UNITED STATES

SECURITIES AND EXCHANGE COMMISSION

Washington, D.C. 20549

Form 6-K

REPORT OF FOREIGN PRIVATE ISSUER PURSUANT TO RULE 13a-16 OR 15d-16 UNDER THE

SECURITIES EXCHANGE ACT OF 1934

For the month of November 2025

Commission File Number: 001-39966

New Found Gold Corp.

(Exact name of registrant as specified in its charter)

1133 Melville Street, Suite 3500,

Vancouver, British Columbia

V6E 4E5 Canada

(Address of principal executive office)

Indicate by check mark whether the registrant files or will file annual reports under cover Form 20-F or 40-F:

Form 20-F ☐ Form 40-F ☒ Pursuant to the requirements of the Securities Exchange Act of 1934, the registrant has duly caused this report to be signed on behalf by the undersigned, thereunto duly authorized.

SUBMITTED HEREWITH

| Exhibit | Description | |

| 99.1 | Feasibility Study Technical Report for the Hammerdown Gold Project in Newfoundland dated October 6, 2022 |

SIGNATURES

| NEW FOUND GOLD CORP. | ||

| (Registrant) | ||

| Date: November 20, 2025 | By: | /s/ Keith Boyle |

| Keith Boyle | ||

| Chief Executive Officer | ||

|

|

DATE AND SIGNATURE PAGE

This report entitled NI 43-101 Feasibility Study Technical Report for the Hammerdown Project, effective as of August 15, 2022 was prepared and signed by the following authors:

Original document signed and sealed by:

| Name "Carolyn Anstey-Moore" | October 6, 2022 |

| Carolyn Anstey-Moore, P.Geo. | Date Signed |

| Name "Joannes Arisz" | October 6, 2022 |

| Joannes Arisz, M.Sc.E., P.Eng., FCSCE | Date Signed |

| Name "Robert Bowell" | October 6, 2022 |

| Robert Bowell, CChem, CGeol, FIMMM | Date Signed |

| Name "Carly Church" | October 6, 2022 |

| Carly Church, P. Eng. | Date Signed |

| Name "Gord Doerksen" | October 6, 2022 |

| Gord Doerksen, P. Eng. | Date Signed |

| Name "Dorota El Rassi" | October 6, 2022 |

| Dorota El Rassi, M. Sc., P. Eng. | Date Signed |

| Name "Michael Franceschini" | October 6, 2022 |

| Michael Franceschini, P. Eng. | Date Signed |

| Name "Stacy Freudigmann" | October 6, 2022 |

| Stacy Freudigmann, P.Eng., F.Aus.IMM. | Date Signed |

| Name "Tysen Hantelmann" | October 6, 2022 |

| Tysen Hantelmann, P. Eng. | Date Signed |

| Name "Pierre Landry" | October 6, 2022 |

| Pierre Landry, P. Geo. | Date Signed |

| Name "Mike Levy" | October 6, 2022 |

| Mike Levy, P.Eng. | Date Signed |

|

|

| Name "Shawn Russell" | October 6, 2022 |

| Shawn Russell, P.Eng. | Date Signed |

| Name "Ivana Sabaj Abumohor" | October 6, 2022 |

| Ivana Sabaj Abumohor, P.Eng. | Date Signed |

| Name "Leanne Stein" | October 6, 2022 |

| Leanne Stein, P.Eng. | Date Signed |

|

|

NOTICE

JDS Energy & Mining, Inc. prepared this National Instrument 43-101 Technical Report, in accordance with Form 43-101F1, for Maritime Resources Corp. The quality of information, conclusions and estimates contained herein is based on: (i) information available at the time of preparation; (ii) data supplied by outside sources, and (iii) the assumptions, conditions, and qualifications set forth in this report.

Maritime Resources Corp. filed this Technical Report with the Canadian Securities Regulatory Authorities pursuant to provincial securities legislation. Except for the purposes legislated under provincial securities law, any other use of this report by any third party is at that party's sole risk.

|

|

Table of Contents

| 1 Executive Summary | 1-1 |

| 1.1 Introduction | 1-1 |

| 1.2 Project Description | 1-1 |

| 1.3 Property Description - Location and Access | 1-2 |

| 1.4 Ownership | 1-2 |

| 1.5 History, Exploration and Drilling | 1-3 |

| 1.6 Geology and Mineralization | 1-3 |

| 1.7 Metallurgical Testing and Mineral Processing | 1-4 |

| 1.8 Mineral Resource Estimate | 1-4 |

| 1.9 Mineral Reserve Estimate | 1-5 |

| 1.10 Mining | 1-6 |

| 1.11 Recovery Methods | 1-7 |

| 1.12 Infrastructure and Facilities | 1-8 |

| 1.13 Environmental Studies, Permitting and Social Impacts | 1-9 |

| 1.14 Operating and Capital Cost Estimates | 1-10 |

| 1.15 Economic Analysis | 1-12 |

| 1.15.1 Main Assumptions | 1-12 |

| 1.15.2 Results | 1-14 |

| 1.15.3 Sensitivities | 1-14 |

| 1.16 Conclusions | 1-14 |

| 1.16.1 Geology and Mineral Resources | 1-15 |

| 1.17 Recommendations | 1-15 |

| 2 Introduction | 2-1 |

| 2.1 Qualified Persons (QPs) | 2-1 |

| 2.1.1 Scope of Work of Contributing Companies | 2-1 |

| 2.1.2 Qualifications and Responsibilities | 2-2 |

| 2.2 Terms of Reference | 2-4 |

| 2.3 Sources of Information | 2-4 |

| 2.4 QP Site Visits | 2-5 |

|

|

| 2.5 List Of Previous Relevant Technical Reports | 2-6 |

| 2.6 Units, Currency and Rounding | 2-7 |

| 3 Reliance on Other Experts | 3-1 |

| 4 Property Description and Location | 4-1 |

| 4.1 Location | 4-1 |

| 4.2 Mineral Tenure | 4-4 |

| 4.3 Royalties and Related Rights | 4-7 |

| 4.4 Environmental Liabilities and Considerations | 4-7 |

| 4.5 Permit Requirements | 4-7 |

| 4.6 Other Relevant Factors | 4-7 |

| 5 Accessibility, Climate, Local Resources, Infrastructure and Physiography | 5-1 |

| 5.1 Accessibility | 5-1 |

| 5.2 Local Resources and Infrastructure | 5-2 |

| 5.3 Climate | 5-3 |

| 5.4 Physiography | 5-3 |

| 6 History | 6-1 |

| 6.1 Production History | 6-3 |

| 7 Geological Setting and Mineralization | 7-1 |

| 7.1 Regional Geology | 7-1 |

| 7.2 Property Geology | 7-3 |

| 7.3 Property Mineralization | 7-6 |

| 7.4 Hammerdown-Rumbullion-Muddy Shag Vein System | 7-8 |

| 7.4.1 Hammerdown Gold Veins | 7-9 |

| 7.4.2 Rumbullion Gold Veins | 7-10 |

| 7.4.3 Muddy Shag Gold Veins | 7-10 |

| 7.4.4 Wisteria Gold Zone | 7-11 |

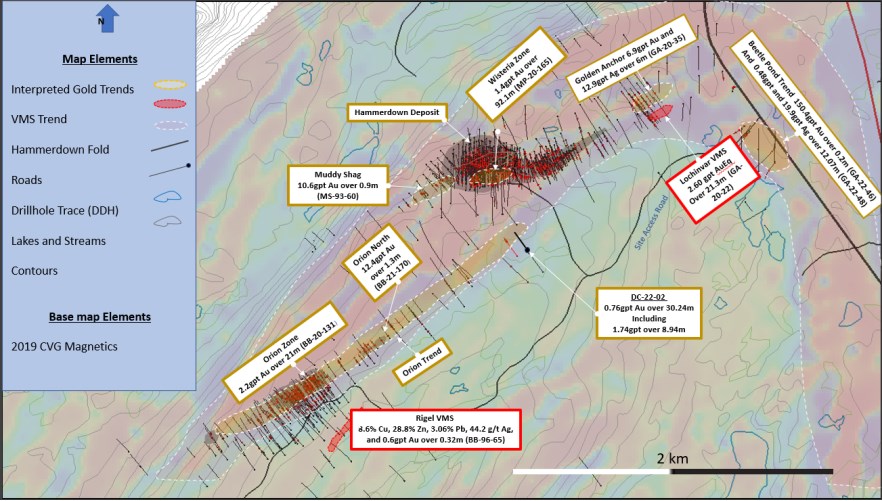

| 7.5 Other Mineralization | 7-13 |

| 7.5.1 Golden Anchor (Zn/Au) - (Peters, 2016), (Maritime, 2019) | 7-14 |

| 7.5.2 Orion Gold Deposit | 7-14 |

| 7.5.3 Lochinvar Deposit (Pb/Zn/Cu/Au/Ag) | 7-19 |

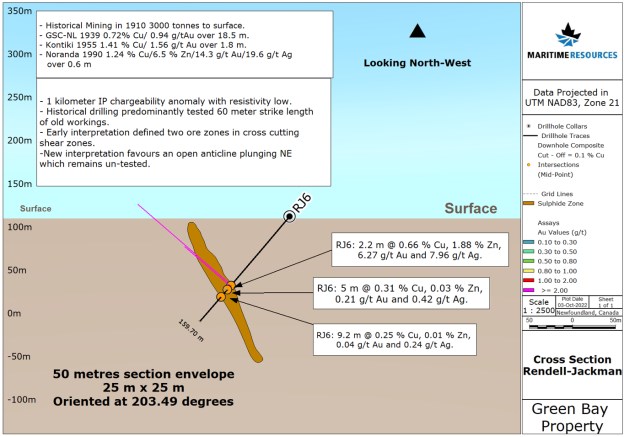

| 7.5.4 Rendell-Jackman Cu/Au Deposit - (Peters, 2016) | 7-21 |

| 7.5.5 Rendell-Jackman Southeast (Au) - (Peters, 2016) | 7-23 |

|

|

| 7.5.6 Whisky Bravo (Cu/Au) - (Mitton, 2005) | 7-23 |

| 7.5.7 Timber Pond VMS (Cu) - (Dyke, B., and Hussey, A.M., 2004) | 7-24 |

| 7.5.8 Timber Pond (Au/Ag) - (Dyke, B., and Hussey, A.M., 2004) | 7-24 |

| 7.5.9 Sprucy Pond Trend (Au) - (Mitton, 2005) | 7-24 |

| 7.5.10 Beetle Pond (Au/Zn) - (Peters, 2016) | 7-25 |

| 7.5.11 Muir Pond (Zn/Pb) - (Moore, P.J., and Mullen, D.V., 2002) | 7-26 |

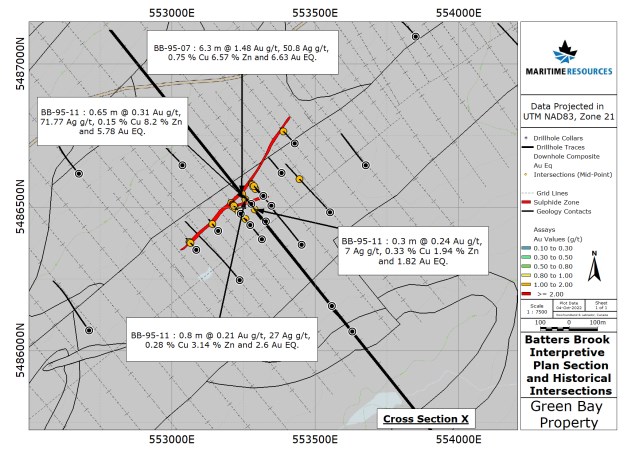

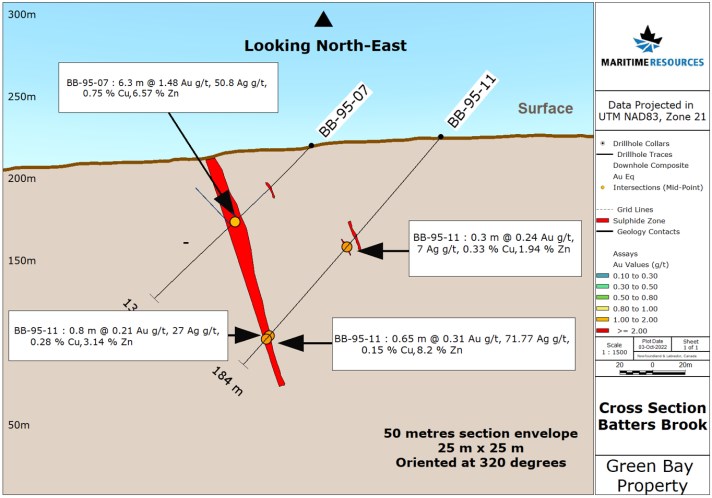

| 7.5.12 Batters Brook (Zn) - (Moore, P.J. and Mullen, D.V., 2002) | 7-27 |

| 7.5.13 Rigel (Zn) - (Moore, P.J., and Mullen, D.V., 2002) | 7-29 |

| 7.5.14 Ursa Major / Ursa Minor / Southern Cross - (Moore, P.J., and Mullen, D.V. 2002) | 7-29 |

| 7.5.15 Pisces (Zn) - (Peters, 2016) | 7-29 |

| 7.5.16 Goldfish (Zn) - (Peters, 2016) | 7-30 |

| 7.5.17 Indian Brook (Zn) - (Moore, P.J., and Mullen, D.V. 2002) | 7-30 |

| 7.5.18 Catchers Valley (Zn) - (Moore, P.J. and Mullen, D.V., 2002) | 7-30 |

| 7.5.19 Harry's Brook (Cu) - (Peters, 2016) | 7-30 |

| 8 Deposit Types | 8-1 |

| 9 Exploration | 9-1 |

| 9.1 Introduction | 9-1 |

| 9.2 2019 Work Program | 9-3 |

| 9.3 Airborne Magnetic-Radiometric-VLF Survey | 9-3 |

| 9.4 IP Survey | 9-6 |

| 9.5 LiDAR Survey | 9-10 |

| 9.6 Diamond Drilling | 9-11 |

| 9.6.1 Golden Anchor Drilling | 9-12 |

| 9.6.2 Hammerdown East-Rumbullion Drilling | 9-14 |

| 9.7 2020 / 2021 Work Programs | 9-16 |

| 9.8 Airborne Magnetics VTEM, AIIP and ZTEM | 9-16 |

| 9.9 Ground SPEM Geophysical Surveys | 9-21 |

| 9.10 2020 to Present | 9-23 |

| 9.11 Orion North Exploration | 9-24 |

| 9.12 Area 22 Exploration | 9-24 |

| 9.13 Golden Anchor and Lochinvar Exploration | 9-27 |

| 9.13.1 Golden Anchor Gold Target | 9-27 |

|

|

| 9.13.2 Lochinvar VMS Target | 9-27 |

| 9.14 Beetle Pond Exploration | 9-27 |

| 10 Drilling (Hammerdown) | 10-1 |

| 10.1 Introduction | 10-1 |

| 10.2 Maritime Resources 2012-2019 Diamond Drill Program | 10-3 |

| 10.2.1 Maritime Resources 2012 Hammerdown Drill Program | 10-3 |

| 10.2.2 Maritime Resources 2012 Rumbullion Channel Sampling Program | 10-3 |

| 10.2.3 Maritime Resources 2017 Hammerdown Channel Sampling Program | 10-3 |

| 10.2.4 Maritime Resources 2018 Hammerdown Drill Program | 10-3 |

| 10.2.5 Maritime Resources 2019 Hammerdown Drill Program | 10-3 |

| 10.3 Maritime Resources 2020-2022 Channel Sampling and Diamond Drill Program | 10-3 |

| 10.3.1 Maritime Resources 2020 Hammerdown Drill Program | 10-4 |

| 10.3.2 2020-2021 Wisteria Channel Sampling Program | 10-6 |

| 10.3.3 2021-2022 Hammerdown Drill Program | 10-6 |

| 10.4 Diamond Drilling Procedures | 10-8 |

| 10.4.1 Drilling Procedures | 10-8 |

| 10.4.2 Surveying: Collar and Downhole Surveys | 10-8 |

| 10.4.3 Core Delivery | 10-8 |

| 10.4.4 Core Logging and Sampling | 10-8 |

| 10.4.5 Core Photography | 10-9 |

| 10.4.6 Core Cutting | 10-11 |

| 10.4.7 Core Storage | 10-12 |

| 10.5 Channel Sampling Procedures | 10-13 |

| 10.6 Drill Hole and Channel Sample Database | 10-13 |

| 10.7 Hammerdown Deposit Results | 10-13 |

| 10.8 2020 Hammerdown Grade Control Diamond Drill Program | 10-26 |

| 11 Sample Preparation, Analyses and Security | 11-1 |

| 11.1 Introduction | 11-1 |

| 11.2 Samples Preparation | 11-1 |

| 11.2.1 Pre-2012 | 11-1 |

| 11.2.2 Maritime Resources | 11-1 |

| 11.3 Analytical Method | 11-2 |

|

|

| 11.3.1 Pre-2012 | 11-2 |

| 11.3.2 Maritime Resources | 11-2 |

| 11.4 Sample Security | 11-2 |

| 11.5 Quality Control & Quality Assurance | 11-3 |

| 11.5.1 Sample Blanks | 11-3 |

| 11.6 Certified Reference Materials | 11-5 |

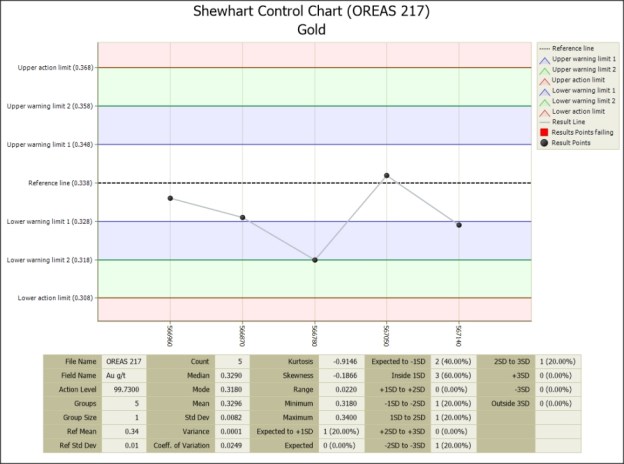

| 11.6.1 OREAS 217 | 11-5 |

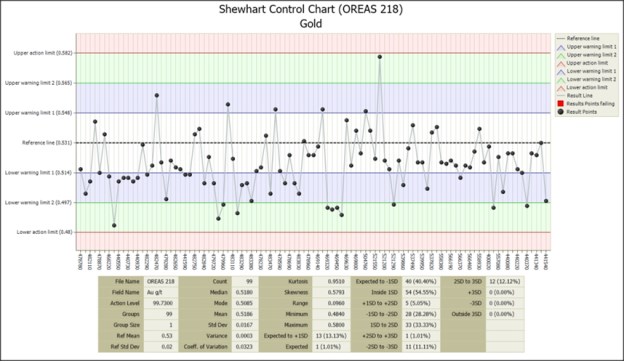

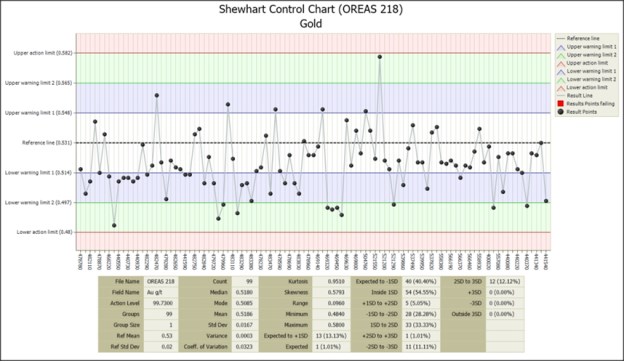

| 11.6.2 OREAS 218 | 11-7 |

| 11.6.3 OREAS 228 | 11-8 |

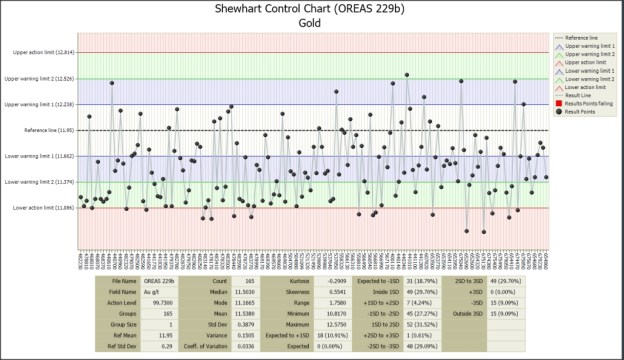

| 11.6.4 OREAS 229b | 11-9 |

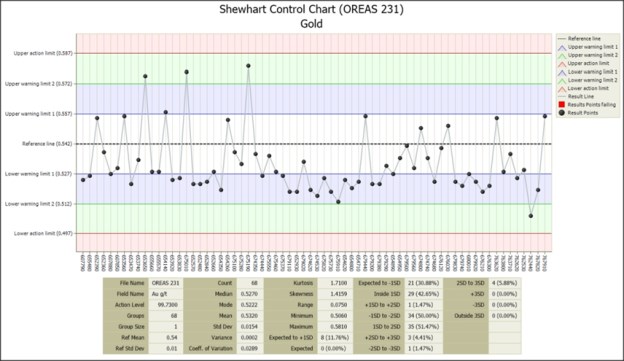

| 11.6.5 OREAS 231 | 11-10 |

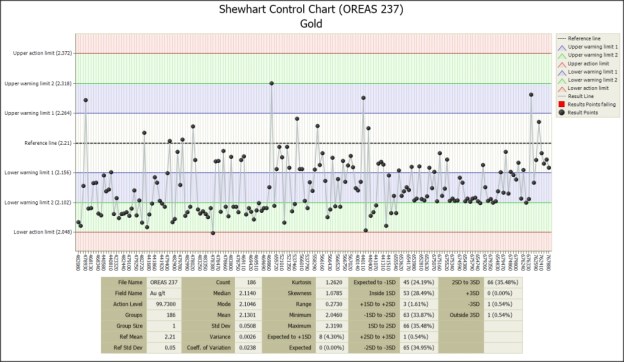

| 11.6.6 OREAS 237 | 11-11 |

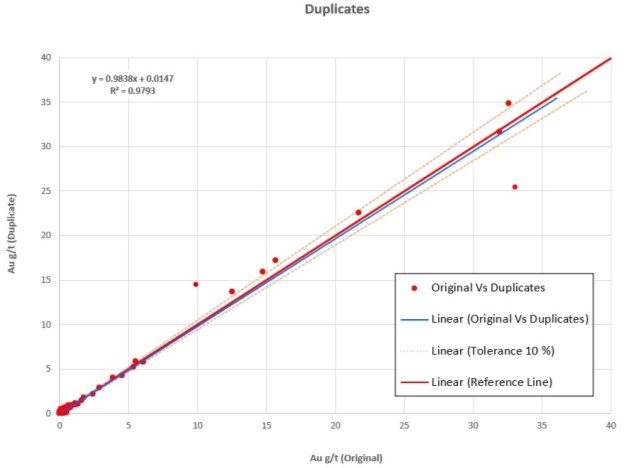

| 11.6.7 Coarse Reject Duplicates | 11-12 |

| 11.7 Qualified Person's Opinion | 11-14 |

| 12 Data Verification | 12-1 |

| 12.1 Verifications by the Authors of this Technical Report | 12-1 |

| 13 Mineral Processing and Metallurgical Testing | 13-1 |

| 13.1 Introduction | 13-1 |

| 13.2 Testing & Procedures | 13-1 |

| 13.3 Mineralogical Evaluations | 13-3 |

| 13.3.1 Mineralogy | 13-3 |

| 13.4 Testwork | 13-3 |

| 13.4.1 Historical Metallurgical Testing | 13-3 |

| 13.4.2 Recent Metallurgical Testing (2021-2022) | 13-5 |

| 13.5 Recovery Predictions | 13-15 |

| 14 Mineral Resource Estimate | 14-1 |

| 14.1 Summary | 14-1 |

| 14.2 Comparison to Previous Estimates | 14-2 |

| 14.3 Resource Database | 14-3 |

| 14.4 Reconciliation to Production Data | 14-6 |

| 14.4.1 Historical Stopes and Development | 14-6 |

| 14.4.2 Comparison | 14-6 |

|

|

| 14.5 Geological Interpretation | 14-7 |

| 14.6 Resource Assays | 14-13 |

| 14.7 Treatment of High Grade Assays | 14-14 |

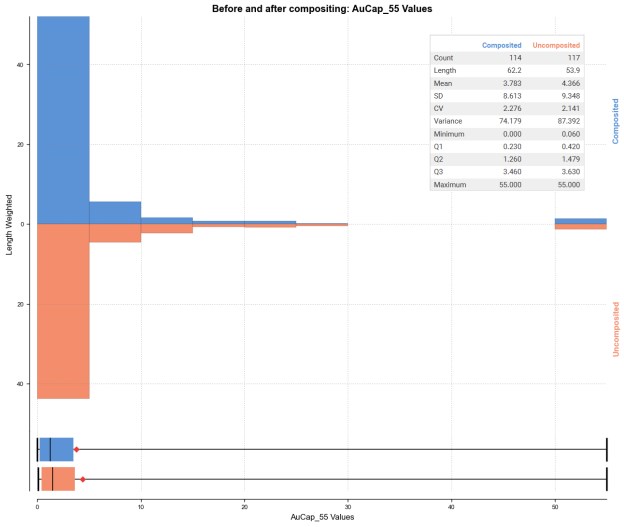

| 14.7.1 Capping | 14-18 |

| 14.7.2 High Grade Restriction | 14-23 |

| 14.8 Compositing | 14-24 |

| 14.9 Trend Analysis | 14-27 |

| 14.9.1 Variography | 14-27 |

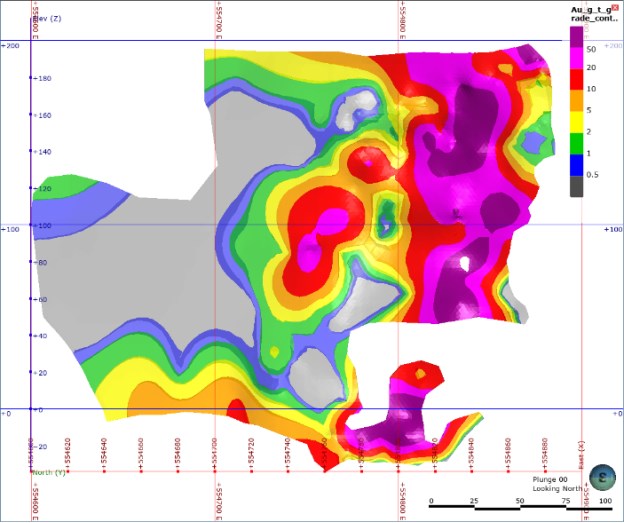

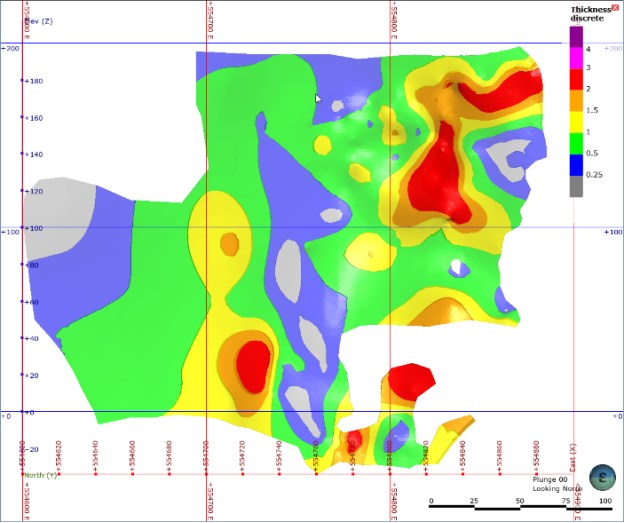

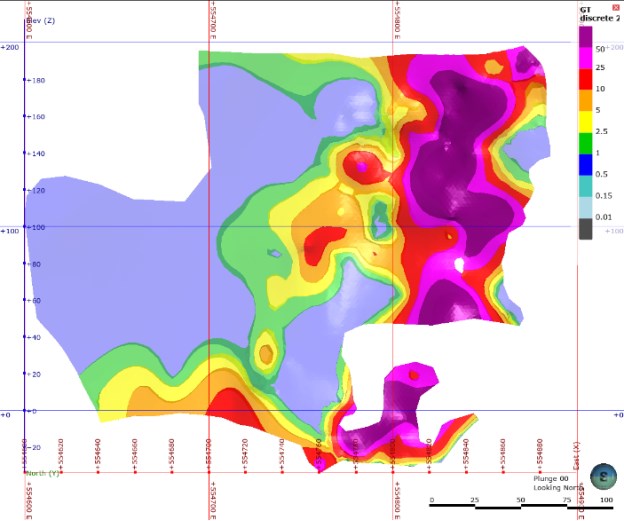

| 14.9.2 Grade Contouring | 14-36 |

| 14.10 Search Strategy and Grade Interpolation Parameters | 14-43 |

| 14.11 Bulk Density | 14-49 |

| 14.12 Block Models | 14-49 |

| 14.13 Cut-off Grade and Whittle Parameters | 14-49 |

| 14.13.1 Cut-Off Grade | 14-50 |

| 14.13.2 Pit shell Optimization | 14-50 |

| 14.13.3 Underground Constraining Shapes | 14-51 |

| 14.14 Classification | 14-51 |

| 14.15 Block Model Validation | 14-64 |

| 14.16 Mineral Resource Reporting | 14-76 |

| 14.16.1 Model Regularization Comparison | 14-78 |

| 15 Mineral Reserve Estimate | 15-1 |

| 15.1 Introduction | 15-1 |

| 15.2 Open Pit Optimization | 15-1 |

| 15.2.1 Basis of Estimate | 15-1 |

| 15.2.2 Open Pit Optimization Input Parameters | 15-3 |

| 15.2.3 Open Pit Optimization Results | 15-4 |

| 15.3 Open Pit Design | 15-8 |

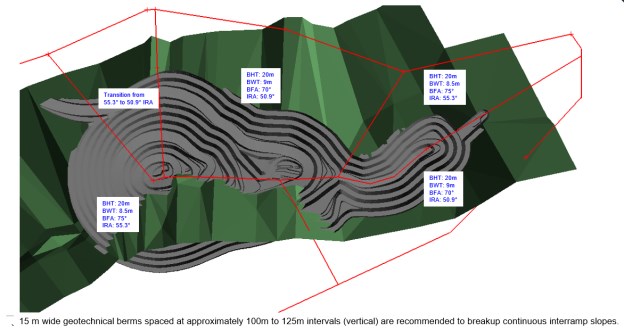

| 15.3.1 Geotechnical Pit Slope Recommendations | 15-11 |

| 15.3.2 Road/Ramp Width | 15-11 |

| 15.4 Mineral Reserve Estimate | 15-12 |

| 16 Mining Methods | 16-1 |

| 16.1 Introduction | 16-1 |

|

|

| 16.2 Deposit Characteristics | 16-2 |

| 16.3 Geotechnical Analysis and Recommendations | 16-4 |

| 16.3.1 Geotechnical Characterization | 16-4 |

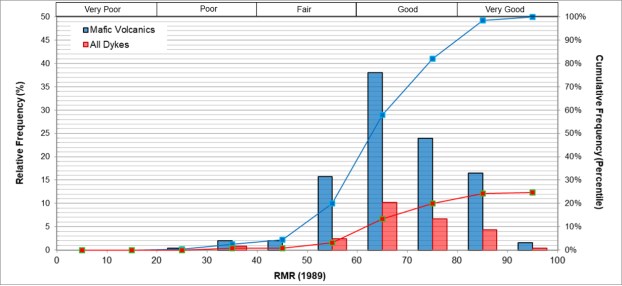

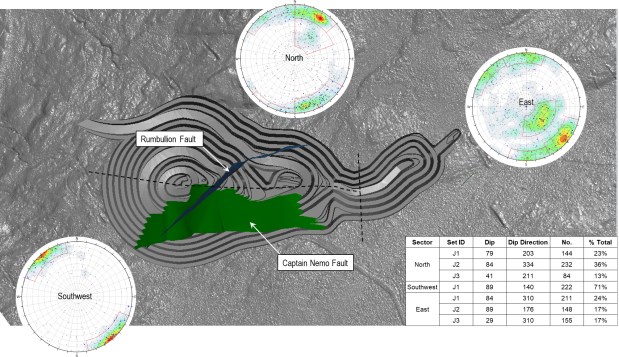

| 16.3.2 Geotechnical Domains and Rock Mass Properties | 16-6 |

| 16.3.3 Slope Stability Analysis | 16-8 |

| 16.3.4 Pit Slope Design Recommendations | 16-9 |

| 16.3.5 Mining Through Historic Underground Workings | 16-10 |

| 16.4 Hydrogeology | 16-10 |

| 16.5 Mining Methods | 16-11 |

| 16.6 Mine Design | 16-11 |

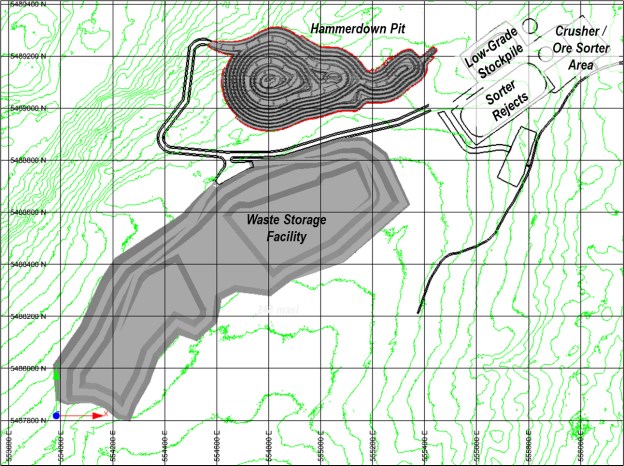

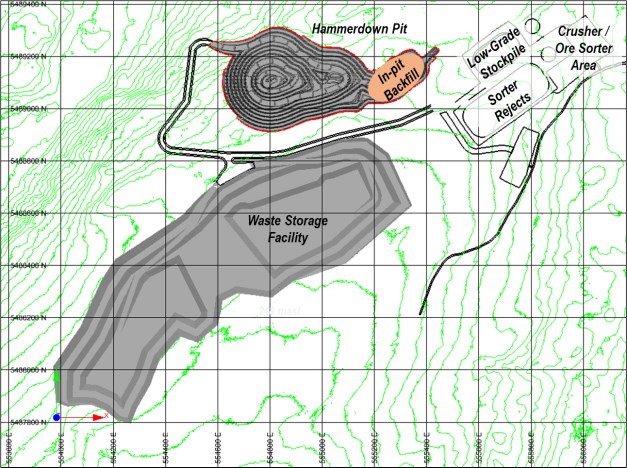

| 16.6.1 Waste Storage | 16-15 |

| 16.7 Mine Production Schedule | 16-16 |

| 16.8 Mine Operations | 16-22 |

| 16.8.1 Drilling | 16-23 |

| 16.8.2 Blasting | 16-23 |

| 16.8.3 Loading | 16-24 |

| 16.8.4 Hauling | 16-25 |

| 16.8.5 Support | 16-25 |

| 16.8.6 Dilution Management | 16-26 |

| 16.9 Mine Equipment | 16-26 |

| 16.10 Mine Personnel | 16-27 |

| 17 Process Description / Recovery Methods | 17-1 |

| 17.1 Introduction | 17-1 |

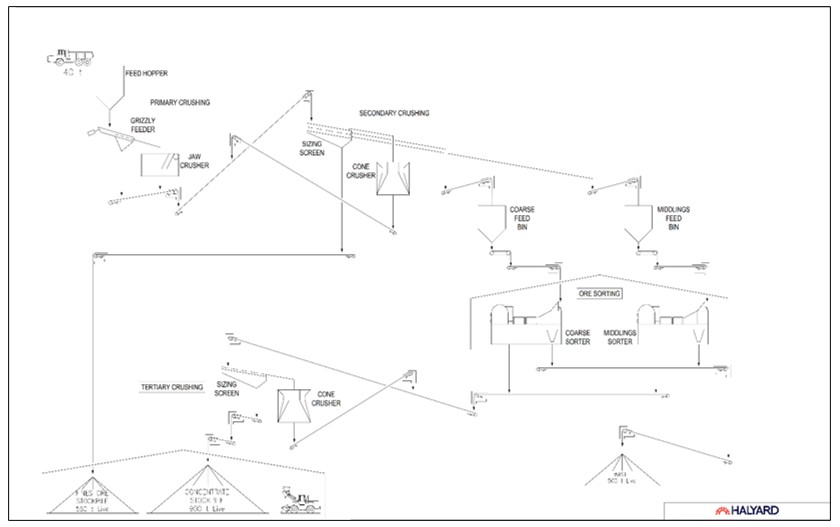

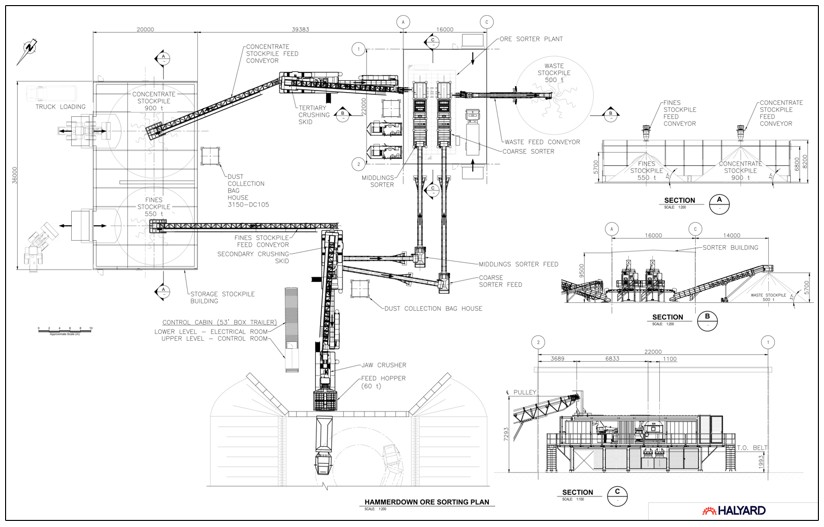

| 17.2 Run-of-Mine Pre-Concentration (Crushing and Sorting) | 17-1 |

| 17.2.1 Crushing and Sorting Process Design Criteria | 17-5 |

| 17.2.2 Primary Crushing | 17-6 |

| 17.2.3 Secondary Crushing and Screening | 17-6 |

| 17.2.4 Sorting | 17-6 |

| 17.2.5 Tertiary Crushing and Screening | 17-7 |

| 17.2.6 Crushed Material Stockpiling | 17-7 |

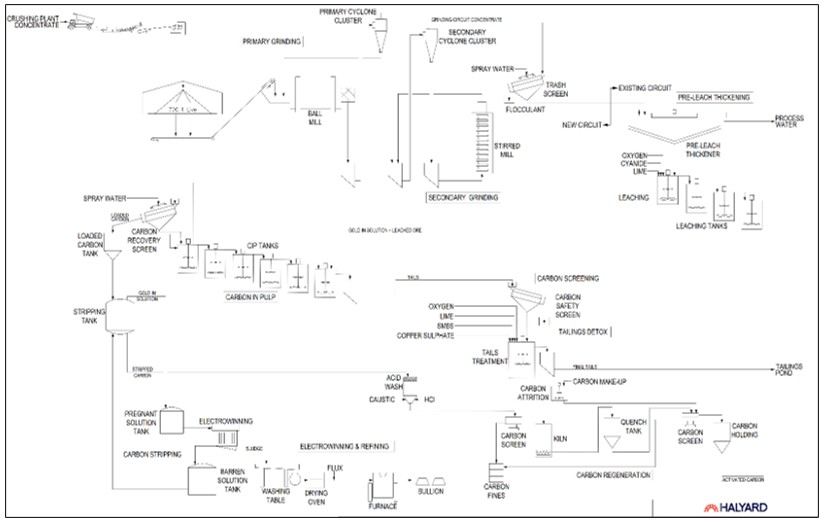

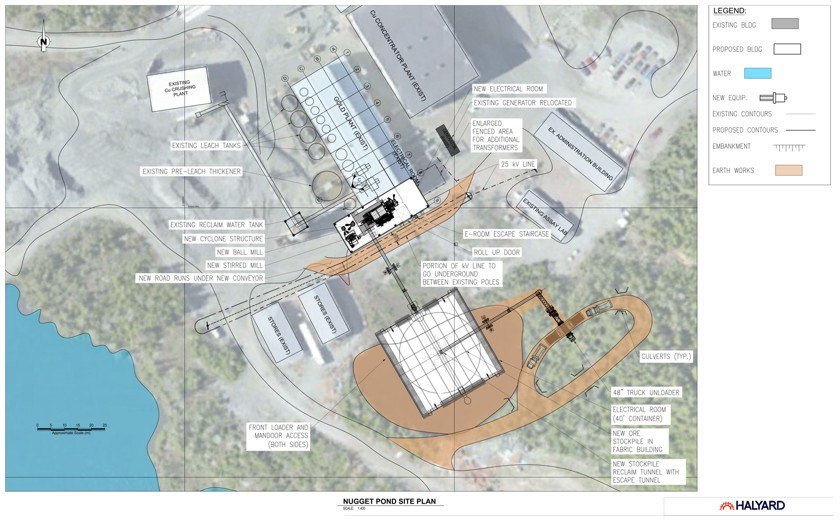

| 17.3 Nugget Pond Mineral Processing | 17-7 |

| 17.3.1 Grinding and CIP Process Design Criteria | 17-12 |

|

|

| 17.3.2 Transportation and Storage | 17-13 |

| 17.3.3 Primary and Secondary Grinding Circuit | 17-15 |

| 17.3.4 Pre-Leach Thickener | 17-17 |

| 17.3.5 Leaching and Carbon-in-Pulp Circuit | 17-17 |

| 17.3.6 Stripping, Refining, and Carbon Regeneration | 17-17 |

| 17.3.7 Tailings and Cyanide Destruction | 17-18 |

| 17.3.8 Process / Reclaim Water | 17-18 |

| 17.3.9 Reagents and Services | 17-18 |

| 18 Project Infrastructure and Services | 18-1 |

| 18.1 Hammerdown Site | 18-1 |

| 18.1.1 Existing Infrastructure | 18-1 |

| 18.1.2 General Site Arrangement | 18-1 |

| 18.1.3 Site Access Road | 18-3 |

| 18.1.4 Site Roads | 18-3 |

| 18.1.5 Buildings and Support Infrastructure | 18-3 |

| 18.1.6 Power | 18-4 |

| 18.1.7 Utilities | 18-5 |

| 18.1.8 Sewage System | 18-5 |

| 18.1.9 Water Management | 18-5 |

| 19 Market Studies and Contracts | 19-1 |

| 19.1 Market Studies | 19-1 |

| 19.2 Royalties | 19-1 |

| 19.3 Metal Prices | 19-1 |

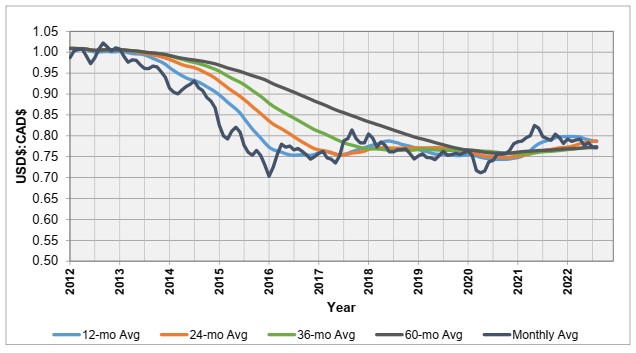

| 19.4 Exchange Rate | 19-2 |

| 19.5 Contracts | 19-3 |

| 20 Environmental Studies, Permitting and Social or Community Impacts | 20-1 |

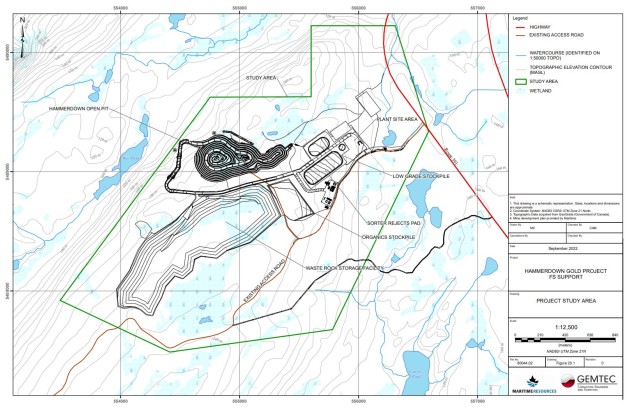

| 20.1 Baseline and Site Characterization Studies | 20-2 |

| 20.2 Environmental Setting | 20-3 |

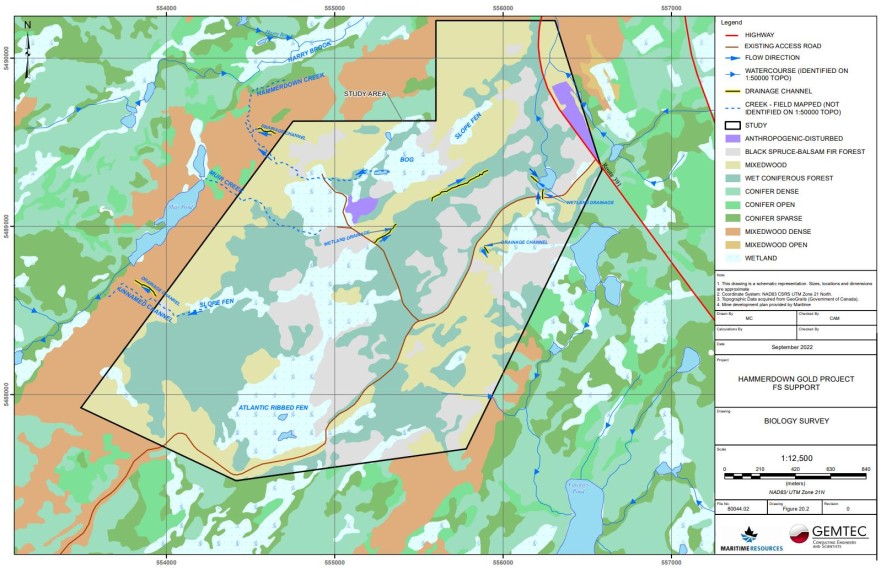

| 20.2.1 Terrestrial Environment | 20-3 |

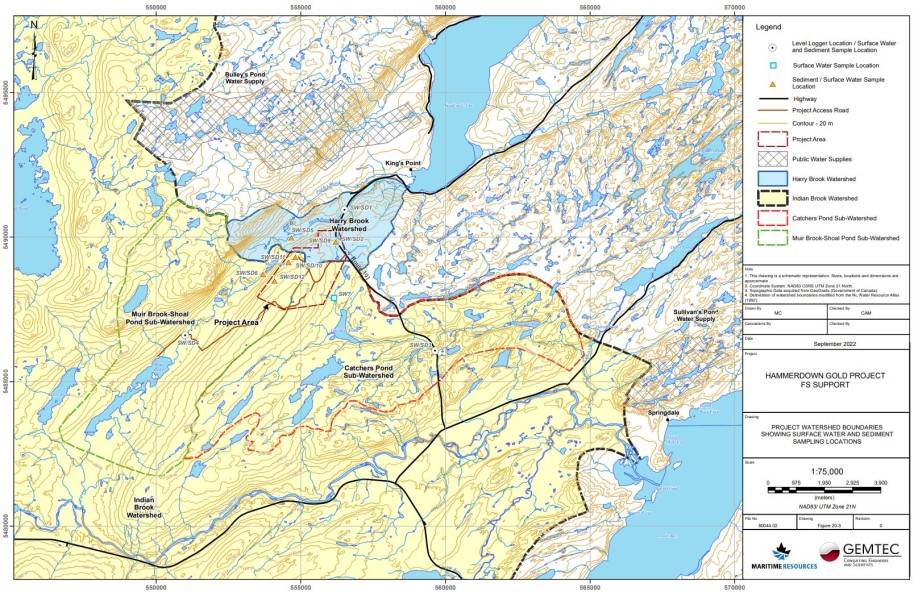

| 20.2.2 Aquatic Environment | 20-6 |

| 20.2.3 Socioeconomic Environment | 20-8 |

| 20.2.4 Hydrology, Surface Water and Sediment Quality Baseline Studies | 20-9 |

| 20.2.5 Hydrogeology Baseline Studies | 20-11 |

|

|

| 20.3 Other Supporting Studies | 20-13 |

| 20.3.1 Site Wide Geotechnical Investigation | 20-13 |

| 20.4 Jurisdiction, Applicable Laws and Regulations | 20-15 |

| 20.4.1 Environmental Assessment Processes | 20-15 |

| 20.4.2 Other Legislation | 20-17 |

| 20.5 Environmental Permitting | 20-19 |

| 20.6 Rehabilitation and Closure Plan | 20-21 |

| 20.6.1 Regulatory Requirements | 20-21 |

| 20.6.2 Objectives and Approach | 20-21 |

| 20.6.3 Progressive Rehabilitation | 20-22 |

| 20.6.4 Closure Rehabilitation | 20-23 |

| 20.6.5 Post-Closure and Long-Term Monitoring | 20-26 |

| 20.6.6 Cost Estimate for Closure | 20-26 |

| 20.6.7 Financial Assurance | 20-27 |

| 20.7 Economic Benefit | 20-27 |

| 20.8 Consultation | 20-27 |

| 20.8.1 Public Consultation | 20-27 |

| 20.8.2 Industry Relations | 20-28 |

| 20.8.3 Regulatory Consultation | 20-28 |

| 20.9 Geochemistry of Mine Waste | 20-29 |

| 20.9.1 Methodology | 20-29 |

| 20.9.2 Results | 20-31 |

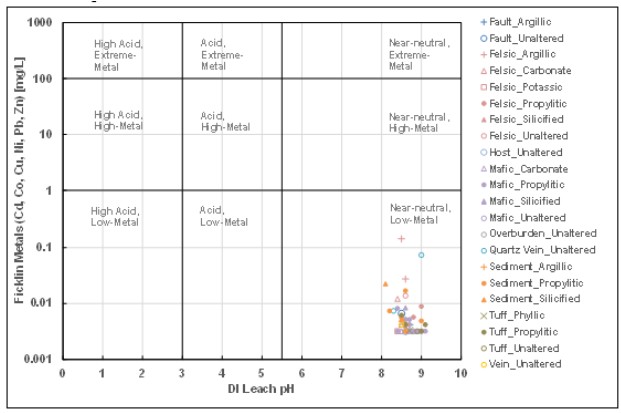

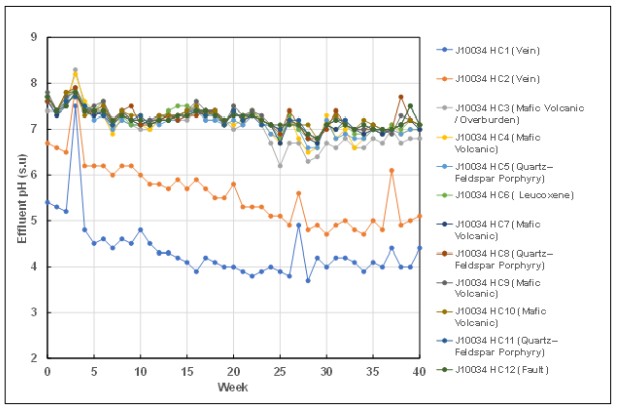

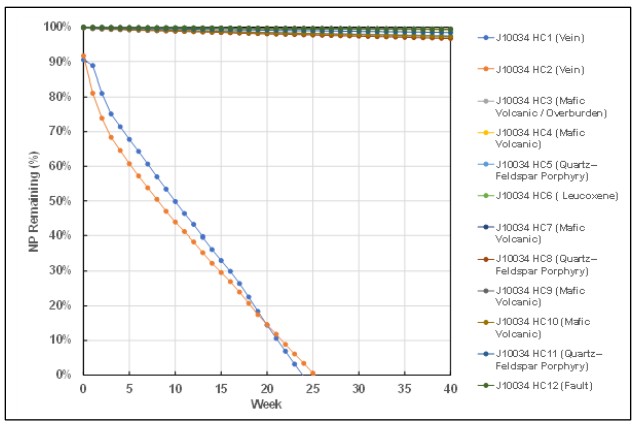

| 20.9.3 Metal Leaching Assessment | 20-34 |

| 20.9.4 Predictive Calculations of Future Water Quality | 20-37 |

| 20.9.5 Summary | 20-38 |

| 21 Capital Cost Estimate | 21-1 |

| 21.1 Capital Cost Summary | 21-1 |

| 21.2 Basis of Estimate | 21-2 |

| 21.3 Mine Capital Cost Estimate | 21-2 |

| 21.4 Site Development and On-Site Infrastructure Direct Cost Estimate | 21-3 |

| 21.4.1 Direct Pre-Production Capital | 21-3 |

| 21.5 Processing Cost Estimate | 21-4 |

| 21.5.1 Processing Infrastructure Capital Cost Methodology | 21-4 |

|

|

| 21.6 Infrastructure Cost Estimate | 21-6 |

| 21.7 Indirect Cost Estimate | 21-6 |

| 21.7.1 EPCM Cost Estimate | 21-7 |

| 21.8 Owners Cost Estimate | 21-8 |

| 21.8.1 Pre-Production G&A - Labour | 21-8 |

| 21.8.2 Pre-Production G&A - Expenses and Services | 21-9 |

| 21.9 Contingency | 21-10 |

| 21.10 Closure Cost Estimate | 21-10 |

| 21.11 Capital Estimate Exclusions | 21-10 |

| 22 Operating Cost Estimate | 22-1 |

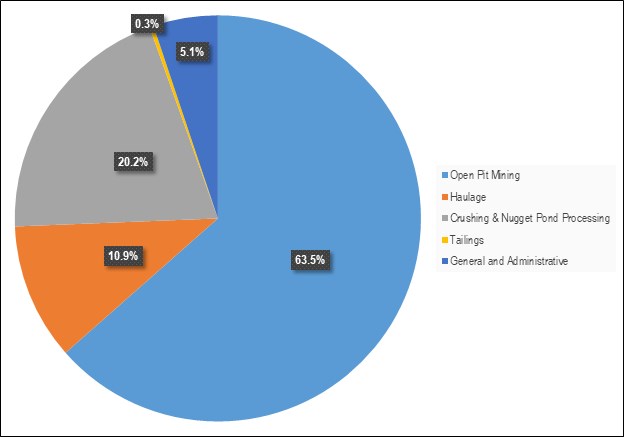

| 22.1 Operating Cost Summary | 22-1 |

| 22.2 Basis of Estimate | 22-3 |

| 22.3 Mine Operating Cost Estimate | 22-3 |

| 22.4 Processing Operating Cost Estimate | 22-4 |

| 22.4.1 Mineral Processing Operating Cost | 22-4 |

| 22.5 Transportation / Haulage Operating Cost Estimate | 22-8 |

| 22.6 Tailings Operating Cost Estimate | 22-8 |

| 22.7 General and Administration Operating Cost Estimate | 22-9 |

| 23 Economic Analysis | 23-1 |

| 23.1 Summary of Results | 23-1 |

| 23.2 Basis of Analysis | 23-2 |

| 23.3 Assumptions | 23-3 |

| 23.4 Taxes | 23-4 |

| 23.5 Royalties | 23-5 |

| 23.6 Results | 23-5 |

| 23.7 Sensitivities | 23-7 |

| 24 Adjacent Properties | 24-1 |

| 25 Other Relevant Data and Information | 25-1 |

| 26 Interpretations and Conclusions | 26-1 |

| 26.1 Geology and Mineral Resources | 26-1 |

| 26.2 Risks | 26-1 |

|

|

| 26.3 Opportunities | 26-4 |

| 27 Recommendations | 27-1 |

| 27.1 Recommendations | 27-1 |

| 27.1.1 Exploration | 27-1 |

| 27.1.2 QA/QC | 27-1 |

| 27.1.3 Mineral Resources | 27-2 |

| 28 References | 28-1 |

| 29 Units of Measure, Abbreviations and Acronyms | 29-1 |

|

|

List of Figures

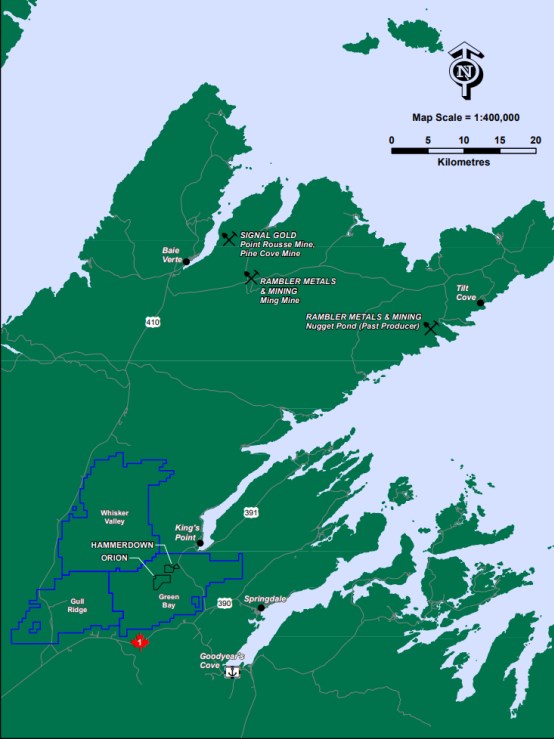

| Figure 4-1: Maritime Resources Gold Project Location Map | 4-2 |

| Figure 4-2: Project Location Map Regional Scale | 4-3 |

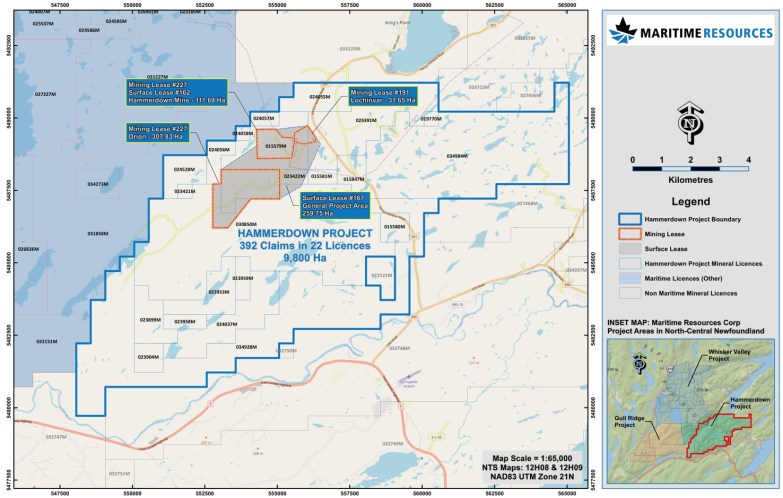

| Figure 4-3: Hammerdown Project Area Mining Licenses and Mining Leases | 4-5 |

| Figure 5-1: King's Point | 5-1 |

| Figure 5-2 Road Access Map | 5-2 |

| Figure 5-3: Typical Landscape in the Project Area | 5-4 |

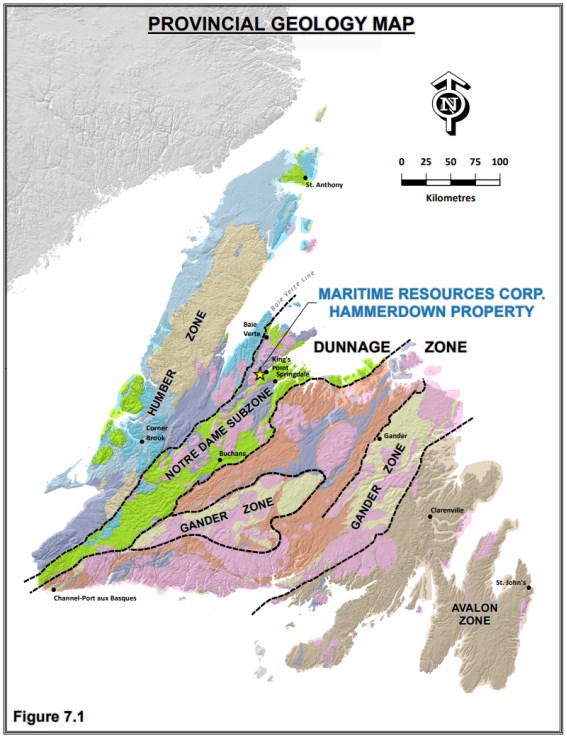

| Figure 7-1: Regional Geology Setting | 7-2 |

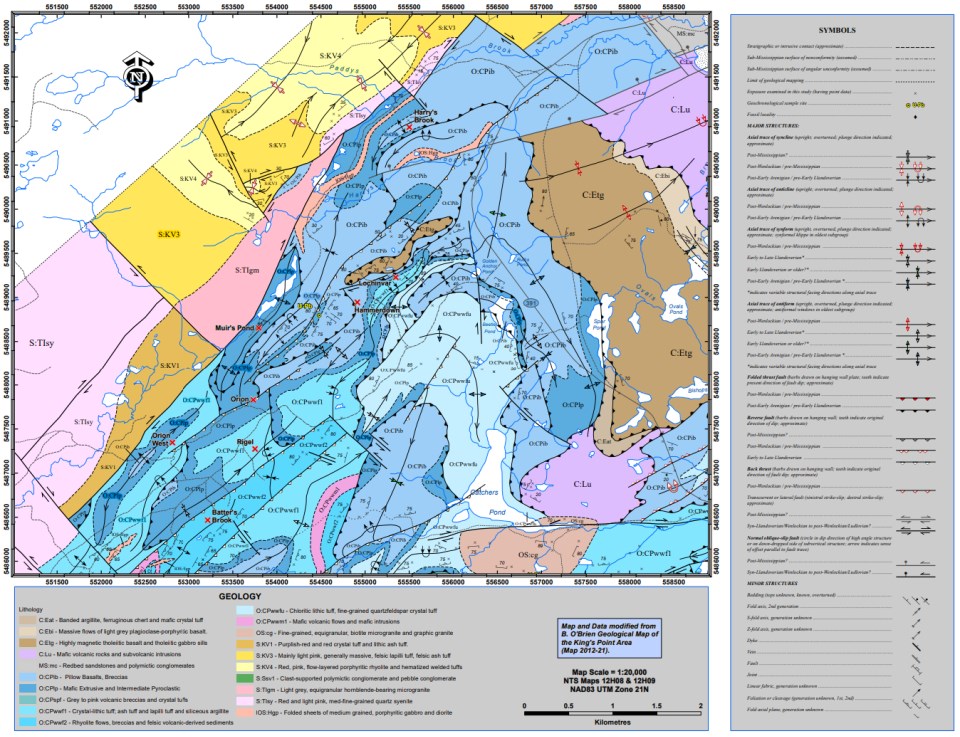

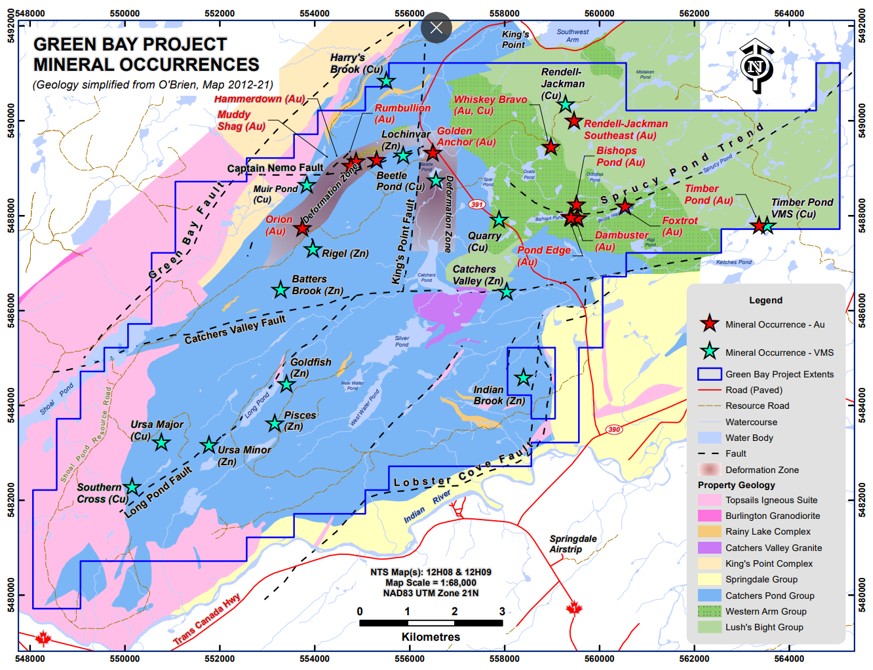

| Figure 7-2: Property Geology | 7-5 |

| Figure 7-3: Property Mineralization | 7-7 |

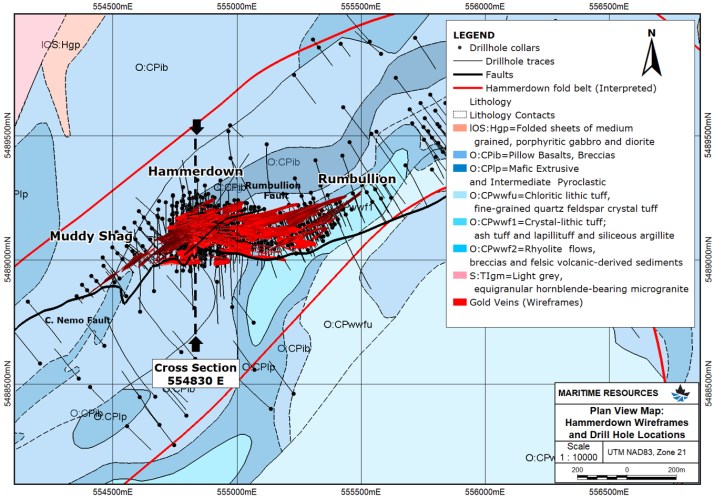

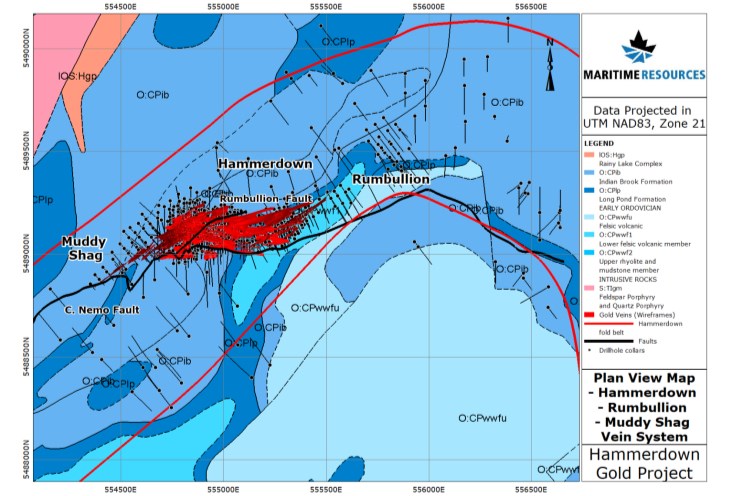

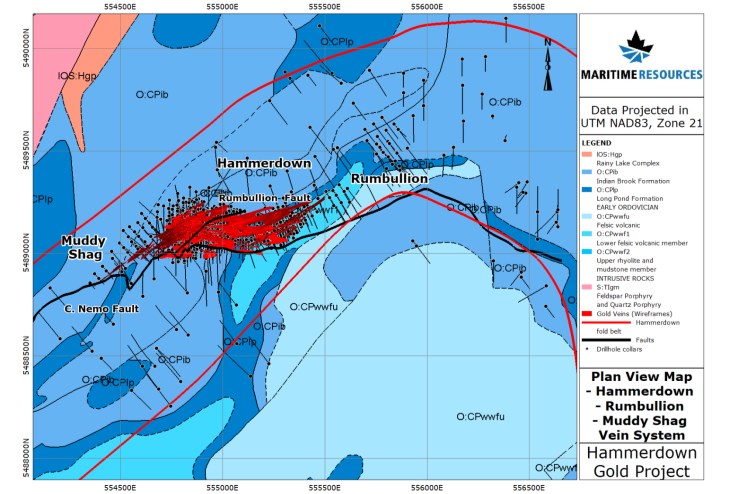

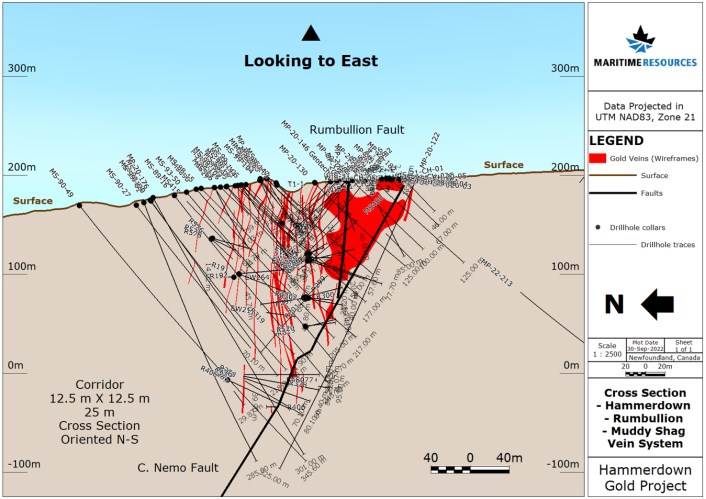

| Figure 7-4: Hammerdown-Rumbullion-Muddy Shag Vein System | 7-12 |

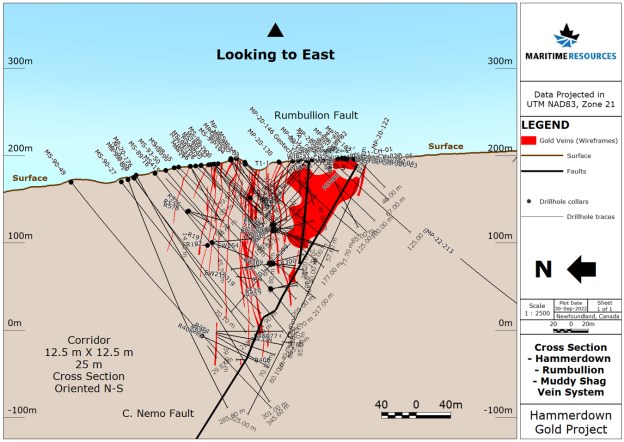

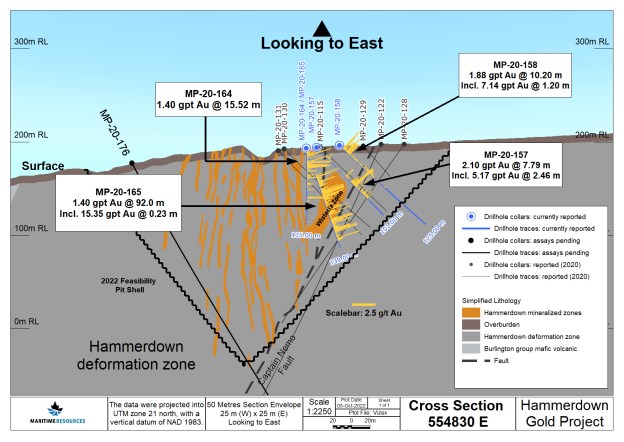

| Figure 7-5: Hammerdown Cross-Section 554830 East | 7-13 |

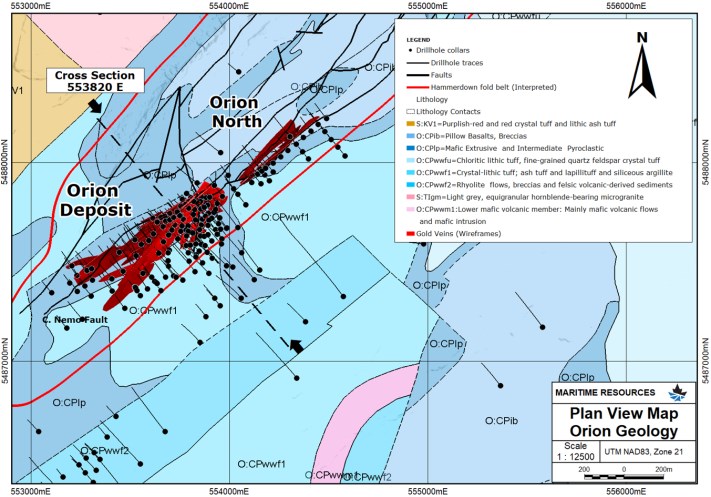

| Figure 7-6: Orion Geology | 7-16 |

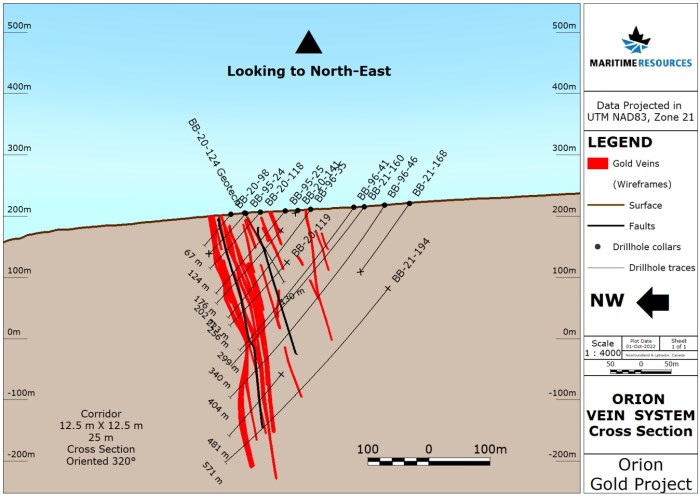

| Figure 7-7: Orion Cross-Section | 7-18 |

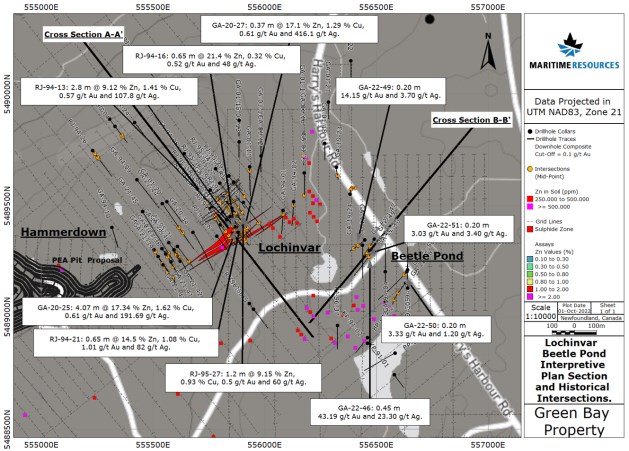

| Figure 7-8: Lochinvar and Beetle Pond Interpretive Plan Section and Historical Intersections | 7-19 |

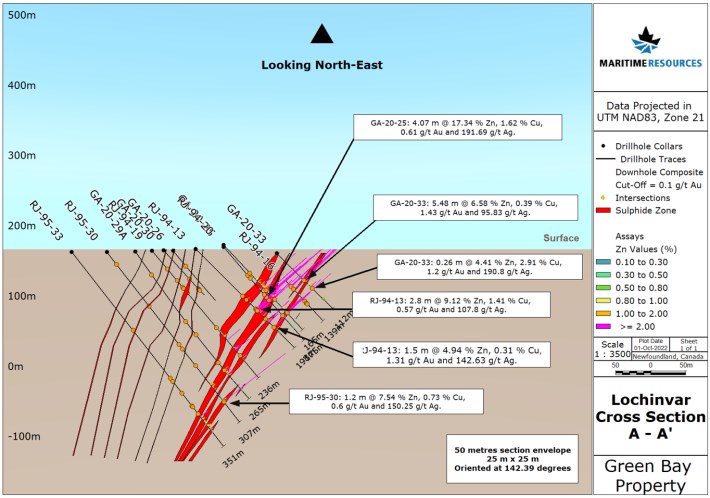

| Figure 7-9: Lochinvar Cross-section and Significant Intersections | 7-20 |

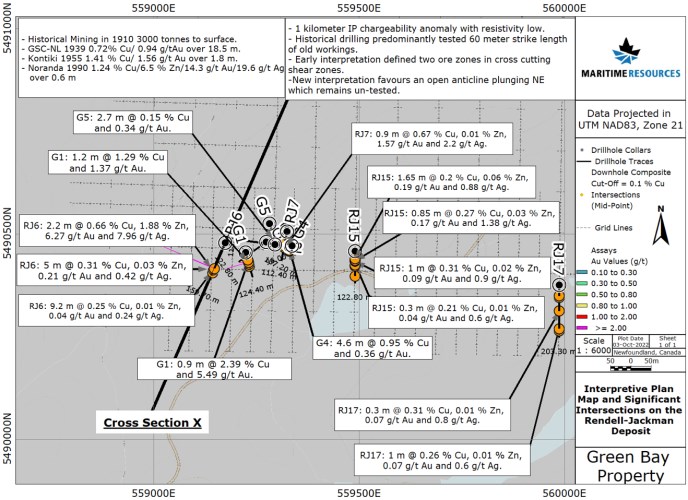

| Figure 7-10: Interpretive Plan Map and Significant Intersections on the Rendell-Jackman Deposit | 7-22 |

| Figure 7-11: Cross-Section of the Rendell-Jackman Deposit with Significant Drill Intersections | 7-23 |

| Figure 7-12: Batters Brook Interpretive Plan Section and Historical Intersections | 7-27 |

| Figure 7-13: Batters Brook Cross-section and Significant Intersections | 7-28 |

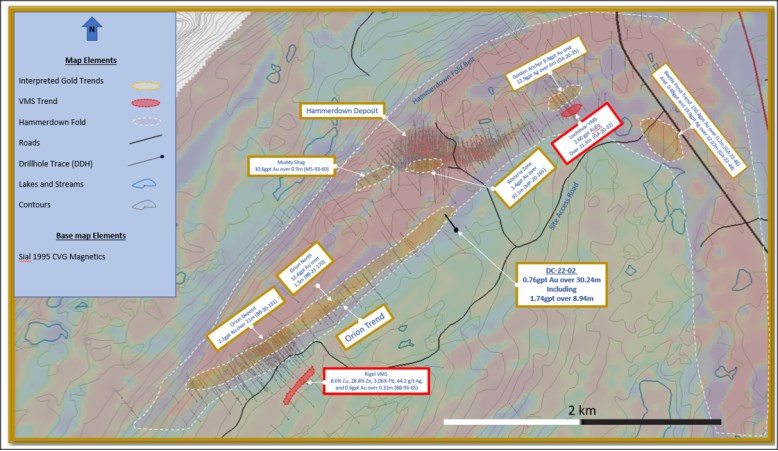

| Figure 9-1: 1995 Sial CVG Magnetics Map Depicting Drilling, PEA Deposit Whittle Shells and Exploration Highlights, Showings and Trends | 9-2 |

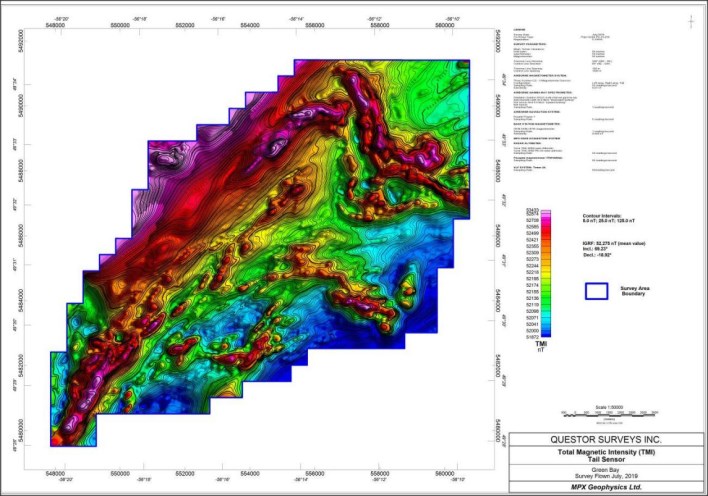

| Figure 9-2: Questor Magnetic Map Products for Green Bay Property | 9-5 |

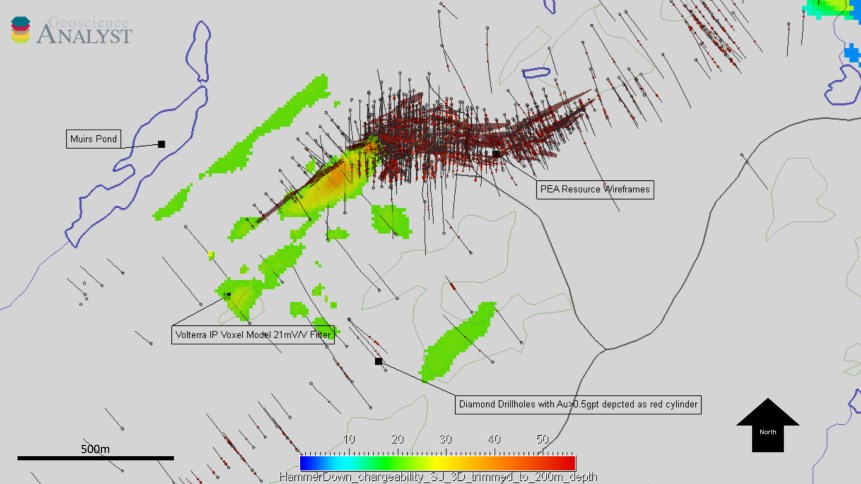

| Figure 9-3: Hammerdown West IP Grid depicting 2019 Volterra 3D IP Chargeability Voxel Model | 9-7 |

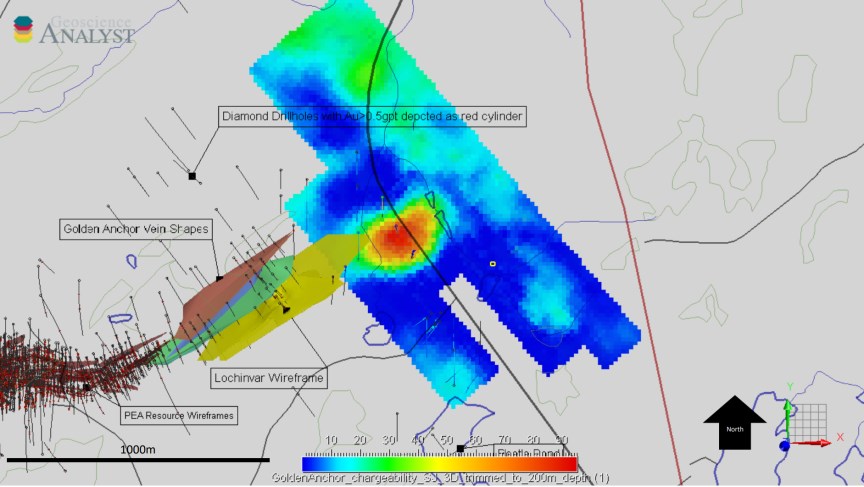

| Figure 9-4: Hammerdown East IP Grid depicting 2019 Volterra 3D IP Chargeability Voxel | 9-9 |

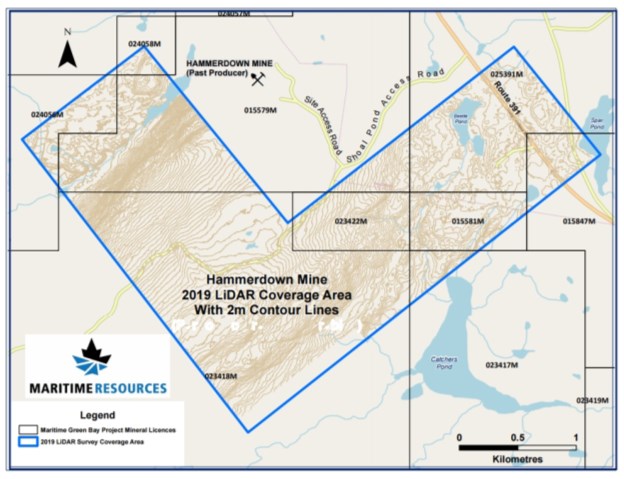

| Figure 9-5: Hammerdown Mine 2019 LiDAR Map | 9-11 |

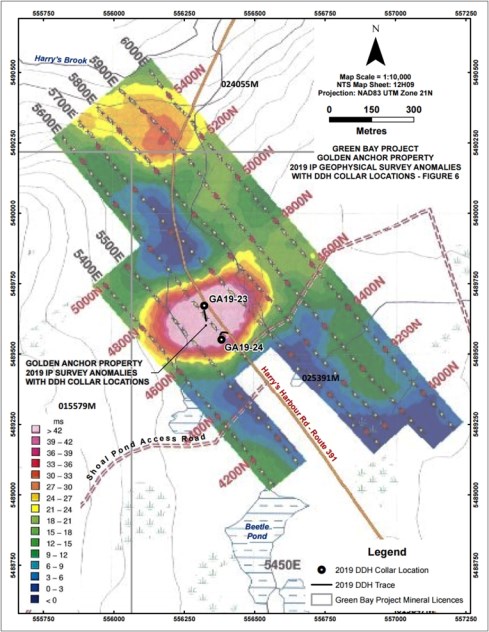

| Figure 9-6: Plan Map of 2019 Eastern IP Grid Depicting drilling locations | 9-13 |

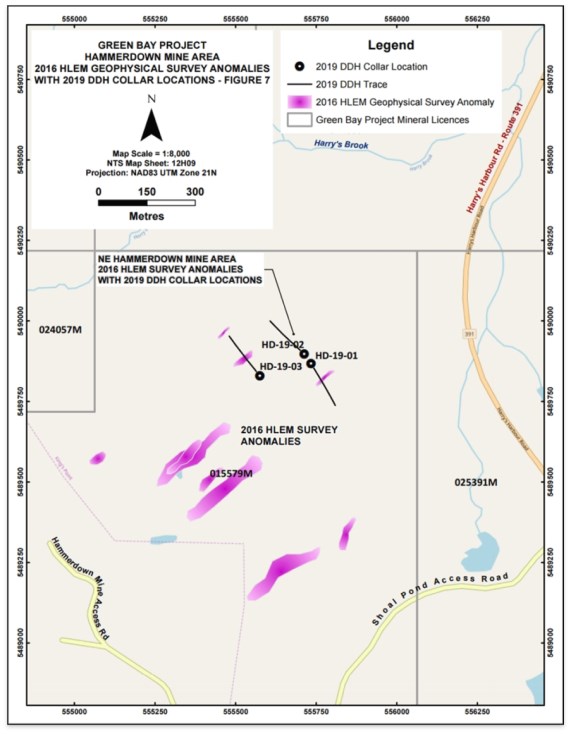

| Figure 9-7: Plan Map depicting 2016 HLEM Geophysical Anomalies | 9-15 |

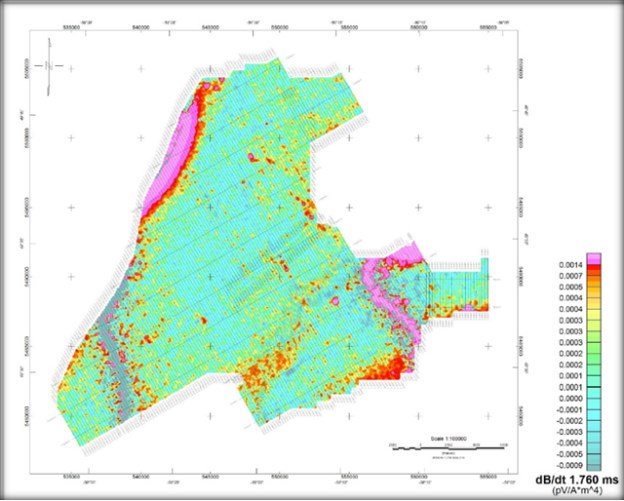

| Figure 9-8: Plan Map Depicting 2020 Geotech VTEM dB/dt Z Component Channel 35 | 9-17 |

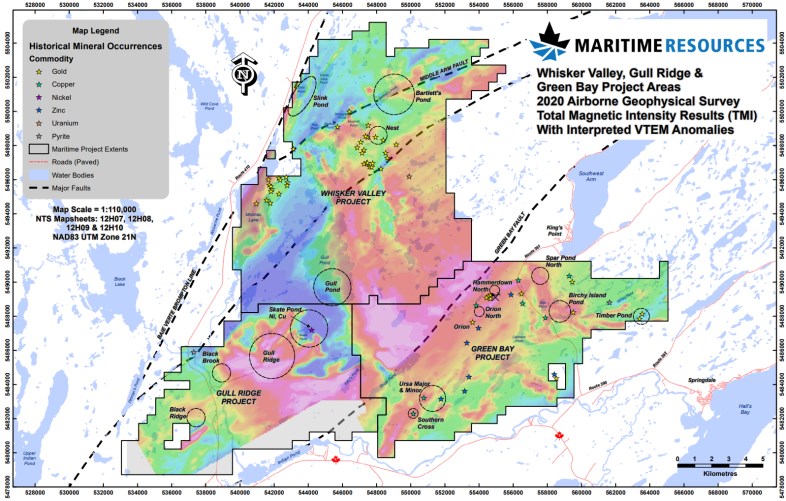

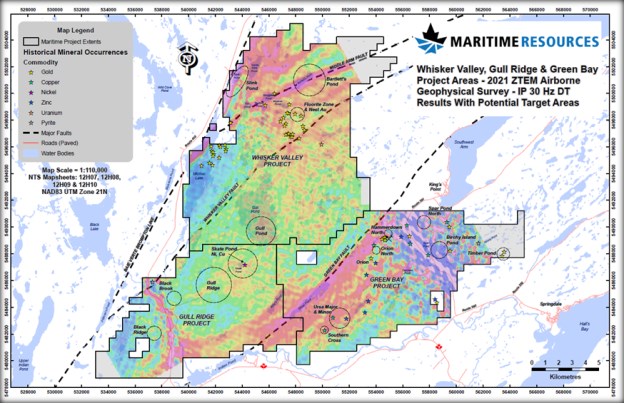

| Figure 9-9: Project Map Depicting Total Magnetic Intensity (TMI), Mineral Occurrences and VTEM Geophysical Targets (dashed circles indicate target areas) | 9-18 |

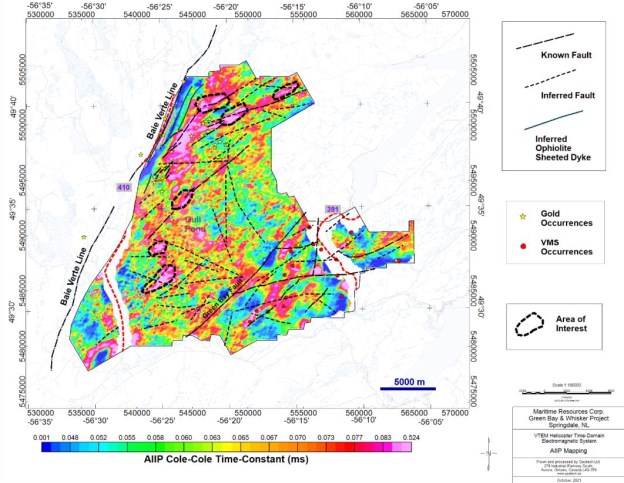

| Figure 9-10: Regional Project Map Depicting AIIP Mapping and Interpreted Fault and Areas of Interest | 9-20 |

|

|

| Figure 9-11: Regional Project Map Depicting ZTEM Shallow 30Hz Channel | 9-21 |

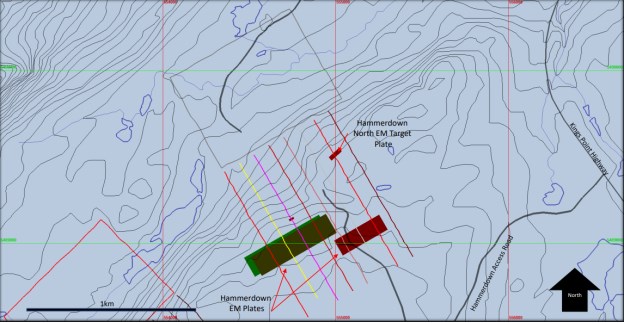

| Figure 9-12: Hammerdown SPEM Loop and Grid Configuration Depicting Modelled Conductive Plates | 9-22 |

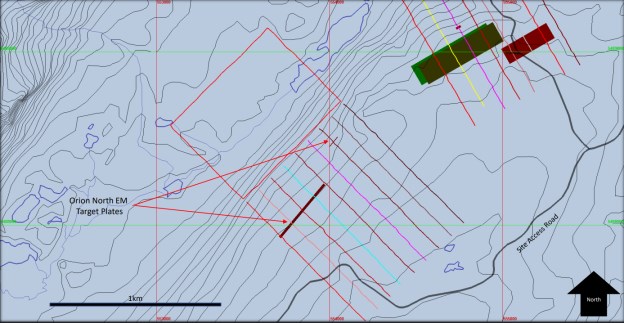

| Figure 9-13: Orion North SPEM Loop and Grid Configuration depicting modelled Conductive Plates | 9-23 |

| Figure 9-14: Plan Map of Orion-Hammerdown Area Depicting Magnetic and Mineralized Trends | 9-25 |

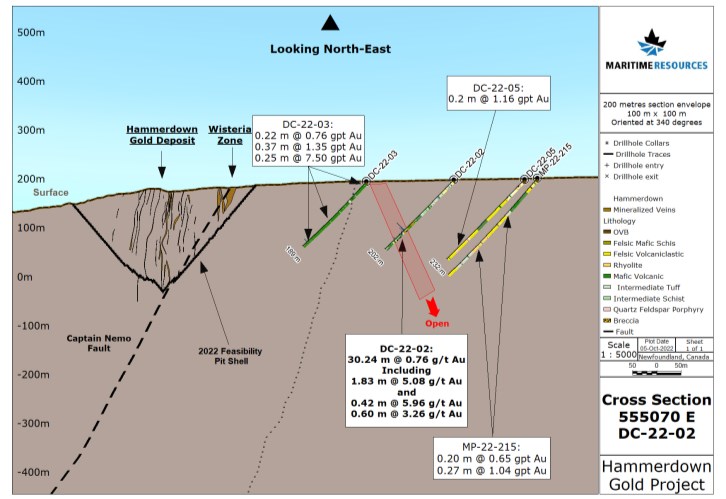

| Figure 9-15: Cross Section of DC-22-02 Intersection and Hammerdown Wireframes and PEA Pit Shape | 9-26 |

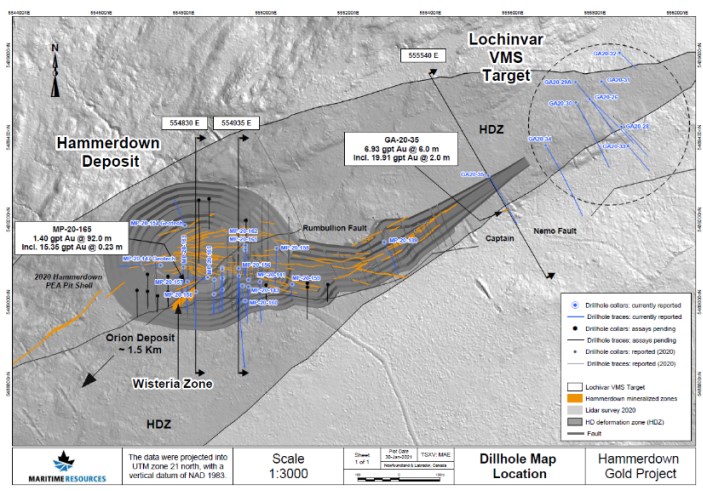

| Figure 10-1: Hammerdown Project Plan Map, Wireframes, and Geology | 10-2 |

| Figure 10-2: Plan Map Depicting 2020 Drilling of Wisteria Zone | 10-5 |

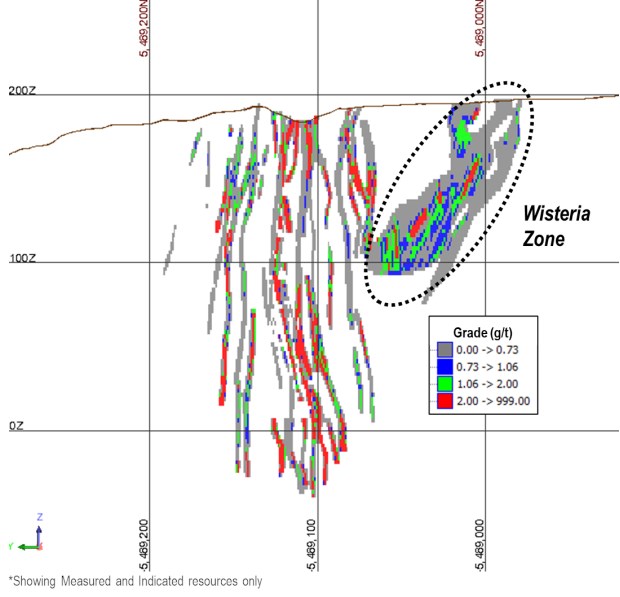

| Figure 10-3: Cross-section Depicting 2020 Drilling of Wisteria Zone | 10-6 |

| Figure 10-4: Core Photography Set-up | 10-10 |

| Figure 10-5: Drill Core Photography Set-Up with Tablet Control | 10-11 |

| Figure 10-6: Maritime Resource Cutting Facility | 10-12 |

| Figure 10-7: Plan View- Hammerdown Wireframes and Drill Hole Locations | 10-14 |

| Figure 10-8: East Orientated Cross-Section Depicting 2022 Hammerdown Wireframes and Drill Hole Locations | 10-15 |

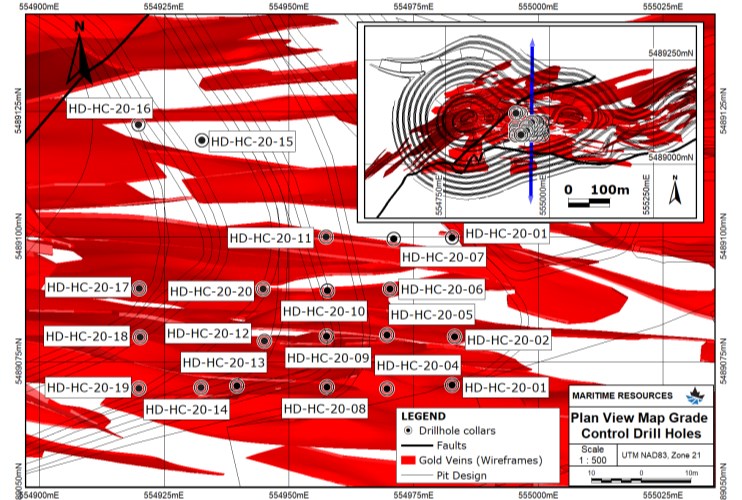

| Figure 10-9: Plan View - Hammerdown Wireframes and Grade Control Drill Hole Locations | 10-27 |

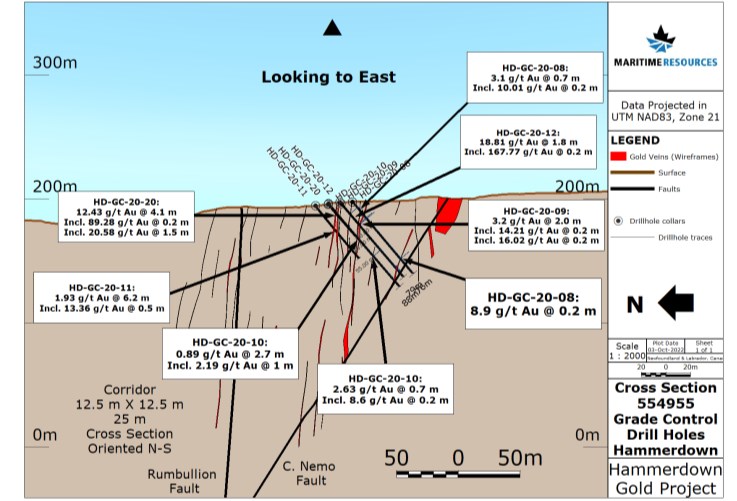

| Figure 10-10: East Facing Cross-Section of Grade Control Diamond Drill Holes with Intercepts Confirming Wireframes | 10-28 |

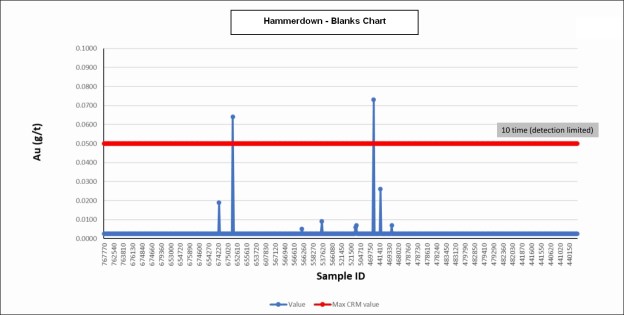

| Figure 11-1: Hammerdown Blanks Chart | 11-4 |

| Figure 11-2: QC Chart for Standard OREAS 217 (2020-2021) | 11-6 |

| Figure 11-3: QC Chart for Standard OREAS 218 (2020-2021) | 11-7 |

| Figure 11-4: QC Chart for Standard OREAS 228 (2020-2021) | 11-8 |

| Figure 11-5: QC Chart for Standard OREAS 229b (2020-2021) | 11-9 |

| Figure 11-6: QC Chart for Standard OREAS 231 (2020-2021) | 11-10 |

| Figure 11-7: QC Chart for Standard OREAS 237 (2020-2021) | 11-11 |

| Figure 11-8: Hammerdown Reject Duplicates Chart | 11-13 |

| Figure 11-9: Hammerdown Reject Duplicates Chart (Axes capped to 7 g/t Au) | 11-14 |

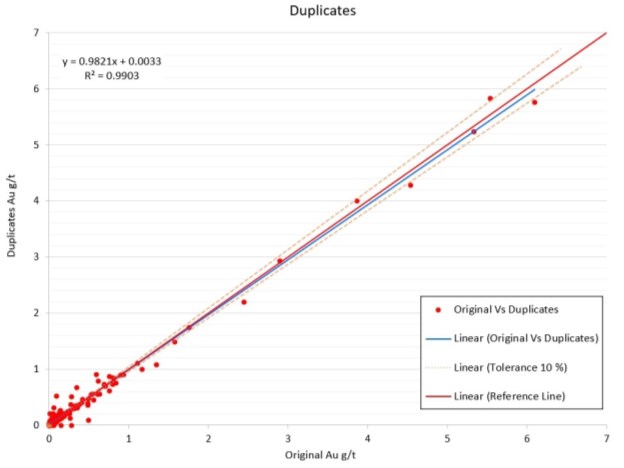

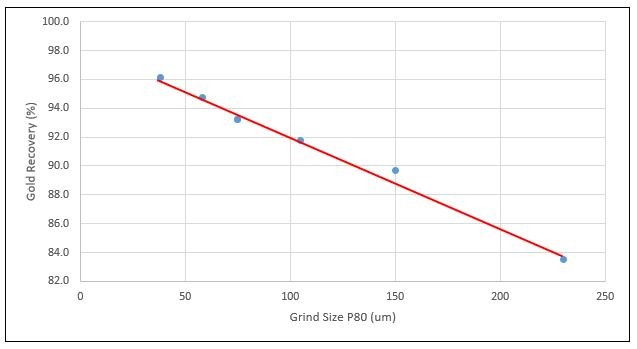

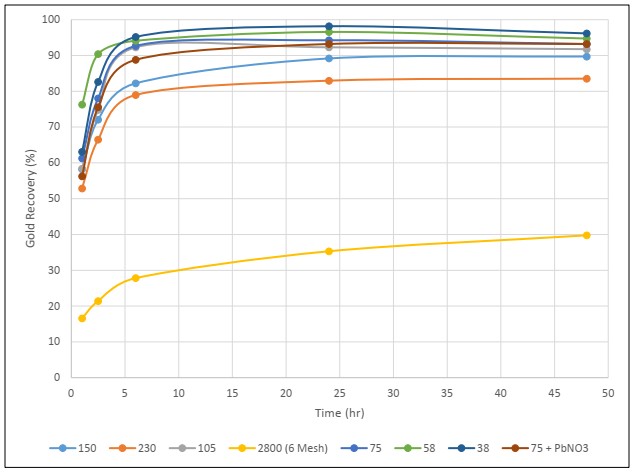

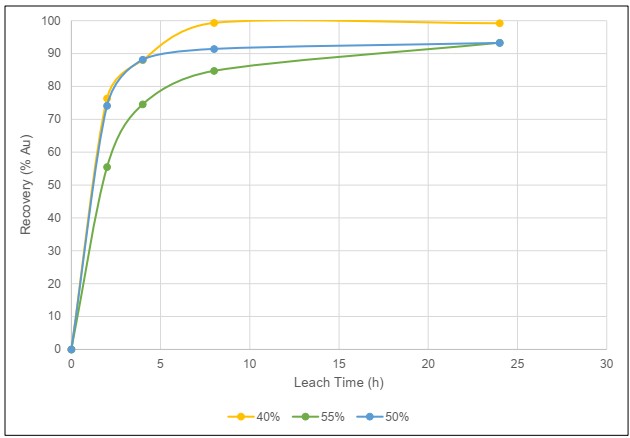

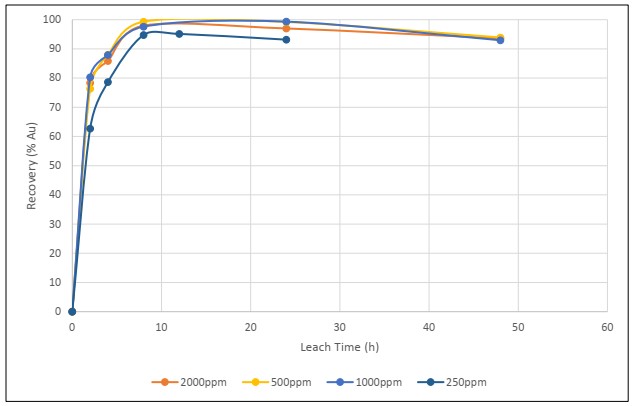

| Figure 13-1: Leach Recovery vs. Grind Size for the Master Composite | 13-4 |

| Figure 13-2: Leach Recovery vs. Time for the Master Composite Under Varying Conditions | 13-5 |

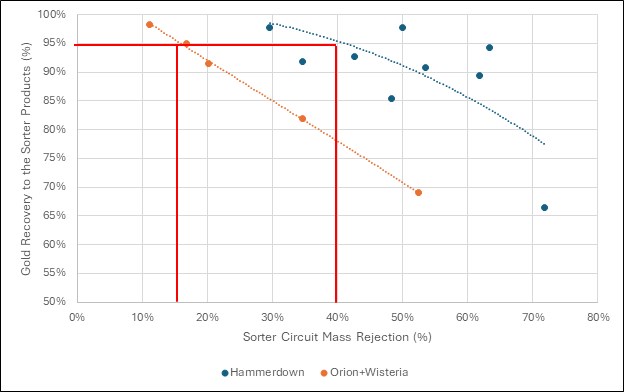

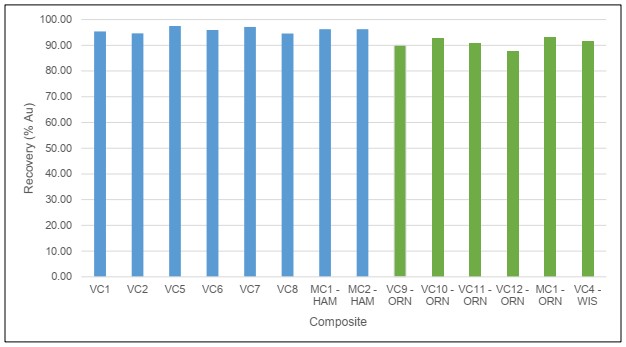

| Figure 13-3: Overall Sorting Circuit Recovery for Hammerdown and Orion Mineralization | 13-6 |

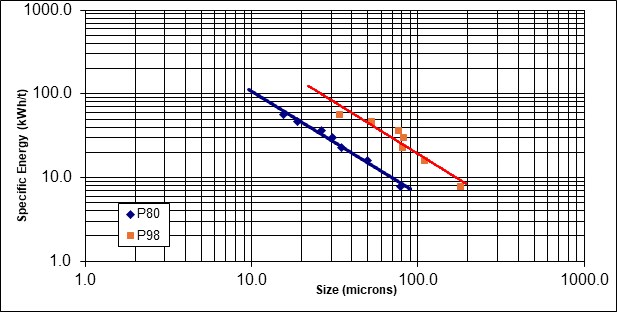

| Figure 13-4: IsaMill Test Graph | 13-9 |

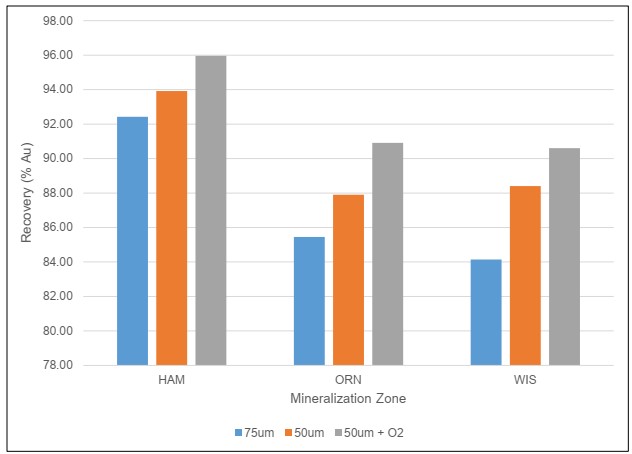

| Figure 13-5: Overall Average Gold Recovery on Different Mineralization Under Varying Conditions | 13-10 |

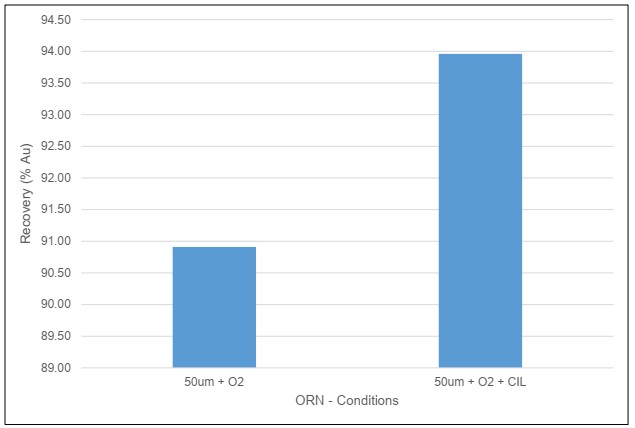

| Figure 13-6: Overall Average Gold Recovery on Orion with Carbon-In-Leach | 13-11 |

| Figure 13-7: Effect of Pulp Density on Hammerdown | 13-12 |

|

|

| Figure 13-8: Effect of NaCN Dose on Hammerdown | 13-13 |

| Figure 13-9: Composite Recoveries | 13-15 |

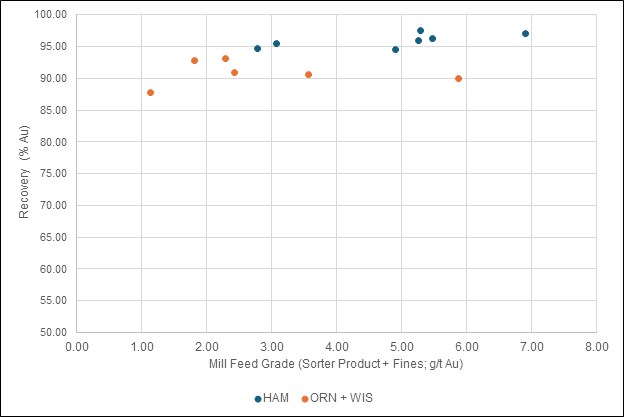

| Figure 13-10: Grade-Recovery | 13-16 |

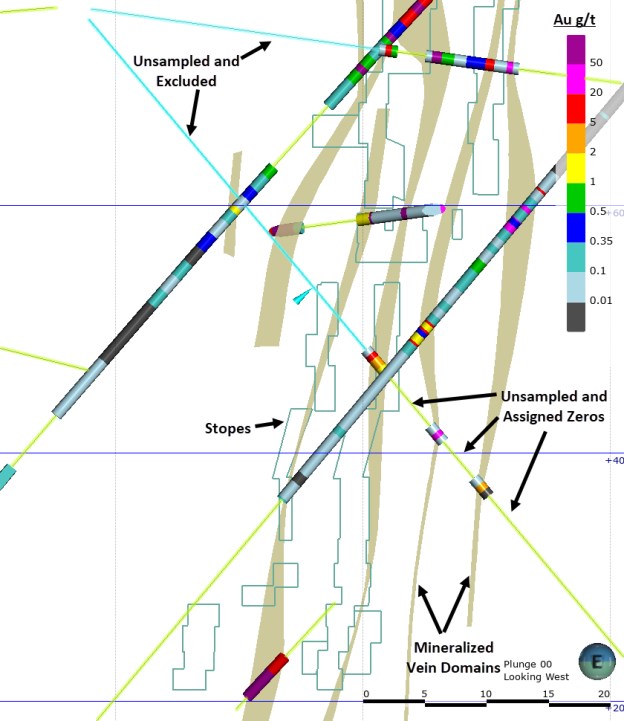

| Figure 14-1: Hammerdown Excluded Interval (6 m Viewing Corridor) | 14-5 |

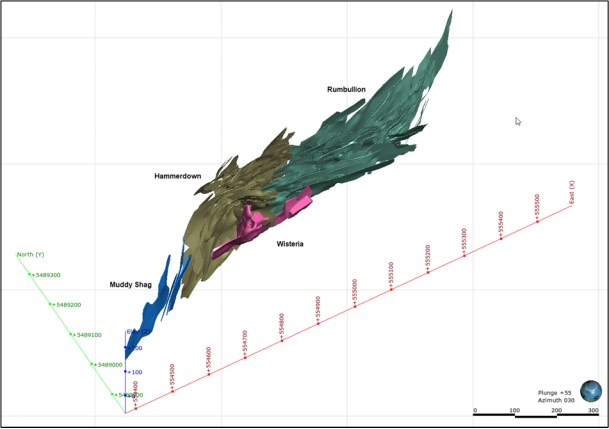

| Figure 14-2: Oblique View of the Muddy Shag, Wisteria, Hammerdown, and Rumbullion Zones, Looking Northeast | 14-9 |

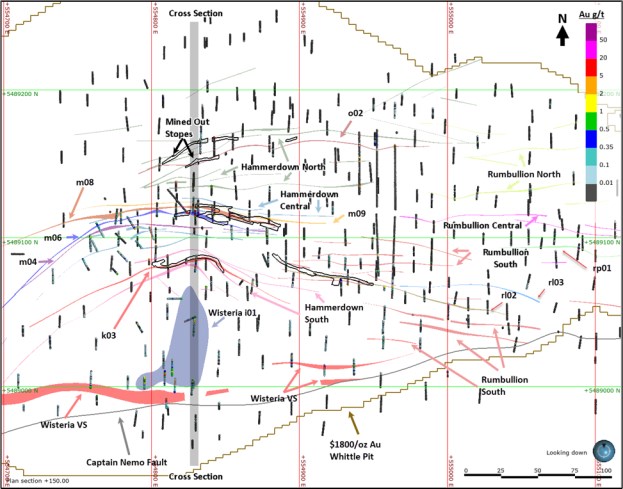

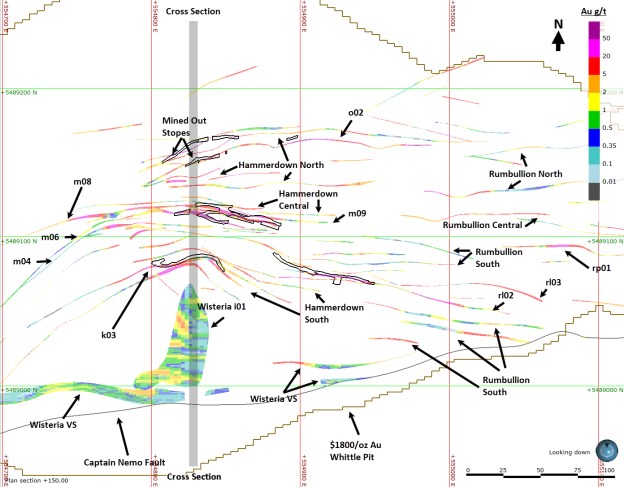

| Figure 14-3: Hammerdown, Wisteria, and Rumbullion Zones Mineralization Model Plan View (10 m Viewing Corridor) | 14-11 |

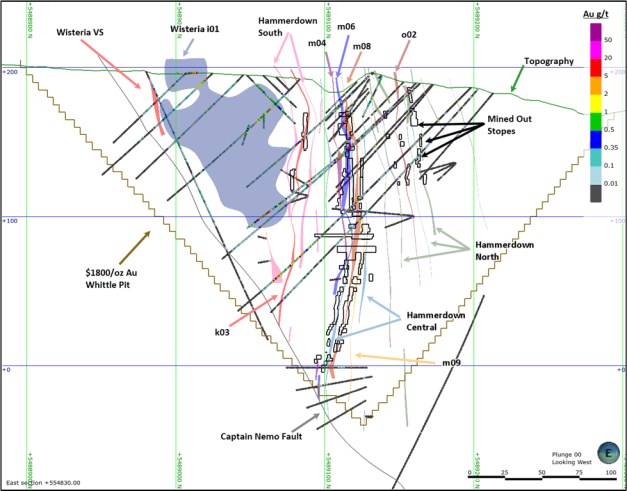

| Figure 14-4: Grouped and Individual Domains Mineralization Model Cross Section (10 m Viewing Corridor) | 14-12 |

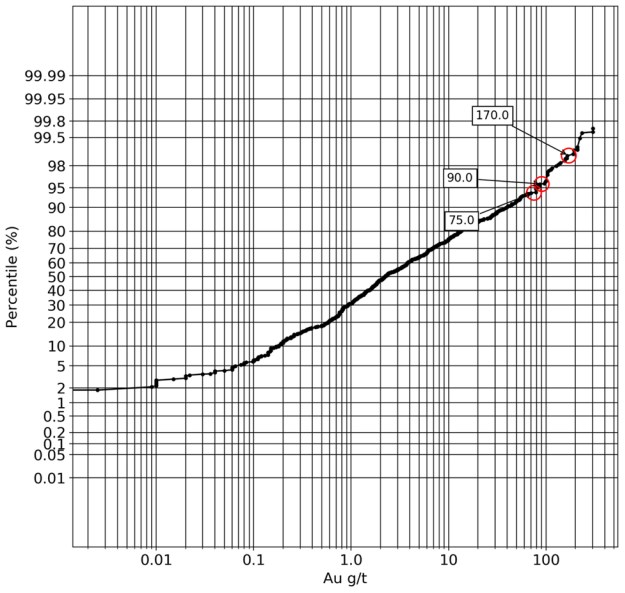

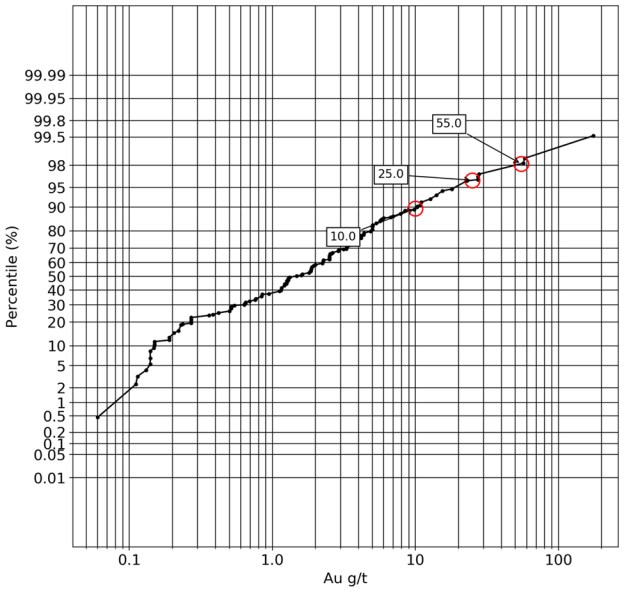

| Figure 14-5: Log Probability Plot for Hammerdown Central Domain (Gold) | 14-15 |

| Figure 14-6: Histogram for Hammerdown Central Domain (Gold) | 14-16 |

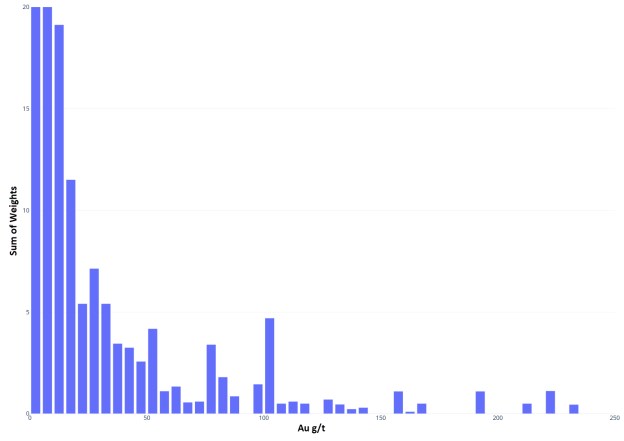

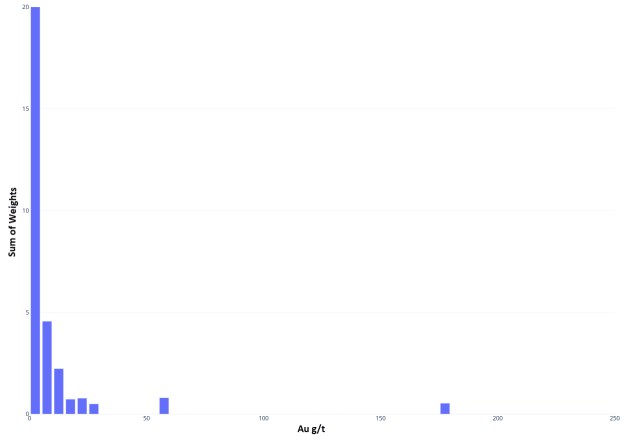

| Figure 14-7: Log Probability Plot for Rumbullion Central Domain (Gold) | 14-17 |

| Figure 14-8: Histogram for Rumbullion Central Domain (Gold) | 14-18 |

| Figure 14-9: Comparison Between Raw Assay and Composite Lengths Rumbullion Central | 14-26 |

| Figure 14-10: Gold Variogram Models - m08 | 14-28 |

| Figure 14-11: Gold Variogram Models -m06 | 14-32 |

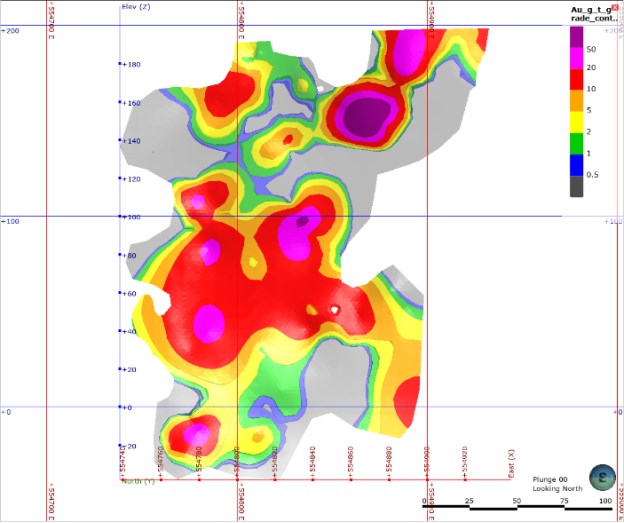

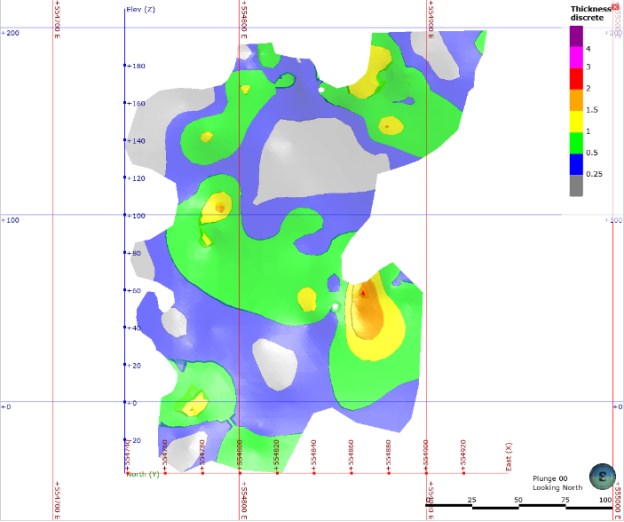

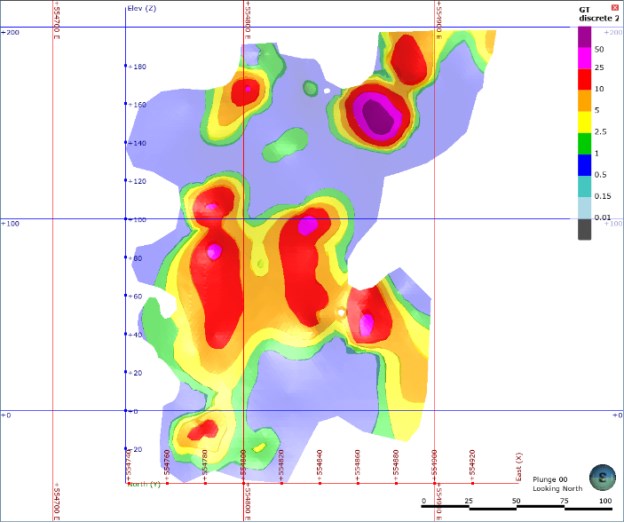

| Figure 14-12: Gold Grade and Thickness Contours - m06 (Grade (g/t Au)) | 14-38 |

| Figure 14-13: Gold Grade and Thickness Contours - m06 (Thickness (m)) | 14-39 |

| Figure 14-14: Gold Grade and Thickness Contours - m06 (Grade x Thickness (g/t-m)) | 14-40 |

| Figure 14-15: Gold Grade and Thickness Contours - m09 (Grade (g/t Au)) | 14-41 |

| Figure 14-16: Gold Grade and Thickness Contours - m09 (Thickness (m)) | 14-42 |

| Figure 14-17: Gold Grade and Thickness Contours - m09 (Grade x Thickness (g/t-m)) | 14-43 |

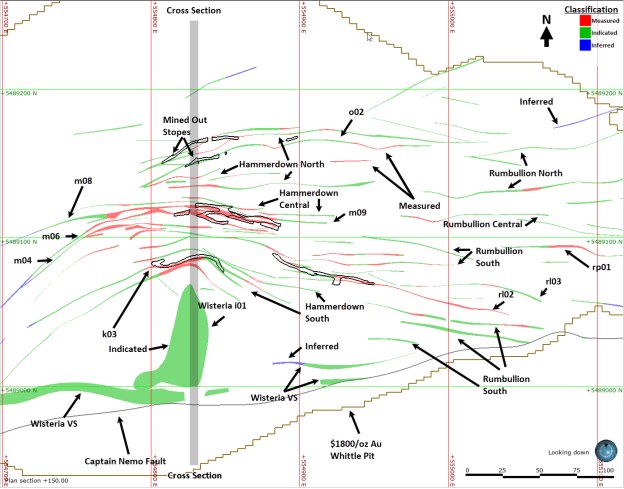

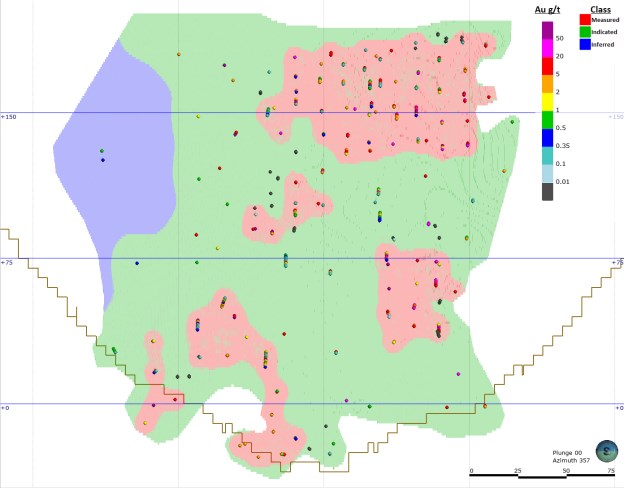

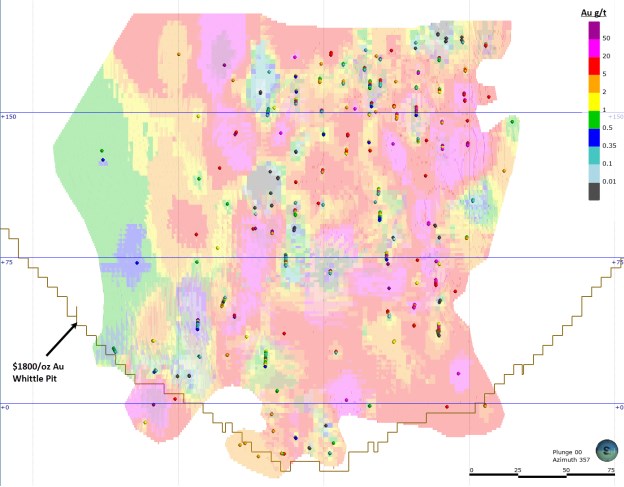

| Figure 14-18: Plan View Classification of Mineral Resources (2.5 m Corridor) | 14-62 |

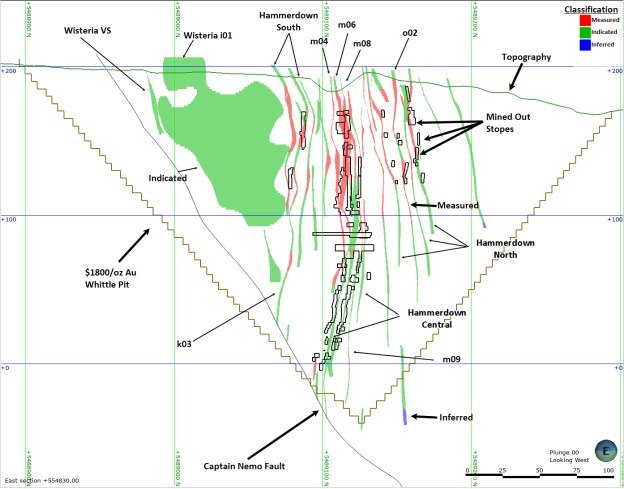

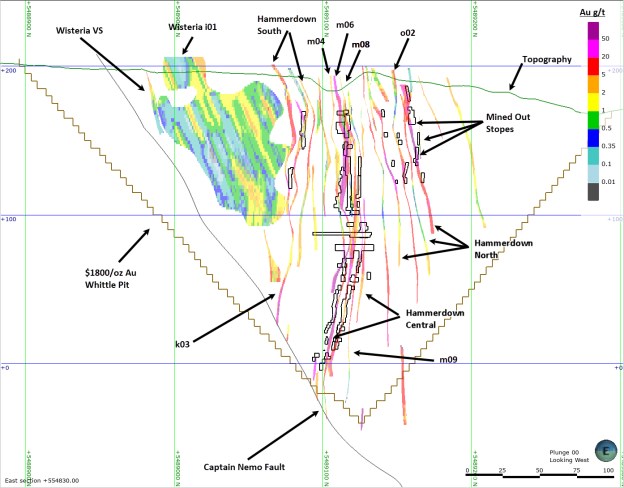

| Figure 14-19: Cross section, Looking West, Classification of Mineral Resources (2.50 m Corridor) | 14-63 |

| Figure 14-20: m08 Classification of Mineral Resources - Hammerdown (Longitudinal View) | 14-64 |

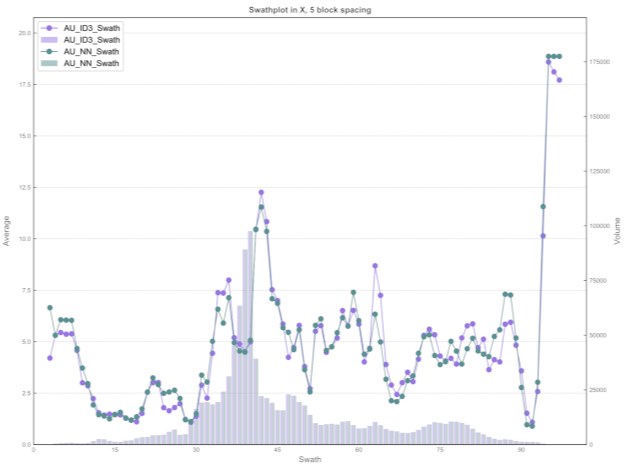

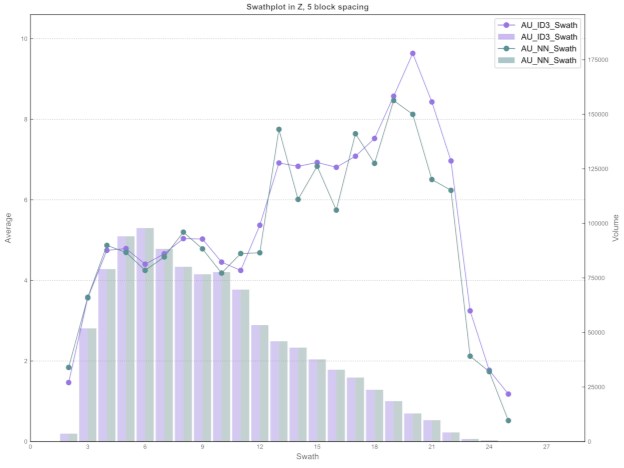

| Figure 14-21: Gold Plots - 5 Block Spacing (X) | 14-71 |

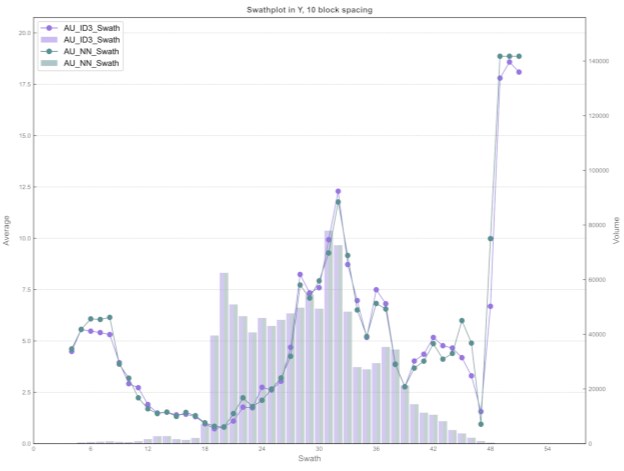

| Figure 14-22: Gold Plots - 10 Block Spacing (Y) | 14-72 |

| Figure 14-23: Gold Plots - 5 Block Spacing (Z) | 14-73 |

| Figure 14-24: Hammerdown and Rumbullion Block Model Plan View 150 EL (10 m Viewing Corridor) | 14-74 |

| Figure 14-25: Hammerdown Block Model Cross Section A-B Looking East (10 m Viewing Corridor) | 14-75 |

| Figure 14-26: m08 Vein Longitudinal View | 14-76 |

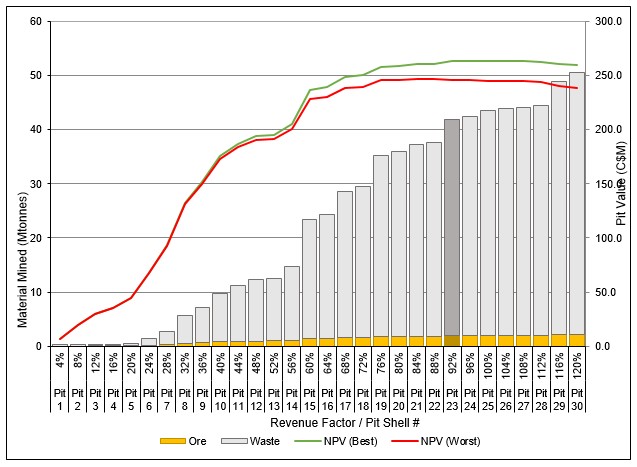

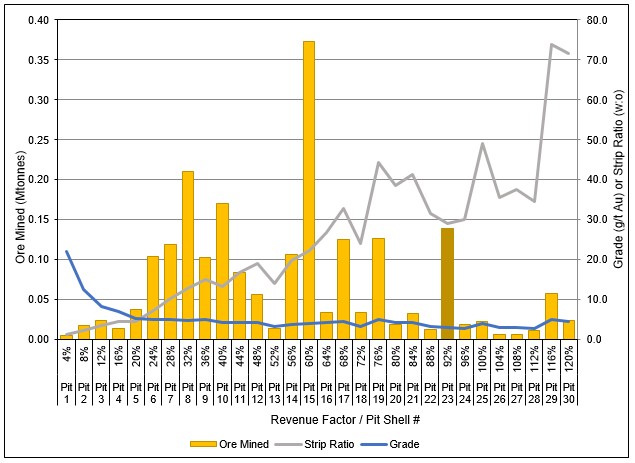

| Figure 15-1: Overall Pit Shell Results for the Hammerdown Optimization | 15-7 |

| Figure 15-2: Incremental Pit Shell Results for the Hammerdown Optimization | 15-8 |

|

|

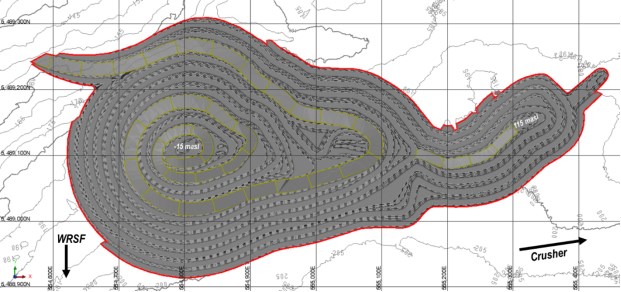

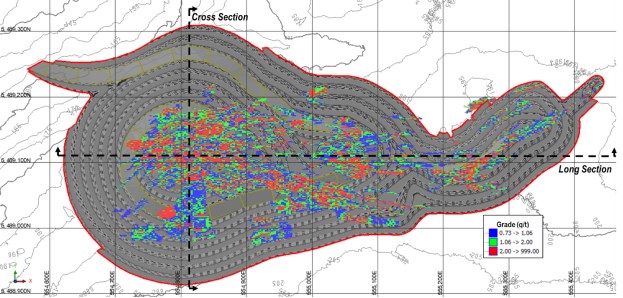

| Figure 15-3: Final Open Pit Design | 15-9 |

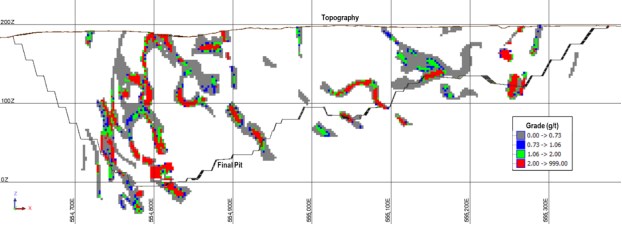

| Figure 15-4: Measured and Indicated Resources Relative to the Final Pit Design | 15-9 |

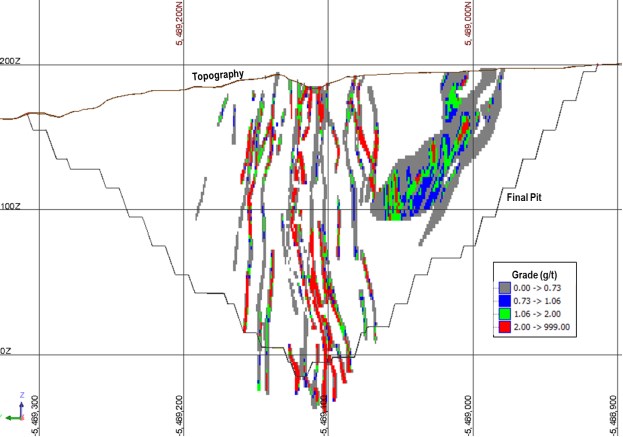

| Figure 15-5: Cross Section of Final Pit Showing Measured and Indicated Resources (554,810E looking East) | 15-10 |

| Figure 15-6: Long Section of Final Pit showing Measured and Indicated Resources (5,489,100N looking North) | 15-10 |

| Figure 15-7: Open Pit Slope Design Recommendations | 15-11 |

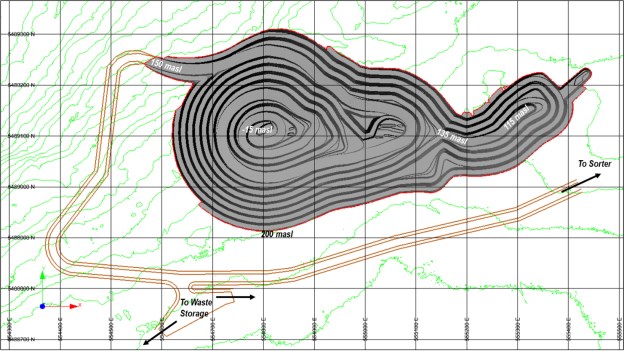

| Figure 16-1: Overall Mine Layout | 16-1 |

| Figure 16-2: Section View of the Hammerdown Deposit (looking East) | 16-3 |

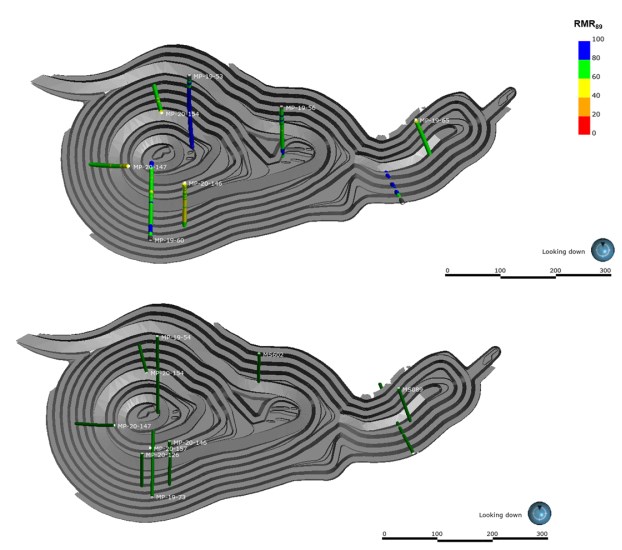

| Figure 16-3: Location of Drillholes Geotechnically Logged (top) and Televiewed (bottom) | 16-5 |

| Figure 16-4: Distribution of RMR for the Mafic Volcanics and Dykes | 16-7 |

| Figure 16-5: Geotechnical Domains and Respective Discontinuity Sets | 16-8 |

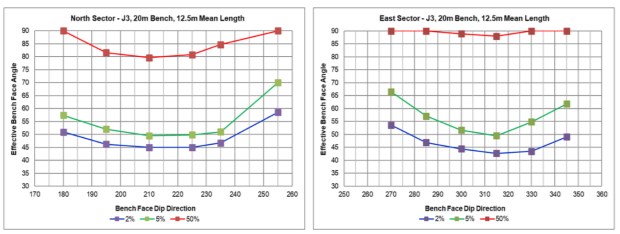

| Figure 16-6: Backbreak Analysis Results for North and East Geotechnical Domains | 16-9 |

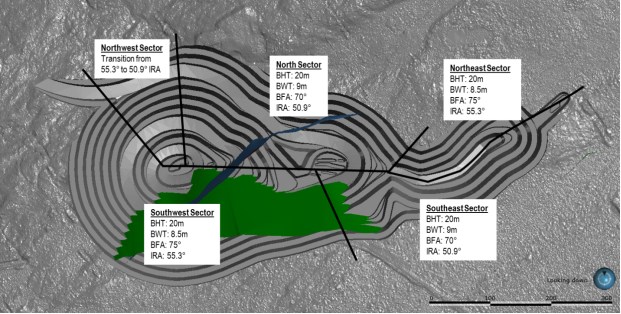

| Figure 16-7: Pit Slope Design Recommendations for Hammerdown Final Pit | 16-10 |

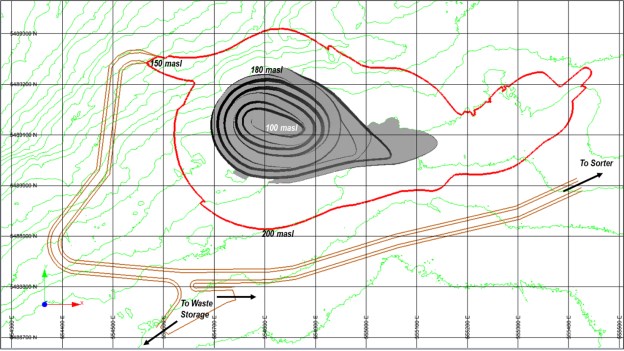

| Figure 16-8: Pushback 1 Design | 16-12 |

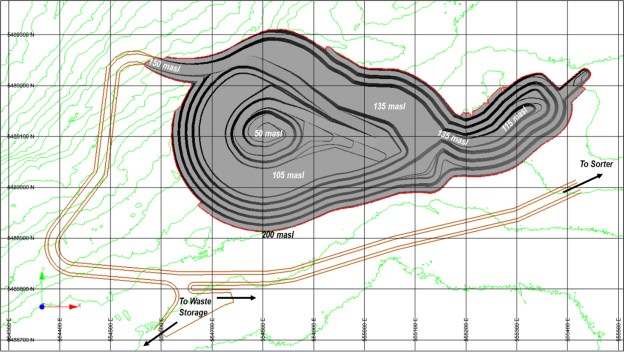

| Figure 16-9: Pushback 2 Design | 16-13 |

| Figure 16-10: Pushback 3 Design (Ultimate Pit) | 16-14 |

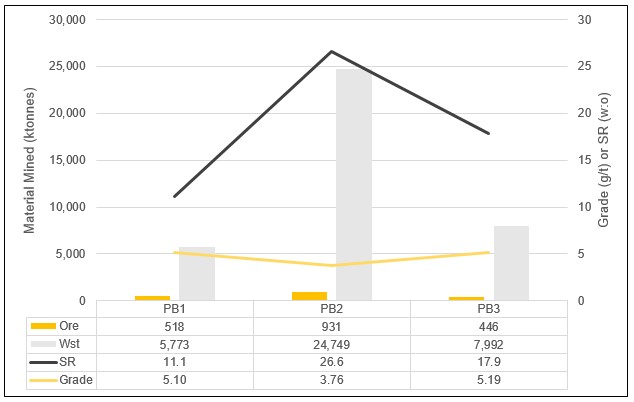

| Figure 16-11: Mining Pushback Summary | 16-15 |

| Figure 16-12: Waste Storage Locations | 16-16 |

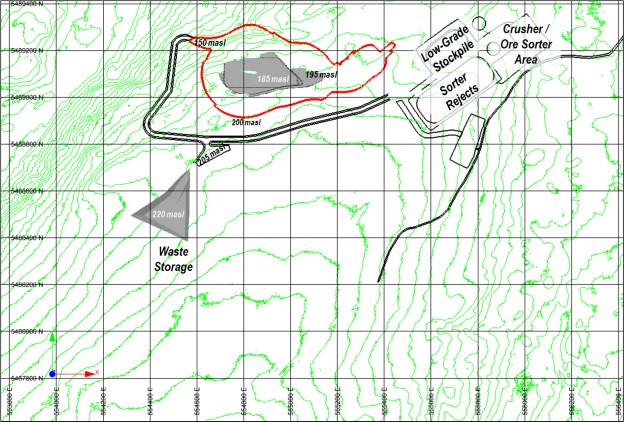

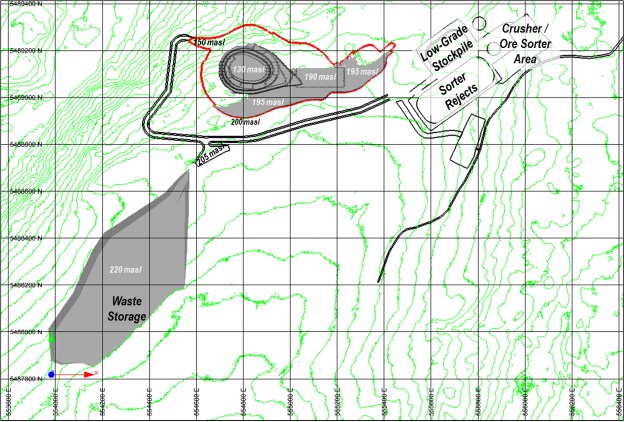

| Figure 16-13: Mine Status Map - End of Pre-production | 16-18 |

| Figure 16-14: Mine Status Map - End of Year 1 | 16-19 |

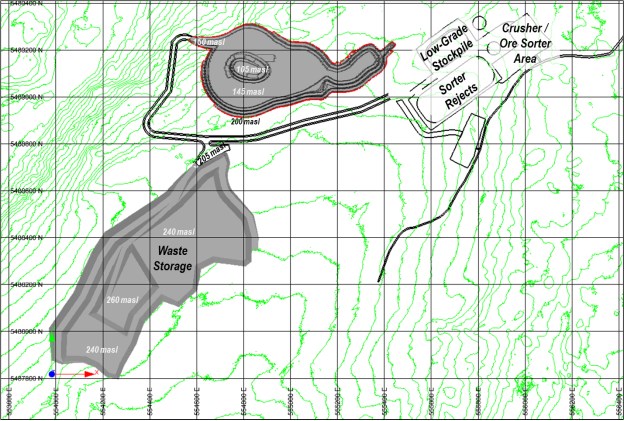

| Figure 16-15: Mine Status Map - End of Year 2 | 16-20 |

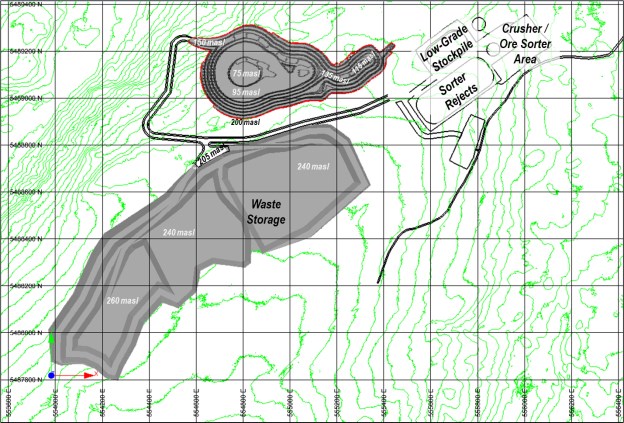

| Figure 16-16: Mine Status Map - End of Year 3 | 16-21 |

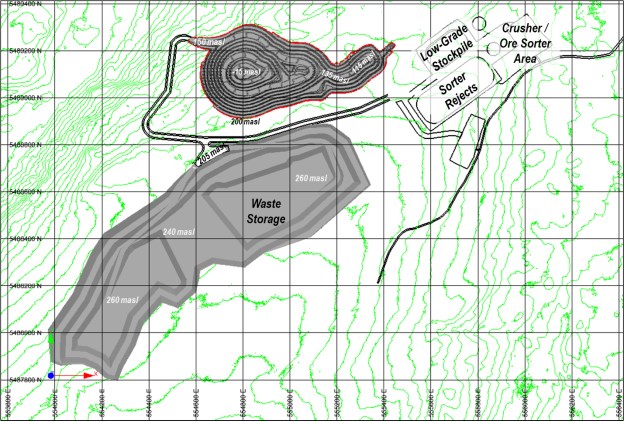

| Figure 16-17: Mine Status Map - End of Year 4 (Final) | 16-22 |

| Figure 17-1: Hammerdown Crushing and Sorting Summary Flowsheet | 17-3 |

| Figure 17-2: Hammerdown Crushing and Sorting Plant Layout | 17-4 |

| Figure 17-3: Nugget Pond Hydrometallurgical Plant | 17-9 |

| Figure 17-4: Nugget Pond Grinding and Gold Recovery Summary Flowsheet | 17-10 |

| Figure 17-5: Nugget Pond Site Plan with New Unloading, Storage and Grinding Circuit | 17-11 |

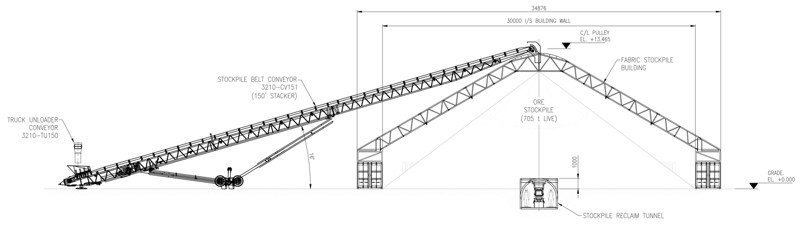

| Figure 17-6: Nugget Pond Stockpile Cover and Reclaim Tunnel Section | 17-14 |

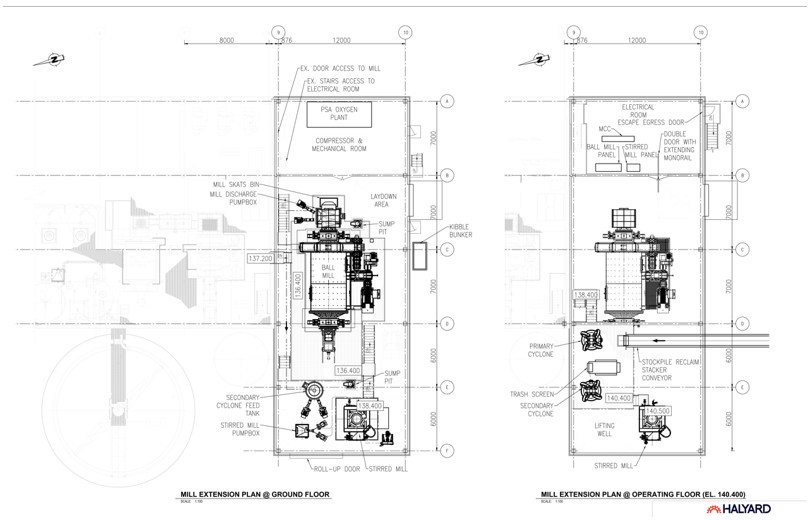

| Figure 17-7: Nugget Pond Grinding Circuit Layout and Building Extension | 17-16 |

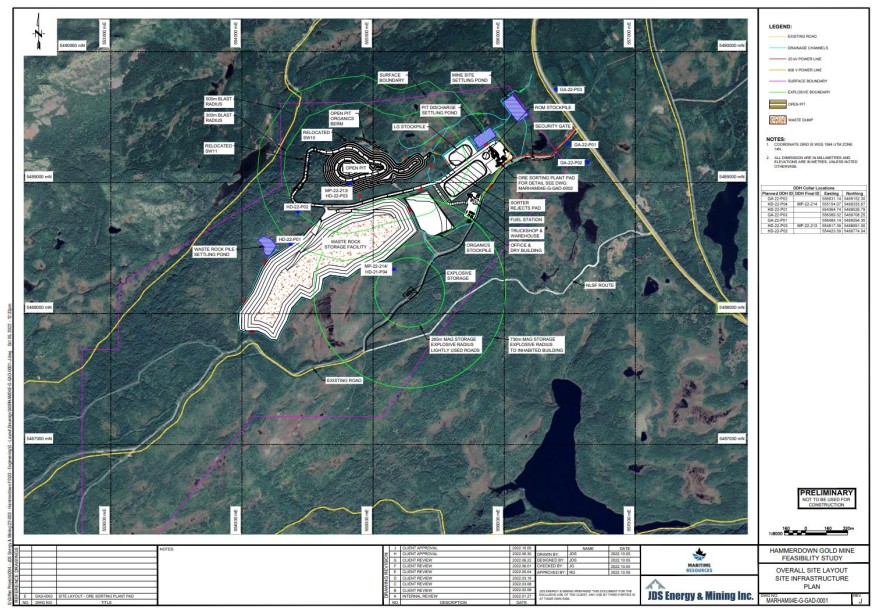

| Figure 18-1: Hammerdown Overall Site Layout | 18-2 |

| Figure 19-1: Historical Gold Price | 19-2 |

| Figure 19-2: Historical USD:CAD Exchange Rate | 19-3 |

|

|

| Figure 20-1: Project Study Area | 20-1 |

| Figure 20-2: Biology Survey | 20-4 |

| Figure 20-3: Project Watersheds Showing Surface Water and Sediment Sampling Locations | 20-7 |

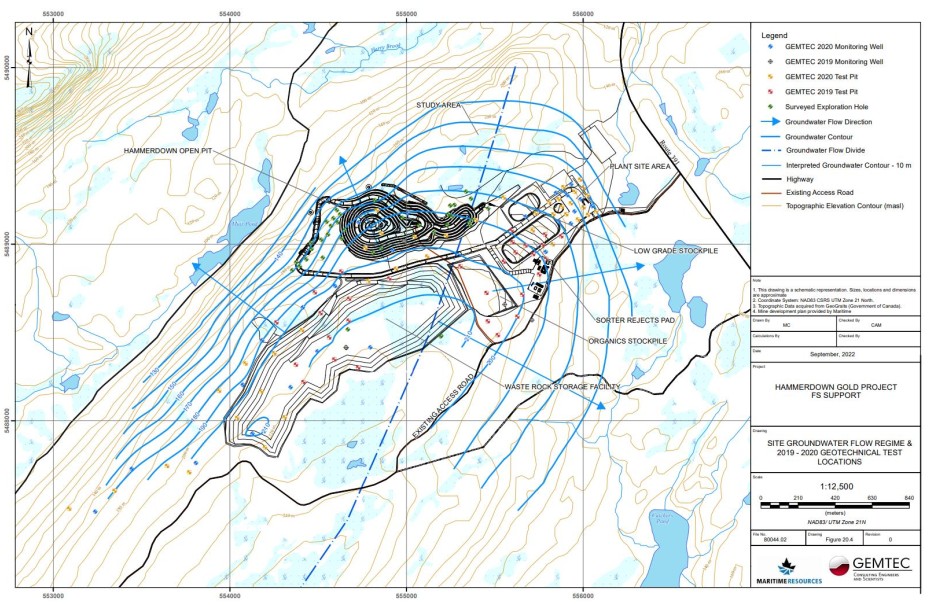

| Figure 20-4: Groundwater Flow - Geotech Test Locations | 20-10 |

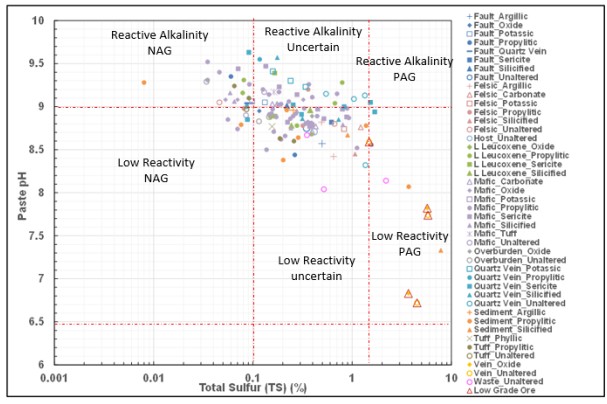

| Figure 20-5: Comparison of Reactivity (paste pH) to Acid Generation Potential (sulfur, wt%) | 20-31 |

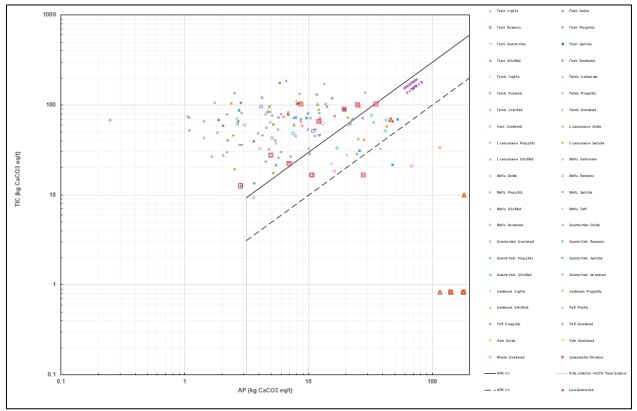

| Figure 20-6: NP vs AGP Prediction, Hammerdown Lithologies. Red Boxes Identify Samples for which Kinetic Tests were Performed | 20-32 |

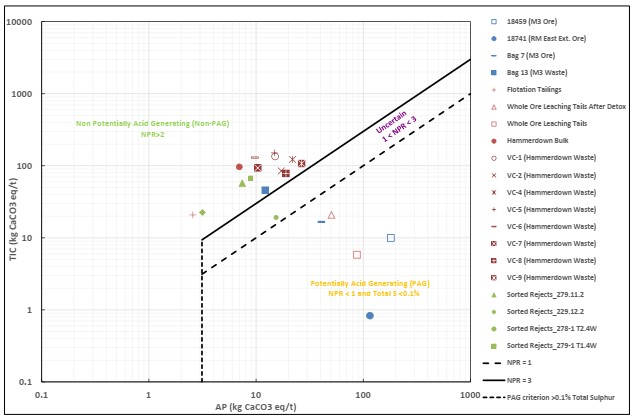

| Figure 20-7: Prediction of Acid Generation from Process Waste, Hammerdown Deposit (Neutralization Potential vs Acid Generation Potential in eq. kg CaCO3/t) | 20-33 |

| Figure 20-8: Ficklin Plots, Hammerdown Project Waste Rock and LGO | 20-34 |

| Figure 20-9: pH Release from HCT's Hammerdown Waste Rock | 20-35 |

| Figure 20-10: Consumption of Neutralization Potential from HCT's Hammerdown Waste Rock | 20-36 |

| Figure 22-1: Breakdown of Estimated Operating Costs | 22-2 |

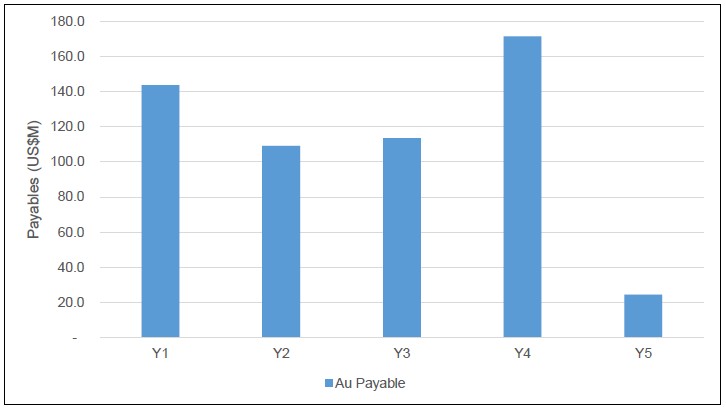

| Figure 23-1: LOM Payable Gold | 23-4 |

| Figure 23-2: Annual After-Tax Cash Flow | 23-6 |

| Figure 23-3: Post-Tax NPV5% Sensitivity | 23-8 |

| Figure 24-1: Property Location Map and Adjacent Areas | 24-2 |

List of Tables

| Table 1-1: Summary of Hammerdown Mineral Resources as of June 30, 2022 | 1-5 |

| Table 1-2: Hammerdown Mineral Reserve Estimate | 1-6 |

| Table 1-3: Open Pit Optimization Parameters | 1-7 |

| Table 1-4: Summary of Capital Cost Estimate ($C) | 1-10 |

| Table 1-5: Summary of Operating Cost Estimate ($C) | 1-11 |

| Table 1-6: Main OPEX Component Assumptions | 1-11 |

| Table 1-7: LOM Summary | 1-12 |

| Table 1-8: Economic Assumptions | 1-13 |

| Table 1-9: Off-site Gold Costs and Payable Assumptions | 1-13 |

| Table 1-10: Gold Value Assumptions | 1-13 |

| Table 1-11: Economic Results | 1-14 |

| Table 1-12: Sensitivity Analysis Results | 1-14 |

| Table 2-1: QP Responsibilities | 2-3 |

|

|

| Table 2-2: QP Site Visits to the Hammerdown Project | 2-5 |

| Table 4-1: Hammerdown Mineral Licenses | 4-6 |

| Table 6-1: Property History Summary | 6-2 |

| Table 6-2: Hammerdown Production Summary | 6-3 |

| Table 9-1: Drillhole Collar Data | 9-12 |

| Table 9-2: 2019 Golden Anchor Drilling Results | 9-14 |

| Table 9-3: 2022 Beetle Pond Drilling Results | 9-28 |

| Table 10-1: Summary of Drilling and Channel Sampling Completed on Hammerdown Property | 10-7 |

| Table 10-2: Key Diamond Drill Hole Parameters Shown in HD Cross-Section | 10-16 |

| Table 10-3: Summary of Hammerdown Cross-Section Diamond Drill Hole Significant Intercepts > 1.0 (g/t) Au | 10-18 |

| Table 10-4: 2021 Wisteria Channel Sample Composite Locations | 10-25 |

| Table 10-5: 2021 Wisteria Channel Sampling Significant Intercepts > 1.0 (g/t) | 10-25 |

| Table 10-6: 2020 Hammerdown Grade Control Diamond Drill Hole Parameters | 10-29 |

| Table 10-7: Summary of 2020 Grade Control Diamond Drill Hole Significant Intercepts > 1.0 (g/t) Au | 10-29 |

| Table 11-1: Example of Hammerdown Blank Failures and Remedial Actions | 11-5 |

| Table 13-1: Summary of Test Work Completed | 13-2 |

| Table 13-2: Bond Ball Mill Work Index Results | 13-8 |

| Table 13-3: Detoxification Result Summary | 13-14 |

| Table 14-1: Summary of Mineral Resources as of June 30, 2022 | 14-1 |

| Table 14-2: Summary of Mineral Resources as of February 29, 2020 | 14-2 |

| Table 14-3: Hammerdown Database | 14-4 |

| Table 14-4: Summary of Historical Production (2001 to 2004) | 14-7 |

| Table 14-5: Summary of Tonnes and Grade from Resource Model for Mined Out Shapes (2001 to 2004) | 14-7 |

| Table 14-6: Mineralization Domains | 14-10 |

| Table 14-7: Raw Assays Au (g/t) | 14-13 |

| Table 14-8: Assay Capping Levels | 14-19 |

| Table 14-9: Raw and Capped Assays Au (g/t) | 14-20 |

| Table 14-10: Search Restriction Thresholds | 14-23 |

| Table 14-11: Composite Statistics (g/t Au) | 14-25 |

| Table 14-12: Selected Hammerdown Gold Variograms | 14-36 |

| Table 14-13: Interpolation and Search Ellipse Parameters | 14-45 |

| Table 14-14: Block Model Definition | 14-49 |

|

|

| Table 14-15: Cut-Off Grade Parameters | 14-50 |

| Table 14-16: Open Pit Optimization Inputs | 14-51 |

| Table 14-17: Classification Volume Weighted Statistics | 14-53 |

| Table 14-18: Gold Assays, Composites, and Blocks Comparison | 14-66 |

| Table 14-19: Mineral Resource Estimate as of June 30, 2022 | 14-77 |

| Table 14-20: Model Comparison: Parent Blocks and Sub-Blocks | 14-80 |

| Table 15-1: Open Pit Optimization Input Parameters | 15-3 |

| Table 15-2: Overall Results of the Hammerdown Deposit Open Pit Optimization | 15-5 |

| Table 15-3: In-Pit Haulage Road Design Parameters | 15-12 |

| Table 15-4: Proven and Probable Mineral Reserve Estimate | 15-13 |

| Table 16-1: Summary of Rock Mass Characteristics by Lithology | 16-6 |

| Table 16-2: Summary of the Mine Material Movement and Mill Schedule | 16-17 |

| Table 16-3: Drilling Productivity | 16-23 |

| Table 16-4: Blasting Patterns and Powder Factors | 16-24 |

| Table 16-5: Loading Parameters | 16-24 |

| Table 16-6: Haulage Cycle Parameters | 16-25 |

| Table 16-7: Equipment Utilization Assumptions | 16-27 |

| Table 16-8: Main Mining Equipment Fleet (average number of units) | 16-27 |

| Table 16-9: Mining Personnel Requirements | 16-28 |

| Table 17-1: Hammerdown Crushing Plant Process Design Criteria | 17-5 |

| Table 17-2: Nugget Pond Grinding, Leach/ CIP Process Design Criteria | 17-12 |

| Table 18-1: Project Power Requirements | 18-5 |

| Table 19-1: Net Smelter Return Assumptions | 19-1 |

| Table 20-1: Environmental Approvals, Authorizations, and Permits Currently in Place | 20-19 |

| Table 20-2: Environmental Approvals, Authorizations, and Permits that may be Required | 20-19 |

| Table 20-3: Lithology and Alteration Sample Selection Matrix (Hammerdown) | 20-30 |

| Table 21-1: Capital Cost Summary | 21-1 |

| Table 21-2: Mining Capital Cost Estimate | 21-2 |

| Table 21-3: Surface Construction Estimate Basis | 21-3 |

| Table 21-4: Process Plant CAPEX | 21-5 |

| Table 21-5: Infrastructure CAPEX | 21-6 |

| Table 21-6: Indirect Cost Basis of Estimate | 21-7 |

| Table 21-7: Project Indirects CAPEX | 21-8 |

| Table 21-8: Owner's Costs CAPEX | 21-8 |

|

|

| Table 22-1: Breakdown of Estimated Operating Costs | 22-1 |

| Table 22-2: Summary of Personnel | 22-2 |

| Table 22-3: Mine Operating Cost Estimate | 22-3 |

| Table 22-4: Mine Personnel Requirement | 22-4 |

| Table 22-5: Mineral Processing Operating Cost | 22-5 |

| Table 22-6: Mineral Processing Electrical Consumption and Cost | 22-6 |

| Table 22-7: Mineral Processing Reagents Consumption and Cost | 22-7 |

| Table 22-8: Mineral Processing Consumable and Major Equipment Wear Components | 22-7 |

| Table 22-9: G&A Costs | 22-9 |

| Table 23-1: Life of Mine (LOM) Summary | 23-2 |

| Table 23-2: Metal Prices and Exchange Rates | 23-3 |

| Table 23-3: NSR Parameters | 23-3 |

| Table 23-4: Summary of Results | 23-6 |

| Table 23-5: Pre-Tax and After-Tax Sensitivity Results on NPV at 5% | 23-7 |

| Table 23-6: Project NPV at Various Discount Rates | 23-8 |

| Table 23-7: Economic Cash Flow Model | 23-9 |

| Table 26-1: Main Controllable Project Risks | 26-2 |

| Table 26-2: Identified Project Opportunities | 26-5 |

|

|

1 EXECUTIVE SUMMARY

1.1 Introduction

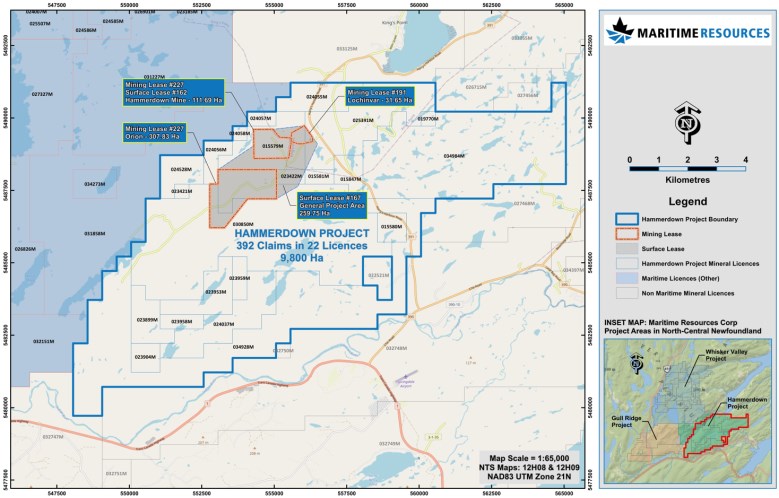

JDS Energy & Mining Inc. (JDS) was commissioned by Maritime Resources Corp. (Maritime) to carry out a Feasibility Study (FS) of the Hammerdown Gold Project (Hammerdown or the Project), a gold resource development project 100% owned by Maritime located within Maritime's 391 km2 land package in the Baie Verte mining district in north-central Newfoundland and Labrador. The Project is located about 5 km southwest of the Town of King's Point and 13 km by road due west of the Town of Springdale.

JDS teamed with Halyard Inc. (Halyard), a Toronto-based multidisciplinary engineering company, that provided mineral processing, mineral handling and Nugget Pond infrastructure details for the project. Canenco Consulting Corp. (Canenco) provided metallurgical expertise for sampling, testing, analysis and recommendations for the mineral processing design and recoveries. SRK Consulting (UK) Ltd. was responsible for geochemistry, waste management and mine closure guidance. GEMTEC was responsible for environmental management and water planning while SLR produced the mineral resource estimate and block model that is the basis for the mine plan and mineral reserve estimate.

1.2 Project Description

The project envisions open pit mining of the Hammerdown deposit, which is made up of a system of narrow, near-vertically dipping veins, and the wider, more continuous, lower-grade Wisteria Zone.

The FS envisions open pit mining of the Hammerdown deposit, which is made up of a system of narrow, near-vertically dipping veins, and the wider, more continuous, lower-grade Wisteria Zone. Unlike the 2020 PEA Technical Report, the FS did not consider any contribution from the Orion deposit as the Orion project is at the exploration stage and requires additional exploration, technical and environmental studies before a feasibility level assessment supporting a stand-alone project can be prepared. In contrast, the Hammerdown project is at an advanced stage of development with feasibility level detail and a release from Environment Assessment by the province of Newfoundland and Labrador in 2021. As well, the Orion project shares no common infrastructure with the Hammerdown project and would require its own dedicated infrastructure for any future development. The infrastructure needed on the Orion project would be vastly different from that of the Hammerdown project given the different project mining concepts applicable to each project - that being an open pit concept for the Hammerdown project, versus a likely underground concept for the Orion project. As such, Maritime is treating the Hammerdown and Orion projects as two separate projects. Open pit mining is planned to produce 1,200 tonnes per day (t/d) of run-of-mine (ROM) ore using conventional equipment of two sizes for ore and waste. The overall strip ratio for the planned open pit is approximately 20:1 but is 16:1 and 12:1 in years -1 and 1 respectively. Narrow vein zones are projected to be mined under geology control using tightly-spaced definition drilling and geologist oversight during loading operations. A stockpile of lower-grade material is planned to be maintained through mine life and processed at the end. ROM ore tonnes and grades are estimated to be approximately 1.9 Mt at a head grade of 4.46 g/t Au over the five-year mine life.

|

|

ROM ore is planned to be crushed and fed to two ore sorters that will pull an estimated 40% of the total feed out as low-grade waste. The upgraded 700 t/d of ore is planned to be trucked 140 km to the Nugget Pond mill mainly on public highways where it is planned to be fed through a new grinding circuit to a CIL gold leach circuit attached to Rambler's Nugget Pond Mill but owned by Maritime. Gold doré will be produced at Nugget Pond and the Hammerdown tailings co-mingled with Rambler's tailings in Rambler's existing, permitted tailings facility.

Payable gold production is planned to be 247,000 oz in total and 50,000 oz annually.

The Hammerdown property is a brownfield site that was previously mined in the 2000s by Richmont Mines using underground methods. The site has had a full geochemical investigation conducted and is not expected to have acid rock drainage or metal leaching (ARD/ML) issues.

1.3 Property Description - Location and Access

The Hammerdown deposit occurs within Hammerdown property located approximately 5 km southwest of King's Point and 10 km west of Springdale, NL. The Hammerdown deposit is centered at approximately:

• 49°33'10" N latitude and 56°14'25" W longitude; or

• 554,900 mE and 5,489,200 mN (NAD 83, Zone 21U).

The Hammerdown deposit is located within Maritime's 390 km2 land package.

The property is comprised of moderate topography at an elevation of about 200 metres above sea level (masl). The Hammerdown deposit, planned sorting plant and infrastructure are located on a broad ridge that splits two drainages, The north side of the ridge drops off to into a NE-SW trending valley while the south side of the ridge is relatively flat.

Birch, black spruce and fir dominate the property flora, although most of the planned site has been logged. Peat bogs occur on the western side of the Hammerdown site.

1.4 Ownership

Maritime Resources Green Bay property encompasses 98 square kilometers (22,216 acres) held under 34 individual mineral licenses. The project area is bounded to the west by Maritime licenses and all of the Hammerdown Project mineral licenses are owned 100% by Maritime either by direct map staking or earned through option agreements.

|

|

1.5 History, Exploration and Drilling

A total of 808 diamond drillholes totaling approximately 85,000 m have been completed on the Project. Most of the drilling was completed by Richmont Mines Inc. (Richmont) while the Hammerdown deposit was in operation.

The Hammerdown deposit was mined by Richmont using underground and open pit methods from 2001 to 2004. Approximately 290,000 t of ore were mined at a grade of 15.74 g/t Au. Richmont utilized the Nugget Pond mill to treat the ore, achieving an average of 97% gold recovery over the mine life. Lack of exploration success at the time lead to the mine shutting down. Gold prices averaged about US$350 /oz from 2002-2004.

1.6 Geology and Mineralization

The Project is located in the northeastern extremity of the Appalachian Orogen of eastern North America, where it is predominantly underlain by Paleozoic volcanic rocks of the Newfoundland Appalachians within the Notre Dame Subzone (Williams et al., 1988) of the Dunnage tectono- stratigraphic sub-division (Williams, 1979).

The rocks underlying the area are represented by volcano-sedimentary assemblages of oceanic supra- subduction zone (ophiolitic) and mature-arc derivations (Szybinski and Jenner, 1989; Swinden, 1991; Kean et al., 1995) accreted to the ancient North American (Laurentian) continental margin during the Taconian Orogeny (Ordovician to Silurian) and further deformed during the Silurian-Devonian, post accretion, Acadian Orogeny (Swinden, 1991).

Other geological elements cover portions of the property including Silurian sub-aerial to fluviatile sediments (conglomerates) of the Springdale Group to the southeast (Kean, 1980; Coyle and Strong, 1987; Kean et al., 1995), Devonian intrusive rocks of the King's Point Complex, Siluro-Devonian intrusive rocks of Burlington Granodiorite to the northwest (Hibbard, 1983), and Devonian granitic intrusive rocks of the Topsails Granite to the southwest (Kean, 1980). A suite of mafic volcanics (informally referred to as the Hammerdown Basalt) in the northeastern part of the area were removed from the Lushs Bight Group and reassigned to the Catchers Pond Group and the Lushs Bight Group (Kean, 1984; Jenner and Szybinski, 1987, O'Brien and Dunning, 2014).

The Property is host to numerous underexplored gold prospects and showings along with VMS style base metal mineralization. The Property is also host to four gold deposits two of which, the Hammerdown and Rumbullion have seen historical mining development.

The most important and well-defined gold deposits include the Hammerdown, Rumbullion, Muddy Shag and Orion deposits, which all occur within the Hammerdown Deformation Zone (HDZ). The HDZ is described has a 100-250 wide structural corridor of strong ductile to brittle shearing hosted in the uppermost units of the Catchers Pond Group. The historic Lochinvar VMS base metal deposit also occurs in the HDZ along with the Golden Anchor gold veins and Beetle Pond VMS alteration zone.

|

|

1.7 Metallurgical Testing and Mineral Processing

A number of test work programs have been undertaken on the Hammerdown project prior to the FS as summarized in the previous reports. The most recent metallurgical test program described in Section 13, is the basis for the process selected for the Hammerdown mineralization. The program included comminution, sorting, gravity separation, flotation, cyanidation, detoxification, and solid/liquid separation studies. Historical and FS test work results indicate that the mineralization responded well to leaching for precious metal extraction.

Grindability test work on the Hammerdown samples indicated that the hardest 75th Percentile Bond Work Index (BWi) of the sorted plant feed was 16.9 kWh/t and the SAG Mill Comminution test (SMC) A*b was 70.6, which places the mineralization in the medium-hard classification for comminution and it is amenable to SAG milling.

The gold leach extractions achieved to date for the Hammerdown composites using the optimized conditions range from 94.6& to 97.5% and average 96.0%. Assuming solution losses of approximately 0.5% the overall Hammerdown gold recovery is predicted to be in the range of 95.5%.

1.8 Mineral Resource Estimate

Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Definition Standards for Mineral Resources and Mineral Reserves (CIM (2014) definitions) were used for Mineral Resource classification. See Table 1-1 for the Mineral Resource Estimate.

|

|

Table 1-1: Summary of Hammerdown Mineral Resources as of June 30, 2022

| Category | Tonnes (kt) |

Grade (g/t Au) |

Contained Metal (000 oz Au) |

| Open Pit Resources | |||

| Measured | 698 | 5.47 | 123 |

| Indicated | 2,146 | 3.00 | 207 |

| Measured + Indicated | 2,845 | 3.61 | 330 |

| Inferred | 302 | 1.31 | 13 |

| Underground Resources | |||

| Measured | 1 | 7.05 | - |

| Indicated | 54 | 5.10 | 9 |

| Measured + Indicated | 55 | 5.10 | 9 |

| Inferred | 66 | 4.00 | 9 |

Notes:

1. Mineral Resource Estimate completed by Pierre Landry, P.Geo., of SLR Consulting (Canada) Ltd. (SLR), an independent qualified person (QP), as defined by NI 43-101.

2. Effective date: June 30, 2022. All Mineral Resources have been estimated in accordance with Canadian Institute of Mining and Metallurgy and Petroleum (CIM) definitions, as required under NI 43-101.

3. Open Pit Mineral Resources are inclusive of Mineral Reserves

4. Open Pit Mineral Resources are estimated at a cut-off grade of 0.50 g/t Au.

5. Open Pit Mineral Resources are reported at a block cut-off from whole blocks measuring 2.5 m x 1.0 m x 2.5 m.

6. Mineral Resources are estimated using a long-term gold price of US$1,800 per ounce, and a US$/C$ exchange rate of 0.75.

7. Bulk density is 2.84 t/m³ for rock and 1.90 t/m³ for mined out areas.

8. Underground Mineral Resources are estimated at a cut-off grade of 2.00 g/t Au.

9. Underground Resources are reported at a block cut-off from whole blocks measuring 2.5 m x 1.0 m x 2.5 m and have been subject to additional reporting shapes to remove isolated blocks.

10. Numbers may not add due to rounding.

11. Mineral Resources reported demonstrate reasonable prospect of eventual economic extraction, as required under NI 43-101.

12. Mineral Resources are not Mineral Reserves and do not have demonstrated economic viability.

13. The Mineral Resources would not be materially affected by environmental, permitting, legal, marketing, and other relevant issues based on information currently available.

Source: SLR (2022)

1.9 Mineral Reserve Estimate

The Mineral Reserve estimation has been constrained to the Hammerdown deposit for this FS. Both Open Pit and Underground mining methods were evaluated but, in the end, the project was designed as an Open Pit only based on the best expected economic outcome. The Mineral Resources were evaluated using open pit optimization software to identify an optimum shell which was then used as a basis for detailed design. The final design along with dilution and mine recovery estimates and a cut-off grade were then used to quantify the final Mineral Reserves.

|

|

The mineral reserves for the Hammerdown deposit are reported below within the final pit design and based on cut-off grades of 0.73 g/t for Vein material and 1.06 g/t for the Wisteria zone. The effective date of the Mineral Reserve stated in this report is August 15, 2022.

The QPs have not identified any known legal, political, environmental, or other risks that would materially affect the potential development of the Mineral Reserves. The mine permitting is well advanced and is not seen as a significant risk.

Table 1-2: Hammerdown Mineral Reserve Estimate

| Zone & Class | Tonnes (kt) |

Diluted Grade (g/t Au) |

Contained Gold (koz) |

| Proven Reserves | |||

| Vein | 556 | 5.94 | 106 |

| Wisteria | 0 | 1.68 | 0 |

| Total Proven | 556 | 5.94 | 106 |

| Probable Reserves | |||

| Vein | 1,134 | 4.19 | 153 |

| Wisteria | 206 | 1.99 | 13 |

| Total Probable | 1,340 | 3.85 | 166 |

| Total Proven and Probable | 1,895 | 4.46 | 272 |

Notes:

1. Mineral Reserve Estimate completed by Tysen Hantelmann, P.Eng. of JDS Energy & Mining Inc. (QP).

2. Mineral Reserves follow CIM definitions and are effective as of August 15, 2022.

3. Mineral Reserves are estimated at a cut-off of 0.73 g/t for Veins and 1.06 g/t for Wisteria Zone based on: Gold price of US$1650/oz; Exchange rate of 0.77 USD:CAD; combined transport, treatment, payables and royalties of US$25/oz; an overall metallurgical recovery (including ore sorting) of 90.25% for Veins and 85.5% for Wisteria; and an overall processing operating cost of C$45/t ore mined for Veins and C$62/t ore mined for Wisteria.

4. The final FS pit design contains an additional 94 kt of Inferred resources above the economic cut-off grade at an average grade of 1.62 g/t. Inferred Mineral Resources are considered too speculative geologically to have economic considerations applied to them that would enable them to be categorized as Mineral Reserves, and there is no certainty that any part of the Inferred Resources could be converted into Mineral Reserves.

5. Tonnages are rounded to the nearest 1,000 t, gold grades are rounded to two decimal places. Tonnage and grade measurements are in metric units; contained gold is reported as thousands of troy ounces.

1.10 Mining

While both open pit and underground mining methods were evaluated, the final design is based on conventional open pit mining (drill, blast, load, and haul) due to its relatively low cost and higher production rates. Ore material will be delivered to a crusher/ore sorter located just South- East of the pit at a nominal rate of 1,200 t/d (426 kt/a) and provide 700 t/d (256 kt/a) to an offsite Mill for final mineral processing. Over the life-of-mine (LOM), the mine will produce 1.9 Mt of ore at an average gold grade of 4.46 g/t. Waste materials (40 Mt) will be contained within a Waste Storage Facility (WSF) located just South of the pit.

|

|

The design parameters used to define the optimum shape and size of the pit are shown in Table 1-3.

Table 1-3: Open Pit Optimization Parameters

| Parameter | Unit | Hammerdown | Wisteria |

| Gold price | US$/oz | 1,650 | 1,650 |

| Payable metal | % | 99.8 | 99.8 |

| TC / RC / Transport | US$/oz | 5.0 | 5.0 |

| Royalty | % | 1 | 1 |

| Gold value per ounce | US$/oz | 1,625 | 1625 |

| Exchange rate | USD:CAD | 0.77 | 0.77 |

| Gold value per gram | C$/g | 67.86 | 67.86 |

| Ore mining cost | C$/t ore mined | 5.00 | 5.00 |

| Waste Mining Cost | $/t waste mined | 4.00 | 4.00 |

| Ore transport | $/t processed | 16.74 | 23.72 |

| Mineral processing | $/t processed | 18.00 | 25.50 |

| G&A | $/t processed | 6.00 | 8.50 |

| Ore sorting mass pull | % | 60 | 85 |

| Ore sorting gold recovery | % | 95 | 95 |

| Milling gold recovery | % | 95 | 90 |

| Overall gold recovery | % | 90.25 | 85.50 |

| External dilution | % | 0 | 0 |

| Mining recovery | % | 100 | 100 |

| In-situ cut-off Au grade | g/t | 0.73 | 1.06 |

Note: No external dilution was validated due to a combination of using an ore sorter as well as the addition of a significant amount of internal dilution within the block model.

1.11 Recovery Methods

The Feasibility Study's approach to mineral processing includes a crushing and ore sorting stage at the Hammerdown mine site to remove dilution and concentrate the ROM ore into a high-grade feed product for the mill. This product will be hauled 140 km to the Nugget Pond mill for final mineral processing including grinding, thickening, carbon in pulp leaching, refining to doré bars and disposal of tailings.

Hammerdown

The processing facilities will be designed to produce a -12 mm minus crushed and sorted product. The crushing and sorting plant will be designed for 1,200 t/d of ROM feed with a maximum capacity of 1,800 t/d.

ROM feed will be subjected to primary and secondary crushing stages to produce a -50 mm sorter feed product. It is estimated that 23% of ROM feed will be rejected as a fine fraction (-12 mm) prior to sorting. The coarse (+25-50 mm) and middling (+12-25 mm) size fractions will be sent to two X-ray transmission (XRT) sorters for concentration.

|

|

The sorting program was completed on several bulk and variability samples and has demonstrated that the crushed mineralization is highly amenable to sorting with an average of 52% of the feed to the sorting circuit being separated as waste material resulting in 40% of the crushing plant feed mass being rejected with approximately 5% gold loss.

Sorted product will be tertiary crushed to -12 mm prior to stockpiling in the storage building and hauled to Nugget Pond. Sorter rejects will be stockpiled and back hauled in mine trucks to the low-grade stockpile.

Nugget Pond Mill

The hydrometallurgical plant was designed and constructed in 1996 and subsequently run by Richmont as a nominal 500 t/d CIP plant at 97% gold recovery. The operational plan for this feasibility study is to process up to 700 t/d at 95.5% gold recovery.

A new truck unloading, storage and reclaim facility will feed a new grinding circuit consisting of ball and vertical grinding mills to achieve a P80 grind size of 50 micron. Post grinding slurry will proceed through the existing leach / carbon in pulp (CIP) circuit to produce gold doré bars. The new circuit will run in parallel with the Rambler copper concentrator.

Residues from the hydrometallurgical plant will be combined with existing flows and stored in the Nugget Pond tailings storage facility.

1.12 Infrastructure and Facilities

At the Hammerdown mine site the main infrastructure will consist of the crushing and ore sorting plant. Other structures have been planned to site operational requirements and will include an administration complex, security gatehouse, explosive storage facility, truck scales, a warehouse, and a mine equipment maintenance shop. Site geotechnical investigations have been performed to support the engineering effort for site infrastructure design. Water from the open pit will be pump and directed to site drainage and pond facilities around the project site. Power will be supplied to the Hammerdown site by a new 570 m long utility line connection to the existing 25 kV grid at Route 391, operated by Newfoundland and Labrador Hydro. The entrance to the Hammerdown site is located a short distance from Route 391 via the Shoal Pond forest access road. A new 2 km bypass road is envisioned to ensure safe passage for the general public, rerouting light vehicle and other traffic away from the Hammerdown mine area.

At the Nugget Pond mill the main facilities will be the material handling system and covered ore stockpile ahead of the grinding and CIP circuits. An existing, operational, and fully permitted tailings storage facility is present and will be operated under a custom processing agreement with Rambler Mining and Metals Canada Limited. Power is supplied by an existing line connection to the provincial power grid. An existing 10 km access road connects Nugget Pond to provincial highway 414. Upgrades to the access road have been incorporated into the Feasibility Study to address widening and culvert replacements in certain areas.

|

|

1.13 Environmental Studies, Permitting and Social Impacts

Maritime has developed a comprehensive environmental baseline that characterizes the existing biophysical environment of the proposed mine development area. A high-level summary of Project environmental baseline conditions is provided in Section 20 of this report and draws on the results of numerous desktop and field studies and assessments undertaken since 2016 including atmospheric, terrestrial, aquatic, hydrological and hydrogeological studies, as well as supporting site-wide geotechnical investigation (for areas outside of the proposed open pit and historical mine workings footprint) and acid rock drainage/metal leaching studies.

In July 2020, the Project was registered as per the requirements of the Newfoundland and Labrador Environmental Assessment Act (Maritime, 2020). Since the proposed mine production capacity is less than the federal Impact Assessment Act trigger of 5,000 t/d, the Project was not required to complete a federal Environmental Assessment (EA) review. Following provincial review of the EA registration document, the Project was subsequently required to prepare an Environmental Preview Report (EPR) (Maritime, 2021a). The EPR was submitted on March 4, 2021, and included additional requested information on the following:

• Water management;

• Greenhouse gas emissions;

• Plans for enhancing positive impacts and mitigating negative impacts of the Project on the health of local residents, visitors, and business owners;

• Further consultation with occupants with nearby properties to address potential land use conflicts;

• Development of a waste management plan;

• Development of a gender equity and diversity plan; and

• Additional information on Project occupations and hiring arrangements.

Following regulatory review of the EPR, the Government of Newfoundland and Labrador approved the Project and issued a release from the EA process in May 2021.

A complete set of provincial and federal approvals, authorizations and permits to approve the construction and operation of the Project have been identified and are in progress. Future permitting in support of the start of construction will focus on the completion and submission of both the Project Development Plan, and the Rehabilitation and Closure Plan (RCP). Provincial regulatory approval of these two plans is required prior to the start of construction.

The RCP will be directly linked to mine development and operation over the life of the mine. Review and revisions of the RCP are needed throughout the development and operational stages of a project, allowing adjustments that reflect the operational and planning changes that can occur. Objectives of rehabilitation and closure will generally be to restore the land to as close to natural conditions as practically possible, minimize any long-term impact of the environment, creation of a landscape which is visually acceptable and compatible with surrounding terrain and land use, mitigation and control to within acceptable levels the potential sources of contamination, pollution, fire risk, and public liability, and provide a safe environment for long term public access. Activities will be undertaken progressively and at end of mine life to meet these objectives. The preliminary cost estimate for closure is estimated to be $3.5 million in 2022 Canadian Funds, excluding Harmonized Sales Tax.

|

|

To date, Maritime has discussed the proposed Project with the towns of King's Point and Springdale as well as a number of provincial and federal government departments and agencies. Maritime will maintain consultation with applicable stakeholders, including government departments throughout the planning, permitting, development, operation, and closure phases of the Project. Carrying out meaningful community consultation is not only important for Maritime to obtain social acceptability but is also necessary to fulfill all the regulatory requirements and expectations under the NL EA process. Maritime carried out its most recent public meeting on November 4, 2020, as per the EPR requirements.

1.14 Operating and Capital Cost Estimates

Capital costs have a basis of estimate at Class 3 (Front End Loading (FEL) 3) with a stated -15% / +30% accuracy (after the Association for the Advancement of Cost Engineering International) and are stated in Q2 2022 Canadian dollars.

Capital cost contingency has been allocated on scopes of work depending on level of completion for each scope. The combined contingency for all scopes of work is equivalent to 9.8% of Direct + Indirect Costs or 20% of direct costs, excluding mining equipment and pre-stripping. More than 82% of equipment costs, bulk materials and labour rates are estimated with budget quotes from vendors. The remaining 18% of costs are estimated from consultant databases on precedent projects, or from factoring such items as freight and construction indirect costs from supply pricing.

Mine equipment is assumed to be acquired through a combination of leasing for most production and support equipment, rentals for pioneering drills, and purchase of some support equipment.

The initial capital cost, including contingency, is estimated at $75.0 million and net LOM sustaining capital cost is estimated at $4.9 million, net of closure costs and salvage values for major equipment, for a total capital cost of $80.0 million. See Table 1-4.

Table 1-4: Summary of Capital Cost Estimate ($C)

| Item | Units | Total |

| Mining | $M | 10.6 |

| Site development | $M | 4.7 |

| Mineral processing | $M | 24.7 |

| Water management | $M | 0.6 |

| On-site infrastructure | $M | 5.9 |

| Project indirect costs | $M | 17.3 |

|

|

| Item | Units | Total |

| Owner's costs | $M | 4.0 |

| Subtotal | $M | 67.9 |

| Contingency | $M | 7.2 |

| Total initial capital | $M | 75.0 |

| Sustaining capital | $M | 11.0 |

| Closure | $M | 3.5 |

| Salvage | $M | 9.6 |

| Total net sustaining capital | $M | 4.9 |

| Total capital | $M | 80.0 |

Mine operating costs, excluding pre-stripping, are estimated at $4.49/t mined with a strip ratio of 20.3 (waste:ore) over the LOM.

Processing and tailings storage related costs are estimated at $48.06/t processed. General and administration costs are estimated at $12.04/t processed. Diesel costs are estimated at $1.53/l and power at $0.085/kWh (net charge for generated power). See Table 1-5 and Table 1-6.

Overall LOM Cash Costs are estimated at US$897 per payable ounce of gold. The LOM All-In Sustaining Costs are estimated at US$912 per payable ounce of gold.

Table 1-5: Summary of Operating Cost Estimate ($C)

| Item | Units | Total |

| Mining costs | $/t mined | 4.49 |

| Trucking | $/t milled | 25.50 |

| Mineral processing | $/t milled | 48.06 |

| G&A | $/t milled | 12.04 |

| Total | $/t milled | 234.45 |

| On-Site OPEX | $M | 278.7 |

Table 1-6: Main OPEX Component Assumptions

| Item | Unit | Value |

| Electrical power cost | $/kWh | 0.085 |

| Average power consumption | MW | 3.39 |

| Overall power consumption (all facilities) | kWh/t processed | 6.26 |

| Diesel cost (delivered) | $/litre | 1.53 |

| LOM average manpower (including contractors, excluding corporate) | employees | 270 |

|

|

1.15 Economic Analysis

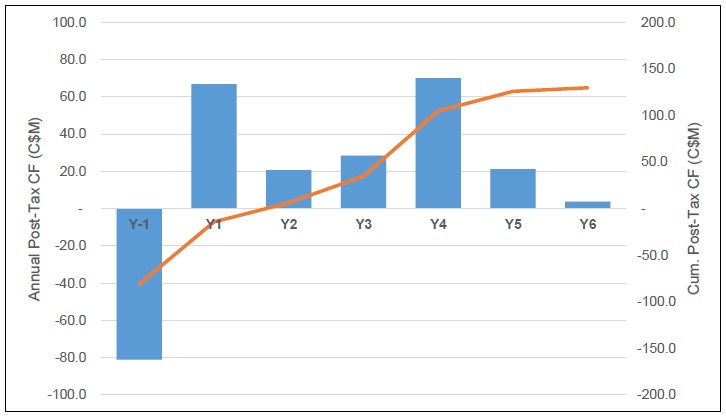

An economic model was developed to estimate annual cash flows and sensitivities of the Project. All costs, metal prices, and economic results are reported in Canadian currency ($C) unless stated otherwise.

Pre-tax estimates of Project values were prepared for comparative purposes, while after-tax estimates were developed to approximate the true investment value. It must be noted, however, that tax estimates involve many complex variables that can only be accurately calculated during operations and, as such, the after-tax results are only approximations.

This Technical Report contains forward-looking information regarding projected mine production rates, construction schedules, and forecasts of resulting cash flows as part of this study. The mill head grades are based on sampling that is reasonably expected to be representative of the realized grades from actual mining operations. Factors such as the ability to obtain permits to construct and operate a mine, to obtain major equipment or skilled labour on a timely basis, or to achieve the assumed mine production rates at the assumed grades may cause actual results to differ materially from those presented in this economic analysis.

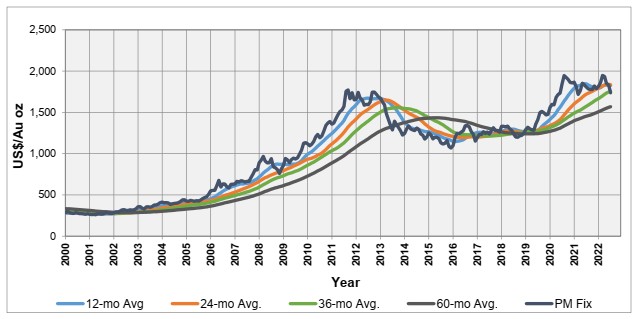

The reader is cautioned that the gold prices and exchange rates used in this study are only estimates based on recent historical performance and there is absolutely no guarantee that they will be realized if the Project is taken into production. The price of gold is based on many complex factors and there are no reliable methods of predicting the long-term gold price.

At the base case gold price (US$1,750/oz Au and a $0.77 US$/C$ exchange rate), the Project is estimated to generate an after-tax NPV5% of $102.8M and an after-tax IRR of 48.1%. Payback on initial capital is calculated to be 1.7 years.

1.15.1 Main Assumptions

Table 1-7 outlines the LOM summary and the basis for the economic analysis.

Table 1-7: LOM Summary

| Parameter | Unit | Value |

| Ore Mined/Sorted | kt | 1,895 |

| Average Mined Gold Grade | g/t | 4.46 |

| Ore Processed | kt | 1,189 |

| Mill Average Daily Production | t/d | 700 |

| Average Gold Mill Grade | g/t | 6.76 |

| Gold Contained* | koz | 258 |

| Gold Recovered | koz | 247 |

| Gold Recovery | % | 95.7 |

|

|

| Parameter | Unit | Value |

| Average Gold Production | koz/year | 52 |

| Initial Capital Cost | $M | 75.0 |

| Sustaining Capital Cost (net of salvage) | $M | 4.9 |

| Life of Mine Capital | $M | 80.0 |

*Contained in sorted tonnes.

The main assumptions used in the economic analysis of the Project are outlined in Table 1-8 and Table 1-9 below.

Table 1-8: Economic Assumptions

| Item | Unit | Value |

| NPV Discount Rate | % | 5 |

| Federal Income Tax Rate | % | 15 |

| Provincial Income Tax Rate | % | 15 |

| Equity Finance | % | 100 |

| Capital Contingency (Overall) | % | 10.3% |

Table 1-9: Off-site Gold Costs and Payable Assumptions

| Off-site Costs and Payables | Unit | Value |

| Payables for Doré | % | 99.97% |

| Doré Refining/Transport Costs | US$/payable oz | 0.38 |

| Transport Cost | US$/payable oz | 1.35 |

Table 1-10 outlines the metal prices and exchange rates used in the economic analysis.

Table 1-10: Gold Value Assumptions

| Assumptions | Unit | Value |

| Au Price | US$/oz | 1,750 |

| FX Rate | US$:C$ | 0.77 |

|

|

1.15.2 Results

The economic results for the Project, based on the assumptions outlined above are presented in Table 1-11.

Table 1-11: Economic Results

| Parameter | Unit | Pre-Tax Results | After-Tax Results |

| NPV0% | M$ | 194 | 130 |

| NPV5% | M$ | 159 | 103 |

| IRR | % | 67.7 | 48.1 |

| Payback period | Production years | 1.0 | 1.7 |

The break-even gold price for the project after-tax (NPV0%) is US$ 1,115/oz.

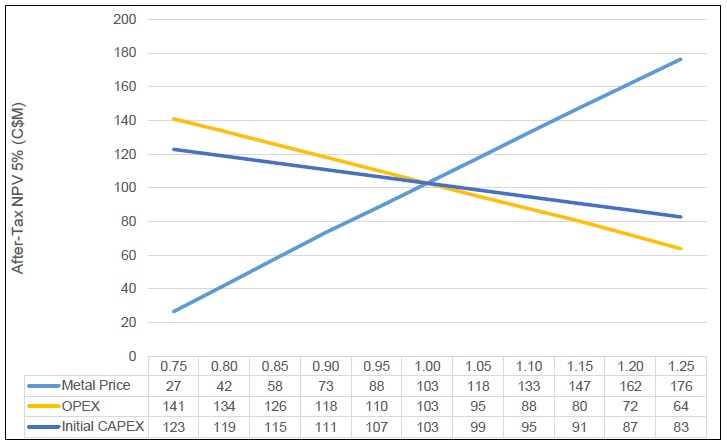

1.15.3 Sensitivities

Sensitivity analyses were performed using metal prices, mill head grade, CAPEX, and OPEX as variables. The value of each variable was changed plus and minus 25% independently while all other variables were held constant. The results of the sensitivity analyses are shown in Table 1-12.

Table 1-12: Sensitivity Analysis Results

| Variable | After-Tax NPV5% (M$) | Pre-Tax NPV5% (M$) | ||||

| -25% Variance |

0% Variance |

25% Variance |

-25% Variance |

0% Variance |

25% Variance |

|

| Metal Price or Head Grade | 27 | 103 | 176 | 37 | 159 | 281 |

| OPEX | 141 | 103 | 64 | 220 | 159 | 97 |

| CAPEX | 123 | 103 | 83 | 179 | 159 | 139 |

1.16 Conclusions

It is the conclusion of the QPs that the FS summarized in this technical report contains adequate detail and information to support a FS-level report. Standard industry practices, equipment and design methods were used in the FS.

Based on the assumptions used for this study, the project shows positive economics and should proceed to permit finalization and expansion of resources through additional drilling.

|

|

The most significant potential risks associated with the project are uncontrolled dilution with waste rock and rock from different mineralized zones, operating and capital cost escalation, permitting and environmental compliance, unforeseen schedule delays, changes in regulatory requirements, ability to raise financing, ability to find and retain qualified personnel and gold price. These risks are common to most mining projects, many of which can be mitigated with adequate engineering, planning and pro-active management.

To date, the QPs are not aware of any fatal flaws for the Project.

1.16.1 Geology and Mineral Resources

• The Hammerdown deposit most closely resembles a mesothermal volcanic hosted (greenstone belt) gold deposit.

• The Hammerdown Mineral Resource estimates were prepared in accordance with Canadian Institute of Mining, Metallurgy and Petroleum (CIM) for Mineral Resources and Mineral Reserves dated May 10, 2014 (CIM (2014) definitions).

• The sampling, sample preparation, analyses, security, and data verification meet industry standards and are appropriate for Mineral Resource estimation.

• Open pit Measured and Indicated Mineral Resources total 2,845 thousand tonnes (kt) at an average grade of 3.61 g/t Au, containing 329,900 oz Au, and Inferred Mineral Resources total 302 kt at an average grade of 1.31 g/t Au, containing approximately 12,700 oz Au.

• Underground Measured and Indicated Mineral Resources total 55 kt at an average grade of 5.10 g/t Au, containing 9,000 oz Au, and Inferred Mineral Resources total 66 kt at an average grade of 4.00 g/t Au, containing approximately 9,000 oz Au.

• A cut-off grade of 0.50 g/t Au was used to report open pit Mineral Resources for the Hammerdown deposit, while a cut-off grade of 2.0 g/t Au was used to report underground Mineral Resources.

1.17 Recommendations

It is recommended that the Project continues to advance towards a construction decision and complete final permitting and additional exploration drilling around the Hammerdown deposit to extend the mine life and improve project economics.

• Project Permitting: File Hammerdown closure and development plans for mine construction permit. The estimated cost of permit application completion is $100,000.

• Exploration drilling near Hammerdown: Focus exploration drilling on the Orion - Hammerdown trend where potential exists to draw new mineral resources into the Hammerdown mine plan. The first phase of drilling should include a 5,000 m program. The cost of the drilling program is estimated to be $1.0M based on a $150 /m drilling cost, all-in, and $0.25M for contingency and QA/QC modifications.

|

|

2 INTRODUCTION

The Hammerdown Gold Project is an advanced stage gold project, located in Newfoundland, Canada. It is located approximately 5 km southwest of the town of King's Point and 13 km west of the town of Springdale, Newfoundland and Labrador. Maritime owns 100% of the Hammerdown and Wisteria deposits, the focus of this FS. In 2021, Maritime Resources commissioned JDS Energy & Mining Inc. (JDS) to lead a feasibility study (FS) on the project. Several other engineering and consulting companies contributed to the FS and Technical Report. A list of contributing companies is shown in Section 2.1.1.

2.1 Qualified Persons (QPs)

2.1.1 Scope of Work of Contributing Companies

This technical report summarizes the work of several consultants with the scope of work for each company listed below, which combined, comprises the total Project scope.

JDS Energy & Mining Inc. (JDS):

• Project management and report compilation;

• Economic modeling;

• Open pit geotechnical analysis;

• Open pit mine planning, project production schedule, CAPEX and OPEX;

• Mineral reserve estimate;

• Hammerdown site infrastructure; and

• Infrastructure and Owner's CAPEX and overall CAPEX compilation.

Halyard Engineering (Halyard):

• Process plant design (crushing/sorting plant and gold leach plant);

• Process infrastructure and power distribution design; and

• Processing CAPEX and OPEX estimation.

Canenco Consulting Corp. (Canenco):

• Metallurgical sample selection;

|

|

• Metallurgical test work planning and management;

• Process design criteria input;

• Interpretation of test work results and estimation of recoveries and concentration factors; and

• Estimation of reagent usage.

GEMTEC Consulting Engineers and Scientists Limited (GEMTEC):

• Environmental Studies and Permitting

• Site Wide geotechnical and hydrogeological investigations

• Water management design; and

• Closure cost estimation.

SLR (SLR):

• Geological investigations; and

• Mineral resource estimation.

SRK Consulting (SRK):

• Waste rock geochemical test management and analysis and interpretation of results.

2.1.2 Qualifications and Responsibilities

The results of this FS are not dependent upon any prior agreements concerning the conclusions to be reached, nor are there any undisclosed understandings concerning any future business dealings between Maritime Resources and the QPs. The QPs are being paid a fee for their work in accordance with normal professional consulting practice and are independent of Maritime as per NI 43-101 definition of independence.

The following individuals, by virtue of their education, experience and professional association, are considered QPs as defined in the NI 43-101, and are members in good standing of appropriate professional institutions / associations. The QPs are responsible for the specific report sections as follows:

|

|

Table 2-1: QP Responsibilities

| QP | Company | QP Responsibility / Role | Report Section(s) |

| Carolyn Anstey-Moore, P.Geo. | GEMTEC | Environmental Studies and Permitting | 1.13, 20.1, 20.2, 20.4, 20.5, 20.7, and 20.8 |

| Hans Arisz, M.Sc.E., P.Eng., FCSCE | GEMTEC | Water Management | 18.1.9 |

| Rob Bowell, CChem, CGeol, FIMMM | SRK | Geochemistry | 20.9 |

| Carly Church, P. Eng. | JDS | Hammerdown site infrastructure design, CAPEX and G&A OPEX | 1.12, 1.14, 18 (except 18.1.6 and 18.1.9), 21 (except 21.3 & 21.5), 22 (except 22.3 & 22.4) |

| Gord Doerksen, P. Eng. | JDS | Overall project management, general information sections and project description, economics, marketing and contracts, conclusions and recommendations | 1.1 to 1.5, 1.15 to 1.17 (except 1.16.1), 2 to 6, 19, 23 to 25, 26.2, 26.3, 27 to 29 |

| Dorota El Rassi, M. Sc., P. Eng. | SLR | Geology, Mineralization, QA/QC and Data Validation | 1.6, 7, 8, 9, 11, 12 |

| Michael Franceschini, P. Eng. | Halyard | Hammerdown and Nugget Pond process plant and process infrastructure design and CAPEX | 18.1.6, 21.5 & 22.4 |

| Ivana Sabaj Abumohor, P.Eng | Halyard | Process design, equipment selection and process OPEX. | 1.11, 17 |

| Stacy Freudigmann, P. Eng. | Canenco | Metallurgical testing program management, analyses and interpretation. Processing circuit design criteria and flowsheet development, gold recoveries and reagent use estimates | 1.7, 13 |

| Tysen Hantelmann, P. Eng. | JDS | Mineral Reserves, Mine planning, production schedule and open pit CAPEX and OPEX | 1.9, 1.10, 15,16 (except 16.3), 21.3, 22.3 |

| Pierre Landry, P. Geo. | SLR | Geology, Mineralization, Drilling, QA/QC, Data Validation and Mineral Resource Estimate | 1.6, 1.8, 1.16.1, 7, 8, 9, 10, 11, 12, 14, 26.1 |