|

Exhibit

|

Description

|

|

|

Press Release – 2025 Rhyolite Ridge Lithium-Boron Mineral Resource Estimate

|

|

ioneer Ltd

|

||

|

(registrant)

|

||

|

Date: March 5, 2025

|

By: /s/ Ian Bucknell

|

|

|

Name:

|

Ian Bucknell | |

|

Title:

|

Chief Financial Officer & Company Secretary | |

|

|

| • |

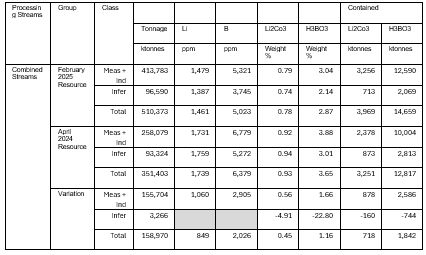

45% increase in the Rhyolite Ridge South Basin Mineral Resource estimate

|

| • |

510 million tonnes (Mt) containing 3.97 Mt of lithium carbonate equivalent and 14.66 Mt of boric acid equivalent – all within the fully permitted Project boundary

|

| • |

81% of the Resource now sits in the Measured & Indicated category

|

| • |

Three distinct Streams provide maximum flexibility around lithium carbonate and boric acid production rates

|

| • |

Underpins forthcoming Ore Reserve estimate, set for April 2025 release

|

|

|

• |

Total Mineral Resource of 510 Mt

|

|

|

• |

Contained lithium carbonate equivalent (LCE) of 3.97 Mt

|

|

|

• |

Contained boric acid equivalent (BAE) of 14.66 Mt

|

|

|

• |

Measured & Indicated Resource for Stream 1 of 152 Mt

|

|

|

• |

Measured & Indicated Resource for Streams 1 & 2 of 366 Mt

|

|

|

• |

Stream 1 – lithium mineralisation with high-boron and low-clay content

179Mt Resource containing 1.54Mt Lithium Carbonate and 12.00Mt Boric Acid.

|

|

|

• |

Stream 2 – lithium mineralisation with low-boron and low-clay content

274Mt Resource containing 1.78Mt Lithium Carbonate and 2.25Mt Boric Acid. |

|

|

• |

Stream 3 – lithium mineralisation with low-boron and high-clay content

58Mt Resource containing 0.64Mt Lithium Carbonate and 0.41Mt Boric Acid.

|

|

Summary of February 2025 Mineral Resource Estimate

|

Contained

|

|||||||

|

Stream

|

Classification

|

Tonnage

(ktonnes)

|

Li

(ppm)

|

B

(ppm)

|

Li2CO3

(Wt.%)

|

H3BO3

(Wt.%)

|

Li2CO3

(ktonnes)

|

H3BO3

(ktonnes)

|

|

1

|

Measured

|

64,380

|

1,752

|

12,670

|

0.93

|

7.24

|

600

|

4,664

|

|

Indicated

|

87,372

|

1,551

|

11,280

|

0.83

|

6.45

|

721

|

5,636

|

|

|

Inferred

|

26,873

|

1,554

|

11,102

|

0.83

|

6.35

|

222

|

1,706

|

|

|

Total

|

178,625

|

1,624

|

11,754

|

0.86

|

6.72

|

1,544

|

12,005

|

|

|

2

|

Measured

|

68,713

|

1,257

|

1,554

|

0.67

|

0.89

|

460

|

611

|

|

Indicated

|

145,061

|

1,196

|

1,583

|

0.64

|

0.90

|

923

|

1,313

|

|

|

Inferred

|

60,199

|

1,249

|

941

|

0.66

|

0.54

|

400

|

324

|

|

|

Total

|

273,973

|

1,223

|

1,434

|

0.65

|

0.82

|

1,783

|

2,247

|

|

|

3

|

Measured

|

19,191

|

2,203

|

1,552

|

1.17

|

0.89

|

225

|

170

|

|

Indicated

|

29,066

|

2,112

|

1,187

|

1.12

|

0.68

|

327

|

197

|

|

|

Inferred

|

9,518

|

1,789

|

716

|

0.95

|

0.41

|

91

|

39

|

|

|

Total

|

57,775

|

2,089

|

1,231

|

1.11

|

0.70

|

642

|

407

|

|

|

ALL

|

Grand Total

|

510,373

|

1,461

|

5,023

|

0.78

|

2.87

|

3,969

|

14,659

|

|

|

Stream 1

|

Stream 2

|

Stream 3

|

|

|

Before Leach

|

|

|

|

|

After Leach

|

|

|

|

|

Boron

|

HIGH

|

LOW

|

LOW

|

|

Clay

|

LOW

|

LOW

|

HIGH

|

|

Units

|

B5, L6

|

S5, L6

|

M5

|

|

Leach Method

|

VAT

|

VAT or HEAP

|

AGITATED TANK

|

|

|

|

Chad Yeftich

|

Ian Bucknell

|

|

U.S. Investor Relations

E: ir@ioneer.com

|

Aus. Investor Relations

E: ir@ioneer.com

|

|

Daniel Francis, FGS Global

|

|

|

U.S. Media Relations

E: daniel.francis@fgsglobal.com

|

|

|

|

Stream

|

Group

|

Classification

|

Tonnage

(ktonnes)

|

Li

ppm

|

B

ppm

|

Li2CO3

Wt. %

|

H3BO3

Wt. %

|

Contained

|

|

|

Li2CO3

(ktonnes)

|

H3BO3

(ktonnes)

|

||||||||

|

Stream 1 (>= 5,000 ppm B)

|

Upper

Zone

B5 Unit

|

Measured

|

38,404

|

1,891

|

15,282

|

1.01

|

8.74

|

386

|

3,356

|

|

Indicated

|

38,670

|

1,743

|

13,996

|

0.93

|

8.00

|

359

|

3,095

|

||

|

Inferred

|

10,627

|

1,712

|

10,564

|

0.91

|

6.04

|

97

|

642

|

||

|

Total

|

87,701

|

1,804

|

14,143

|

0.96

|

8.09

|

842

|

7,092

|

||

|

Upper

Zone

M5

Unit

|

Measured

|

4,562

|

2,350

|

7,592

|

1.25

|

4.34

|

57

|

198

|

|

|

Indicated

|

4,224

|

2,231

|

7,450

|

1.19

|

4.26

|

50

|

180

|

||

|

Inferred

|

763

|

2,197

|

6,515

|

1.17

|

3.73

|

9

|

28

|

||

|

Total

|

9,549

|

2,285

|

7,443

|

1.22

|

4.26

|

116

|

406

|

||

|

Upper

Zone

S5 Unit

|

Measured

|

3,693

|

1,419

|

7,641

|

0.75

|

4.37

|

28

|

161

|

|

|

Indicated

|

4,747

|

1,285

|

7,415

|

0.68

|

4.24

|

32

|

201

|

||

|

Inferred

|

1,572

|

1,400

|

6,469

|

0.75

|

3.70

|

12

|

58

|

||

|

Total

|

10,012

|

1,352

|

7,350

|

0.72

|

4.20

|

72

|

421

|

||

|

Upper

Zone

Total

|

Measured

|

46,659

|

1,899

|

13,926

|

1.01

|

7.96

|

471

|

3,715

|

|

|

Indicated

|

47,641

|

1,741

|

12,760

|

0.93

|

7.30

|

441

|

3,476

|

||

|

Inferred

|

12,962

|

1,703

|

9,829

|

0.91

|

5.62

|

117

|

728

|

||

|

Total

|

107,262

|

1,805

|

12,913

|

0.96

|

7.38

|

1,030

|

7,920

|

||

|

Lower Zone

L6 Unit

|

Measured

|

17,721

|

1,366

|

9,362

|

0.73

|

5.35

|

129

|

949

|

|

|

Indicated

|

39,731

|

1,324

|

9,507

|

0.70

|

5.44

|

280

|

2,160

|

||

|

Inferred

|

13,911

|

1,415

|

12,288

|

0.75

|

7.03

|

105

|

977

|

||

|

Total

|

71,363

|

1,352

|

10,013

|

0.72

|

5.73

|

514

|

4,086

|

||

|

Total

Stream 1 (all zones)

|

Measured

|

64,380

|

1,752

|

12,670

|

0.93

|

7.24

|

600

|

4,664

|

|

|

Indicated

|

87,372

|

1,551

|

11,280

|

0.83

|

6.45

|

721

|

5,636

|

||

|

Inferred

|

26,873

|

1,554

|

11,102

|

0.83

|

6.35

|

222

|

1,706

|

||

|

Total

|

178,625

|

1,624

|

11,754

|

0.86

|

6.72

|

1,544

|

12,005

|

||

|

Stream 2 ($16.54/tonne net value cut-off grade, Low Clay)

|

Upper

Zone

B5 Unit

|

Measured

|

4,963

|

2,229

|

2,213

|

1.19

|

1.27

|

59

|

63

|

|

Indicated

|

4,734

|

2,120

|

2,515

|

1.13

|

1.44

|

53

|

68

|

||

|

Inferred

|

3,616

|

1,715

|

1,805

|

0.91

|

1.03

|

33

|

37

|

||

|

Total

|

13,313

|

2,050

|

2,210

|

1.09

|

1.26

|

145

|

168

|

||

|

Upper

Zone

S5 Unit

|

Measured

|

21,087

|

1,090

|

1,281

|

0.58

|

0.73

|

122

|

154

|

|

|

Indicated

|

26,144

|

988

|

1,242

|

0.53

|

0.71

|

138

|

186

|

||

|

Inferred

|

11,925

|

1,003

|

1,206

|

0.53

|

0.69

|

64

|

82

|

||

|

Total

|

59,156

|

1,027

|

1,248

|

0.55

|

0.71

|

323

|

422

|

||

|

Upper

Zone

Total

|

Measured

|

26,050

|

1,307

|

1,458

|

0.70

|

0.83

|

181

|

217

|

|

|

Indicated

|

30,878

|

1,162

|

1,437

|

0.62

|

0.82

|

191

|

254

|

||

|

Inferred

|

15,541

|

1,169

|

1,345

|

0.62

|

0.77

|

97

|

120

|

||

|

Total

|

72,469

|

1,215

|

1,425

|

0.65

|

0.81

|

469

|

590

|

||

|

Lower Zone

L6 Unit

|

Measured

|

42,663

|

1,227

|

1,613

|

0.65

|

0.92

|

279

|

393

|

|

|

Indicated

|

114,183

|

1,206

|

1,622

|

0.64

|

0.93

|

733

|

1,059

|

||

|

Inferred

|

44,658

|

1,277

|

800

|

0.68

|

0.46

|

304

|

204

|

||

|

Total

|

201,504

|

1,226

|

1,438

|

0.65

|

0.82

|

1,315

|

1,657

|

||

|

Total

Stream 2 (all zones)

|

Measured

|

68,713

|

1,257

|

1,554

|

0.67

|

0.89

|

460

|

611

|

|

|

Indicated

|

145,061

|

1,196

|

1,583

|

0.64

|

0.90

|

923

|

1,313

|

||

|

Inferred

|

60,199

|

1,249

|

941

|

0.66

|

0.54

|

400

|

324

|

||

|

Total

|

273,973

|

1,223

|

1,434

|

0.65

|

0.82

|

1,783

|

2,247

|

||

|

Stream 3($16.54/tonne net value cut-off grade,

High Clay)

|

Total

Stream 3 (M5 zone)

|

Measured

|

19,191

|

2,203

|

1,552

|

1.17

|

0.89

|

225

|

170

|

|

Indicated

|

29,066

|

2,112

|

1,187

|

1.12

|

0.68

|

327

|

197

|

||

|

Inferred

|

9,518

|

1,789

|

716

|

0.95

|

0.41

|

91

|

39

|

||

|

Total

|

57,775

|

2,089

|

1,231

|

1.11

|

0.70

|

642

|

407

|

||

|

Grand Total All Streams and All Units

|

Measured

|

152,284

|

1,585

|

6,253

|

0.84

|

3.58

|

1,285

|

5,445

|

|

|

Indicated

|

261,499

|

1,417

|

4,779

|

0.75

|

2.73

|

1,971

|

7,146

|

||

|

Inferred

|

96,590

|

1,387

|

3,745

|

0.74

|

2.14

|

713

|

2,069

|

||

|

Total

|

510,373

|

1,461

|

5,023

|

0.78

|

2.87

|

3,969

|

14,659

|

|

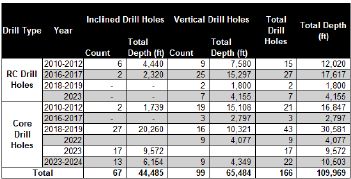

Processing Stream

|

Group

|

Classification |

Tonnes

(M)

|

Li

(ppm)

|

B

(ppm)

|

Li2CO3

(wt.

%)

|

H3BO3

(wt.

%)

|

Li2CO3

(kt)

|

H3BO3

(kt)

|

|

Combined Streams

|

February

2025

Resource

|

Mea + Ind

|

413.8

|

1,479

|

5,321

|

0.79

|

3.04

|

3,256

|

12,590

|

|

Inf

|

96.6

|

1,387

|

3,745

|

0.74

|

2.14

|

713

|

2,069

|

||

|

Total

|

510.4

|

1,461

|

5,023

|

0.78

|

2.87

|

3,969

|

14,659

|

||

|

April

2024 Resource

|

Mea + Ind

|

258.1

|

1731

|

6779

|

0.9

|

3.9

|

2,378

|

10,004

|

|

|

Inf

|

93.3

|

1759

|

5272

|

1.0

|

3.0

|

873

|

2,813

|

||

|

Total

|

351.4

|

1739

|

6379

|

0.9

|

3.6

|

3,251

|

12,817

|

||

|

Variation

|

Mea + Ind

|

155.7

|

1,060

|

2,905

|

0.56

|

1.66

|

878

|

2,586

|

|

|

Inf

|

3.3

|

-4.91

|

-22.80

|

-160

|

-744

|

||||

|

Total

|

159.0

|

849

|

2,026

|

0.45

|

1.16

|

718

|

1,842

|

|

|

• |

The change in the calculation of acid consumption during processing and accounting for this cost has lowered the process costs; the extraction of calcium (Ca) in seam S5 was reduced from 100% to 80% and in seam L6 from 100% to 89% when

Ca <= 10% and 64% when Ca > 10%, based on metallurgical test work, thus lowering the acid consumption.

|

|

|

• |

The definition of the resource pit shell includes a G&A cost of $US 16.54/tonne (not included for the April 2024 resource pit shell), but this cost did not negatively impact the size of the resource pit

shell.

|

|

|

• |

The removal of the 1090 ppm Lithium cutoff for Streams 2 and 3, replacing it with a $US 16.54/tonne net value cutoff. This increased the amount of lower grade Lithium tonnage to be included in the mineral resource.

|

|

|

• |

The Rhyolite Ridge Mineral Resource area extends over a north-south strike length of 4,240 m (from 4,337,540 mN – 4,341,780mN), has a maximum width of 2,110m (863,330 mE – 865,440 mE) and includes the 585 m vertical interval from

2,065mRL to 1,480 mRL.

|

|

|

• |

The Rhyolite Ridge Project tenements (unpatented mining claims) are owned by Ioneer Minerals Corporation, a company wholly owned by Ioneer Ltd. The unpatented mining claims are located on US federal land administered by the Bureau of

Land Management (BLM).

|

|

|

• |

Lithium and boron mineralisation is stratiform in nature and is hosted within Late Miocene-age carbonate-rich sedimentary rock, deposited in a lacustrine environment in the Basin and Range terrain of Nevada, USA.

|

|

|

• |

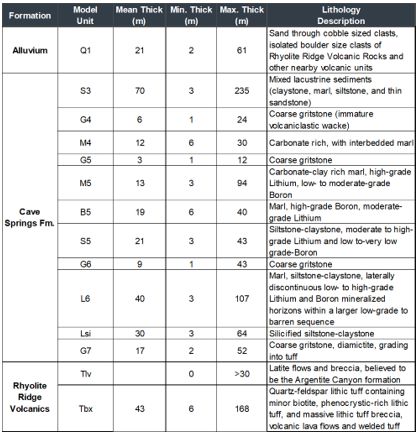

Drill holes used in the Mineral Resource estimate included 50 reverse circulation (RC) holes and 110 core holes for a total of 32,530m within the defined mineralisation. The full database for the

South Basin contains records for 166 drill holes for 33,519m of drilling.

|

|

|

• |

Drill hole spacing is 100m by 100m (or less) over most of the deposit.

|

|

|

• |

Drill holes were logged for a combination of geological and geotechnical attributes. The core has been photographed and measured for RQD and core recovery.

|

|

|

• |

Drilling was conducted by American Lithium Minerals Inc., the previous owner of the property between 2010 and 2011 and by ioneer in 2017 to 2019 and 2022 to 2024. For RC drilling, a 12.7-centimetre (cm)

hammer was used with sampling conducted on 1.52m intervals and split using a rig mounted rotary splitter. The hammer was replaced with a tri-cone bit in instances of high groundwater flow. For diamond core, PQ and HQ core size diameter with

standard tube was used. Core recoveries of 93% were achieved by ioneer at the project. The core was sampled as half core at 1.52m intervals using a standard electric core saw.

|

|

|

• |

Samples were submitted to ALS Minerals Laboratory in Reno, Nevada for sample preparation and analysis. The entire sample was oven dried at 105˚C and crushed to -2 millimetre (mm). A sub-sample of

the crushed material was then pulverised to better than 85% passing -75 microns (µm) using a LM5 pulveriser. The pulverised sample was split with multiple feed in a Jones riffle splitter until a

100-200 gram (g) sub-sample was obtained for analysis.

|

|

|

• |

Analysis of the samples was conducted using aqua regia 2-acid for ICP-MS on a multi-element suite. This method is appropriate for understanding sedimentary lithium deposits and is a total method.

|

|

|

• |

Standards for lithium and boron and blanks were routinely inserted into sample batches and acceptable levels of accuracy were reportedly obtained. Based on an evaluation of the quality assurance and quality control (QA/QC) results all assay data has been deemed by the IMC Competent Person as suitable and fit for purpose in Mineral Resource estimation.

|

|

|

• |

The Mineral Resource estimate presented in this Report has been constrained by the application of an optimized Mineral Resource pit shell. The Mineral Resource pit shell was developed using the Independent

Mining Consultants, Inc. (IMC) Mine Planning software.

|

|

|

• |

The Mineral Resource estimate assumes the use of three processing streams: one which can process ore with boron content greater than 5,000 ppm and two which can process ore with boron content less than 5,000

ppm.

|

|

|

• |

The Mineral Resource estimate has been constrained by applying a 5,000 ppm Boron cut-off grade to HiB-Li mineralisation within the B5, M5, S5 and L6 geological units as well as a $16.54/tonne net value cut-off grade to LoB-Li

mineralisation in the M5, B5, S5 and L6 geological units.

|

|

•

|

Key input parameters and assumptions for the Mineral Resource pit shell included the following:

|

|

|

• |

B cut-off grade of 5,000 ppm for HiB-Li processing stream and no B cut-off grade for LoB-Li processing stream

|

|

|

• |

No Li cut-off grade for HiB-Li processing stream and net value cutoff of $16.54/tonne for LoB-Li processing stream

|

|

|

• |

Overall pit slope angle of 42 degrees in all rock units (wall angle guidance provided by Geo-Logic Associates who developed the geotechnical design).

|

|

|

• |

Fixed mining cost of US$1.69 /tonne and a variable incremental mining cost of $0.005/tonne per vertical meter from reference elevation of 6,210ft amsl

|

|

|

• |

G&A cost of US$16.54/tonne processed

|

|

|

• |

Ore processing and grade control costs include a fixed cost per tonne and a variable cost of acid based on the acid consumption rate which is calculated for each block within the mineralized seams. For HiB-Li Processing Stream the fixed

cost is $30.50/mt and the acid costs range between $30.93/mt to $52.12/mt based on the average grades per seam. For LoB-Li Processing Streams, the fixed cost ranges between $17.53/mt to $30.80/mt and the acid costs range between $26.33/mt

to $50.01/mt based on the average grades per seam.

|

|

|

• |

Boron and Li recovery of 80.2% and 85.7% respectively for HiB-Li Processing Stream.

|

|

|

• |

Boron Recovery for LoB-Li Processing Stream variable by lithology as follows: 65% in M5 Unit, 80.2% in B5 unit, 50% in S5 unit, and 37.3% in L6 unit.

|

|

|

• |

Lithium Recovery for LoB-Li Processing Streams variable by lithology as follows: 78% in M5 unit, 85.7% in B5 unit, 88% in S5 unit, and 85% in L6 unit.

|

|

|

• |

Boric Acid sales price of US$1,172.78/tonne.

|

|

|

• |

Lithium Carbonate sales price of US$19,351.38/tonne.

|

|

|

• |

Sales/Transport costs are included in the process cost.

|

|

|

• |

Drill core samples were assayed on nominal 1.52 m lengths and this data set was composited to 1.52m lengths which respected seam contacts and was used for the interpolation of grade data into a 1.52m bench height block model. The data

set honoured geological contacts (i.e. assay intervals did not span unit contacts).

|

|

|

• |

Based on a statistical analysis, extreme B grade values were identified in some of the units other than the targeted G5, B5, M5, S5, G6, L6 and Lis units. The units other than these units were not estimated so no grade capping was

applied to the drill hole database. The units B5, M5, S5 and L6 are the units of economic interest and the grades in these units and the adjacent units were estimated for completeness when re-blocking to a 9.14m bench height block model

used to tabulate the mineral resource.

|

|

|

• |

The geological model was developed as a gridded surface stratigraphic model with fault domains included which offset the stratigraphic units in various areas of the deposit. The geological model was developed by GSI under direction of

ioneer and provided to IMC as the geologic basis for grade estimation. IMC has reviewed the geological model and accepts the interpretation.

|

|

|

• |

Domaining in the model was constrained by the roof and floor surfaces of the geological units. The unit boundaries were modelled as hard boundaries, with samples interpolated only within the unit in which they occurred.

|

|

|

• |

The geological model used as the basis for estimating Mineral Resources was developed as a stratigraphic gridded surface model using a 7.6m regularized grid. The grade block model was developed using a 7.6m north-south by 7.6m east-west

by 1.52m vertical block dimension (no sub-blocking was applied). The grid cell and block size dimensions represent 25 percent of the nominal drill hole spacing across the model area. The model was reblocked to 9.14 m high blocks (six 1.52m

blocks combined vertically) for assigning the economic attributes and tabulating the mineral resource.

|

|

|

• |

Inverse Distance Squared (‘ID2’) grade interpolation was used for the estimate, constrained by stratigraphic unit roof and floor surfaces from the geological model. The search direction for estimating grade varied and followed

the floor orientation of the seams which changed within some of the fault block domains. The search distances ranged from 533 m in B5 to 229 m in S5. The number of drill hole composites used to estimate the grades of a model block ranges

from a minimum of two composites to a maximum of 10 composites, with no more than 3 composites from one drill hole.

|

|

|

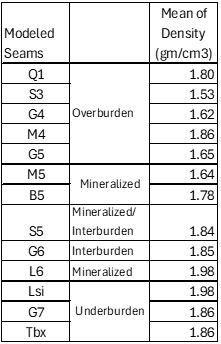

• |

The density values used to convert volumes to tonnages were assigned on a by-geological unit basis using mean values calculated from 120 density samples collected from drill core during the 2018 and more recent 2022-2023 P1 and P2

drilling programs. The density values by seam ranged from 1.53 grams per cubic centimeter (‘g/cm3’) for S3 to 1.98/cm3 in seam L6. The density analyses performed by geotechnical consultants present during both the

2018 and 2022-2023 drilling programs (P1 and P2) followed a strict repeatable process in sample collection and analysis utilizing the Archimedes-principle (water displacement) method for density determination, with values reported in dry

basis. This provided consistent representative data. The 2018 and 2022-2023 data aligned well and proved to be representative across the resource.

|

|

|

• |

Estimated Mineral Resources were classified as follows:

|

|

|

• |

Measured: Between 107 and 122m spacing between points of observation depending on the seam, with sample interpolation from a minimum of four drill holes.

|

|

|

• |

Indicated: Between 168 and 244m spacing between points of observation depending on the seam, with sample interpolation from a minimum of two drill holes.

|

|

|

• |

Inferred: To the limit of the estimation range (maximum 533m, depending on the seam), with sample interpolation from a minimum of one drill hole (2 composites).

|

|

|

• |

The Mineral Resource classification included the consideration of data reliability, spatial distribution and abundance of data and continuity of geology, fault structures and grade parameters.

|

|

|

• |

The Mineral Resource estimate presented in this Report was developed with the assumption that the HiB-Li mineralization within the Mineral Resource pit shell has a reasonable prospect for eventual economic extraction using current

conventional open pit mining methods.

|

|

|

• |

The basis of the mining assumptions made in establishing the reasonable prospects for eventual economic extraction of the HiB-Li mineralization are based on preliminary results from mine design and planning work that is in-progress as

part of an ongoing update to the Feasibility Study for the Project based on new information.

|

|

|

• |

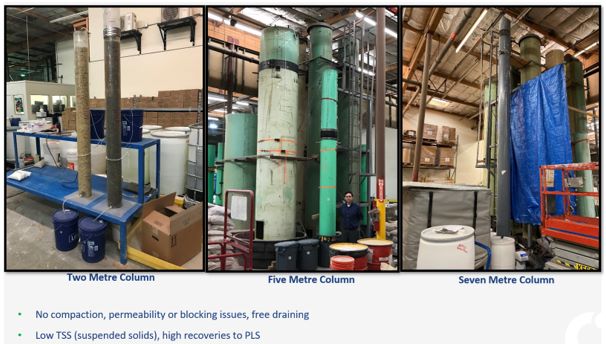

The basis of the metallurgical assumptions made in establishing the reasonable prospects for eventual economic extraction of the HiB-Li (Stream 1) mineralization are based on results from metallurgical and material processing work that

was developed as part of the ongoing Feasibility Study for the Project. This test work was performed using current processing and recovery methods for producing Boric acid and Lithium carbonate products.

|

|

|

• |

A second process stream (Stream 2) to recover Li from low boron mineralized- low clay (LoB-Li) units has been confirmed. Current results indicate a reasonable process and expectation for economic extraction of the LoB-Li from the S5, B5

and L6 units. This test work was performed using current processing and recovery methods for producing Boric acid and Lithium carbonate products.

|

|

|

• |

A third process stream (Stream 3) to recover Li from low boron high clay mineralized (LoB-Li) units has been confirmed. Current results indicate a reasonable process and expectation for economic extraction of the LoB-Li from M5 unit.

This test work was performed using current processing and recovery methods for producing Boric acid and Lithium carbonate products.

|

|

|

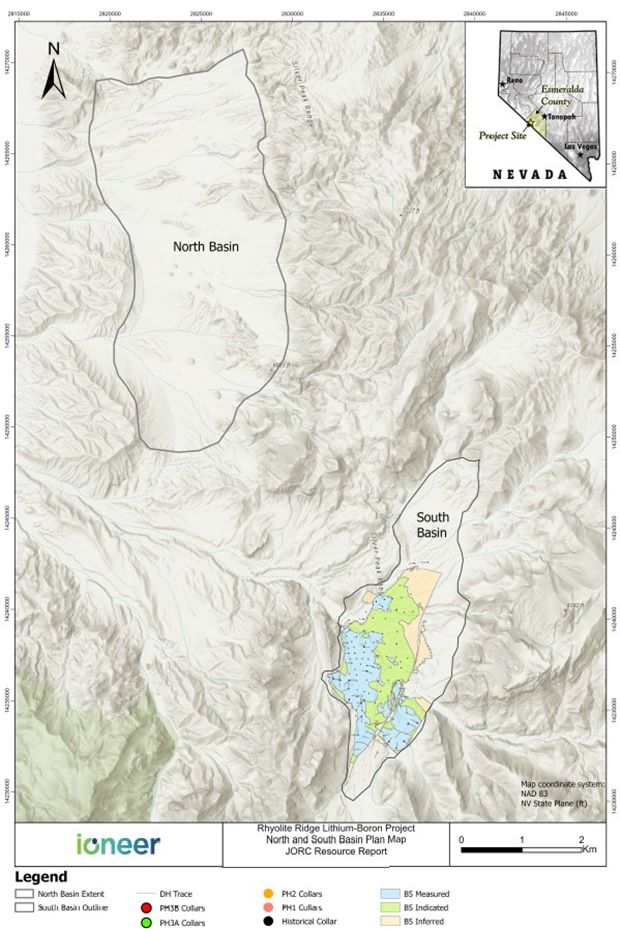

1. |

North and South Basin plan showing the location of drill holes, Resource and tenement boundary.

|

|

|

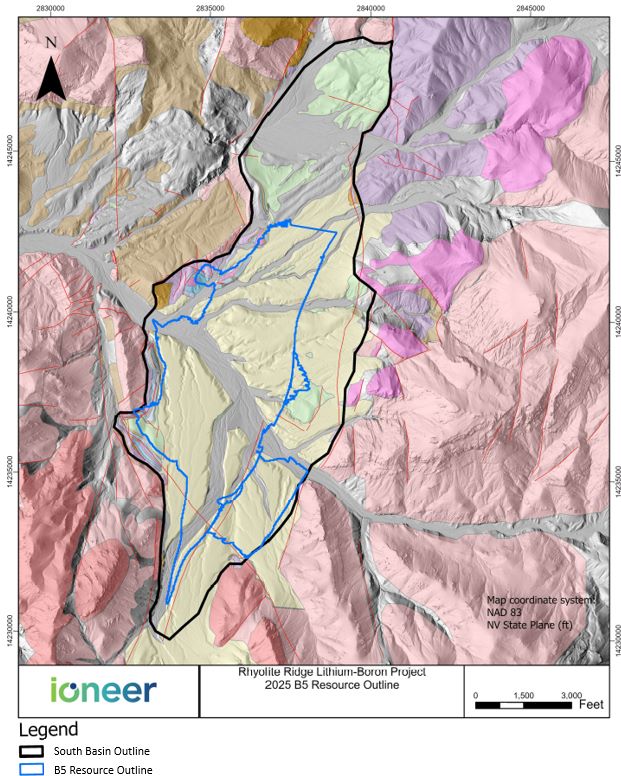

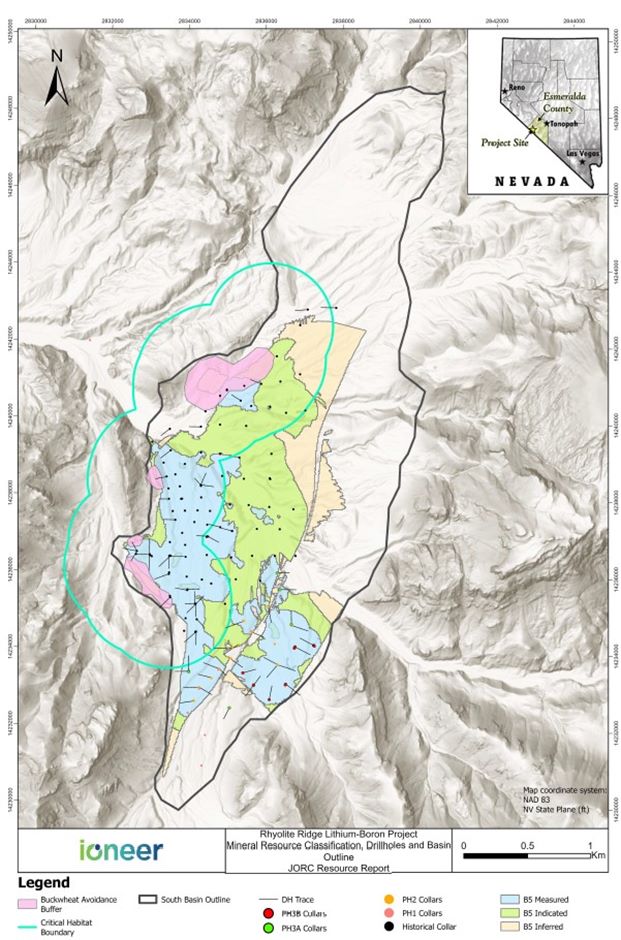

2. |

South Basin plan showing outlines of Measured, Indicated and Inferred Mineral Resources

|

|

|

3. |

South Basin South- North Cross Section looking West

|

|

|

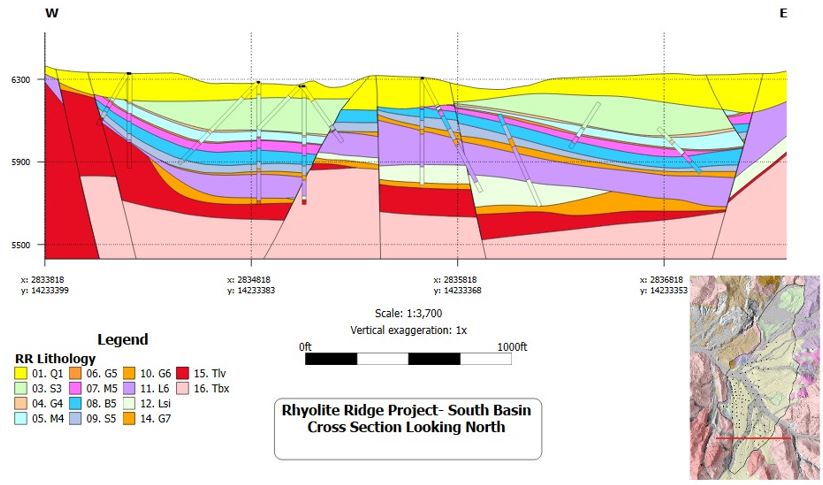

4. |

South Basin Cross Section Looking North

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

Sampling Techniques

|

• Nature and quality of sampling (e.g. cut channels, random chips, or specific specialised industry

standard measurement tools appropriate to the minerals under investigation, such as down hole gamma sondes, or handheld XRF instruments, etc.). These examples should not be taken as limiting the broad meaning of sampling

|

• The nature and quality of the sampling from the various sampling programs includes the following:

• Reverse circulation (RC) Drilling: a sample was collected every 1.52 metre (m) from a 127-millimetre (mm)

diameter drill hole and split using a rig-mounted rotary splitter. Samples, with a mean weight of 4.8 kilograms (kg) were submitted to ALS Minerals laboratory in Reno, NV where they were processed for

assay. RC samples represent 49% of the total intervals sampled to date.

• Core Drilling: Core samples were collected from HQ (63.5 mm core diameter) and PQ (85.0 mm core diameter) drill core, on a mean interval of

1.52 m, and cut using a water-cooled diamond blade core saw. Samples, with a mean weight of 1.8 kg, were submitted to ALS where they were proceeded for assay.

• Drill Hole Deviation: Inclined core drill holes were surveyed to obtain downhole deviation by the survey company (International Directional

Services, LLC) or drilling company (Idea Drilling, Alford Drilling, IG Drilling, Boart Long Year, Major Drilling,) with a downhole Reflex Mems Gyros and Veracio TruShot tools and, for all but three of the drill holes. One drill hole could

not be surveyed due to tool error (SBH-72), and two were intentionally surveyed using an Acoustic Televiewer (SBH-60, SBH-79).

• Trenches: In addition to sampling from drill holes, samples were collected from 19 mechanically excavated trenches in 2010. The trenches

were excavated from the outcrop/subcrop using a backhoe and or hand tools. Chip samples were then collected from the floor of the trench. Due to concerns with correlation and reliability of the results from the trenches, The Competent

Person has not included any of this data in the geological model or Mineral Resource estimate.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

• Include reference to measures taken to ensure sample representivity and the appropriate calibration of

any measurement tools or systems used.

|

• Measures taken to ensure sample representivity include the following:

• Due to the nature of RC samples, lithological boundaries are not easily honoured; therefore, continuous 1.52 m sample intervals were taken

to ensure as representative a sample as possible. Lithological boundaries were adjusted as needed by a senior Ioneer geologist once the assay results were received.

• Core sample intervals were selected to reflect visually identifiable lithological boundaries wherever possible, to ensure sample

representivity. In cases where the lithological boundaries were gradational, the best possible interval was chosen and validated by geochemical assay results.

• All chip and core sampling were completed by or supervised by a senior Ioneer geologist. The senior Ioneer, Newfield’s and WSP geologists

referenced here, and throughout this Table 1, have sufficient relevant experience for the exploration methods employed, the type of mineralization being evaluated, and are registered professional geologists in their jurisdiction; however,

they are not Competent Persons according to the definition presented in JORC as they are not members of one of the Recognized Professional Organization” included in the ASX list referenced by JORC.

• The Competent Person was not directly involved during the exploration drilling programs and except for observing sampling procedures on

two drill holes during the site visit (August 10, 2023), was not present to observe sample selection. Based on review of the procedures during the site visit and subsequent review of the data, it is the opinion of the Competent Person that

the measures taken to ensure sample representivity were reasonable for the purpose of estimating Mineral Resources.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

• Aspects of the determination of mineralisation that are Material to the Public Report. In cases

where ‘industry standard’ work has been done this would be relatively simple (eg ‘reverse circulation drilling was used to obtain 1 m samples from which 3 kg was pulverised to produce a 30 g charge for fire assay’). In other

cases more explanation may be required, such as where there is coarse gold that has inherent sampling problems. Unusual commodities or mineralisation types (e.g. submarine nodules) may warrant disclosure of detailed information

|

• Aspects of the determination of mineralization included visual identification of mineralized intervals by a senior Ioneer geologist using

lithological characteristics including clay and carbonate content, grain size and the presence of key minerals such as Ulexite (hydrated sodium calcium borate hydroxide) and Searlesite (sodium borosilicate). A visual distinction between

some units, particularly where geological contacts were gradational was initially made. Final unit contacts were then determined by a senior Ioneer geologist once assay data were available.

• The Competent Person was not directly involved during the exploration drilling programs; however, the visual identification of mineralized

zones and the process for updating unit and mineralized contacts was reviewed with the Ioneer senior geologist during the site visit. The Competent Person evaluated the identified mineralized intervals against the analytical results and

agrees with the methodology used by Ioneer to determine material mineralization.

|

|

|

Drilling

techniques

|

• Drill type (e.g. core, reverse circulation, open-hole hammer, rotary air blast, auger, Bangka, sonic,

etc..) and details (e.g. core diameter, triple or standard tube, depth of diamond tails, face-sampling bit or other type, whether core is oriented and if so, by what method, etc.).

|

• Both RC and core drilling techniques have been used on the Project. Exploration drilling programs targeting Lithium-Boron (Li-B) mineralization on the Project have been implemented by American Lithium Minerals Inc. (2010-2012) and Ioneer (formerly Global Geoscience) in 2016, 2017, 2018, 2019, 2022, and 2023.

• Prior to 2018, all RC drilling was conducted using a 127 mm hammer. All pre-2018 core drill holes were drilled using HQ sized core with a

double-tube core barrel.

• For the 2018-2023 drilling programs, all core holes (vertical and inclined) were tricone drilled through unconsolidated alluvium, then

cored through to the end of the drill hole. A total of 91 core holes were drilled, 64 holes were PQ diameter and 27 were drilled as HQ diameter. Drilling was completed using a triple-tube core barrel (split inner tube) which was preferred

to a double-tube core barrel (solid inner tube) as the triple-tube improved core recovery and core integrity during core removal from the core barrel.

|

|

Drill sample recovery

|

• Method of recording and assessing core and chip sample recoveries and results assessed.

|

• Prior to 2017, chip recovery was not recorded for the RC drilling therefore the Competent Person cannot comment on drill sample recovery

for this period of drilling.

For the 2017 RC drilling program, the drill holes were geologically logged as they were being drilled; however, no estimates of chip recoveries were recorded.

Therefore, the Competent Person cannot comment on drill sample recovery for this period of drilling.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

• For the 2010-2012 and 2016 core drilling programs, both core recovery and rock quality index (RQD) were recorded for each cored interval.

Core recovery was determined by measuring the recovered linear core length and then calculating the recovered percentage against the total length of the core run from the drill advance. The core recovery for all the drilling ranged from

0% to 100%, with over 65 % of the drill holes having greater than 80% mean core recovery. The core recovery values were recorded by the logging geologist and reviewed by the senior Ioneer geologist. The majority of the 2010-2012 and 2016

core drill holes reported greater than 95% recovery in the B5, M5 and L6 mineralized intervals.

• For the 2018-2019 drilling program, both core recovery and RQD were recorded for each cored interval. Core recovery was determined by

measuring the recovered linear core length and then calculating the recovered percentage against the total length of the core run from the drill advance. The core recovery for all the drilling ranged from 41% to 100%, with over 65% of the

drill holes having greater than 90% mean core recovery. The core recovery values were recorded by the logging geologist and reviewed by the senior Ioneer geologist. In the target mineralized intervals (M5, B5 & L6), the mean core

recovery was 86% in the B5, 87% in the M5 and 95% in the L6 units, with most of the drill holes reporting greater than 90% recovery in the mineralized intervals.

• The Competent Person considers the core recovery for the 2023, 2022, 2018- 2019, 2016 and 2010-2012 core drilling programs to be acceptable

based on statistical analysis which identified no grade bias between sample intervals with high versus low core recoveries. On this basis, the Competent Person has made the reasonable assumption that the sample results are reliable for use

in estimating Mineral Resources.

|

||

|

• Measures taken to maximise sample recovery and ensure representative nature of the samples.

|

• Chip recoveries were not recorded for the 2010-2012 and 2017 RC drilling programs, and there is no indication of measures taken to maximize

sample recovery and ensure representative nature of samples.

• No specific measures for maximizing sample recovery were documented for the 2010-2012 and 2016 core drilling programs.

• During the 2018-2023 drilling programs, Ioneer used a triple-tube core barrel to maximize sample recovery and ensure

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

representative nature of samples. The use of triple-tube was originally used during the 2018 drill program. A triple-tube core barrel

generally provides improved core recovery over double-tube core barrels, resulting in more complete and representative intercepts for core logging, sampling and geotechnical evaluation. It also limited any potential sample bias due to

preferential loss/gain of material.

|

||

|

• Whether a relationship exists between sample recovery and grade and whether sample bias may have

occurred due to preferential loss/gain of fine/coarse material.

|

• Chip recovery was not recorded for the 2010-2012 and 2017 RC drilling program and, therefore, there is no basis for evaluating the

relationship between grade and sample recovery for samples from these programs.

• Based on the Competent Person’s review of the 2010-2012, 2016 and 2018-2019, 2022-2023 drilling recovery and grade data there was no

observable relationship between sample recovery and grade.

|

|

|

Logging

|

• Whether core and chip samples have been geologically and geotechnically logged to a level of detail to

support appropriate Mineral Resource estimation, mining studies and metallurgical studies.

|

• All core and chip samples have been geologically logged to a level of detail to support appropriate Mineral Resource estimation, such that

there are lithological intervals for each drill hole, with a correlatable geological/lithological unit assigned to each interval.

• The 2018-2019 and 2022-2023 drilling were also geotechnically logged to a level of detail to support appropriate Mineral Resource

estimation.

• The Competent Person has reviewed all unit boundaries in conjunction with the Ioneer senior geologist, and where applicable, adjustments

have been made to the mineralized units based on the assay results intervals to limit geological dilution.

|

|

• Whether logging is qualitative or quantitative in nature.

|

• The RC and core logging were both qualitative (geological/lithological descriptions and observations) and quantitative (unit lengths, angles

of contacts and structural features and fabrics).

|

|

|

• Core (or costean, channel, etc.) photography.

|

• All chip trays and Core photography was completed on every core drill hole for the 2010-2012, 2016, 2018-2019 and 2022-2023 drilling

programs.

|

|

|

• The total length and percentage of the relevant intersections logged.

|

• Prior to 2018, a total length of 8,900 m of RC drilling and 6,000 m of core drilling was completed for the Project, 100% of which was

geologically logged by a logging geologist and reviewed by the senior Ioneer geologist.

• For the 2018-2019 drilling, a total length of 548 m of RC drilling and

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

• The total length and percentage of the relevant intersections logged.

(Con’t)

|

9,321 m of core drilling was completed for the Project, 100% of which was geologically logged by a logging geologist and reviewed by the

senior Ioneer geologist

• For the 2018-2019 drilling, 86% of the 9,321 m of core was geotechnically logged by an engineering geologist/ geotechnical engineer and

reviewed by the senior Ioneer geologist.

• For the 2022-2023 drilling, 100% of the 7,362m of core was geotechnically logged by an engineering geologist/ geotechnical engineer and

reviewed by the senior Ioneer geologist

The Competent Person reviewed the geological core logging and sample selection for two drill holes.

|

|

|

• If core, whether cut or sawn and whether quarter, half or all core taken.

|

• The following sub-sampling techniques and sample selection procedures apply to drill core samples:

• During the 2010-2012 and 2016 program, core samples were collected on a mean 1.52 m down hole interval and cut in two halves using a manual

core splitter. The entire sample was submitted for analysis with no sub-sampling prior to submittal.

• During the 2018-2019 drilling program, core samples were collected for every 1.52 m down hole interval and cut using a water-cooled diamond

blade core saw utilizing the following methodology for the two target units. For the M5 unit, ½ core samples were submitted for assay, while the remaining ½ core was retained for reference. For the B5 unit, ¼ core samples were submitted for

assay, while ¼ was reserved for future metallurgical test work and ½ core was retained reference.

• During the 2022-2023 drilling programs, core samples were collected for target units every 1.52 m down hole interval. Target units were cut

using a water-cooled diamond blade core saw utilizing the following methodology for the target units. For the M4, M5, B5, S5 and L6 unit, ½ core samples (HQ) or ¼ core samples (PQ) were submitted for assay, while the remaining ½- ¾ core was

retained for reference.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

Sub-sampling

techniques

and sample

preparation

Sub-sampling

techniques

and sample

preparation

|

• If core, whether cut or sawn and whether quarter, half or all core taken. If non-core, whether riffled, tube sampled, rotary split,

etc. and whether sampled wet or dry.

|

• The following sub-sampling techniques and sample selection procedures apply to drill core samples:

• During the 2010-2012 and 2016 program, core samples were collected on a mean 1.52 m down hole interval and cut in two halves using a

manual core splitter. The entire sample was submitted for analysis with no sub-sampling prior to submittal.

• During the 2018-2019 drilling program, core samples were collected for every 1.52 m down hole interval and cut using a water-cooled

diamond blade core saw utilizing the following methodology for the two target units. For the M5 unit, ½ core samples were submitted for assay, while the remaining ½ core was retained for reference. For the B5 unit, ¼ core samples were

submitted for assay, while ¼ was reserved for future metallurgical test work and ½ core was retained for reference.

• During the 2022-2024 drilling programs, core samples were collected for target units every 1.52 m down hole interval. Target units were

cut using a water-cooled diamond blade core saw utilizing the following methodology for the target units. For the M4, M5, B5, S5 and L6 unit, ½ core samples (HQ) or ¼ core samples (PQ) were submitted for assay, while the remaining ½-

¾ core was retained for reference.

• The following sub-sampling techniques and sample selection procedures apply to RC Chip Samples:

• Pre-2017 RC chips samples were collected using a wet rotary splitter approximately every 1.52 m depth interval. Two samples were

collected for every interval (one main sample and one duplicate). Only the main sample was submitted for analysis.

2017 RC chip samples were collected using a wet rotary splitter attached to a cyclone. One, approximately 10 kg, sample was collected every 1.52 m depth

interval. All samples were submitted for analysis.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

• For all sample types, the nature, quality and appropriateness of the sample preparation

technique.

|

• The Competent Person considers the nature, type and quality of the sample preparation techniques to be appropriate based on the

general homogeneous nature of the mineralized zones and the drilling methods employed to obtain each sample (i.e., RC and core).

|

|

|

• Quality control procedures adopted for all sub-sampling stages to maximise representivity of

samples.

|

• Quality control procedures adopted for sub-sampling to maximize representivity include the following:

• During 2016-2017 and 2018-2023 drilling programs, field duplicate/replicate samples were obtained. For the 2017 and 2023 RC drilling,

a duplicate sample was collected every 20th sample. For the 2016 and 2018-2023 core drilling programs two ¼ core samples were taken at the same time and were analysed in sequence by the laboratory to assess the representivity.

• Twin drill holes at the same site were drilled during the 2010- 2012 drilling program. The twin drill hole pairing comprises one RC

drill hole (SBH-04) and one core drill hole (SBHC-01). The Competent Person recommends twinning additional drill hole pairs as part of any future pre-production or infill drilling programs to allow for a more robust review of sample

representivity.

• The Competent Person reviewed the results of the duplicate/replicate sampling and twin drill holes. For the duplicate/replicate

samples, the R2 value is 0.99, which is very good. Visual observation of the lithological intervals and the assays for the twin drill holes show that they are very similar, despite the difference in drilling techniques.

|

|

|

• Measures taken to ensure that the sampling is representative of the in situ material collected,

including for instance results for field duplicate/second-half sampling.

|

• The Competent Person considers the samples to be representative of the in-situ material as they conform to lithological boundaries

determined during core logging. A review of the primary and duplicate sample analyses indicates a high degree of agreement between the two sample sets (R2 value of 0.99).

|

|

|

• Whether sample sizes are appropriate to the grain size of the material

being sampled.

|

• The Competent Person Considers the sample sizes to be appropriate given the general homogeneous nature of the mineralized zones. The two main types of

mineralization are lithium mineralization with high boron >/=5,000 parts per million (ppm) (HiB-Li) and lithium mineralization with low boron <5,000

ppm (LoB-Li). The HiB-Li mineralization occurs consistently throughout the B5, M5 and L6 target zones, while LoB-Li mineralization occurs throughout the M5, S5 and L6 units, and is not nuggety

or confined to discreet high-grade and low-grade bands.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

Quality of

assay data

and

laboratory

tests

|

• The nature, quality and appropriateness of the assaying and laboratory procedures used and whether the technique is

considered partial or total.

|

• The nature and quality of the assaying and laboratory procedures used include the following:

• All RC and core samples were processed, crushed, split, and then a sub-sample was pulverized by ALS Minerals in Reno, Nevada.

• All sub-samples were analysed by Aqua Regia with ICP mass spectrometry (ICP-MS) finish for

51 elements (including Lithium (Li)) and Boron (B) by Na2O2 fusion/ICP high grade analysis (>/=10,000 ppm B).

• Additionally, 95% of the 2018-2019 samples were analysed for Inorganic Carbon and 30% were analysed for Fluorine (F).

• The laboratory techniques are total.

• The Competent Person considers the nature and quality of the laboratory analysis methods and procedures to be appropriate for the

type of mineralization.

|

|

• For geophysical tools, spectrometers, handheld XRF instruments, etc., the parameters used in

determining the analysis including instrument make and model, reading

times, calibrations factors applied and their derivation, etc..

|

• Not applicable to this Report, no geophysical tools, spectrometers, handheld XRF instruments were used on the Project.

|

|

|

• Nature of quality control procedures adopted (e.g. standards, blanks, duplicates, external

laboratory checks) and whether acceptable levels of accuracy (i.e. lack of bias) and precision have been established.

|

• The following Quality Assurance and Quality Control (QA/QC) procedures were adopted for

the various drilling programs:

• During the 2010-2012 program, Standard Reference Material (SRM) samples and a small number of field blanks were also

inserted regularly into the sample sequence to QA/QC of the laboratory analysis.

• For 2016-2017 program, a duplicate sample was collected every 20th primary sample. Field blanks and SRM’s were also inserted

approximately every 25 samples to assess QA/QC.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

Quality of assay data and

laboratory

(Con’t)

|

• During the 2018-2019 and 2022-2023 programs, QA/QC samples comprising 1 field blank and 1 SRM standard inserted into each

sample batch every 25 samples. Submission of field duplicates, laboratory coarse/pulp replicates and umpire assays were submitted in later stages of the 2018-2019 and 2022-2023 drilling programs.

• The Competent Person reviewed the SRM, field blanks and field duplicates and determined the following:

• SRMs: Review of the five SRMs used determined that there was a reasonable variability for Li between the upper and lower control

limits (± 2 standard deviation (SD)), however B shows an overall bias towards lower than expected values (i.e. less than the mean) for all sample programs. For each of the 5 SRMs, there were

some sample outliers (both low and high); however, the majority fell within the control limits. It is recommended that two additional SRM samples be added which have grades between current high and low grade samples and are closer

to the cutoff range for boron ( 5,000 ppm).

• Field Blanks: Review of the field blanks indicate that there is some variability in both the Li and B results. There are several

samples that return higher than expected values, with an increased number being from the 2018-2019 drilling program. Further review is required to determine if this is a result of the material used for field blanks (coarse

dolomite) or a problem with the laboratory analysis.

• Field Duplicates: No field duplicates were submitted for the pre-2018 drilling programs. Review of the 230 field duplicate sample

pairs from the 2018-2019 drilling program determined that there was a strong correlation between each pair, as evidenced by an R2 value of 0.99 for Li.

• Umpire Laboratory Duplicates: 20 assay pulp rejects were sent from ALS to American Assay Laboratories (AAL) in Sparks, NV for umpire laboratory

analysis. Review of the 20 umpire duplicate pairs found a strong correlation between each pair, with B returning an R2 value of 0.98.

• The Competent Person reviewed the control charts produced for each SRM, field blank and field duplicate, and determined that there

was an acceptable level of accuracy and precision for each for the purpose of estimating Mineral Resources.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

Verification of sampling and assaying

|

The verification of significant intersections by either independent or alternative company personnel.

|

• Significant intersections have been verified by visual inspection of the drill core intervals by at least two Ioneer geologists for all drilling

programs.

|

|

The use of twinned holes.

|

• One pair of twin drill holes at the same site were drilled during the 2010-2012 drilling program. The twin drill hole pairing

comprises one RC drill hole (SBH-04) and one core drill hole (SBHC-01).

• The Competent Person reviewed and assessed two drill holes and the variance for thickness and grade parameters were within acceptable levels.

|

|

|

Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols.

|

• For the 2022-2023 drilling programs, the field protocols utilized in the 2018-2019 drilling program were reviewed by both Ioneer

and WSP. These protocols were refined and improved to assure proper compliance. Formal Documentation and enforcement by WSP and Ioneer personnel actively involved in the program.

• For the 2018-2019 drilling program, Newfields developed a series of field protocols covering all aspects of the exploration

program, including surveying, logging, sampling and data documentation. These protocols were followed throughout the 2018-2019 drilling program. Formal documentation of field protocols does not exist prior to the 2018-2019

program; however, the same senior personnel were involved in the earlier programs and field protocols employed were essentially the same as those documented in the 2018-2019 protocols.

• Primary field data was captured on paper logs for the 2010-2012 drilling program, then transcribed into Microsoft (MS) Excel files. For the 2016 through 2019 drilling, all field data was captured directly into formatted MS Excel files by logging geologists. All primary field data was reviewed by the senior

ioneer geologist.

• Data is stored in digital format in a MS Access database. This database was compiled, updated and maintained by Newfields

personnel during the 2018-2019 drilling program.

|

|

|

Documentation of primary data, data entry procedures, data verification, data storage (physical and electronic) protocols.

|

• The Competent Person used the relevant information from various tabular data files provided by ioneer and Newfields in a MS

Access database, which was reviewed and verified by the Competent Person prior to inclusion in the geological model.

|

|

|

Discuss any adjustment to assay data.

|

• There has been no adjustment to assay data.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

Location of data points

|

• Accuracy and quality of surveys used to locate drill holes (collar and down-hole surveys), trenches, mine

workings and other locations used in Mineral Resource estimation.

|

• Accuracy and quality of surveys used to locate drill holes is as follows:

• All inclined core drill holes were surveyed to obtain downhole deviation using a downhole Reflex Mems Gyros tool, except for

SBH-72, which could not be surveyed due to tool error. Two core drill holes (SBH-60, SBH-79) were surveyed using an Acoustic Televiewer instead of the Gyros tool.

• All 2018-2019 drill hole collars were surveyed using a differentially corrected GPS (DGPS).

• Locatable pre-2018 drill holes that were previously only surveyed by handheld GPS have been re-surveyed in 2019 using DPGS. Some

pre-2018 drill holes could not be located by the surveyor in 2019, and the original locations were assumed to be correct.

• Upon completion, drill casing was removed, and drill collars were marked with a permanent concrete monument with the drill hole

name and date recorded on a metal tag on the monument.

|

|

• Specification of the grid system used.

|

• All pre-2018 and 2018-2019 drill holes were originally surveyed using handheld GPS units in UTM Zone 11 North, North American

Datum 1983 (NAD83) coordinate system. Pre-2018 drill holes were re-surveyed using DPGS in NAD83 in 2017/2018.

• All 2018-2019 drill holes and locatable pre-2018 drill holes were re-surveyed in 2019 using DPGS in NAD83 coordinate system. All

surveyed coordinates were subsequently converted to Nevada

• State Plane Coordinate System of 1983, West Zone (NVSPW 1983) for use in developing the

geological model. Those holes that could not be located had the original coordinates converted to NVSPW 1983 and their locations verified against the original locations.

• All 2022-2023 holes were surveyed Nevada State Plane Coordinate System of 1983, West Zone (NVSPW 1983) for use in

developing the geological model.

|

|

|

• Quality and adequacy of topographic control.

|

• The quality and adequacy of the topographic surface and the topographic control is very good based on comparison against survey

monuments, surveyed drill hole collars and other surveyed surface features.

• A 2018 satellite survey with an accuracy of ± 0.17 m was produced for the Project by PhotoSat Information Ltd. The final report

generated by PhotoSat stated that the difference between the satellite and ioneer provided ground survey control points was less than 0.8 m.

|

|

|

|

• The topographic survey was prepared in NAD83, which was converted to NVSPW 1983 by Newfields prior to geological modelling.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

Data spacing

and

distribution

|

• Data spacing for reporting of Exploration Results.

|

• Drill holes are generally spaced between 90 m and 170 m on east- west cross-section lines spaced approximately 180 m apart.

There was no distinction between RC and core holes for the purpose of drill hole spacing.

• For the 2018-2023 drilling program, there were multiple occurrences where several inclined drill holes were drilled from the

same drill pad and oriented at varying angles away from each other. The collar locations for these inclined drill holes drilled from the same pad varied in distance from 0.3 m to 6.0 m apart; intercept distances on the floors of

the target units were typically in excess of 90 m spacing.

|

|

• Whether the data spacing and distribution is sufficient to establish the degree of

geological and grade continuity appropriate for the Mineral Resource and Ore Reserve

estimation procedure(s) and classifications applied.

|

• The spacing is considered sufficient to establish geological and grade continuity appropriate for a Mineral Resource

estimation.

|

|

|

• Whether sample compositing has been applied.

|

• Samples were predominately (91%) 1.52 m intervals honouring lithological boundaries. The sample intervals were composited to

1.52m lengths, respecting the seam contacts to regularize the database used for grade estimation. The 1.52 m sample length represents the modal value of the sample length distribution and the 1.52m vertical block height in the

model.

|

|

|

Orientation of

data in relation

to geological structure

|

Whether the orientation of sampling achieves unbiased sampling of possible structures and the extent to which this is known, considering the deposit type.

|

• Drill holes were angled between -45 and -90 degrees from horizontal and at an azimuth of between 0- and 350-degrees.

• Inclined drill holes orientated between 220- and 350-degrees azimuth introduced minimal sample bias, as they primarily intercepted the mineralization at

angles near orthogonal (94 drill holes with intercept angles between 70-90 degrees) to the dip of the beds, approximating true-thickness.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

• If the relationship between the drilling orientation and the orientation of key mineralised

structures is considered to have introduced a sampling bias, this should be assessed and reported if material.

|

• Inclined drill holes orientated between 0- and 220-degrees azimuth, especially those that were drilled at between 20- and

135-degrees azimuth, generally intercepted the beds down dip (14 drill holes with intercept angles between 20-70 degrees), exaggerating the mineralized zone widths in these drill holes.

|

|

|

Sample

security

|

• The measures taken to ensure sample security.

|

• The measures taken to ensure sample security include the following:

• For the 2010-2012 drill holes, samples were securely stored on-site and then collected from site by ALS. Chain of custody forms

were maintained by ALS.

• For the 2016-2017 drill holes, samples were securely stored on-site and then collected from site by ALS and transported to the

laboratory by truck. Chain of custody forms were maintained by ALS.

• For the 2018-2019 and 2022-2023 drill holes, core was transported daily by ioneer and/or Newfields personnel from the drill site to

the ioneer secure core shed (core storage) facility in Tonopah. Core awaiting logging was stored in the core shed until it was logged and sampled, at which time it was stored in secured sea cans inside a fenced and locked core

storage facility on site. Samples were sealed in poly-woven sample bags, labelled with a pre-form numbered and barcoded sample tag, and securely stored until shipped to or dropped off at the ALS laboratory in Reno by either ioneer

or Newfields personnel. Chain of custody forms were maintained by either Newfields or ioneer and ALS.

|

|

Audits

or

reviews

|

• The results of any audits or reviews of sampling techniques and data.

|

• There were no audits performed on the RC sampling or for the pre-2018 drilling programs.

• The Competent Person reviewed the core and sampling techniques during a site visit in August 2023. The Competent Person found

that the sampling techniques were appropriate for collecting data for the purpose of preparing geological models and Mineral Resource estimates.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

Mineral

tenement and

land tenure

status

|

• Type, reference name/number, location and ownership including agreements or material issues

with third parties such as joint ventures, partnerships, overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings.

|

• The mineral tenement and land tenure for the South Basin of Rhyolite Ridge (the Project) comprise 386 unpatented Lode Mining

Claims (totalling approximately 3,150 hectare (Ha)); claim groups SLB, SLM and RR, spatial extents of which are presented in maps and tables within the body of the Report are held by Ioneer

Minerals Corporation, a wholly owned subsidiary of Ioneer. The Competent Person has relied upon information provided by Ioneer regarding mineral tenement and land tenure for the Project; the Competent Person has not performed any

independent legal verification of the mineral tenement and land tenure.

• The Competent Person is not aware of any agreements or material issues with third parties such as joint ventures, partnerships,

overriding royalties, native title interests, historical sites, wilderness or national park and environmental settings relating to the 386 Lode Mining Claims for the Project.

• The mineral tenement and land tenure referenced above excludes

241 additional unpatented Lode Mining Claims (totaling approximately 2,000 Ha) for the North Basin which are located outside of the current South Basin

Project Area presented in this Report. These additional claims are held by Ioneer subsidiaries (NLB claim group; 160 claims and BH claim group; 81 claims).

|

|

• The security of the tenure held at the time of reporting along with any known impediments

to obtaining a licence to operate in the area.

|

• There are no identified concerns regarding the security of tenure nor are there any known impediments to obtaining a license to

operate within the limits of the Project. The 386 unpatented Lode Mining Claims for the Project are located on federal land and are administered by the United States Department of the Interior - Bureau of Land Management (BLM).

|

|

|

Exploration

done by other parties

|

• Acknowledgment and appraisal of exploration by other parties.

|

• There have been two previous exploration campaigns targeting Li-B mineralization at the Project site.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

|

|

• US Borax conducted surface sampling and drilling in the 1980s, targeting B mineralization, with less emphasis on Li

mineralization. A total of 44 drill holes (totalling approximately 14,900 m) were drilled in the North Borate Hills area, with an additional 16 drill holes (unknown total meterage) in the South Basin area. These drill holes were

not available for use in the current Study.

• American Lithium Minerals Inc and Japan Oil, Gas and Metals National Corporation (JOGMEC)

conducted further Li exploration in the South Basin area in 2010-2012. The exploration included at least 465 surface and trench samples and 36 drill holes (totalling approximately 8,800 m), of which 21 were core and 15 were RC.

Data collected from this program, including drill core, was made available to ioneer. The Competent Person reviewed the data available from this program and believes this exploration program, except for the trench data, was

conducted appropriately and the information generated is of high enough quality to include in preparing the current geological model and Mineral Resource estimate.

• Due to concerns regarding the ability to reliably correlate the trenches with specific geological units as well as concerns

regarding representivity of samples taken from incomplete exposures of the units in the trenches, the Competent Person does not feel the trench sample analytical results are appropriate for use and has excluded them from use in

preparing the geological model and Mineral Resource estimate.

|

|

Geology

|

• Deposit type, geological setting and style of mineralisation.

|

• The HiB-Li and LoB-Li mineralization at Rhyolite Ridge occurs in two separate late-Miocene sedimentary basins; the North Basin

and the South Basin, located within the Silver Peak Range in the Basin and Range terrain of Nevada, USA. The South Basin is the focus of the Study presented in this Report and the following is focused on the geology and

mineralization of the South Basin.

• The South Basin stratigraphy comprises lacustrine sedimentary rocks of the Cave Spring Formation overlaying volcanic flows and

volcaniclastic rocks of the Rhyolite Ridge Volcanic unit. The Rhyolite Ridge Volcanic unit is dated at approximately 6 mega-annum (Ma) and comprises rhyolite tuffs, tuff breccias and flows.

|

|

APPENDIX D: JORC Code, 2012 Edition - Table 1

|

|

Criteria

|

JORC Code 2012 Explanation

|

Commentary

|

|

The Rhyolite Ridge Volcanic rocks are underlain by sedimentary rocks of the Silver Peak Formation.

• The Cave Spring Formation comprises a series of 11 sedimentary units deposited in a lacustrine environment, as shown in the

following table. Within the study area the Cave Spring Formation can reach total thickness in excess of 400 m. Age dating of overlying units outside of the area and dates for the underlying Rhyolite Ridge Volcanic unit bracket

deposition of the Cave Spring Formation between 4-6 Ma; this relatively young geological age indicates limited time for deep burial and compaction of the units. The Cave Spring Formation units are generally laterally continuous

over several miles across the extent of the South Basin; however, thickness of the units can vary due to both primary depositional and secondary structural features. The sedimentary sequence generally fines upwards, from coarse

clastic units at the base of the formation, upwards through siltstones, marls and carbonate units towards the top of the sequence.

• The key mineralized units are in the Cave Spring Formation and are, from top to bottom, the M5 (high-grade Li, low- to

moderate- grade B bearing carbonate-clay rich marl), the B5 (high-grade B, moderate-grade Li marl), the S5 (low- to high Li, very low B) and the L6 (broad zone of laterally discontinuous low- to high- grade Li and B mineralized

horizons within a larger low-grade to barren sequence of siltstone-claystone). The sequence is marked by a series of four thin (generally on the scale of several meters or less) coarse gritstone layers (G4 through G7); these units

are interpreted to be pyroclastic deposits that blanketed the area. The lateral continuity across the South Basin along with the distinctive visual appearance of the gritstone layers relative to the less distinguishable sequence

of siltstone-claystone-marl that comprise the bulk of the Cave Spring Formation make the four grit stone units good marker horizons within the stratigraphic sequence.