mineralization.

Gold mineralization at the Snip Project has been reported from at least six historical zones, the Main Twin Zone, the 150 Vein, the 130 Vein, the Hangingwall Zone, the Footwall Zone, and the Twin-West Zone. The Main Twin Zone shear-vein system which averages 2.5 m in width and dips 30-60°to the southwest is characterized by mineralogical banding of chlorite-biotite, calcite, quartz, and pyrrhotite-pyrite, with wallrock alteration dominated by inner biotite and outer K-feldspar-calcite-quartz-sericite. Metal association and the importance of potassic alteration suggest a magmatic origin for the ore fluid, supported by the proximity of the Main Twin Zone to the Red Bluff porphyry and lead-isotopic data. More distal veins to the Red Bluff porphyry contain higher zinc, lead and silver contents as expected in a zoned porphyry system. The distribution and abundance of biotite in areas distal to the Red Bluff porphyry and extensive areas containing mineralized veins, suggest a more regional fluid source, possibly an underlying batholithic parent to the Red Bluff porphyry.

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

A distinctive unit at Snip is the Biotite Spotted Unit, a basic to intermediate biotitic dyke that has intruded the vein mineralization. Widths range from several decimeters up to five m with an average width of 2.5-3 m. Although it is unmineralized, it is moderately to strongly altered and biotitized with calcite-pyrite-quartz-sericite-chlorite alteration and is considered to have been emplaced late in the deformation history, after ore formation, but during the waning stages of the hydrothermal system.

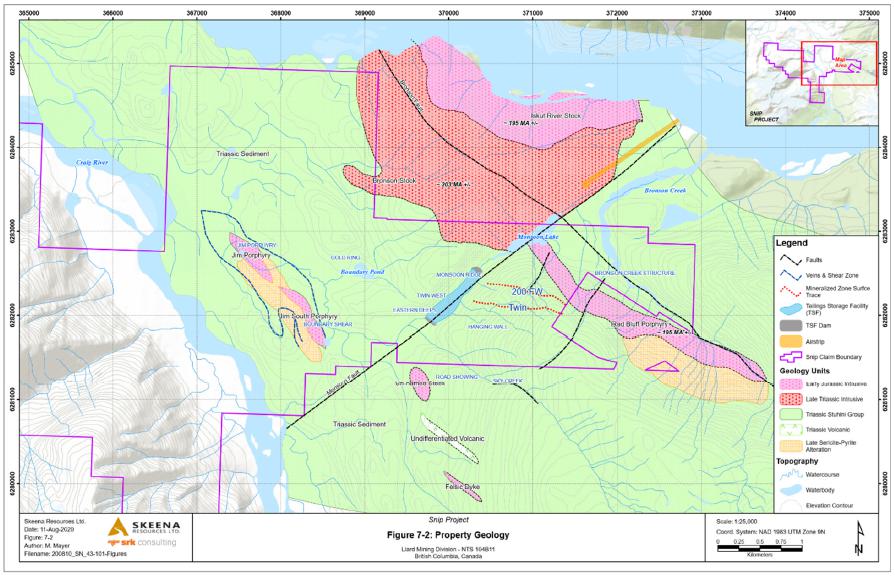

In addition to the Red Bluff porphyry other intrusives recognised on the property include the Bronson stock, a poorly documented heterogeneous, medium-grained equigranular plagioclase-rich clinopyroxene-amphibole bearing diorite; the Jim Porphyry stock, interpreted solely from drill hole information comprising both felsic extrusive and intrusive units; and recent lamprophyre and basalt dykes.

| 1.6 | Metallurgical Test Work |

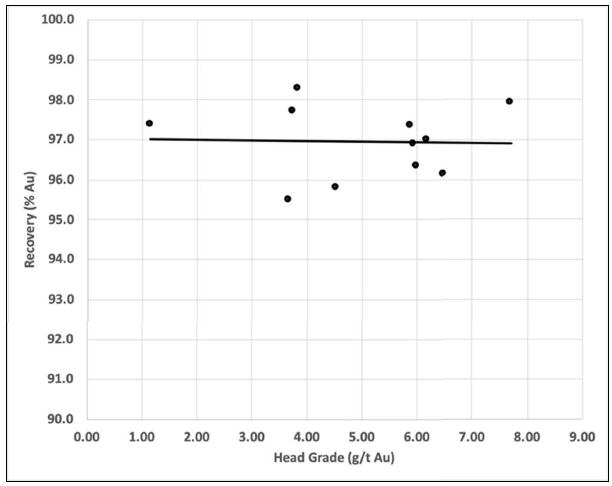

The objective of the metallurgical testing program was to quantify the metallurgical response of samples from the Snip deposit. The programs were designed with the intent to confirm the parameters for process design criteria. The 2020 metallurgical program was completed at Base Metallurgical Laboratories Ltd. (BaseMet Labs) in Kamloops, BC as Project BL661. The testing scope included chemical composition, mineralogy, comminution testing, flotation and gravity testing on two composite samples. Both samples showed excellent gold recovery of 96% and 98%. A Phase 1 metallurgical program was completed in 2021 at BaseMet Labs in Kamloops, BC as Project BL891. The testing scope included mineralogy, gravity concentration testing, flotation and leaching testing on a single composite sample. The sample showed high amenability to gravity concentration, flotation and leaching. The Phase 2 was performed in 2022 also at BaseMet identified as BL1002 on 18 samples. Samples were designed to represent a range of potential mining options and, the range of expected grades. The testing scope included mineralogy, comminution tests, gravity concentration, flotation, leach tests and cyanide destruction tests. The samples showed high resistance to impact breakage and medium hardness in ball mill grinding. Scaled up gravity gold recoveries ranged from 28% to 37%. Combined gravity and flotation gold recoveries ranged from 85% to 96%. Combined gravity and leach gold extractions averaged 96.9% from all samples. Average reagent consumptions included 0.49 kg/t for sodium cyanide and 0.57 kg/t for hydrated lime. Review of the leach test results showed a minor relationship between head grade and leach residue grade but showed no relationship between head grade and recovery. A constant recovery was estimated for economic analysis. The overall plant gold recovery used in the economic analysis is 96%.

| 1.7 | Mineral Resource and Mineral Reserve Estimates |

The Mineral Resource Estimate for the Snip Project (the “2023 Mineral Resource Estimate”) herein was prepared by Skeena Resources using all available information and reviewed and validated by Ms. S. Ulansky, Professional Geologist of SRK Consulting (Canada).

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

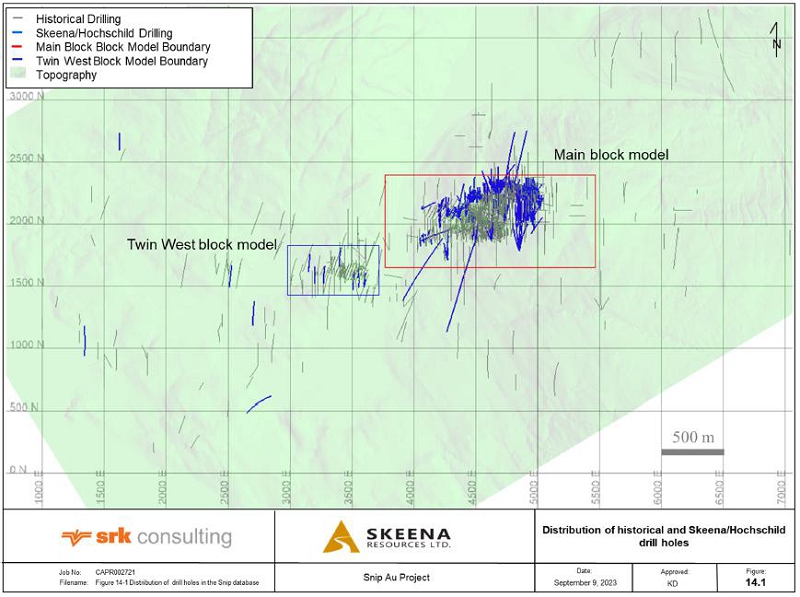

The resource is based on historical surface and underground diamond drilling completed by previous Operators in addition to holes drilled on surface and underground by Skeena (2016 to 2021) and Hochschild (2022). The database used to estimate the Snip resource contains a total of 3,999 drill holes for 355,388 m of drilling. Of this total amount, historical holes total 3,542 for a meterage of 279,971 m. Skeena has drilled a total of 388 holes totalling 65,040 m, and Hochschild has drilled 69 holes totalling 10,377 m. All historical and recent drilling was audited by SRK. SRK believes that the drilling information is sufficiently reliable to interpret with confidence the boundaries for gold mineralization domains, and that assay data is sufficiently reliable to support estimating mineral resources.

In the opinion of SRK, the block model resource estimates reported herein are a reasonable representation of the global gold mineral resources found on the Snip Project at the current level of sampling. Mineral resources are reported in accordance with the guidelines of the Canadian Securities Administrators National Instrument 43-101; and have been estimated in conformity with generally accepted CIM “Estimation and Mineral Resource and Reserve Best Practices” guidelines (CIM, 2019). Mineral resources are not mineral reserves and do have demonstrated economic viability.

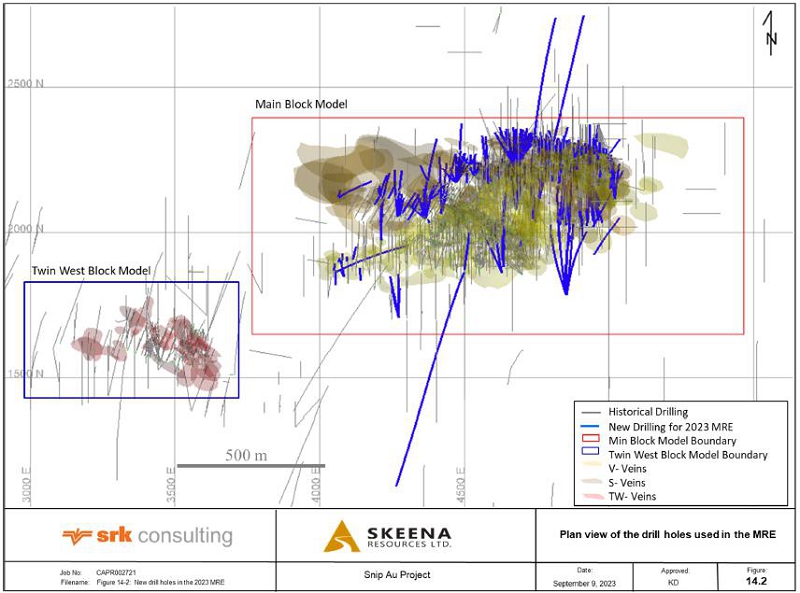

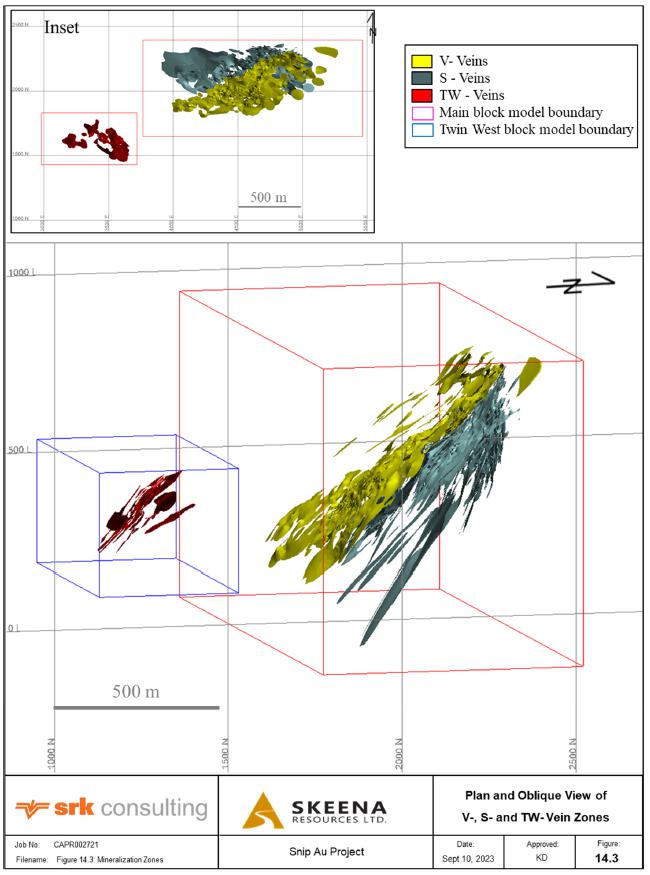

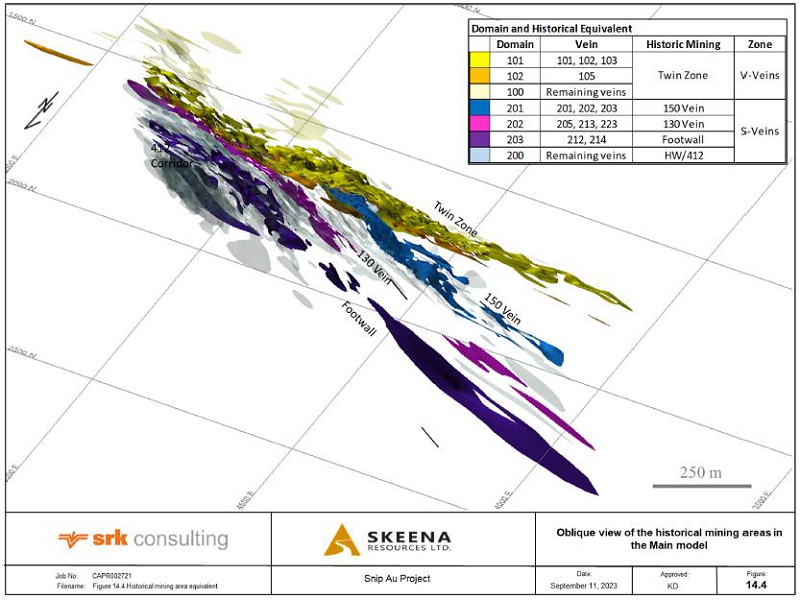

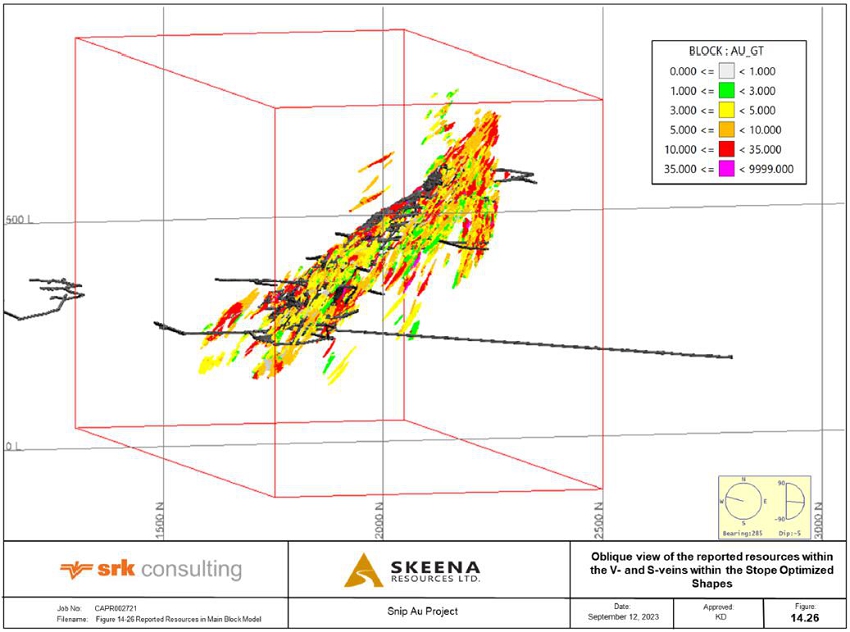

The vein model was created in Leapfrog GeoTM using economic composite intervals greater than or equal to 1.0 g/t Au if following interpreted structures and displaying mineralization continuity. Locally, lower grades were included in the veins if continuity was displayed. Local minor edits were performed in Maptek Vulcan software. Ninety-four high-grade veins were created to constrain the block model estimate. These were combined into three broad and distinct zones (V-Veins, S-Veins, and TW-Veins), which are unique in orientation, structural interpretation, and statistics; therefore, they were made discrete for resource estimation purposes.

Mineral resources were estimated using Maptek’s Vulcan® software. Two block models were created for computer efficiency: (1) the Main block model, which encompasses the V- and S- Veins and the (2) Twin West block model which encompasses the TW-Veins. Both models were created with 4 m x 4 m x 4 m parent block sizes and 0.5 m x 0.5 m x 0.5 m sub blocks sizes. The models were unrotated.

Assays were composited to 1.5 m using distributed tails methodology within the wireframes, which were also length weighted during estimation. Outlier composites were capped prior to estimation with gold capping values of 350 g/t Au, 100 to 215 g/t Au and 45 to 110 g/t Au in the V-, S- and TW- Veins, respectively.

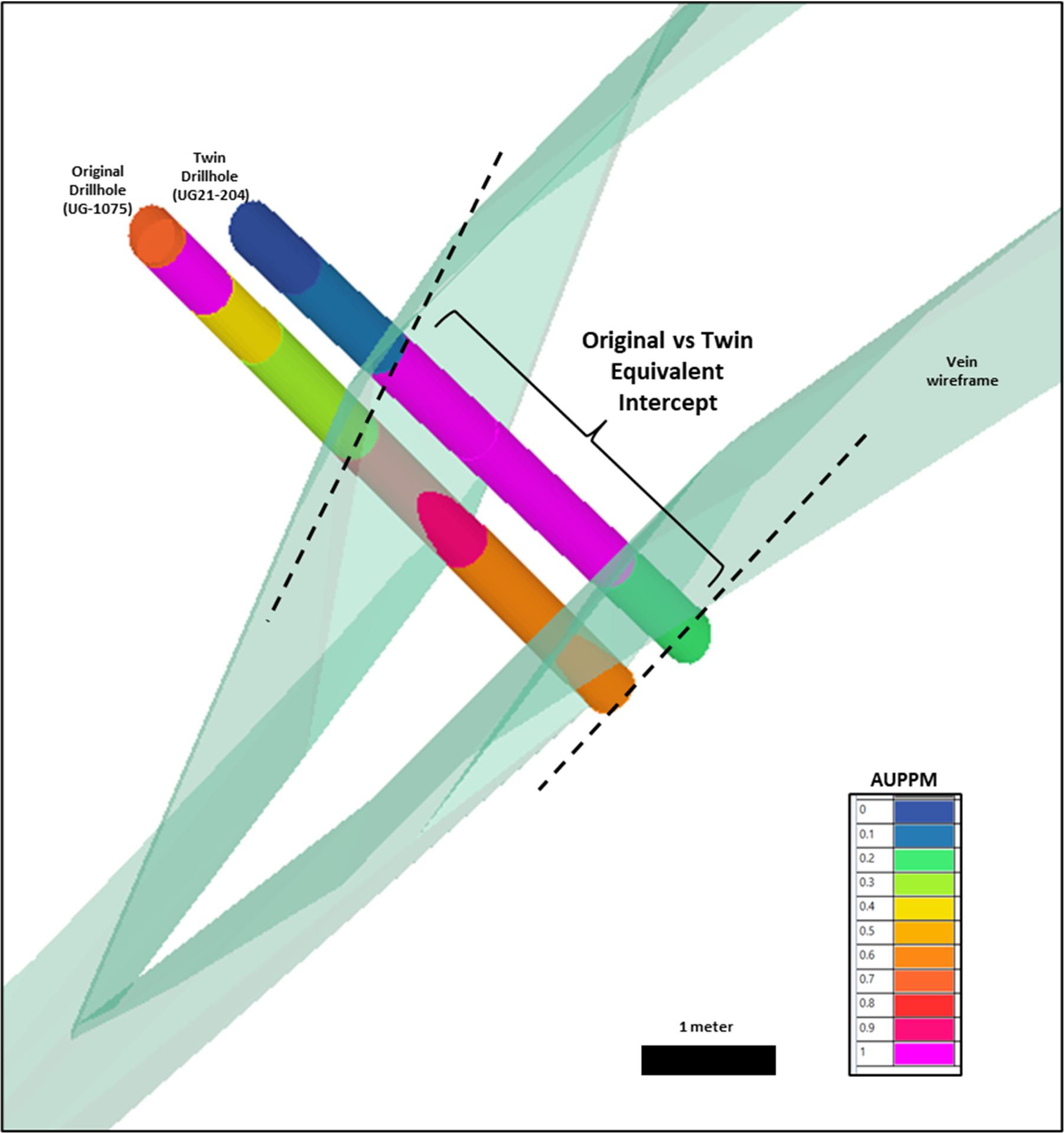

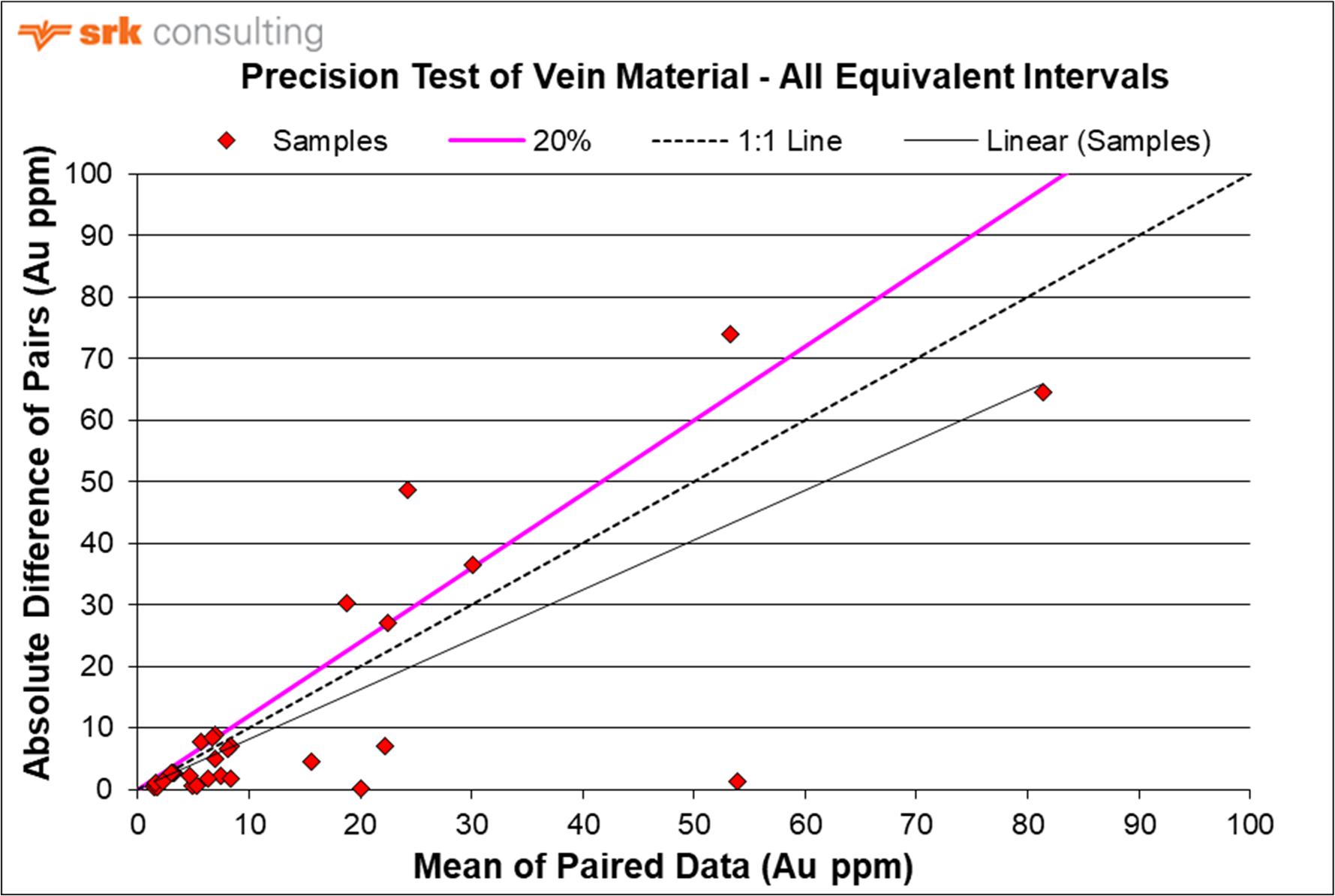

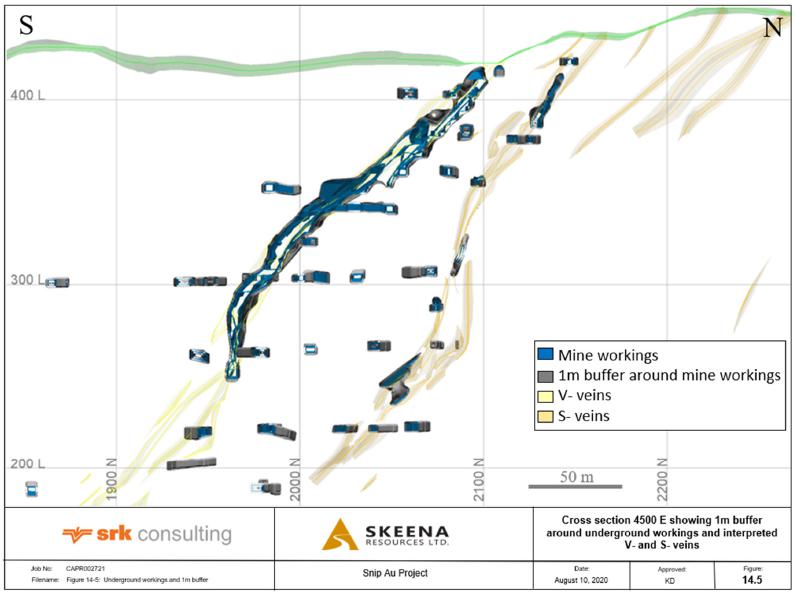

Variograms were used to determine nuggets, sills and ranges used during estimation as well as for search orientations. In the V- and -S veins that were continuous and greater than 235,000 tonnes, and TW-veins greater than 100,000 tonnes, a dynamic anisotropy (DA) surface was utilized during estimation to honour locally varying vein orientations. Gold grades were estimated in three progressively larger passes using Ordinary Kriging, along with inverse distance squared and polygonal methods for comparisons and validation. The models were validated using visual and statistical methods as well as swath plots. Block tonnages were estimated from volumes using a density of 2.91 g/cm3 within the veins, except for the unmineralized BSU (Biotite Spotted Unit) which used a density of 2.84 g/cm3. The historical holes were validated from a set of twin holes drilled by Skeena and Hochschild in 2021 and 2022. Comparative statistics showed good correlations between the historical and the twin hole gold assays. Blocks within the BSU were coded as waste. Mineral resources have been depleted to account for past production as well as exclude mineralization within a 1 m buffer around historical underground development.

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

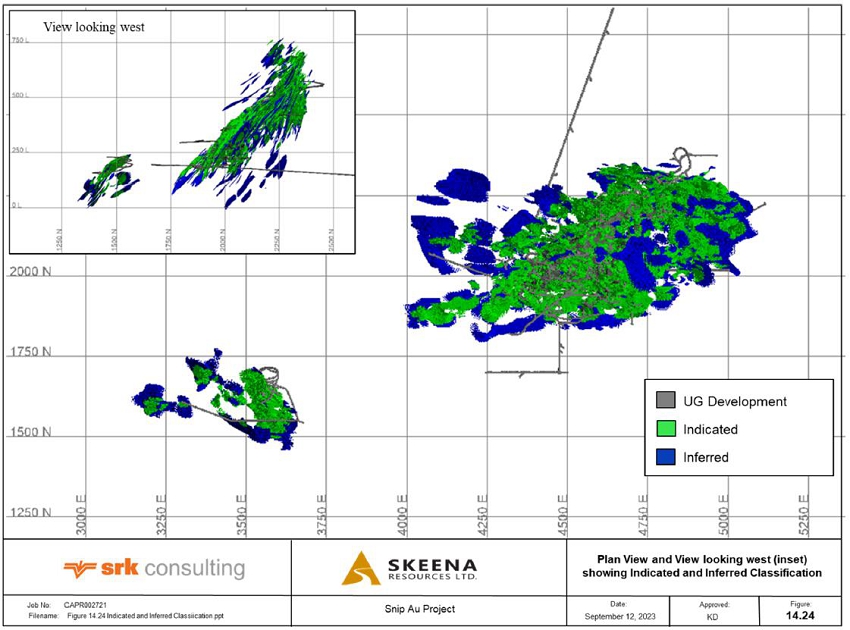

Classification followed CIM guidelines (CIM, 2019) and Indicated and Inferred resources were classified as follows.

| · | The Indicated category is defined by blocks interpolated during Pass 1 and 2 only, using a minimum of 3 drill holes, and an average distance of less than 35 meters (approximately 70% of the average variogram range). |

| · | The Inferred category is defined by blocks interpolated during Pass 1, 2 and 3, using a minimum of 2 drill holes and an average distance less than 75 meters (approximately 50% more than the average variogram range) |

| · | Blocks were locally reclassified to reduce ‘spotted’ Indicated resources within Inferred resources, and vice versa. |

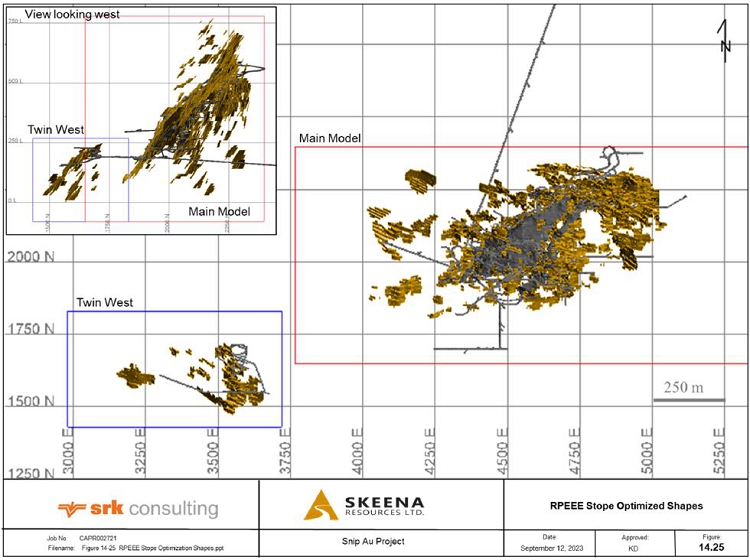

The calculated underground cut-off grade was determined to be 2.5 g/t Au. Reasonable prospects for eventual economic extraction were determined by means of applying reasonable stope optimizer parameters in Deswik® software. The resources are reported in-situ and undiluted within the veins in potentially economical and minable underground long hole stope shapes.

The Snip Project contains 2.739 million tonnes grading 9.35 g/t Au in the Indicated category and 0.499 million tonnes grading 7.10 g/t Au in the Inferred category. The mineral resources as estimated and reported on September 05, 2023, are summarized in Table 1-1.

Table 1-1: Mineral Resource Statement*, Snip Project, Iskut River Region, SRK Consulting, effective date September 05, 2023

| Category | Zone | Tonnes (000) |

Contained Grade Au (g/t) |

Contained Ounces Au (000) |

||||||||||

| Main – V | 850 | 9.59 | 262 | |||||||||||

| Indicated | Main – S | 1,718 | 9.28 | 513 | ||||||||||

| Twin West | 171 | 8.69 | 48 | |||||||||||

| Total Indicated | 2,739 | 9.35 | 823 | |||||||||||

| Main – V | 115 | 7.38 | 27 | |||||||||||

| Inferred | Main – S | 323 | 6.22 | 65 | ||||||||||

| Twin West | 61 | 11.02 | 22 | |||||||||||

| Total Inferred | 499 | 7.10 | 114 | |||||||||||

*Notes to accompany the Mineral Resource Estimate statement:

| · | Mineral resources are not mineral reserves as they do not have demonstrated economic viability. |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| · | As defined by NI 43-101, the Independent and Qualified Person is Ms. S. Ulansky, PGeo of SRK Consulting (Canada) who has reviewed and validated the Mineral Resource Estimate. |

| · | The effective date of the Mineral Resource Estimate is September 05, 2023. |

| · | The number of metric tonnes and ounces were rounded to the nearest thousand. Any discrepancies in the totals are due to rounding. |

| · | Reasonable prospects for eventual economic extraction were determined by means of applying stope optimization parameters summarized in Table 14-14. Resources are reported in-situ and undiluted within the veins contained in potentially economical and minable underground long hole stope shapes. |

| · | Cut-off grades are based on a price of US$1,700 per ounce of gold. |

| · | Estimates use metric units (meters, tonnes and g/t). Metals are reported in troy ounces (metric tonne * grade / 31.10348) |

| · | CIM definitions were followed for the classification of mineral resources. |

| · | Neither the company nor SRK is aware of any known environmental, permitted, legal, title-related, taxation, socio-political, marketing or other relevant issue that could materially affect this mineral resource estimate. |

| 1.8 | Interpretations and Conclusions |

Key interpretations and conclusions are based on SRK’s development of the Mineral Resource estimate, knowledge of the Snip mineralization system, as well as from site visit evaluations conducted in July 2020:

| · | Gold mineralization occurs in structurally controlled mineralized veins in a brittle-ductile shear zone system, hosted within a sequence of laminated turbidites of the Upper Triassic Stuhini Group. Mineralization has both Orogenic style gold characteristics as well as mineralogical and paragenetic similarities to porphyry related vein systems, being contemporaneous with the adjacent Early Jurassic Red Bluff porphyry, a calc-alkaline, I-type, magnetite-series intrusion of quartz monzodioritic composition. |

| · | Ninety-four narrow, high-grade lodes were modelled, which were combined into three distinct zones based on structure and orientation (V-, S-, TW- Veins). |

| · | The understanding of the regional geology and lithological and structural controls of mineralization are sufficient to support estimation of Mineral Resources. |

| · | The quantity and quality of the lithological, collar and down-the-hole survey data collected are sufficient to support Mineral Resources. Sample data density and distribution is adequate to build meaningful litho-structural models reflective of the overall deposit type. |

| · | SRK reviewed the database and is of the opinion that the current sample preparation, security, and analytical procedures meet industry-standard practices. SRK also believes that the Skeena validated database is of a standard that is acceptable for creating an unbiased, representative Mineral Resource Estimate of the Snip deposit. |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| · | SRK reviewed the analytical quality control data accumulated by Skeena during 2016 to 2021 and Hochschild in 2022. SRK confirms that gold grades are reasonably well reproduced and reliable for resource estimation purposes. Similarly, a QA/QC analysis showed no obvious bias or errors. |

| · | Twin drill hole evaluations of historical and recent drill holes show comparable gold intercepts and grade, allowing the historical dataset to be utilized without any constraints. |

| · | Geostatistical analyses were carried out on the composite data to select capping levels and derive estimation parameters. Gold was estimated into the block model using Ordinary Kriging informed from capped, composited data. Density, used for deriving tonnages, was coded into each block based on specific gravity measurements in select lithology groupings. |

| · | Mineral Resources were estimated and classified following CIM best practices. |

| · | The 2023 Mineral Resource demonstrates that the project has development potential as an underground mining operation. Stope optimized shapes were created using reasonable assumptions for long hole mining with a cut-off grade of 2.5 g/t Au. |

| · | Modelled veins delineate in-situ gold grade and do not consider minimum width or potential planned mining dilution, which would be considered during conversion of mineral resources to mineral reserves. |

| · | Indicated Mineral Resources are estimated to be 2.739 million tonnes grading 9.35 g/t Au. |

| · | Inferred Mineral Resources are estimated to be 0.499 million tonnes grading 7.10 g/t Au. |

| · | Approximately one tenth of the resource is classified as Inferred. It is reasonable to expect that part of the Inferred mineral resource may be upgraded to the Indicated mineral resource category with continued drilling. |

| · | Additionally, it is reasonable to expect an increase to the Inferred category if future exploration campaigns test underexplored areas and/or the continuity of sparsely drilled regions. |

The 2023 Mineral Resource Estimate involves several key changes when compared to the 2020 Mineral Resource Estimate. The changes are as follows:

| · | Additional drill holes included. |

| · | Expanded and updated mineralization vein model volumes. |

| · | Overall reduction in grade in the additional drill holes. |

| · | Twin drilling program validation of all historical holes. |

| · | Lifting of the 2020 40-meter omnidirectional 3-D buffer for the Indicated category due to the twin drilling program. |

| · | Stope optimizer adjustments. |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| · | Additional specific gravity measurements collected and used to update the model density values. |

| 1.9 | Recommendations |

In reviewing the compiled drill hole database, geological interpretation and mineral resource estimate for the Snip Project, SRK makes the following recommendations:

| 1.9.1 | Geology/Exploration |

| · | The intimate association of biotite with shear zones and veining and overall homogeneity of potassic (biotitic) alteration suggests that the alteration envelope may help constrain fluid and mineralization pathways. It is recommended that alteration data are used to investigate the potential to delineate alteration domains and generate alteration models to identity potential ore shoots within the shear zone system. This should be completed as a part of the standard geological logging and mapping observations, and as such, does not need a separate budget. |

| · | All occurrences and locations of visible gold should be standardized and combined with drill hole data to generate a high-grade gold model. This should be used to define zones of high grade that can potentially be used as a predictive tool to delineate further zones of higher-grade gold and/or ore shoots within the shear zone system. This will assist in improved local resolution of high-grade zones for resource estimation. This should be completed as a part of the standard geological logging and mapping process, and as such, would not require a separate budget. |

| · | A detailed vein model was constructed in Leapfrog Geo®. To further substantiate the model and elucidate the finer project scale structural details that are relevant to Snip mineralization, an onsite structural mapping survey is recommended. Budget recommendations are provided in Table 18-1. |

| · | Regional geology and structure play a significant role in interpreting exploration geological datasets. To effectively understand geological context within the broader district, an improved regional geology map needs to be sourced and included into the Leapfrog Geo® model. |

| · | The existing LiDAR survey covers the mineral lease area only. To extract subtle property-wide structural details, which may be applied to regional exploration, an expanded LiDAR survey that covers the entire property is recommended with an appropriate structural interpretation: |

| – | In tandem with the LiDAR survey, a high-resolution magnetics survey using drone surveying technologies would enhance future structural interpretations. This geophysical survey may be combined with the regional LiDAR survey to reduce exploration costs. Costs associated with this LiDAR-add one have not been included. |

| · | Knowing that Snip ore is structurally controlled, advancing the project depends heavily on understanding the structural complexities of the deposit. Oriented core drilling facilitates measurements of the directional properties in the rock and is used to measure bedding, foliation, vein orientations, shear fabrics and other kinematic indicators. SRK recommends the use of oriented core drilling for future drilling campaigns. |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| · | Limited drilling has been conducted on the Jim Porphyry and Jim Porphyry south areas which exhibit similar alteration and lithological similarities with the Main Twin Zone. Knowing the narrow and variable nature of mineralization on the property, an additional 2 holes are recommended to fully test these targets. |

| 1.9.2 | Sampling |

| · | The grade appropriate standard needs to be inserted into the sample series. This is particularly important for the high-grade standards where they should, ideally, be inserted into a series of high-grade intervals only. |

| · | Preparation and pulp duplicates are inserted by the lab at a sequence that the lab defines. Additional preparation and pulp duplicates should be requested at intervals defined by Skeena to avoid intralab bias and to reflect the entire gold range that defines the Snip Project. This should be completed as a part of the standard sampling process, and as such, does not need a separate budget. |

| · | External check samples need to be consistently taken and processed at SGS Canada in a timely manner. This should be completed as a part of the standard sampling process, and as such, does not need a separate budget. |

| · | Sample rejects and pulps are not currently saved and stored. In the event of core damage, loss or tampering, rejects and pulps will serve to validate the deposit’s primary asset – the assay database. Therefore, sample rejects and pulps should be stored as a part of the standard QA/QC process, and as such, does not need a separate budget. |

| 1.9.3 | Resource Model |

| · | Due to the high degree of grade variability within the Snip deposit, SRK recommends conducting a conditional simulation study to assess the impact of localized grade variability within the mineral resource estimate and on future mine design and production planning. The simulated model could also be used to reconcile against historical production based on available historical stope and underground development wireframes. |

| 1.9.4 | Historical Confirmation |

| · | A basic property survey was conducted in 2017, whereby a new survey control point network was established. Differential GPS points from the 300-level portal were expanded underground and traversed up the ramp using a total station. To further this survey and to validate the volume of depleted material, a study to determine the accuracy of the levels relative to the historical wireframes is recommended. This should be completed as part of the standard data management process for the Snip Project, and as such, does not need a separate budget: |

| – | Depending on the outcome of the study, and if there are major differences in elevation and position, a more detailed survey will need to be undertaken. |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| – | Measured blocks have not been accounted for in the 2023 Mineral Resource Statement due to Client-specific requests. However, blocks that qualify in terms of having quantity, grade or quality, densities, shape and physical characteristics that are estimated with confidence to allow the application of modifying factors, are currently accessible. To convert additional areas from Indicated to Measured, having approximately 12.5 m centers, updated classification parameters need to be generated in future resource model runs. This process may be conducted as part of SRK’s proposed resource model conditional simulation study, whereby mineral resource classification criteria are reassessed to potentially support Measured resources. |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

Table of Contents

| 1 | Executive Summary | ii | ||

| 1.1 | Introduction | ii | ||

| 1.2 | Property Location and Ownership | ii | ||

| 1.3 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | iii | ||

| 1.4 | History, Exploration and Drilling | iii | ||

| 1.5 | Geology and Mineralization | v | ||

| 1.6 | Metallurgical Test Work | vi | ||

| 1.7 | Mineral Resource and Mineral Reserve Estimates | vi | ||

| 1.8 | Interpretations and Conclusions | ix | ||

| 1.9 | Recommendations | xi | ||

| 1.9.1 | Geology/Exploration | xi | ||

| 1.9.2 | Sampling | xii | ||

| 1.9.3 | Resource Model | xii | ||

| 1.9.4 | Historical Confirmation | xii | ||

| 2 | Introduction and Terms of Reference | 1 | ||

| 2.1 | Scope of Work | 1 | ||

| 2.2 | Work Program | 2 | ||

| 2.3 | Basis of Technical Report | 2 | ||

| 2.4 | Qualifications of SRK and SRK Team | 3 | ||

| 2.5 | Site Visit | 4 | ||

| 2.6 | Acknowledgement | 4 | ||

| 2.7 | Declaration | 4 | ||

| 3 | Reliance on Other Experts | 5 | ||

| 4 | Property Description and Location | 6 | ||

| 4.1 | Mineral Tenure | 8 | ||

| 4.2 | Underlying Agreements | 11 | ||

| 4.3 | Barrick Agreement | 11 | ||

| 4.4 | Hochschild Option | 11 | ||

| 4.5 | Historical NSR | 12 | ||

| 4.6 | Environmental Issues | 12 | ||

| 5 | Accessibility, Climate, Local Resources, Infrastructure and Physiography | 13 | ||

| 5.1 | Accessibility | 13 | ||

| 5.1.1 | Aircraft Infrastructure | 13 | ||

| 5.1.2 | Road Access | 15 | ||

| 5.2 | Local Resources and Infrastructure | 15 | ||

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| 5.3 | Climate and Vegetation | 15 | ||

| 5.3.1 | Climate | 15 | ||

| 5.3.2 | Vegetation | 16 | ||

| 5.4 | Physiography | 16 | ||

| 6 | History | 18 | ||

| 6.1 | Exploration, 1900 - 1987 | 18 | ||

| 6.2 | Development and Mining, 1988 – 1999 | 19 | ||

| 6.3 | Post Mining, 1999-2016 | 25 | ||

| 6.4 | Mine Closure | 25 | ||

| 6.5 | Environmental Monitoring | 26 | ||

| 7 | Geological Setting and Mineralization | 27 | ||

| 7.1 | Regional Geology | 27 | ||

| 7.2 | Property Geology | 29 | ||

| 7.2.1 | Lithology | 31 | ||

| 7.3 | Structure | 33 | ||

| 7.4 | Mineralization | 34 | ||

| 8 | Deposit Types | 36 | ||

| 9 | Exploration | 38 | ||

| 9.1 | 2016 | 38 | ||

| 9.1.1 | Geochemistry | 38 | ||

| 9.1.2 | Geophysics | 41 | ||

| 9.2 | 2017 | 41 | ||

| 9.2.1 | LiDAR Survey | 41 | ||

| 9.3 | 2019 | 41 | ||

| 9.3.1 | Petrography | 41 | ||

| 10 | Drilling | 44 | ||

| 10.1 | Historical Drilling (pre-1999) | 44 | ||

| 10.2 | Skeena Resources Drilling (2016 to 2021) | 47 | ||

| 10.3 | Hochschild Drilling (2022) | 47 | ||

| 10.4 | Drill Coordinates, Downhole Surveys and Contractors | 48 | ||

| 10.4.1 | Historical | 48 | ||

| 10.4.2 | Skeena Drilling | 48 | ||

| 10.4.3 | Hochschild Drilling | 49 | ||

| 10.5 | Drill Hole Logging | 50 | ||

| 10.6 | Recovery | 50 | ||

| 10.7 | Completion of Drilling | 50 | ||

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| 10.8 | Skeena Drilling | 50 | ||

| 10.8.1 | 2016 – Surface Drilling | 50 | ||

| 10.8.2 | 2017 – Underground Drilling | 51 | ||

| 10.8.3 | 2018 – Surface Drilling | 54 | ||

| 10.8.4 | Skeena Underground Drilling, 2018 | 54 | ||

| 10.8.5 | Skeena Surface Drilling, 2019 | 56 | ||

| 10.8.6 | Skeena Surface Drilling, 2020 | 56 | ||

| 10.8.7 | Skeena Surface Drilling, 2021 | 56 | ||

| 10.8.8 | Skeena Underground Drilling, 2021 | 57 | ||

| 10.8.9 | Hochschild Surface Drilling, 2022 | 57 | ||

| 10.8.10 | Hochschild Underground Drilling, 2022 | 57 | ||

| 10.9 | SRK Comments | 57 | ||

| 11 | Sample Preparation, Analyses, and Security | 59 | ||

| 11.1 | Sample Preparation, Analysis, and Security | 59 | ||

| 11.1.1 | Drill Hole Sampling | 59 | ||

| 11.1.2 | Sample Preparation and Analysis by Analytical Laboratory | 61 | ||

| 11.1.3 | Specific Gravity and Bulk Density | 62 | ||

| 11.2 | Quality Assurance and Quality Control | 62 | ||

| 11.3 | Qualified Person’s Opinion on Quality Assurance and Quantity Control | 76 | ||

| 12 | Data Verification | 78 | ||

| 13 | Mineral Processing and Metallurgical Testing | 83 | ||

| 13.1 | Introduction | 83 | ||

| 13.2 | Metallurgical Test Work | 83 | ||

| 13.2.1 | Historical Operations at the Snip Mine | 83 | ||

| 13.2.2 | 2020 Metallurgical Test Work Program | 83 | ||

| 13.2.3 | 2021 Phase 1 Metallurgical Test Work Program | 87 | ||

| 13.2.4 | Phase 2 2022 Metallurgical Testing Program | 91 | ||

| 13.3 | Deleterious Elements | 104 | ||

| 13.4 | Recovery Estimates | 104 | ||

| 14 | Mineral Resource Estimates | 105 | ||

| 14.1 | Introduction | 105 | ||

| 14.2 | Resource Database | 106 | ||

| 14.3 | Solid Body Modelling | 109 | ||

| 14.3.1 | Geological Modelling | 109 | ||

| 14.3.2 | Mineralization Model | 109 | ||

| 14.3.3 | Historical Mining Zones | 112 | ||

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

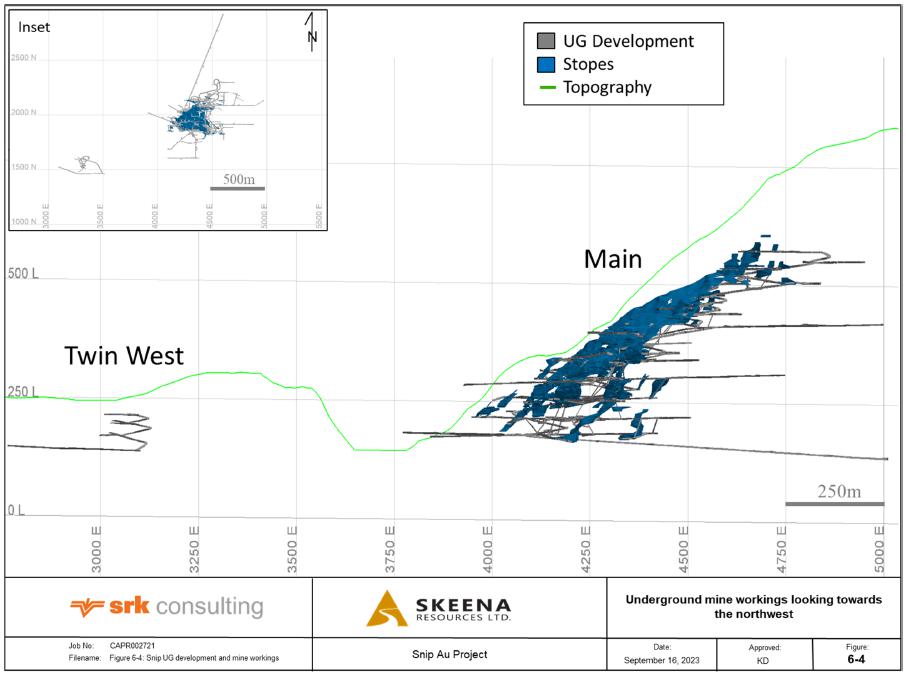

| 14.3.4 | Underground Workings | 114 | ||

| 14.4 | Data Analysis | 116 | ||

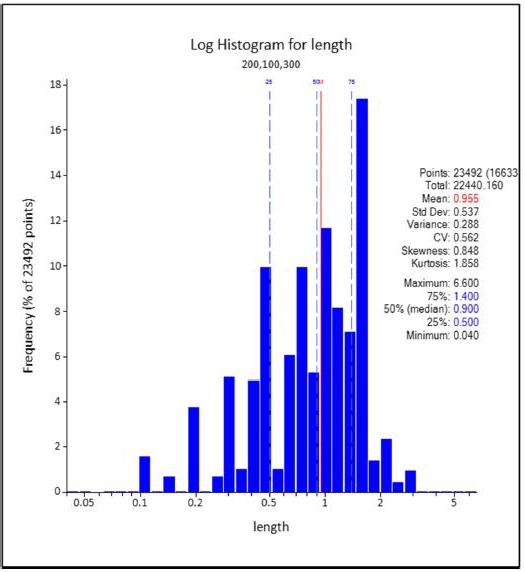

| 14.4.1 | Sample length | 116 | ||

| 14.4.2 | Assay Grade Summary | 117 | ||

| 14.4.3 | Unsampled Intervals | 117 | ||

| 14.5 | Compositing | 118 | ||

| 14.6 | Evaluation of Outliers | 119 | ||

| 14.7 | Statistical Analysis and Variography | 123 | ||

| 14.8 | Specific Gravity | 128 | ||

| 14.9 | Block Model and Grade Estimation | 129 | ||

| 14.10 | Model Validation | 133 | ||

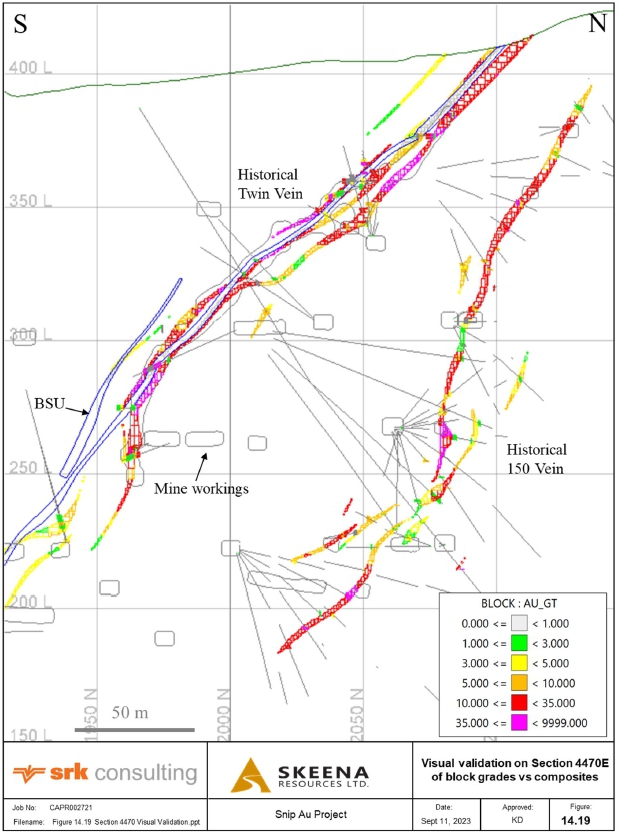

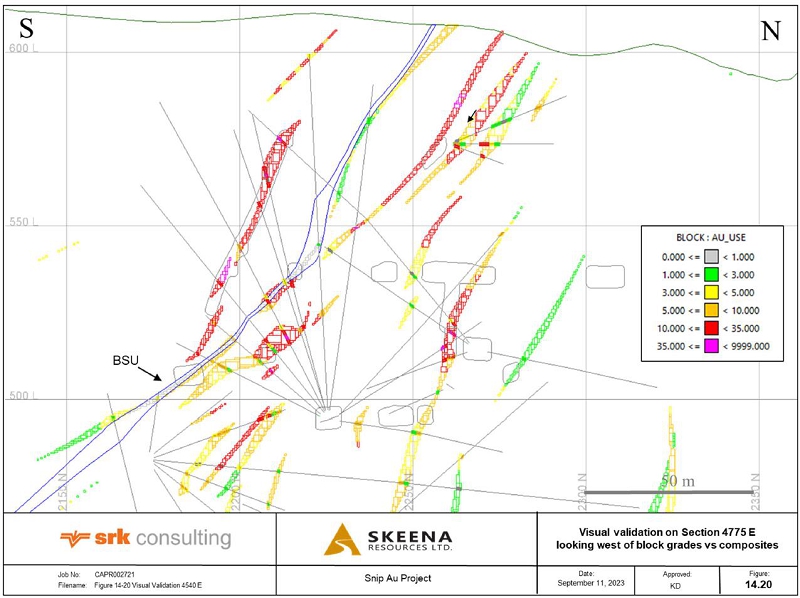

| 14.10.1 | Block Model Visual Validation | 133 | ||

| 14.10.2 | Global Grade Bias Check | 137 | ||

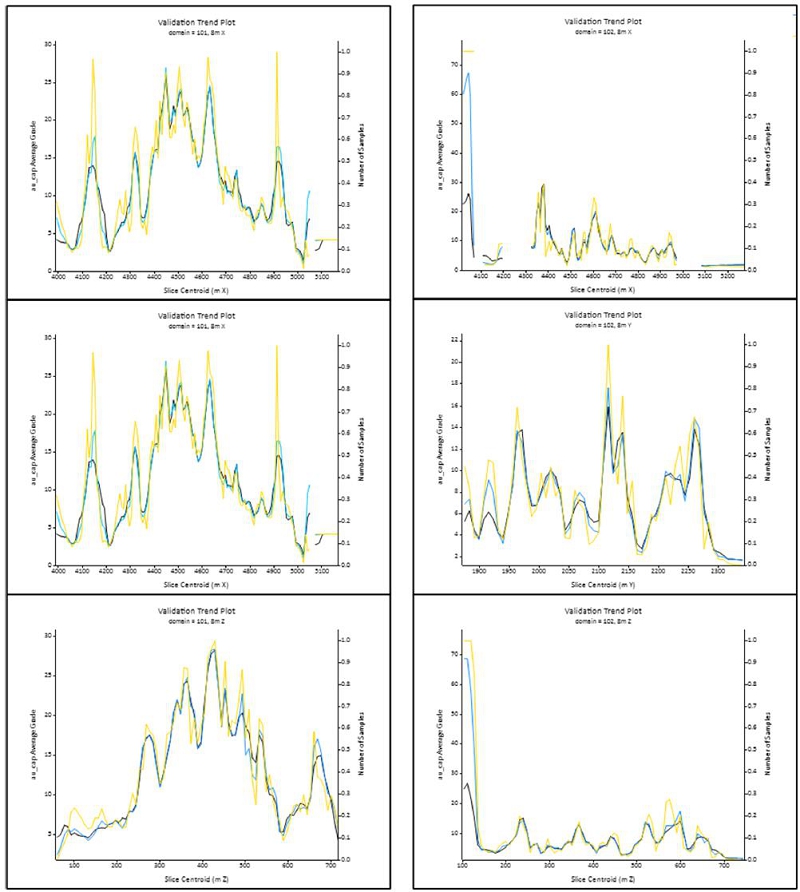

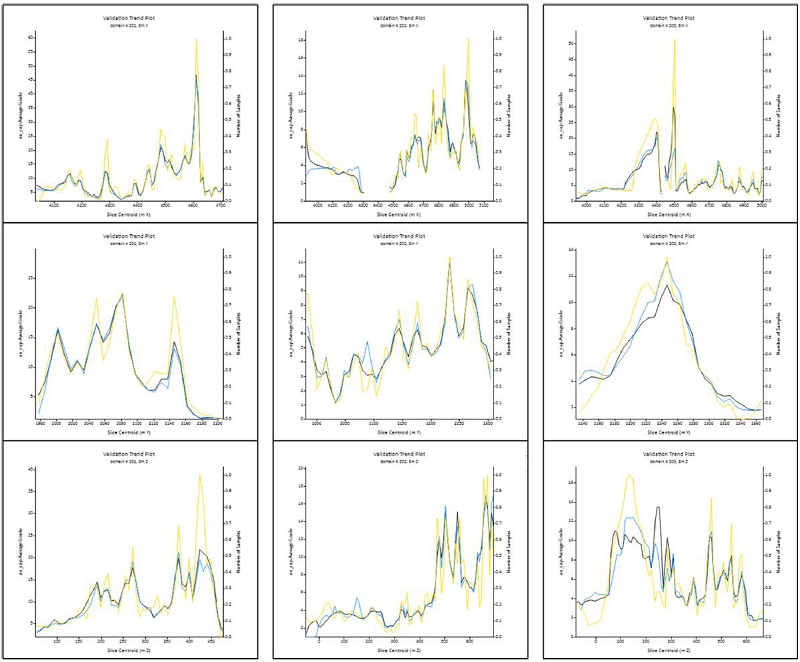

| 14.10.3 | Local Grade Bias Check | 137 | ||

| 14.11 | Mineral Resource Classification | 141 | ||

| 14.12 | Mineral Resource Statement | 143 | ||

| 14.13 | Comparison to Previous Mineral Resource Estimate | 149 | ||

| 14.14 | Factors that May Affect the Mineral Resource Estimates | 150 | ||

| 14.15 | Responsibility for the Snip Resource Estimate | 151 | ||

| 15 | Adjacent Properties | 152 | ||

| 15.1 | SnipGold Corp. (a Subsidiary of Seabridge Gold) | 152 | ||

| 15.1.1 | Stonehouse Deposit | 152 | ||

| 15.1.2 | Bronson Slope | 154 | ||

| 16 | Other Relevant Information | 155 | ||

| 16.1 | Road Access | 155 | ||

| 16.2 | Hydroelectric Infrastructure | 155 | ||

| 17 | Interpretation and Conclusions | 156 | ||

| 17.1 | Mineral Tenure, Surface Rights, Agreements, and Royalties | 156 | ||

| 17.2 | Geology and Mineralization | 156 | ||

| 17.3 | Data Analysis | 156 | ||

| 17.4 | Mineral Resource Estimation | 157 | ||

| 18 | Recommendations | 158 | ||

| 18.1 | Geology/Exploration | 158 | ||

| 18.2 | Sampling | 159 | ||

| 18.3 | Resource Model | 159 | ||

| 18.4 | Historical Confirmation | 159 | ||

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| 19 | Acronyms and Abbreviations | 161 |

| 20 | References | 162 |

| 21 | Date and Signature Page | 166 |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

List of Tables

| Table 1-1: Mineral Resource Statement*, Snip Project | viii |

| Table 2-1: Qualified Persons who prepared or contributed to the Technical Report | 3 |

| Table 2-2: Other Experts who assisted the Qualified Persons | 3 |

| Table 4-1: Mineral claim information | 10 |

| Table 4-2: Mineral lease information | 10 |

| Table 6-1: Snip Mine production by zone (Homestake, 1998) | 21 |

| Table 6-2: Snip Mine production by mining method | 21 |

| Table 6-3: Plant production annual summaries | 22 |

| Table 7-1: Mineralization types in the Main Twin Zone (Rhys, 1993) | 35 |

| Table 10-1: Summary of historical surface and underground holes drilled by year | 44 |

| Table 10-2: Skeena surface and underground drill hole targets | 47 |

| Table 10-3: Skeena surface and underground drill hole targets | 47 |

| Table 10-4: Significant Intercepts from the 2016 drill program | 51 |

| Table 10-5: Significant Intercepts from the 2019 drill program | 56 |

| Table 11-1: Sample preparation and analytical methods conducted on Snip Project | 61 |

| Table 11-2: Specific gravity measurements between 2016 and 2022 | 62 |

| Table 11-3: Summary of field control samples per assay year | 65 |

| Table 11-4: Standards utilized between the 2016 and 2022 drilling campaigns | 66 |

| Table 11-5: Summary of standards inserted per assay year, including failure results | 66 |

| Table 11-6: Blank failures per assay year | 72 |

| Table 11-7: No. of duplicates and percentages per year | 74 |

| Table 13-1: 2020 Samples - Chemical Analysis | 84 |

| Table 13-2: Bond Mill Work Index Determination Determined at 106 microns Classification Size | 85 |

| Table 13-3: Rougher/Gravity results | 86 |

| Table 13-4: 2021 Master Composite Sample Assays | 88 |

| Table 13-5: 2021 Master Composite Sample - Bulk Mineralogy Analysis | 88 |

| Table 13-6: 2021 Master Composite Sample Sulphur Deportment Results | 89 |

| Table 13-7: Snip 2021 E-GRG Test Results | 89 |

| Table 13-8: Snip Phase 1 Leach Test Conditions | 90 |

| Table 13-9: Snip 2021 Leach Test Results | 90 |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| Table 13-10: Snip 2021 Combined Gravity/Flotation Leach Test Results | 90 |

| Table 13-11: 2022 Metallurgical Samples | 91 |

| Table 13-12: Snip Phase 2 Sample Assays | 94 |

| Table 13-13: 2022 Samples Bulk Mineralogy Analysis (BMA) | 95 |

| Table 13-14: Snip Comminution Tests Results | 97 |

| Table 13-15: Snip Phase 2 E-GRG Test Results | 97 |

| Table 13-16: Snip 2022 Flotation Tests Results | 98 |

| Table 13-17: 2022 Leach Test Results | 99 |

| Table 13-18: 2022 Variability Samples Leach Test Result | 100 |

| Table 13-19: Snip Pre-Leach Dynamic Thickening Results | 103 |

| Table 13-20: Snip Pre-Leach Thickener Underflow Rheology Test Results | 103 |

| Table 14-1: Skeena drill hole database | 106 |

| Table 14-2: Zone volume difference between 2020 and 2023 | 109 |

| Table 14-3: Model naming convention and volumes | 110 |

| Table 14-4: Zones, number of veins, and associated historical name equivalents | 112 |

| Table 14-5: Summary statistics of length-weighted gold assays by zone | 117 |

| Table 14-6: Number of meters and percent of non-sampled meters within each of the zones | 118 |

| Table 14-7: Comparison of assay data to 1.5 m gold composites by domain | 119 |

| Table 14-8: Outlier threshold values and summary statistics of 1.5 m gold composites | 120 |

| Table 14-9: Gold variogram parameters per domain | 124 |

| Table 14-10: Specific gravity by lithology | 128 |

| Table 14-11: Block model details and specifications | 129 |

| Table 14-12: Estimation parameters | 132 |

| Table 14-13: Global gold grade bias | 137 |

| Table 14-14: Assumptions considered for stope optimization | 143 |

| Table 14-15: Snip underground Mineral Resource Statement as of September 05, 2023. | 144 |

| Table 14-16 Mean assay grade comparison | 149 |

| Table 14-17: Percent difference between the 2020 and 2023 MRE’s | 150 |

| Table 18-1: Estimated Cost for the Exploration Program Proposed for the Snip Project | 160 |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

List of Figures

| Figure 4-1: General location of the Snip Project | 7 |

| Figure 4-2: Land tenure map | 9 |

| Figure 5-1: Project access | 14 |

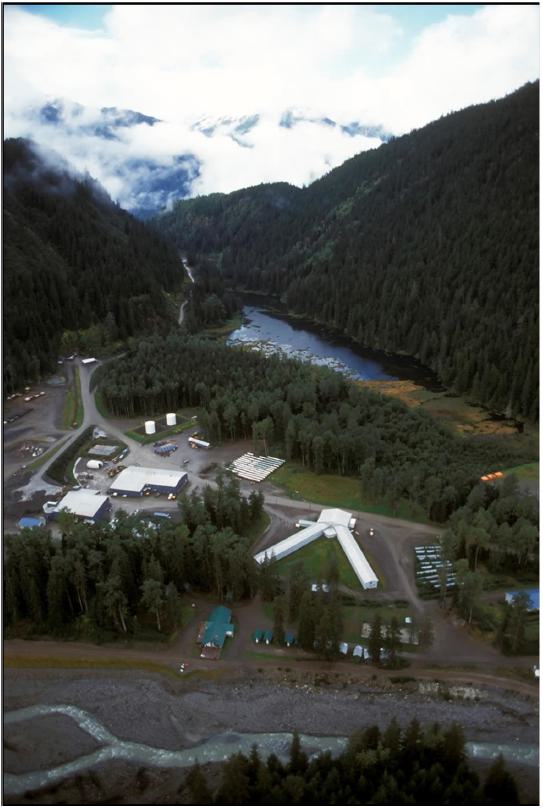

| Figure 5-2: View of the Snip Project looking south west | 17 |

| Figure 6-1: Snip mining operation, circa 1998, looking southwest | 20 |

| Figure 6-2: Recovery of gold from historical Snip Mine, circa 1998 | 22 |

| Figure 6-3: Mining at the historical Snip Mine, circa 1998 | 23 |

| Figure 6-4 Snip Mine underground mine workings | 24 |

| Figure 7-1: Regional Geology of the Bronson corridor area (Kyba and Nelson, 2015) | 28 |

| Figure 7-2 Property geology map | 30 |

| Figure 8-1: Schematic Geologic History of the Iskut River | 37 |

| Figure 9-1: Gold soil survey sample locations in ppb | 40 |

| Figure 9-2: 2016 geophysical survey magnetics, total field intensity | 42 |

| Figure 9-3: LiDAR survey map of Twin West and the Main Twin Zone area | 43 |

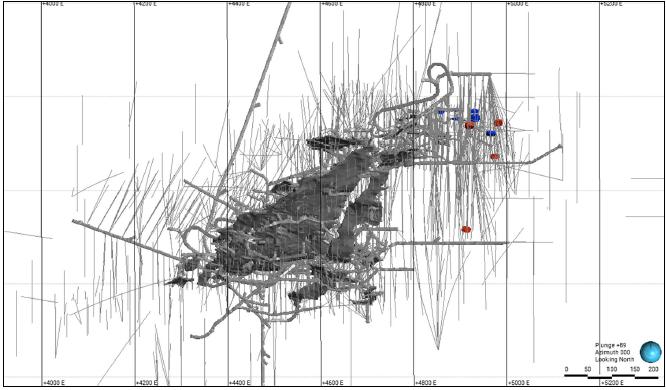

| Figure 10-1 Distribution of surface drilling on the Snip Project | 45 |

| Figure 10-2 Distribution of underground drilling at the Snip Project | 46 |

| Figure 10-3: Cross section 4895E of the unmined eastern Main Twin Zone | 52 |

| Figure 10-4: Cross section 4475E of the lower unmined Main Twin Zone | 53 |

| Figure 10-5: Cross section 4850E of the eastern Main Twin Zone | 55 |

| Figure 10-6: Cross section 4850E of the 412 area showing expansion of the veins from the 2021 drill program | 58 |

| Figure 11-1: Snip camp site core shack | 59 |

| Figure 11-2: Drill core cross piles at the Snip camp (photograph courtesy of C. Chung, 2020) | 60 |

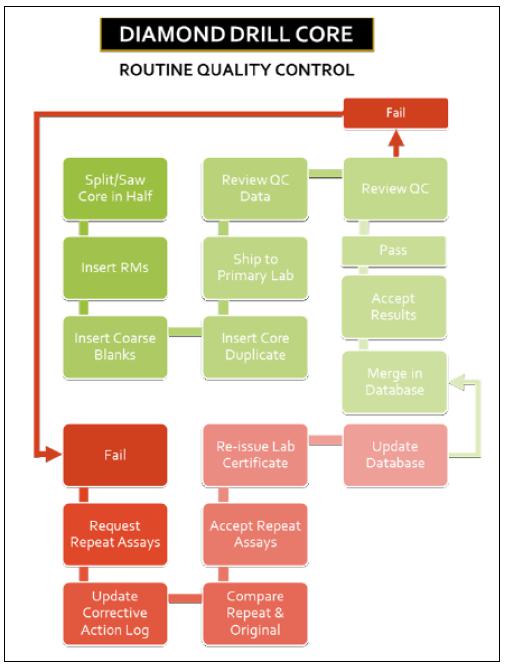

| Figure 11-3: Routine quality control flow chart | 63 |

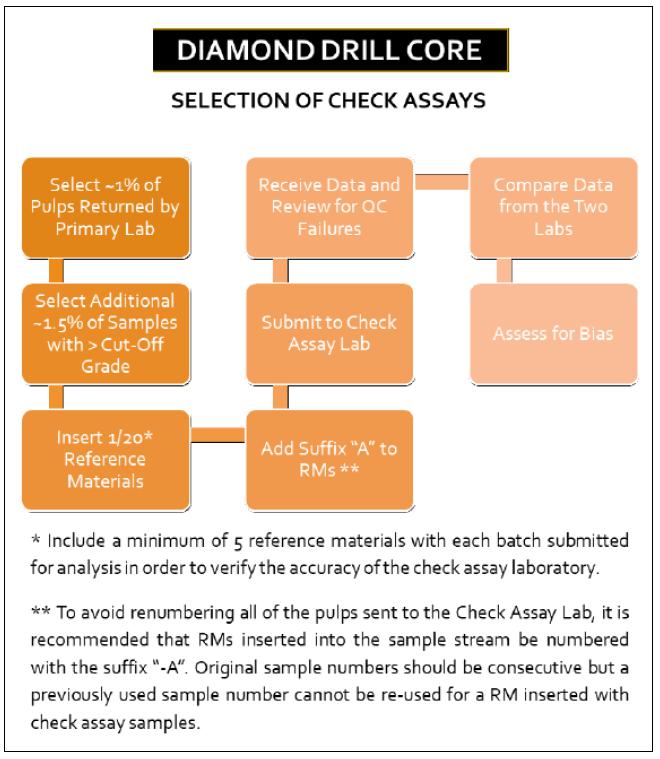

| Figure 11-4: Quarterly quality control flow chart | 64 |

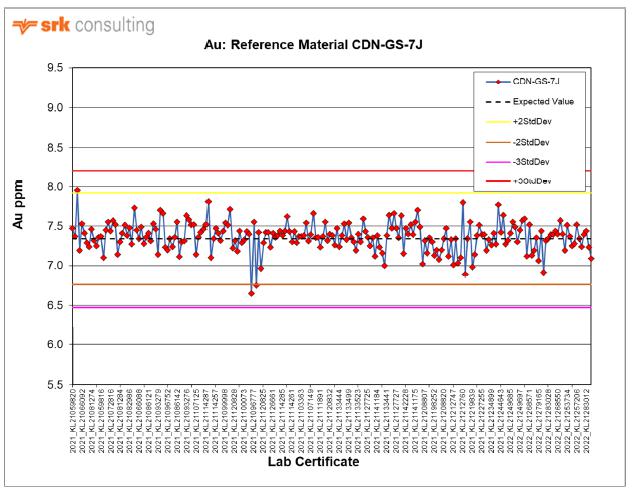

| Figure 11-5: 2021 and 2022 gold control chart for standard CDN-GS-7J | 68 |

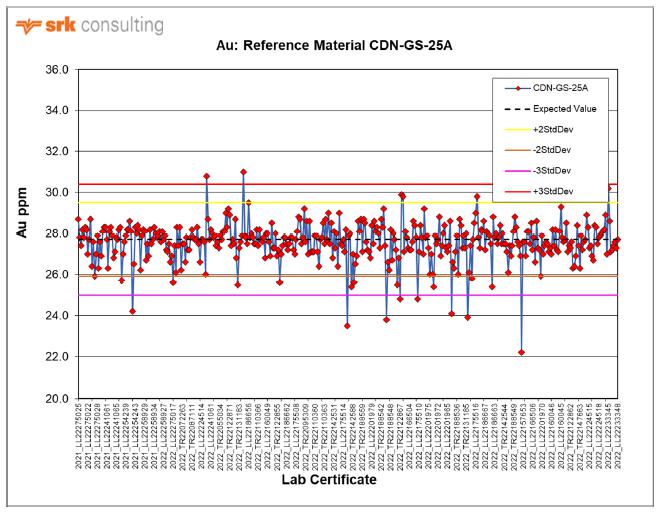

| Figure 11-6: 2021 and 2022 gold control chart for standard CDN-GS-25A | 69 |

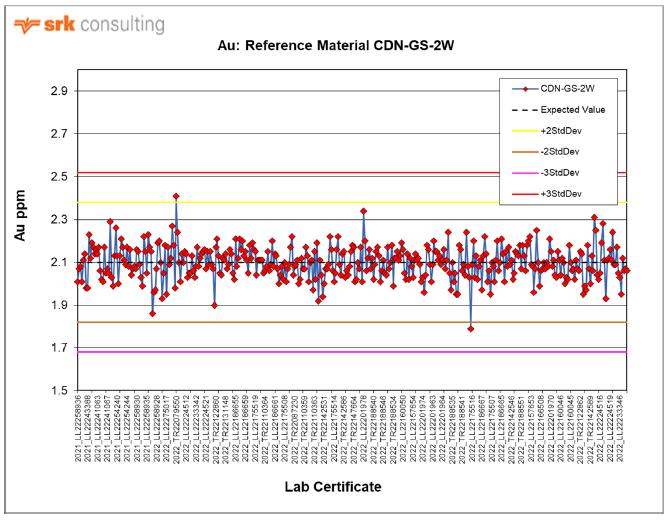

| Figure 11-7: 2021 and 2022 gold control chart for standard CDN-GS-2W | 70 |

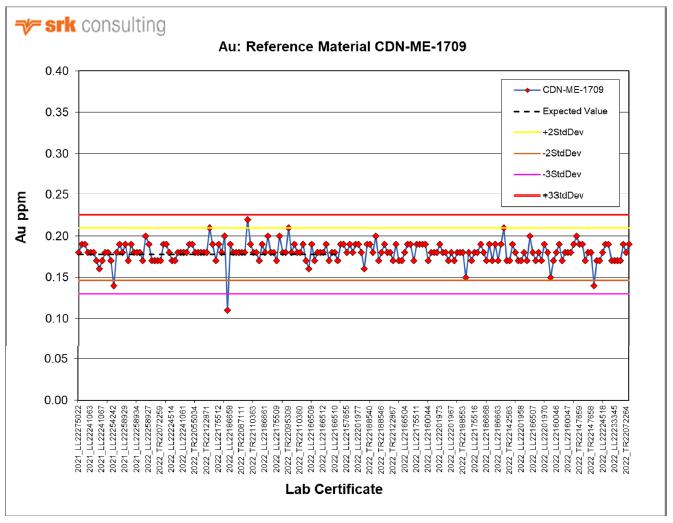

| Figure 11-8: 2021 and 2022 gold control chart for standard CDN-ME-1709 | 71 |

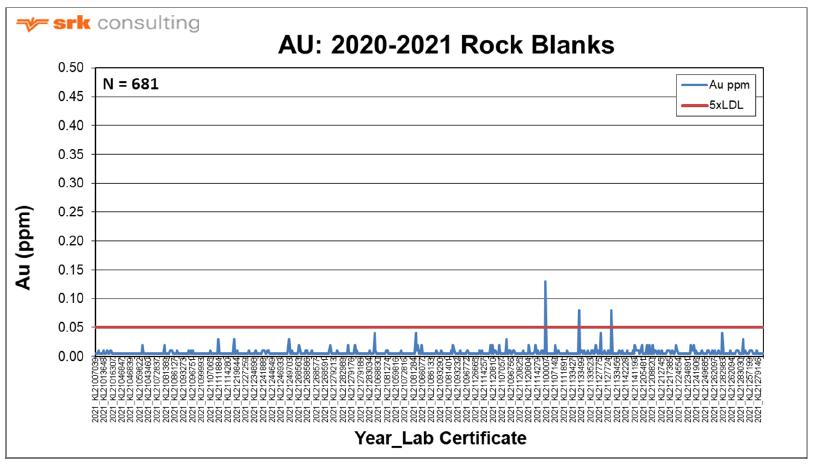

| Figure 11-9: 2020 to 2021 marble garden rock blanks | 72 |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

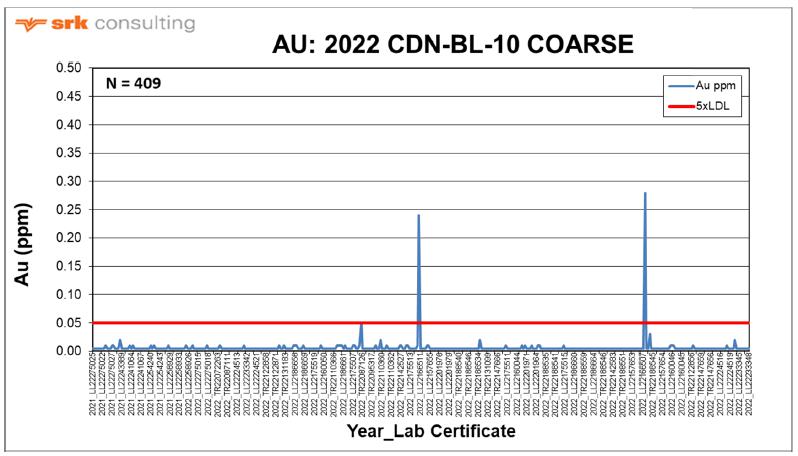

| Figure 11-10: 2022 certified blank material (CDN-BL-10 Coarse) | 73 |

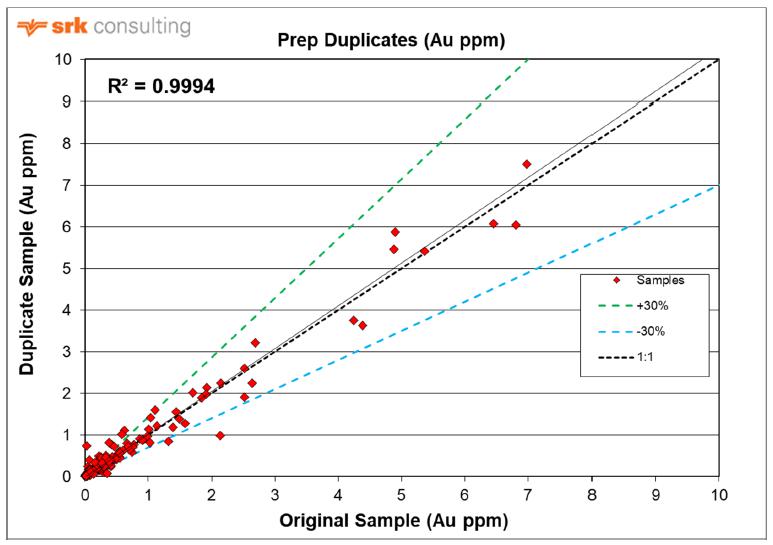

| Figure 11-11: 2022 prep duplicate scatter plot | 74 |

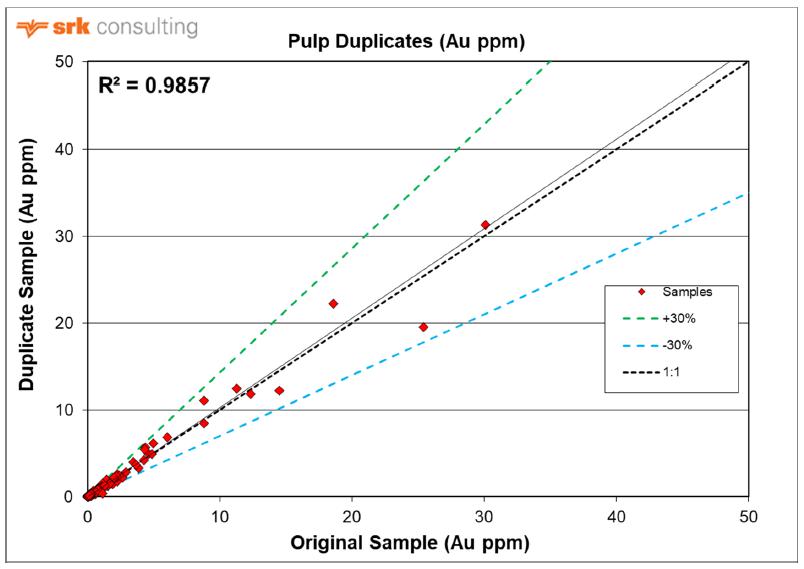

| Figure 11-12: 2022 pulp duplicate scatter plot | 75 |

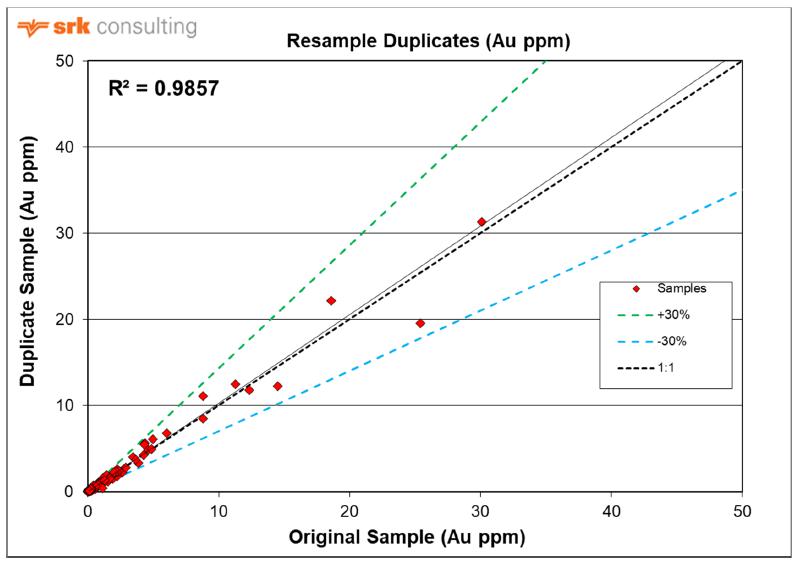

| Figure 11-13: 2022 resample duplicate scatter plot | 75 |

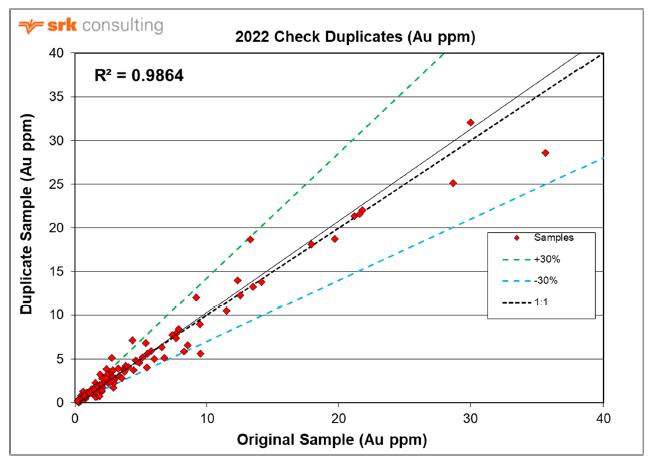

| Figure 11-14: 2022 check assay chart | 76 |

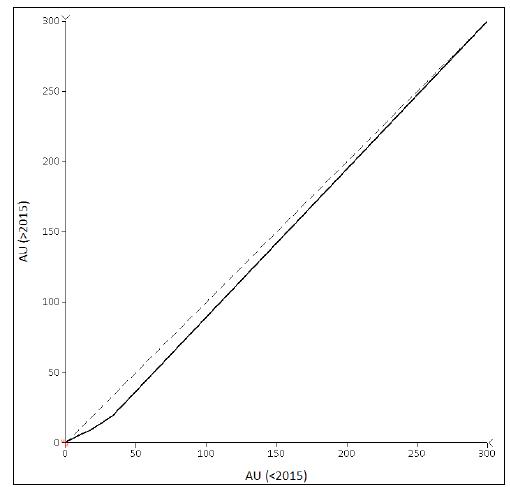

| Figure 12-1: Log Q-Q plot of historical holes (Y axis) | 78 |

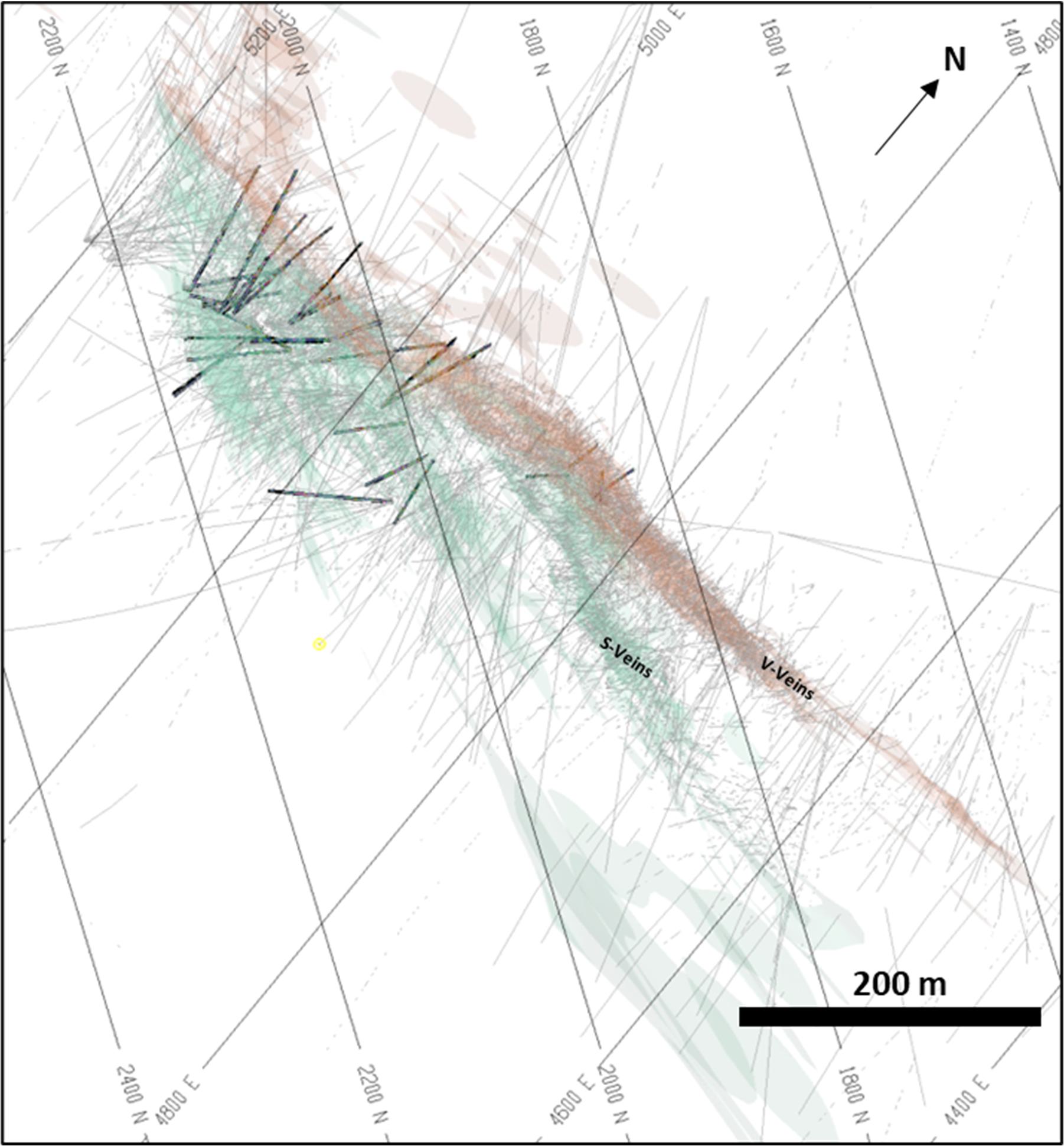

| Figure 12-2: Down dip view of all twin holes (in black) in relation to all Snip drilling | 79 |

| Figure 12-3. Equivalent vein intercepts for a twin pair | 80 |

| Figure 12-4. Thompson Howarth plot of all the equivalent vein intercept pairs | 81 |

| Figure 13-1: Sample Locations of the 2020 Metallurgical Intervals. Red = Composite 1 and Blue = Composite 2 | 84 |

| Figure 13-2: 2021 Snip Metallurgical Drill Hole Locations | 87 |

| Figure 13-3: Snip Phase 2 Metallurgical Test Samples Locations; Part 1 | 93 |

| Figure 13-4: 2022 Metallurgical Test Samples Locations; Part 2 | 93 |

| Figure 13-5: 2022 Comminution Test Samples Locations | 94 |

| Figure 13-6: 2022 Leach Tests Recovery as a Function of Head Grade | 101 |

| Figure 13-7: Dynamic Thickening Test Apparatus | 102 |

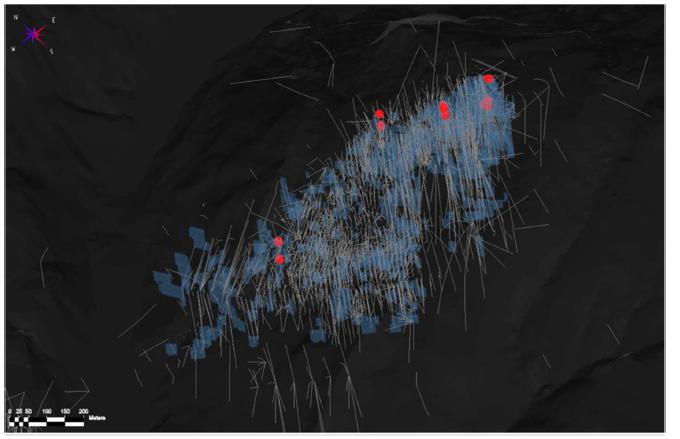

| Figure 14-1: Plan view of drill hole traces in the Snip database, excluding furthermost holes | 107 |

| Figure 14-2: Plan view of the new drill holes used in the updated 2023 MRE | 108 |

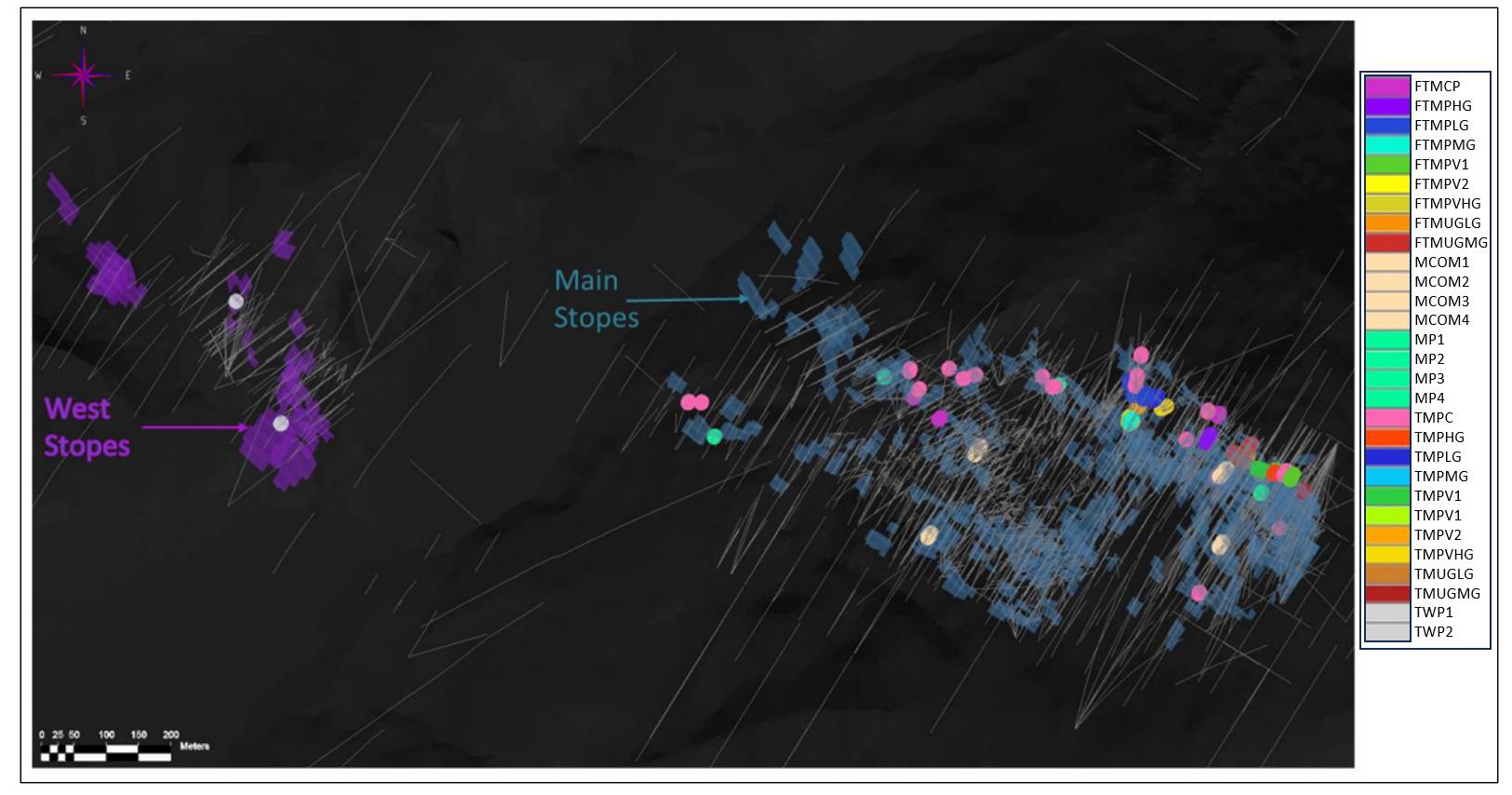

| Figure 14-3: Oblique view of the Snip vein model showing the V-veins | 111 |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

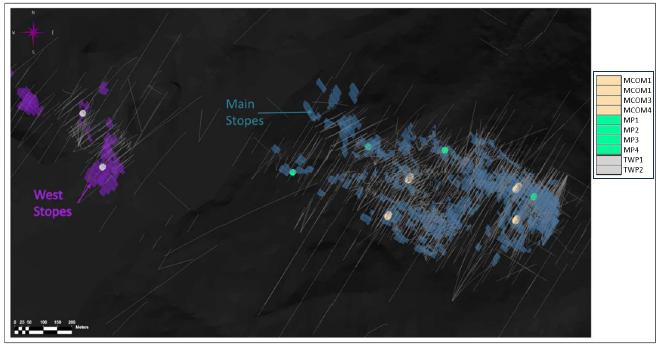

| Figure 14-4: Oblique view showing the V- and S- vein domains in relation to historical areas | 113 |

| Figure 14-5: Section 4500E showing historical underground development | 115 |

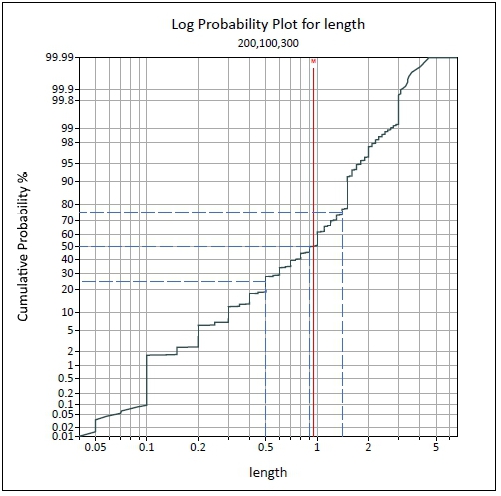

| Figure 14-6: Histogram statistics of vein-coded assay sample lengths | 116 |

| Figure 14-7: Log probability curve | 117 |

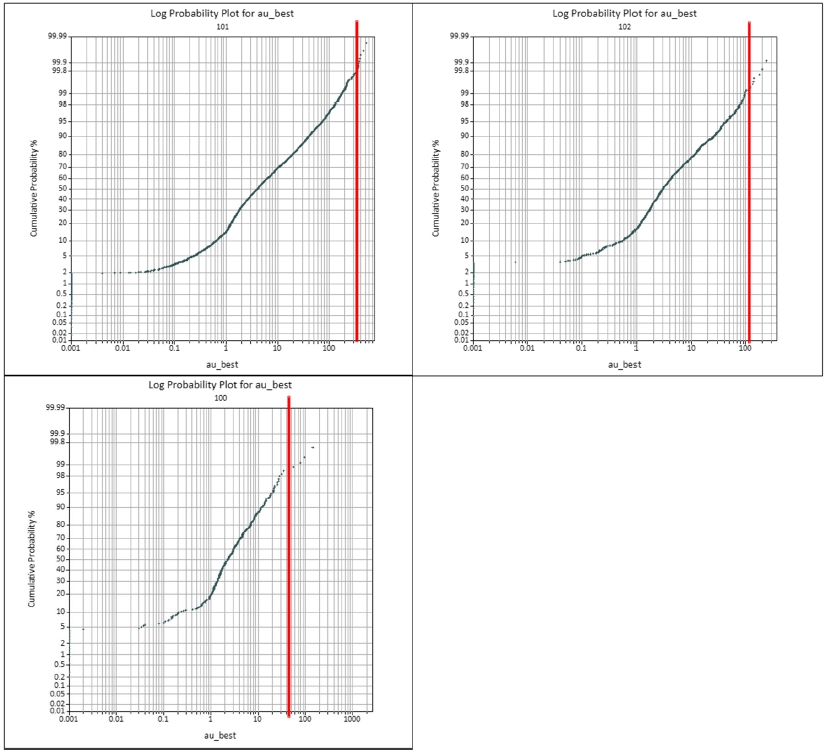

| Figure 14-8: V-veins cumulative log probability showing the chosen capping threshold for each domain | 121 |

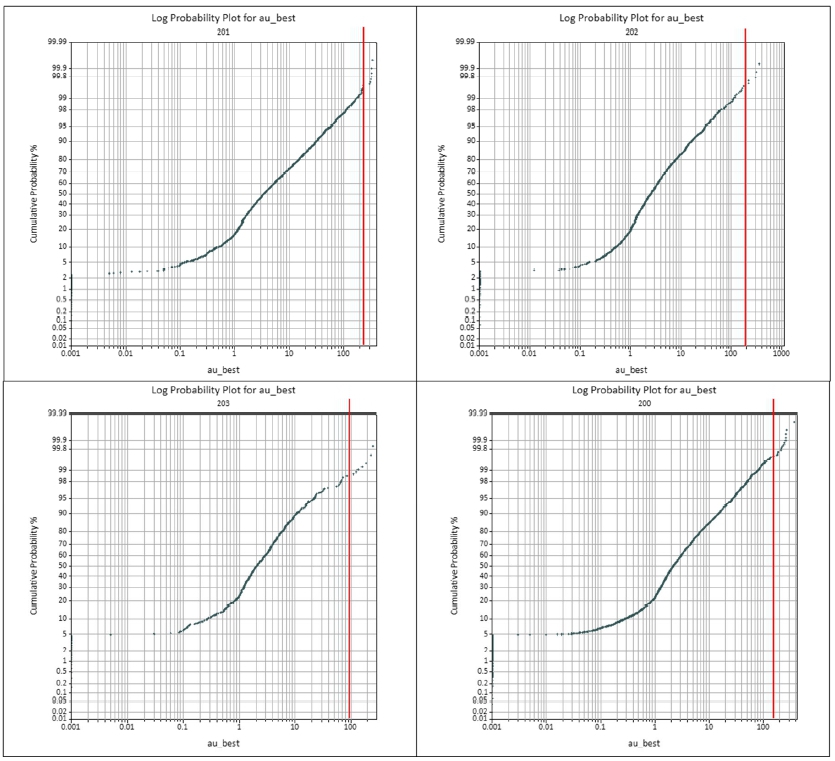

| Figure 14-9: S-veins cumulative log probability plot showing the chosen capping thresholds for each domain | 122 |

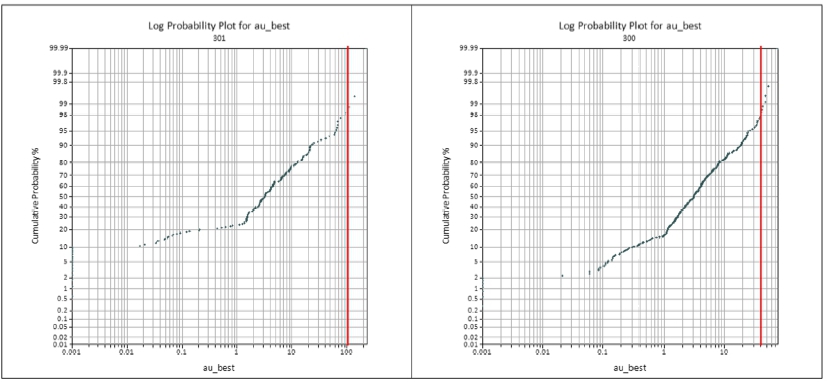

| Figure 14-10: TW-veins cumulative log probability plot showing the chosen capping thresholds for each domain | 123 |

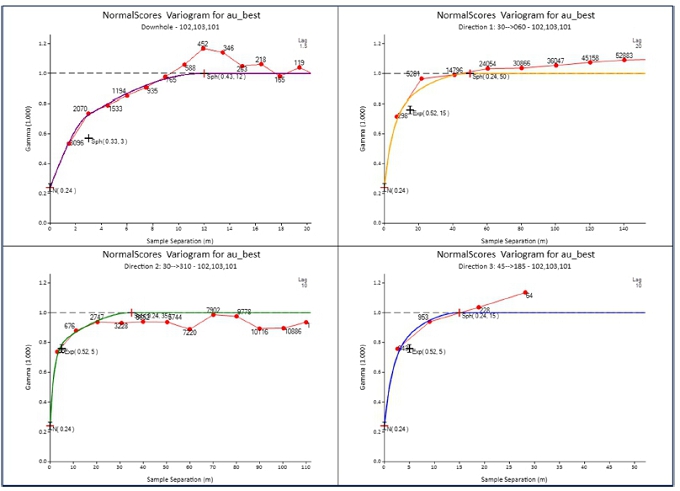

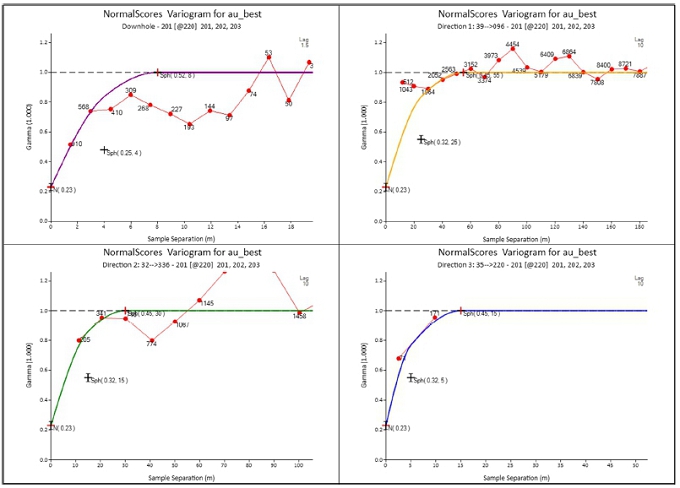

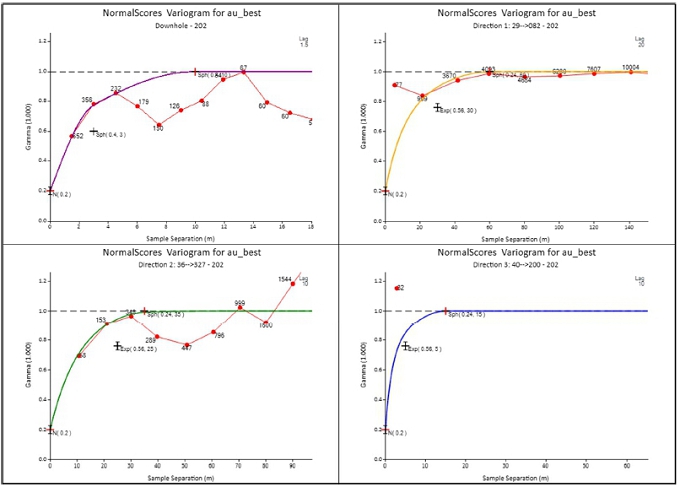

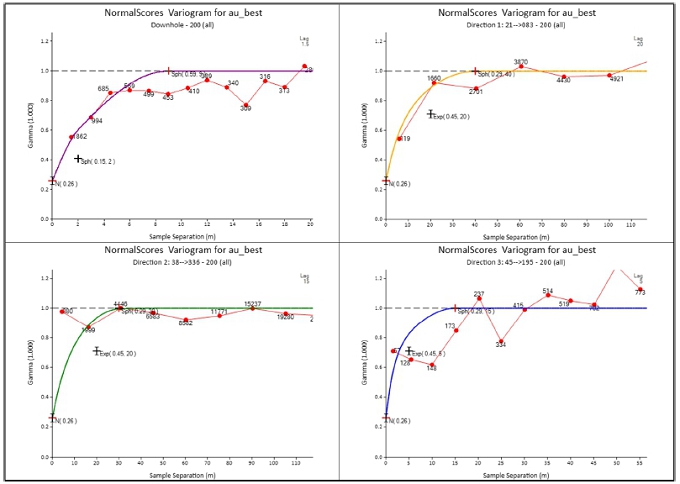

| Figure 14-11: V-veins experimental variograms and models | 125 |

| Figure 14-12: S-vein experimental variograms and models in domain 201 only | 125 |

| Figure 14-13: S-vein experimental variograms and models vein in domain 202 only | 126 |

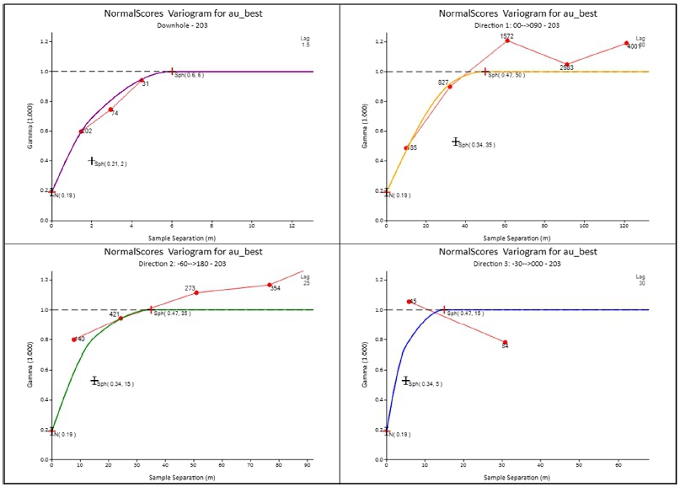

| Figure 14-14: S-vein experimental variograms and models in domain 203 only | 126 |

| Figure 14-15: S-vein experimental variograms and models in domain 200 (all remaining veins) | 127 |

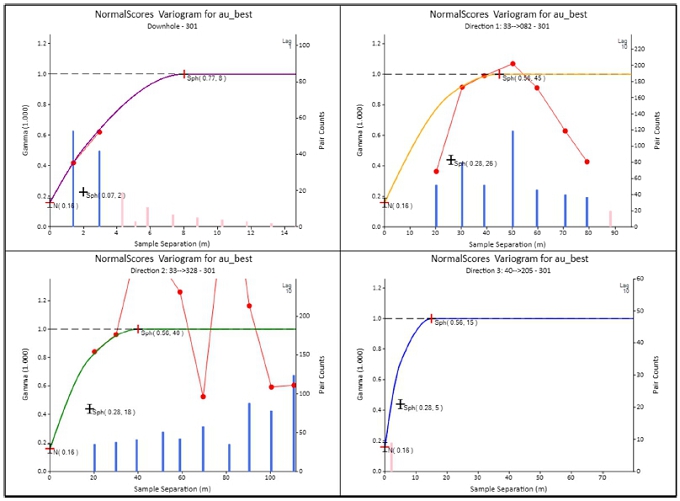

| Figure 14-16: TW experimental variograms and models | 127 |

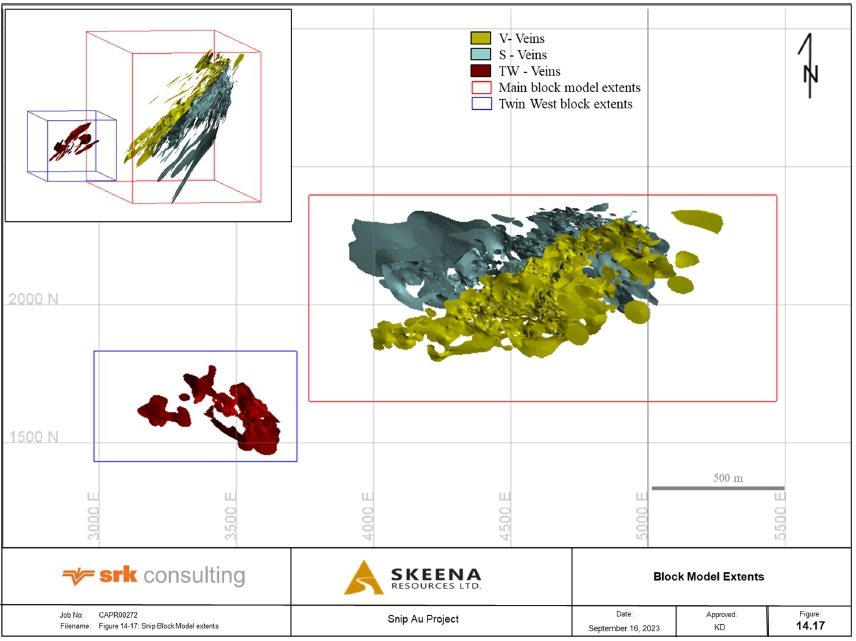

| Figure 14-17: Snip Project block model extents for the Main and Twin West block model areas | 130 |

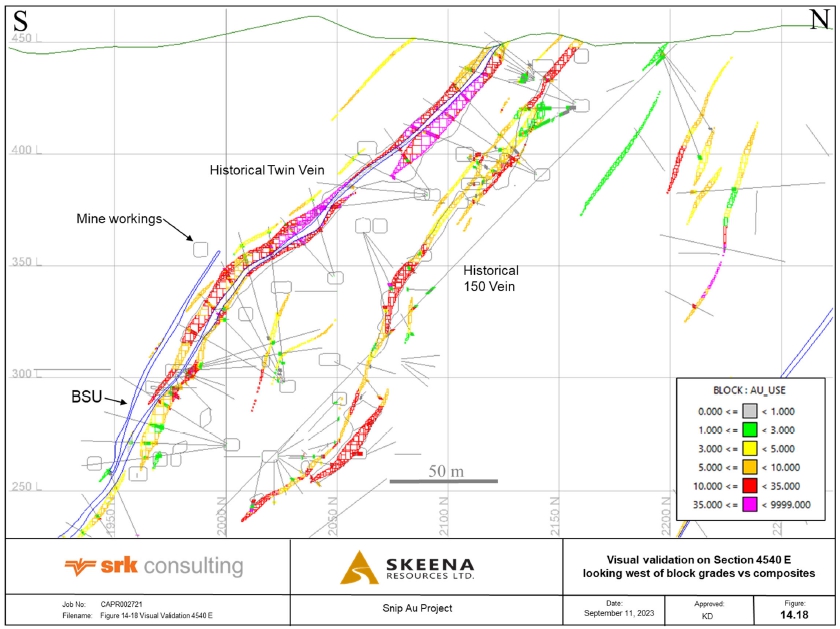

| Figure 14-18: Visual validation of blocks grades versus composites on Section 4540E, looking west | 134 |

| Figure 14-19: Visual validation of blocks grades versus composites on Section 4470E, looking west | 135 |

| Figure 14-20: Visual validation of blocks grades versus composites on Section 4775E, looking west | 136 |

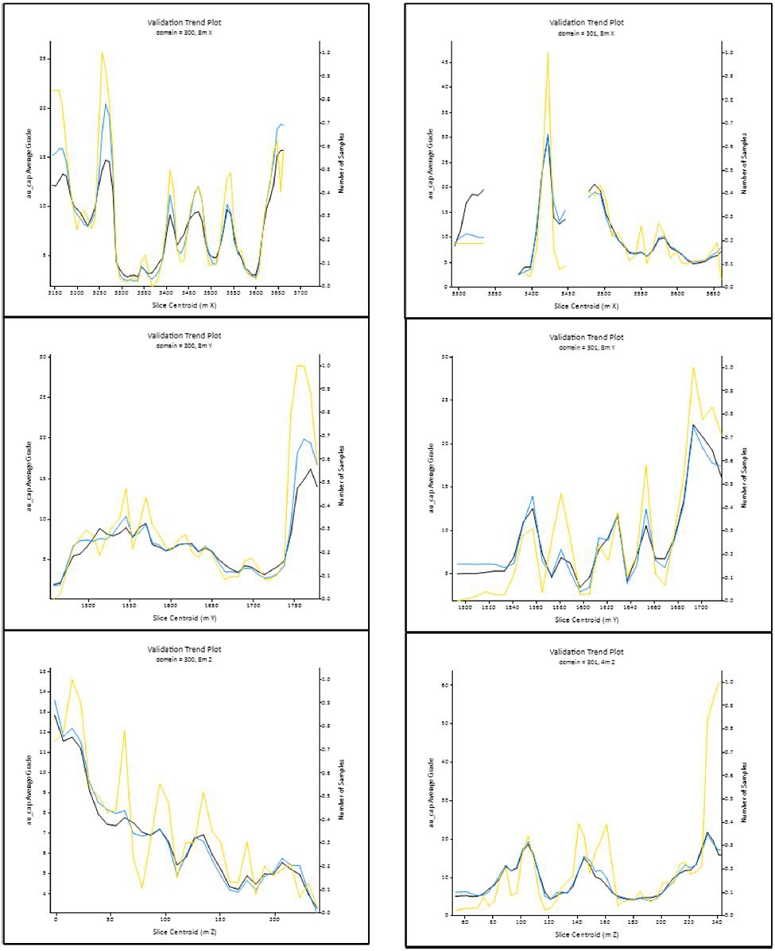

| Figure 14-21: Swath plots for the domains 101 (left) and 102 (right) of the V-veins. Black= OK model, blue= ID2 model, yellow =NN_declus model | 138 |

| Figure 14-22: Swath plots for the domains 201 (left), 202 (middle), and 203 (right) domains of the S-veins. Black= OK model, blue= ID2 model, yellow =NN_declus model | 139 |

| Figure 14-23: Swath plots for the domains 301 (left) and 300 (right) domains of the TW-Veins. Black= OK model, blue= ID2 model, yellow =NN_declus model | 140 |

| Figure 14-24: Plan view of the distribution of Indicated and Inferred classed blocks | 142 |

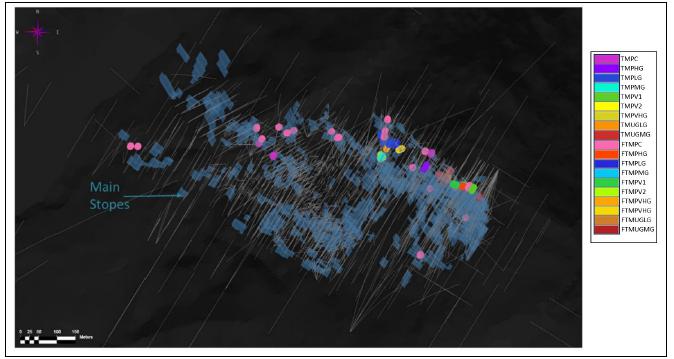

| Figure 14-25 Plan view and view looking west (inset) of the distribution of potentially economical minable underground stope shapes (orange) | 146 |

| Figure 14-26 Oblique view looking west of the reported resources within the stope optimized shapes in the Main Model | 147 |

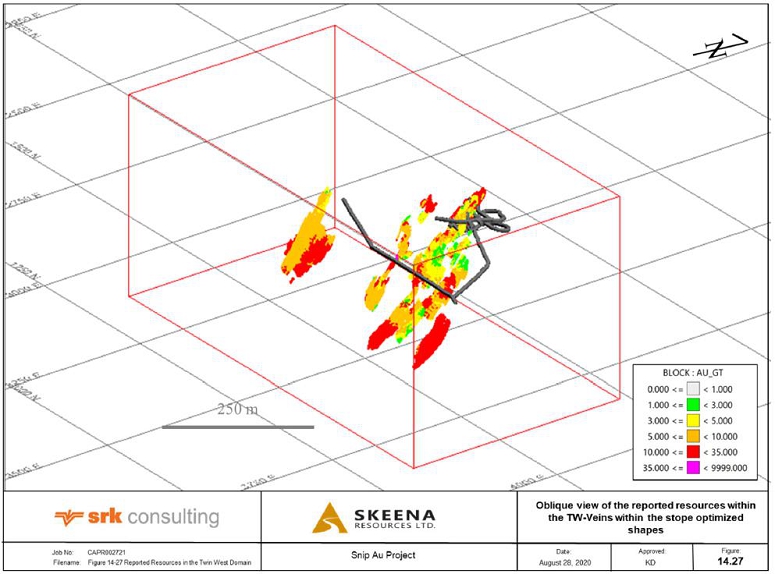

| Figure 14-27: Oblique view of the distribution of the reported resources within the stope optimized shapes in the Twin West Model. | 148 |

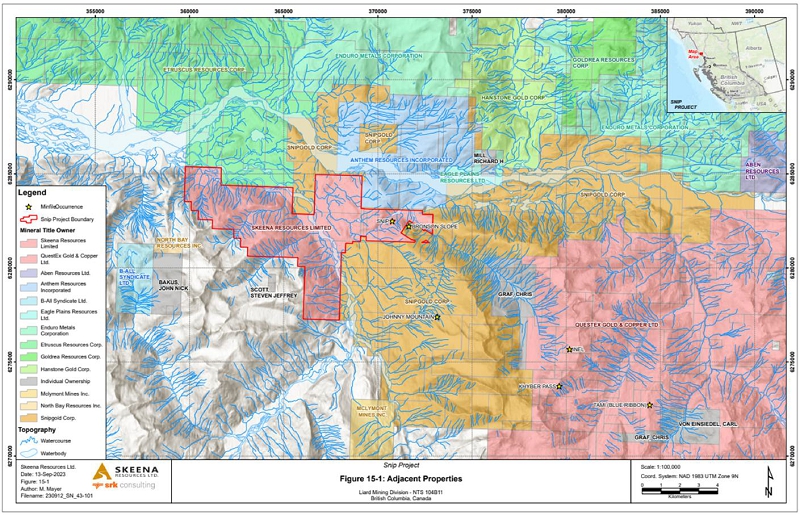

| Figure 15-1: Adjacent properties to the Snip Project | 153 |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| 2 | Introduction and Terms of Reference |

The Snip Project, located in northwest BC, is a high-grade underground gold deposit that has been historically partially mined. The Project is located in the Iskut River region in the Golden Triangle of British Columbia.

Skeena, a junior Canadian mining exploration company focused on developing prospective precious and base metal properties in the Golden Triangle of northwest British Columbia, Canada, owns 100% of the Snip Project.

On June 07, 2023, Skeena commissioned SRK to provide technical support and validation of the updated in-house resource model for the Snip Project, together with an NI 43-101 compliant resource estimate and report. The services were rendered between June and September 2023 leading to the preparation of the mineral resource statement reported herein that was disclosed publicly by Skeena in a news release on September 05, 2023 with a release date of September 26, 2023 for the Technical Report.

This Technical Report documents the mineral resource statement for the Snip Project validated by SRK. It was prepared following the guidelines of the Canadian Securities Administrators’ National Instrument 43-101 and Form 43-101F1. The Mineral Resource Statement reported herein was prepared in conformity with generally accepted CIM “Estimation of Mineral Resources and Mineral Reserves Best Practice Guidelines”.

| 2.1 | Scope of Work |

The scope of work, as defined in a letter of engagement executed on June 07, 2023 between Skeena and SRK, was to provide Skeena with ongoing support and validation of an updated in-house resource estimate that will be used for future preliminary engineering, accompanied by the preparation of an independent technical report published by SRK in compliance with National Instrument 43-101. This work involved the creation, review, and assessment of the following aspects of this project:

| · | Perform a thorough review of the Client-provided database and quality control and quantity control (QA/QC) data and assess for errors or flaws that may hinder the mineral resource estimation process. |

| · | Review the twin drilling data to assess for gold assay and mineralized interval similarities or differences. From the results, evaluate the risk of allowing all historical drill holes (without a 40 m buffer constraint) into the Indicated category, if fulfilling the additional class requirements. |

| · | Review the Snip deposit estimation domains ensuring that they are consistent and appropriate for the underlying interpretation of lithology and mineralization. |

| · | Provide resource estimate guidance and complete an independent check model on the Snip deposit. SRK will suggest appropriate exploratory data analysis values and estimation input parameters. |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| · | Fulfill Reasonable Prospects of Eventual Economic Extraction (RPEEE) criteria by running a stope optimizer on the underground resources. |

| · | Review, update, validate and sign-off on a NI 43-101 compliant technical report. |

| · | Recommendations for additional work. |

| 2.2 | Work Program |

The mineral resource statement reported herein is a collaborative effort between Skeena and SRK personnel. The exploration database was compiled and maintained by Skeena and was subsequently audited by SRK. The geological structural model and mineralization domains were initially constructed by SRK in 2020 but have subsequently been updated by Skeena with the 2020 to 2022 drilling data. In the opinion of SRK, the geological model is a reasonable representation of the distribution of the targeted mineralization at the current level of sampling. The geostatistical analysis, variography and grade models were validated by SRK during the months July and August 2023. The mineral resource statement reported herein was disclosed publicly in a news release dated September 05, 2023

The mineral resource statement reported herein was prepared in conformity with generally accepted CIM “Exploration Best Practices” and “Estimation of Mineral Resource and Mineral Reserves Best Practices” guidelines. This technical report was prepared following the guidelines of the Canadian Securities Administrators National Instrument 43-101.

The technical report was assembled in the SRK Vancouver office during the month of September 2023.

| 2.3 | Basis of Technical Report |

This report is based on information provided by Skeena throughout the course of SRK’s investigations. SRK performed a site visit to the Snip Project on July 27 to July 30, 2020 and has no reason to doubt the reliability of the information provided by Skeena. This technical report is based on the following sources of information:

| · | Regional geological maps, papers and assessment reports; |

| · | Property geology maps, papers, assessment reports and data; |

| · | Rhys (1993) Master’s Thesis; |

| · | Discussions with Skeena personnel; |

| · | Inspection of the Snip Project area, including portals, outcrop and drill core surface collars; and |

| · | Drill core evaluations and inspection. |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| 2.4 | Qualifications of SRK and SRK Team |

The SRK Group comprises over 1,000 professionals, offering expertise in a wide range of resource engineering disciplines. The SRK Group’s independence is ensured by the fact that it holds no equity in any project and that its ownership rests solely with its staff. This fact permits SRK to provide its clients with conflict-free and objective recommendations on crucial judgment issues. SRK has a demonstrated track record in undertaking independent assessments of Mineral Resources and Mineral Reserves, project evaluations and audits, technical reports and independent feasibility evaluations to bankable standards on behalf of exploration and mining companies and financial institutions worldwide. The SRK Group has also worked with a large number of major international mining companies and their projects, providing mining industry consultancy service inputs.

The resource evaluation work and the compilation of this technical report was completed by Ms. Kathi Dilworth, GIT under the supervision of the Qualified Person, Ms. Sheila Ulansky, PGeo [EGBC#36085] (Table 2-1). By virtue of her education, membership to a recognized professional association and relevant work experience, Ms. Ulansky is an independent Qualified Person as this term is defined by National Instrument 43-101. The names and details of Other Experts who have contributed to this Technical Report are listed in Table 2-2. Mr. Andre Deiss, Pr.Sci.Nat Principal Resource Geologist with SRK, reviewed and provided guidance with estimation parameters. He also reviewed drafts of this technical report prior to delivery to Skeena as per SRK internal quality management procedures.

Table 2-1: Qualified Persons who prepared or contributed to the Technical Report

| Qualified Person | Company | Responsibility

/ Role |

Site Visit | Report Section(s) |

| Sheila Ulansky, P.Geo. | SRK | Mineral Resource Estimation | July 2020 | 1 to 12, 14 to 18 |

| Diana Nakou, P.Eng. | SRK | Stope Optimization | n/a | 14 |

| Andre Deiss, Pr,Sci.Nat. | SRK | Peer Review | n/a | All |

| Jeff Austin, P.Eng. | International Metallurgical and Environmental Inc. | Metallurgy | n/a | 13 |

Table 2-2: Other Experts who assisted the Qualified Persons

| Expert | Company | Position | Report Sections |

| Katherine (Kathi) Dilworth GIT | Skeena Resources | Director: Resources and Reserves | 1 to 10, 14 to 16 |

|

Michael Mayer, ADP GIS |

Skeena Resources | Manager, Technical Services | Maps and Figures |

| SU/AD | September 2023 |

| SRK Consulting (Canada) Inc Skeena Resources Limited NI 43 -101 Snip Project Canada |

Page |

| 2.5 | Site Visit |

In accordance with National Instrument 43-101 guidelines, Ms. Ulansky visited the Snip Project between July 27 and July 31, 2020 accompanied by Ms. Dilworth of Skeena Resources.

The purpose of the site visit was to ground truth historical and current surface collar locations, examine drill core intervals within the main lodes, and collect all relevant information for the compilation of this technical report.

During the visit, attention was given to geological and structural controls on the distribution of gold mineralization to validate the extent that mineralization had been extended in the three-dimensional gold mineralization vein model.

SRK was given full access to relevant data and conducted interviews with Skeena’s personnel to obtain information on past exploration work, and to understand procedures used to collect, record, store and analyze historical and current exploration data.

| 2.6 | Acknowledgement |

SRK would like to acknowledge the support and collaboration provided by Skeena personnel for this assignment. Their collaboration was greatly appreciated and instrumental to the success of this project.

| 2.7 | Declaration |